Many owners of domestic cars are thinking about modifying their “iron horses”. Considering that more modern models are equipped with injectors, it is possible to install a 16-valve power unit on them. The Niva-Chevrolet with an engine from the Priora, as well as classic VAZ models with a similar modified engine, are widely popular.

Niva with a Priora engine: all the features and advantages of a swap on a Niva

Chevrolet Niva with an engine from Priora installation

Niva 4x4 - installation of a 1.9 l, 16 cl engine - 126 horsepower, e-gas

Niva Chevrolet after Priora. First impressions.

NIVA with an engine from PRIORA, Well, AVTOVAZ.

NIVA TUNING installation of a 16 valve engine, dream Niva water

Niva Chevrolet with an engine from Priora issue 2

Review of the most powerful production Chevrolet Niva FAM-1 with Opel Z18XE engine (122 HP)

Chevy Niva 16V Turbo

Niva with Z18XE engine.

Replacing an engine with a unit from Priora (VAZ-2170) is not a difficult procedure, because the installation is similar to installing an engine 2112 or 21124 and takes place without significant differences. Replacement is possible on all cars of the Lada Samara-2 family, but in the article we will consider case 2114.

So, the progress of work on changing the VAZ-2114 engine with your own hands:

First of all, you need to install the receiver (not an easy task, I tell you),

We also extend the wires to the phase sensor,

You need to pull out the wire from the pigtail to the oil pressure sensor, the rest is fine.

The ECU can be left stock.

Unfortunately, the systems are completely different.

If you have the financial opportunity, you need to replace the radiator with a 2112 (slightly changing the seat, since the 12th one is slightly wider). As a last resort, you can leave the “native” one.

The thermostat fits the factory one (where the heater connects directly to it, and not to the reservoir hose). Imported analogues are no different. Depending on the old thermostat, it may be necessary to replace the hoses on the radiator (the upper one comes from 2112, the lower one from Kalina),

The cooling fan does not fit and touches the receiver; installing a fan from the Niva (which has two impellers on the outside) saves the day. But in this case it is necessary to install an intermediate relay (since the safety block does not pull). If you can figure out how to do it differently, write to us and we’ll discuss it.

In general, with this design of the system, everything is in order with cooling, but it is still better to replace the radiator with a 2112.

The generator with a standard belt fits well on the bracket from 2114.

The original ECU is capable of starting the engine without flashing it.(!) So you can get to the mechanic on your own. Sometimes it stalls, the consumption is high, but it still drives not bad.

If desired, install an additional (fourth) engine mount. It's not expensive, but it's a cool thing.

That's all, tuning the VAZ-2114 by changing the engine is over. Have a nice ride!

Many owners of domestic cars are thinking about modifying their “iron horses”. Considering that more modern models are equipped with injectors, it is possible to install a 16-valve power unit on them. The Niva-Chevrolet with an engine from the Priora, as well as classic VAZ models with a similar modified engine, are widely popular.

Poor interior options

There have been many more changes in the internal appearance of the car. You could even say that the interior has changed completely. And it’s not surprising, because Italian designers were involved in its development. The interior is decorated with damage-resistant, pleasant-to-touch material, and the doors are equipped with fairly powerful speakers. The modern Lada Priora 2022 2021 boasts expensive equipment, including:

- touchscreen;

- multimedia system;

- Cruise control.

To entertain passengers, the cabin was equipped with a good entertainment system. The latest navigation system can show you the right path in any area. The car seats also underwent changes, which “grew” in height by as much as 40 mm. As can be seen in the photo of the updated Lada Priora 2022, for greater comfort they were given a more curved shape and high-density lateral support was added.

Thanks to the increased range of steering wheel adjustment, today this car is designed for 2-meter drivers who will feel quite comfortable in it. For additional comfort, the seat backs can be adjusted using a special mechanism, and the seat heating system will not allow you to freeze even in severe frost. All interior changes can be seen in the photos and videos of the Lada Priora after restyling.

Pricing information

- sedan;

- five-door hatchback;

- station wagon

The price of the restyled Lada Priora will depend on this and the internal filling. It will look like this in rubles:

- sedan – from 355,600;

- hatchback – from 380,400;

- station wagon - 384,000.

The updated model will be equipped with a pre-heater, cable gearbox and automatic transmission. The cheapest equipment surprises with remote-controlled central locking, as well as airbags. An improved modification of the new Lada Priora 2022, the price of which is quite reasonable, is equipped with a large selection of bells and whistles:

- powerful stereo system;

- electric booster;

- air conditioner;

- weather sensors.

Technical characteristics of the people's Priora

The updated model will be presented with three petrol engine options:

- The 8-valve, 1.6-liter engine will provide a power of 87 hp. With.;

- A 16-valve unit of similar volume will be able to produce up to 106 horses;

- The 16-valve, 1.8-liter engine produces at least 123 horsepower.

