The ball joint is one of the most important components of the front suspension of front-wheel drive cars, including the Lada Kalina. The main purpose of the ball joint is to be the connecting link between the steering wheel hub and the suspension arms. That is, during vertical movement, the hub rotates, but the horizontal position of the wheel remains unchanged. The condition of the ball joint should be carefully monitored. Otherwise, there is a high probability of serious consequences, especially if the breakdown occurs while driving. If the ball joint fails, the wheel will turn outward and the car is guaranteed to fall onto the wing. If you imagine such a situation at high speed, there is a high probability that its development will lead to a serious accident.

Characteristics of the ball joint on the Lada Kalina

This unit holds the wheel in a certain position, while at the same time allowing the hub to rotate and maintain horizontal stability. The ball joint is called because of the ball-shaped tip. Structurally, it is a cone-shaped unit.

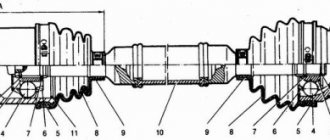

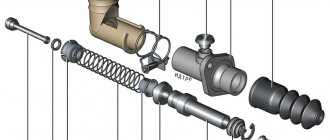

The Lada Kalina uses a modern collapsible element, although the first VAZ models had stamped assemblies from several parts, and then cast structures. The ball joint installed on a Lada Kalina car, regardless of modification and generation, has a standard device that includes several main components:

- frame;

- a part in the form of a cone (another name is “finger”);

- rubber protective boot (prevents dirt and dust from entering).

The main elements are made of high quality steel. This is due to the fact that during operation the working parts are constantly exposed to load, friction and, as a result, high temperatures. The only exception is the hollow part of the body, which is covered with polymer materials. Plastic is mainly used for these purposes.

The main advantage of the Kalina ball joint is the extreme simplicity and efficiency of the design, which allows the contacting parts to move freely at equal angles.

Looking at the structure of the ball in more detail, it can be noted that it is actually a steel finger, which on one side ends with a tip in the form of a small ball. The tip rests on a plastic (or polyurethane) gasket. The bushing and ball end are located in the body and are rolled to prevent flyout. The body is additionally galvanized against corrosion. It is fixed to the upper or lower control arm and the threaded part is secured with a knuckle nut. Thanks to this, the fist is not fixed too tightly, which allows it to rotate along with the wheel hub, and the vertical position is maintained when the vehicle’s suspension is operating.

The ball joint is a fairly reliable and durable unit if you follow the operating rules. The long service life of the ball joint is possible thanks to the lubricant located in the part of the housing where it comes into contact with the working part. Insufficient lubrication, its leakage and moisture entering the internal cavity can cause premature failure of the entire assembly. To protect the working parts, a special boot made of rubber that is resistant to aggressive environments is used.

In order for the ball joint to last as long as possible, every car enthusiast should check the condition of the suspension from time to time, paying special attention to the rubber boots. There should be no cracks or other visible damage on their surface. If there are defects, it is recommended to check the condition of the entire assembly for wear.

Features of individual designs

As mentioned above, this is only the most common version of the ball joint. But there may be, as they say, options.

- removable ball joint.

- a ball joint made integral with the lever.

The same fault detection method is used for all versions.

Video - how a ball joint works when a car is moving:

Important:

Despite its simplicity and reliability, the ball joint has a limited service life. The worse the quality of the road surface on which the car is driven, the greater the chance that the part will fail ahead of time. Failure of this important component can cause a serious accident. The malfunction should be identified at an early stage of its occurrence.

Diagnostics of ball joints and reasons for their failure

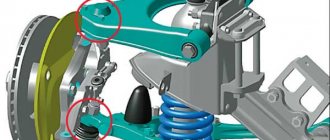

Like all budget front-wheel drive cars, the Lada Kalina is equipped with a MacPherson-type front suspension. Briefly, the design consists of an upper support in the form of a strut with a shock absorber and a spring, and a lower support in the form of a wishbone. This lever is connected to the wheel hub (via the steering knuckle) using a ball joint. The design is elementary and therefore reliable, but the presence of moving elements makes diagnostics a difficult task, requiring certain skills and knowledge.

Signs of a ball joint malfunction

The most common symptoms of problems with this unit include the following:

- when driving at low speed over uneven surfaces, a knock is heard from the front suspension;

- when turning the steering wheel, a slightly greater force is required;

- when turning the steering wheel, the front suspension begins to creak;

- Tires wear out differently;

- The car pulls