The car can accelerate to 100 km/h within 11 seconds, while consuming about 8 liters of fuel. The manufacturer has proposed an automatic transmission and, accordingly, a manual one, with the help of which the Priora can reach a speed of 180 km on the speedometer. Read our new reviews about Gazelle Next 2022 and Gazel Farmer 2020.

Features of installation of the power unit

Installing a Priora engine on a Niva-Chevrolet or VAZ 2107 will take one or two days from a specialist. But first you should devote a lot of time and money to preparatory work. First you need to buy the engine itself. If you purchased a used motor, you need to rebuild it, which will further extend its service life.

Another advantage of disassembling and inspecting the unit is the ease of installation of transition elements, especially if the parts for the Chevrolet Niva with the Priora engine were made by hand. It is better to carry out manipulations with a screwed oil pan, which will also require modification.

Owner reviews

The best recommendations can be given by the direct owners of the model in question, who have tested the car in various weather and road conditions. If you take a Chevrolet Niva with an engine from a Priora, reviews from owners indicate that the car has changed for the better. Special benefits include the following:

- the power unit has a solid reserve before major overhaul;

- fuel consumption has decreased, quite noticeably;

- high speed characteristics and power;

- reliability of the unit;

- high performance characteristics of the motor.

It’s not difficult to create a Niva-Chevrolet with an engine from a Priora. Some modifications to the cooling system and the seat for the unit will be required. All manipulations can be completed in just a couple of days.

The disadvantages of the device in question include one point that was noticed by some owners and specialists. If the timing belt breaks, the pistons inevitably interact with the valves, causing the latter to bend. To avoid this, you can purchase special pistons with recesses for the valves.

Start of preparatory work

Preparations for installation should begin by dismantling the flywheel of the new power unit. Its teeth will be incorrectly positioned in relation to the starter gear. It is necessary to purchase a suitable crown and place it on the flywheel.

It must be taken into account that the Chevrolet Niva with the Priora engine is modified only in the engine part. The gearbox remains unchanged, so care should be taken to ensure reliable and correct joining of these two blocks. It is optimal to carry out this operation using a special adapter plate. You can buy a ready-made element or make it to order. An alternative to connecting the gearbox and engine would be to fix the engine cylinder block directly to the gearbox. In this case, only three mounting bolts will be involved. Many car enthusiasts who have tested this in practice claim that the clutch is quite reliable.

Modified options

Which is better Chevrolet Niva or Niva 2131

Since it is not always possible to supply an engine of a certain foreign car, it is worth considering imported production options that require a little modification:

- The first candidate will again be the French engine from Peugeot XUD 11 series. Since the power of this unit is higher than that of the previous model, some changes will need to be made to the design of the Niva - replacing the gearbox. An acceptable option is a gearbox from Fiat Polonez. In addition, a good solution would be to replace the front supports of the power plant fasteners, pan and exhaust system. It is also worth replacing the drive elements with similar parts from the Chevrolet Niva.

"Niva-Chevrolet" with an engine from "Priora": the main stage of preparatory work

The updated engine will be slightly moved towards the cabin. To install it correctly, it is necessary to cut out a part of the metal partition separating the engine unit and the interior of the car. It is recommended to carry out the manipulation carefully so as not to cut out the excess part, since the element being processed ensures the rigidity of the body. Alternatively, you can use a grinder saw if you have the appropriate experience.

The end part of the crankshaft of the newly installed engine will require the installation of a VAZ-2107 and with an engine from Priora the element will need to be adjusted. Any turner will help you cope with this problem; the work will not take much time. Adapters with holes should be prepared for the motor mounting pads.

The final stage of preparatory work

If the car being modified was equipped with a carburetor system, you should install a remote electric fuel pump, a gas pedal drive with a cable, and a fuel filter. A Volga injection element with an injector is quite suitable. You will also need to install a special adapter for the clutch block.

If the car is equipped with a fuel injection system, then installing and connecting the control electronics will not pose any special problems. When installing a VAZ-2112 or Priora engine on a Niva, you will have to spend a lot of time on preparation. However, the subsequent effect and the new “heart” of the iron horse are worth all the effort.

Risks when replacing an engine

Since the new engine is still not original, we have to cut the partition that connects it to the passenger compartment. If this action is going to be carried out by a driver without the appropriate experience, then there is a risk that it will not be possible to cut exactly along the required boundaries. Therefore, it is still advisable to carry out this work directly to qualified specialists who will do this as accurately as possible. As a rule, a grinder is used for this action, so without experience you can make a hole much larger than necessary. To install the engine, other adjustments to the car will be necessary, so you should make changes to the fuel pump, reconfigure the cable that leads to the gas pedal. The quality of work associated with the preparation of all components determines how quickly the engine replacement will be performed and, as a result, the use of this vehicle to perform current tasks.

Installation of the power unit

Having completed all the preparatory work, you can begin installing the motor. For a professional repairman, this process rarely takes more than one day. Personal participation will require more time and effort.

The greatest amount of work will have to be done with the modification of the cooling and exhaust systems. An old manifold from a VAZ of early production will not fit the “Prior” engine, as well as connecting pipes and some elements of the cooling system. It is difficult to purchase the parts in question ready-made, but they can be made to order or using gas welding.

Technical characteristics of the VAZ 2123 engine

The VAZ 2123 power unit has a working volume of 1690 cubic meters. cm. It is naturally aspirated and runs on gasoline fuel. His weight is 127 kilograms. The electronic fuel injection system increased engine power to 80 hp, and the torque is 127 NxM, which becomes available at around 4000 rpm.

On the highway the car can reach a speed of 140 km/h. A five-speed manual gearbox is responsible for shifting gears. Highway consumption does not exceed 8.5 liters per 100 km. In the city it increases to 14 liters per 100 kilometers. In such an engine, for its stable operation and responsive traction, it is recommended to fill AI-95 gasoline.

A timing belt with a hydraulic chain tensioning system requires increased oil pump performance. To increase productivity without increasing power, engineers reduced the number of teeth on the pump drive gear.

Also interesting: What kind of oil to pour into the VAZ 21214 Niva injector engine

To lubricate the engine, 3.5 liters of oil is required. Both synthetic and semi-synthetic oils are suitable. The only thing that requires attention is the viscosity indicator, which must correspond to the 5W30 index. To preserve the life of the Chevrolet Niva engine for many years, it is recommended to change the oil every 10,000 km.

Target audience of the new Lada 4x4

The restyled version of the 2014 Lada 4x4 will be intended mainly for rural residents and farmers. It will also be relevant for hunters and fishermen. As you know, they all often have to drive off-road, and this car is suitable for this like no other. This SUV will be indispensable in difficult off-road conditions, and at the same time you can move along the highway without any problems. According to preliminary estimates, the cost of the new Lada may be 600-700 thousand rubles.

The car is expected to increase in size, as the luggage compartment has become larger. The demand for the car is expected to be high. AVTOVAZ plans to produce about 80 thousand SUVs per year.

New items equipped with the engine in question

Soon, VAZ developers plan to put into mass production the updated Niva, which will be equipped with an engine from the Priora. The new power unit will make it possible to significantly reduce fuel consumption, while increasing the vehicle’s speed performance.

The plant is actively working to adapt the engine to the Niva. The car can be produced in two variations: with a unit with a capacity of 98 horsepower or a modified analogue that pulls 106 horses and has a torque of 148 Nm. In addition to the updated engine, the car in question will receive a new steering rack, subframe, improved seats, heating, and air conditioning will be installed.

Work order

First, all attachments are dismantled - the receiver, exhaust manifold, etc. After this, the engine is installed on standard mounts and connected to the gearbox. To avoid problems with changing the fuel pump and when laying a new fuel line, you need to purchase a standard ramp.

In addition to the ramp, you will need longer fuel injectors. The ramp does not connect to the engine immediately. You must first install the receiver. This process is quite labor-intensive - you need to tighten all the cushions and raise the car with a jack. After this, you can push the receiver through and insert the ramp with injectors. The ramp is screwed after the nozzles are installed on the wells. After this, the receiver sits in place and is secured. When performing work, care must be taken to ensure that the rubber seals on the receiver are not damaged. Next, all elements of attachments are installed in their standard places.

Now you can do the electrical wiring. First you need to disassemble the ignition. Since the car does not have four ignition coils, a standard one is installed, and only high-voltage wires are needed from the Priora. It will be necessary to increase the wiring by about 40 cm, since its length may not be sufficient. The same applies to the phase sensor.

Next you need to deal with the exhaust. It is necessary to dismantle the old exhaust manifold with the catalyst, and in its place a 4-2-1 “spider” system with holes for the DC is installed. The corrugation is also placed there. The exhaust pipe is completely replaced, and the standard can is modified.

It is not necessary to change the thermostat - you can leave the standard one, but it will need to be configured correctly. If the cooling fan is in contact with the receiver, you can replace it with a Niva fan, which has two impellers on the outside. The hoses on the radiator need to be replaced. The generator is mounted on standard mountings; its belt does not need to be changed.

In order for the engine to operate normally, the injectors must be flashed and calibrated. The decorative engine grille can be left in place, you just have to make cuts on its front side. The entire structure can be significantly strengthened by installing a brace with a fourth mount for the power unit - this will not cost much at all.

After all installation work has been completed, new filters are installed, oil is added and the engine is run in. You cannot immediately accelerate the engine to maximum speed, since at this time the engine components are grinding in - parts can become deformed from excessive load, which can lead to engine failure. In the corresponding section of our website you can find an article about

Good afternoon, I haven’t written for a long time: (because I didn’t have time... I assembled my Priora’s engine a long time ago, and even managed to break it in;) I drove 2000 km on it. Well, now about the most important thing... how and from what we assembled the new heart :) Action plan: 1. I decided that I was making a motor for myself, which means I will sharpen the block + After boring, do honing. I didn’t think for a long time and turned to Auto VAZ at Chekistov :) where the mechanic guy kindly and clearly explained everything that first buy the pistons, and then I’ll make everything the right size for you. 2. An hour later I was already at the 50th Anniversary of October in the Ladya store. It was this store that became my favorite in Tyumen:) the sellers understand what they are selling + an adequate price tag for spare parts and their availability. Of course, there is also a defect there, which I changed without problems after 2 weeks :) the timing belt roller made noise... I bought: STK pistons VAZ 21126 - 82.5 (Splitless with anti-friction coating) for a 75.6 mm crankshaft in a 197.1 mm block, for connecting rods 133.3 mm and pins d18 mm) rings 1.2 mm/1.5 mm/2.0 mm

STK plug-inless with a displacer To compensate for the compression ratio, the pistons have a displacer, and according to the manufacturer, the compression ratio with these pistons remains unchanged.

Piston ring set d82.50 mm “PRIMA” 1.2 mm, 1.5 mm, 2 mm

Started in Auto VAZ for boring. I liked that I drove up to the machine itself by car, otherwise I had bad thoughts about how to carry the block through the whole workshop :)

First of all, the Master bored out the damaged cylinder, and then all the others. I liked that the Master answered all my questions that I asked :) he even explained why and what he was doing! A big + and respect to the master for his patience))) because after finishing the boring I took out another crankshaft and asked him to check it, he kindly agreed and checked it for free... I'M SHOCKED 0_0!

3. In the evening we already started assembling the beast... I won’t describe everything there are too many little details :) I’ll highlight only the most important things...

Methods of payment for goods

- It is possible to send cargo with a thirty percent (30%) advance payment with blocking and removal of blocking upon full payment.

- It is possible to send cargo without prepayment, provided that the buyer pays for the services of the transport company in both directions at the branch of the transport company.

- Sending by PEC by cash on delivery with the condition of prepayment of delivery in both directions (this way we are safe from fraudsters) - in PEC before payment you can inspect the goods received, PEC charges a commission for this service in the amount of: 1.5% for cash and 3% for non-cash calculation

You can make any changes (tuning/additions) to the standard engine configuration BUT the warranty will be 3000 km or 3 months of operation

You can also make any set of attachments (standard and non-standard) if you have some of the equipment - write what to add/exclude from the set, the manager will write a price change.

Number of cylinders: 4

Cylinder displacement, l: 1,690

Compression ratio: 9.3

Rated power at a crankshaft speed of 5000 rpm: 59.5 kW - (81 hp)

Cylinder diameter, mm: 82

Piston stroke, mm: 80

Number of valves: 8

Minimum crankshaft speed, rpm: 750-800

Maximum torque at 4000 rpm, N*m: 127.5

Cylinder firing order: 1-3-4-2

Gasoline octane number: 95 (unleaded)

Fuel supply system: Electronically controlled distributed injection

Spark plugs: AU17DVRM, BCPR6ES(NGK)

What does the engine package include: Block, crankshaft, pistons, rings, connecting rods, bearings, half rings, oil seals, cylinder head assembly with camshaft, crankshaft pulley, flywheel, oil pump with oil receiver, iron oil pan (aluminum can be installed - check price with manager), valve cover, gas distribution mechanism with a closed cover, spark plugs, generator with mount (bracket), distributor (if equipped), carburetor, fuel pump (if carburetor), intake and exhaust manifold receiver (cat. manifold), throttle valve (if injector), all rubber hoses, all small brackets, all belts: generator, toothed, on classic engines: - chain. Dipstick ramp with injectors and injector wiring. Sensors: oil, temperature, phase sensor (if injector), knock sensor, antifreeze drain plug, dipstick, break-in oil (10v40 Lukoil semi-synthetic, recommended after break-in 1000-1500 km, oil change).

Packaging: everything is mounted on a wooden stable pallet, screwed on, the engine itself is made of cardboard on all sides and wrapped with stretch film. The transport company is packed in a wooden box. At the request of the client, we can dismantle any component of the engine or replace it with a non-standard sports or tuned part.

Motor device

Briefly about how the VAZ 2123 Chevrolet Niva engine works.

Cylinders

They were combined with the upper part of the crankcase. Like most VAZ engines, this power unit has cylinders operating in a 1-3-4-2 pattern. The lower part of the cylinder block is connected on five supports to the crankshaft.

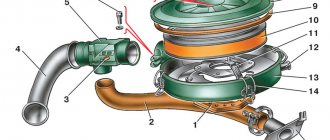

1 — tension roller of the air conditioning compressor drive belt; 2 — air conditioning compressor drive belt; 3 — air conditioning compressor clutch; 4 — thermostat; 5 — throttle assembly; 6 — outlet pipe of the cooling jacket; 7 — coolant pump pulley; 8 - phase sensor; 9 — tension roller for the auxiliary drive belt; 10 — cylinder head; 11 - generator; 12 — power steering pump pulley; 13 — support roller for the auxiliary drive belt; 14 — cylinder block; 15 — auxiliary drive belt; 16 — crankshaft position sensor; 17 — auxiliary drive pulley; 18 — air conditioning compressor drive pulley; 19 — oil pan; power unit support; an exhaust manifold; receiver; cylinder head cover;

What should you prepare?

First of all, of course, the new engine itself. In the case when a used motor is purchased (as most often happens), there is no doubt about the need to disassemble and inspect it, so that you do not have to do this later and disassemble everything again. This approach provides one more advantage: if you decide to make the transitional fastening parts that are needed to install the 21126 engine in the body of a Niva or classic on your own, then in disassembled form it is easier to try on the cylinder block in place and find out the dimensions of the parts.

It is better to perform this operation with the oil pan screwed on, because it also requires modification. The Priorovsky pallet simply rests against the cross beam of the VAZ 21213 Niva; it needs to be carefully straightened, trying it on in place. The refractory steel from which the latter is stamped allows such modifications to be made to it. Here are general recommendations for performing preparatory work:

- First you need to remove the flywheel from the newly installed motor and remove the old crown from it. Its teeth will not coincide with the classic starter gear, so you need to purchase a suitable ring and install it on the flywheel.

- Since only the unit itself changes, and the Lada Niva or 2107 gearbox remains in place, you need to properly connect these two units. Ideally, this is done using an adapter plate, which can be ordered from a milling machine or purchased ready-made; everyone decides for themselves what to do. One of these solutions is not to install an adapter plate at all, and mount the Priora cylinder block directly to the classic. In this case, one hole on the mounting flange of the block will remain without a bolt and the units will be attached to each other using three connections instead of four. This cannot be said to be a wrong decision. Car enthusiasts who have not installed the adapter plate confirm that the three-bolt units are held very securely.

- Since the newly installed engine will be somewhat recessed towards the car's interior, you will have to cut out a small part of the metal partition that separates the Lada Niva engine compartment from the interior. It is recommended to do this using a gas torch, carefully so as not to cut out excess, since this partition is the rigidity of the body. Some craftsmen use an angle grinder, but this is associated with inconvenience.

- At the end of the crankshaft of the 21126 engine, it is necessary to install a support bearing, which is present on all classic Zhiguli models, but is not present on front-wheel drive cars. The fact is that in the same VAZ 21213 Niva the rear crankshaft bearing is a support for the input shaft of the gearbox. Therefore, you will have to turn to a turner on this issue, who will help you grind the end and install the bearing. Considering the great similarity of the nodes, this will not take much time.

- For the landing pads for the power unit, you need to prepare adapter plates with holes.

- If your Lada Niva or S7 car had a fuel system with a carburetor, then you will have to worry about purchasing a remote electric fuel pump, a cable drive for the gas pedal and a fuel filter. The pump can be taken from the injection Volga.

- You should prepare a special adapter for the clutch.

1 — bracket for mounting the generator and the front support of the power unit; 2 - generator; 3 — generator drive belt; 4 — bracket for the upper mounting of the generator; 5 — bracket for the right support of the power unit; 6 - phase sensor; 7 — front upper timing cover; 8 — rear timing drive cover; 9 — inlet pipeline; 10 — ignition coil; 11 — throttle assembly; 12 — oil filler cap; 13 — cylinder head cover; 14 — low oil pressure indicator sensor; 15 — camshaft bearing housing; 16 — cylinder head; 17 — thermostat housing; 18 — thermostat cover; 19 — supply pipe of the coolant pump; 20 — oil level indicator in the gearbox; 21 — bracket for the left support of the power unit; 22 — gearbox; 23 — starter; 24 — coolant drain plug; 25 — crankcase ventilation hose; 26 — knock sensor; 27 — oil pan; 28 — oil level indicator; 29 - cylinder block

Nuances when installing an engine from Priora to Niva

Let's consider the main nuances that may arise during the installation of the Priora power unit:

Of course, in addition to the above points, certain problems may arise after installing the motor. For example, inaccessibility in the timing mechanism - in this case, when replacing the belt, you often have to drain the coolant. Due to the alteration of the sump, another negative point appears - now there is less oil in it than it should have been from the factory - this can lead to negative consequences under critical loads on the engine.

The clutch, according to reviews of many owners with already converted engines from Priora, is somewhat worse than on the same Chevrolet Niva, so its service life is reduced, and accordingly, you have to bother with replacement more often. But, as they say, everyone understands perfectly well what they are getting into when installing an engine of greater power and with non-standard mounts.

If you want to see what usually results from such tuning, the video review below will be a visual aid.

Such tuning takes a lot of effort and time, but this stopped few people in such cases!

Modernization of the heating device in a Chevrolet Niva car

Chevy Niva electrical diagram

Before the heater is improved, it is necessary to understand the principle of operation of the dampers. Then you should completely dismantle the decorative panels located on the left side of the Chevrolet Niva stove. The next step is to remove the regulator responsible for the position of the dampers. When optimizing your car, you need to understand the design of the heating device, which will allow you to dismantle the “unnecessary” equipment without unnecessary delays. The motorist must remove the lower part of the regulator, through which the front flap is activated.

When dismantling all the plastic elements, you should not try to abruptly remove the parts, since almost all the components of the device being disassembled are made of fragile plastic, which breaks even under more or less significant impact. If, however, due to haste or carelessness of the owner of the movable property, the lower part of the device being removed gets a crack, it can be hidden with a soldering iron.

Modifying the Chevrolet Niva stove with your own hands involves the need to secure the lower damper so that it is tightly closed in the upper position. Of course, such a modernization completely eliminates the ability of the motorist to take advantage of the “front” position, however, it provides many other more significant advantages.

To tightly fix the front flap, you will have to make a small-sized bracket with your own hands (it is best to resort to using a simple tin), which will be held on by a self-tapping screw.

Once the “front” of the stove is in the closed position, you will need to think through the trajectory of the element that regulates the simultaneous supply of heat to the glass and legs. It is worth noting that skilled craftsmen, when upgrading their Chevrolet Niva, use all available means, in particular, an ordinary discount card will be useful for optimizing the stove. By means of which a cut line is drawn, then the element is glued with cyanoacrylate and filed to size with a file.

The modification of the Chevrolet Niva heater should be completed after the hand-cut part is glued with superglue.

In fact, modifying the Chevrolet Niva stove can largely correct the position of the standard device. As a result of simple manipulations and cheap expenses, the motorist will receive a more advanced heater, through which it becomes possible to smoothly regulate the volume of warm air flow entering the cabin, warming not only the face, but also the legs.

Peculiarities

The Niva-Chevrolet with the Priora engine has some features compared to similar classic VAZ models. Firstly, installation of the power unit is simplified, since the location of the motor is identical. Secondly, variations were produced with almost the same engine as the Priora. In addition, a new production version of the domestic SUV is being developed, to which the engine from Priora, considered one of the best among our manufacturers, is adapted.

Considering the high service life and versatility of the motor in question, its installation is advisable on many VAZ models. Moreover, relatively modern modifications will require a minimum of modifications, while more classic versions will gain new power and speed.

Having studied all the characteristics of the engine, it can be noted that the Priora power unit is a reliable and well-developed engine. The use of modern technologies and new developments has allowed domestic developers to create a reliable and high-quality unit.

Additionally, this unit is supported by reviews from owners and the desire of many car enthusiasts, despite the additional costs of time and money, to equip their vehicle with a Priora engine.

So, if you decide to change the motor in the shnivka, then I advise you to use the Priora (21126), because it is the most powerful and the most successful, its disadvantage is the bending of the valves when the timing belt breaks, but there are already plug-in pistons, so you can immediately modify it, I installed a motorcycle kit from a “super auto” in it to increase the volume to 1.8, if the budget allows, then Take it, you won’t regret it, it costs 25 rubles. Let's start, to swap a prioromotor you will need: a welder, a turner, a milling machine operator, a car mechanic, welding, an angle grinder, a drill, a sledgehammer)), a great desire and straight hands..., I’ll write right away that the work is not easy and if you think that by downloading the description from the drive everything will work out, it’s not a fact, it turns out that AvtoVAZ doesn’t have all its cars exactly made, some have gaps with a difference of up to 5 mm, and this can become a problem... if this doesn’t scare you, then before the swap we do preparatory work, namely, we order coolant outlets for the classic 16kl (there are many offices, for example atmo-tuning.ru or club-turbo.ru) and they come in different shapes, in some the outlet from the cylinder head passes from the side of the dipstick, and in some above the exhaust manifold, I like the second option better, because .To. for a Chevrolet Niva it is more convenient, but alas, I found out about this late and I got a front outlet near the dipstick, the outlets are not expensive, about 1.5 rubles, then we buy a used engine from Priora with a timing case, gears and a flywheel, but with a flywheel it is for us It will be useful no matter what they write, but my version of the flywheel is the most convenient and easiest to manufacture. So, we read carefully, the kv from the Priora is shorter than the Nivov one and the input shaft fits into it by only 2-3 mm, so there is no need to sharpen the crankshaft, but we do this: from the Priora flywheel (or any one from 2108) we cut out the middle from the turner, such a snout with holes diameter

90mm is quite enough, we will use it as a spacer between the kv and the standard Shniv flywheel, we take our flywheel from the Shniv to the milling machine with this spacer and ask them to drill holes for the bolts as on our heel, ask for better alignment, there are Shniv flywheels on sale with already modified with such oval holes, you can buy it, it doesn’t matter, then we go to the UAZ Gas store and buy the flywheel mounting bolts from the UAZ, they are longer just by the size of our spacer, we also buy a input shaft bearing that should be inserted into the CV, install We insert our spacer on the knee into it (it fits tightly into it), then our Shniv flywheel, spacer plate and bolts from the UAZ, we fasten the whole thing with a torque of 8-9 kgf, having previously lubricated the threads with gray sealant or thread locker..., and that’s it... now we there is no need to resharpen the crown, there is no need to put a spacer under the release lever and there is also no need to put washers under the starter, in fact everything is easy and simple here... The pallet gave me a lot of trouble, I took a 16kL ready for the classics (as it turned out, this was in vain) it is completely different , it’s easier to make from 2108, my collective farm one is leaking, I’ll make the right one one of these days, so I’ll post a photo of the pan later, the exhaust is also not easy, they say you can take a ready-made 16kL from the classics and modify it for the field, I clamped 4p and made it from the exhaust manifold from priors (I got it, a new 1r) without kata which are sold, here I had to cut and cook from the heart, I don’t know who came up with the idea of putting a downpipe above the stabilizer on the shnivy, well, what the heck with it, I also docked them and the rest is all original..., well he doesn’t even say anything about the engine mounts, they fit the holes, just drill out the left bracket holes from 8mm to 10mm, now about the power steering: you can buy a power steering bracket for 2110 at a disassembly or in a store, it is compatible with ours, except for the pulley, the pulley is also needed from 2110 tk. the offset is different (here’s the catalog number, I took a new one 2110-3407180), a small part stopped the whole process for me, it’s called the generator belt roller bracket, here’s the number 21104-1041084-00, it’s better to get it from disassembly, these parts don’t break and there’s usually plenty of them, too you will need a generator bracket from a Priora with a steering wheel or a condenser and a front side engine mount, cut off the nose protruding from it, as an option, you can take a broken one at disassembly, they gave it to me for free, we need it for the correct installation of the generator, in short, we need everything here as on the Priora with a guru, you can change the alternator pulley from the Priora (in the field there are 5 streams on the Priora 6) and then the belt will be needed 6rk1113-6rk1120, I didn’t bother and set it to 5rk, so far it’s fine; the fuel rail from Priora fits perfectly, just straighten the tube carefully and connect it to ours; you can leave the receiver plastic, but then the air filter will be above the manifold, I have a snorkel and I had to order a ready-made one with the throttle turned to the battery, you can leave your thermostat, or you can use one from 2101, then as your imagination allows, you can buy additional pipes in the store and connecting is not difficult, it is not necessary to connect the throttle heating, but it is convenient to vent air through it..., now about the setup: I was able to rebuild my friend’s 21124 engine with a native Bosch 7.9.7+ engine without problems, only the throttle had to be changed to a regular one (Niva has a channel рхх more), in my case it turned out to be more difficult, if the operating modes were not able to be rebuilt, then a problem arose with xx, so I changed the unit to Itelma M73 with additional soldering of the necessary elements for the operation of the second speed of the fan, you can install January 7.2 from Kalina and you will also have to to rebuild the whole thing..., the wiring for the sensors had to be gutted in order to get everything to its place, except for the wire to the crankshaft sensor, it needs to be extended. The whole alteration took a week, a lot of time was spent on the pan and exhaust.

Bottom line

Having studied all the characteristics of the engine, it can be noted that the Priora power unit is a reliable and well-developed engine. The use of modern technologies and new developments has allowed domestic developers to create a reliable and high-quality unit.

Additionally, this unit is supported by reviews from owners and the desire of many car enthusiasts, despite the additional costs of time and money, to equip their vehicle with a Priora engine.

That very moment: test drive of LADA 4×4 with LADA Priora engine

I just want to exclaim: “Well, AVTOVAZ, why the hell couldn’t you do this yourself?!” But we won't shout. Because, firstly, we roughly know what the hell (about a billion different reasons), and secondly, we are not going to ask stupid questions. It’s much more interesting to ride and understand whether the mutant turned out to be suitable.

The flocked panel no longer looks so orphan-like, the leather steering wheel is a little more comfortable to grip, and it’s more comfortable to sit on the seats, which, in addition to the leather upholstery, have a reinforced frame. It’s just a pity that such a seat cannot fundamentally change the driving position of a Niva anyway. The “tuning” combination is also not bad (it’s certainly more interesting than the standard one), and the only thing that infuriates it is the blue background of the trip computer display. The fuel remaining indicator is incredibly simple - just a stupid arrow, no red zones or buzzer. Thanks to this, we returned from the test with one liter of fuel on board - we only noticed the shortage at the very end.

Needless to say, we got carried away by the trip! A steel roof rack would be useful on a long journey, but power bumpers (the front one has a built-in winch) and a “ski” for protecting units made of five-millimeter metal may well come in handy even on a short outing. After all, the car is a real provocateur: the rear self-block, suspension lift, toothy off-road tires and arches cut out for this purpose are enough for Niva to gain almost complete freedom on the roads.

Where on a stock car you will definitely “throw away”, on this one you can fly almost without looking back. The car swallows huge holes, does not nod and does not “goat”. Calmly passes mind-blowing “diagonals”. Cheerfully flies into brutal climbs. Exactly cheerfully - so that you clearly understand: a standard car would have “died” even in the middle of this ascent. And the reason for the cheerfulness is the VAZ-21126 engine, mated to a completely standard Nivov transmission.

And the VAZ is still there

This 1.6-liter 98-horsepower sixteen-valve engine is found on the LADA Priora, Kalina and Granta, and along with the eight-valve engine from front-wheel drive cars, AVTOVAZ engineers have long been trying on the LADA 4×4. However, things would still be there (read - the project would remain a project), if not for the world of tuning. In the case of the presented “patient” we are dealing with a completely serious approach to the matter. The guys who built the car have an engineering staff and a production workshop with modern equipment. The car was built to order in a single copy, but the solutions found on it are planned to be replicated and offered to customers, both in the form of a turnkey car, and in the form of a kit for self-installation.

The engine was placed longitudinally under the hood, and so that it would not rest against the engine shield, it had to be moved forward a little. As we can see, there is minimal space at the engine shield, but there is even plenty of space left for the radiator. It would be possible to move the box forward, but then it would rest against the steering rods. Therefore, the box remained in place, a spacer appeared between the crankshaft and the engine flywheel, and the box is connected to the engine through another spacer, consisting of three parts. Such solutions are not new, but subsequent reliability, as a rule, is greatly affected by the level of execution.

The updated Lada 4×4 will receive a Priora engine and a new subframe in 2015

The portal CARobka.ru has already reported that the updated version of the VAZ Lada 4×4 SUV will receive a new engine from the front-wheel drive model, and the engine will be positioned longitudinally. Several concrete facts have appeared about what awaits the Lada 4×4 '2015 and whether it awaits at all?

A short wheelbase, an 83-horsepower engine, all-wheel drive and a manual transmission - everything is simple, but how does it overcome off-road conditions?!

All this will entail several more changes that will have to be made to the design: the oil pan will have to be replaced, and the cardan joints in the transmission will give way to CV joints (constant velocity joints).

Only the fate of the Lada 4×4 raises some concerns among Russian Automotive journalists, namely: the Niva could be killed by Alliance partners, GM-Avtovaz and the new president of AVTOVAZ, Bo Andersson. Hack, of course, is a strong word. Rather, “friends” can hinder the development of the project for deep modernization and the creation of a new Lada 4×4 as much as possible. We do not know what levers they have for these purposes. In general, such rumors have been circulating for a long time, since the appearance of the Duster, now they have strengthened in light of the release of the Indian Nissan Terrano, and next year they may become a postulate when Chevrolet introduces a new generation of the Niva model. As for Andersson, who came to AVTOVAZ, they say that he may take the side of the controlling shareholder and help drown out the glorious ballad of Lada 4x4. We very much doubt this. In addition, lately there has been a lot of talk about the VAZ SUV. Vice President for Products and Programs of AVTOVAZ OJSC Mikhail Ryabov said that the new Lada 4×4 will appear at the end of 2017-beginning of 2022 and will retain the inherent brutality of this model.

Model

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more". The new model was first shown at the Moscow Motor Show in 1998, it was assumed that the launch into series would occur in the same year

But the crisis did not allow the manufacturer to start production. As a result, small-scale assembly began only in 2001, and full-scale production began in 2002, having organized a joint venture with General Motors.

The new model was first shown at the Moscow Motor Show in 1998, and it was assumed that the series launch would occur in the same year. But the crisis did not allow the manufacturer to start production. As a result, small-scale assembly began only in 2001, and full-scale production began in 2002, having organized a joint venture with General Motors.

Initially it was assumed that this model would replace the regular Niva, but in the end both models began to be produced in parallel. Moreover, Chevrolet Niva occupied the more expensive segment.

Produced all the time at the plant in Togliatti. This is the base site of AvtoVAZ. Most of the components are produced here. Only the Z18XE engine used in the pre-restyling version of the car was imported from abroad. Used only until 2009. This engine was produced at the Szentgotthard engine plant.

Advantages of the Priora engine

Based on all the characteristics and descriptions of the engine, we can say that it will be a reliable and efficient component of the vehicle, which will improve and increase its service life. It is worth noting that domestic manufacturers have been using the most modern techniques and developments for a long time, which allows them to create high-quality car components. That is why drivers have been making decisions to replace engines in their fields for a long time. Such a replacement increases the performance of the vehicle, and the costs relative to the purchase of a new car are not large.

Source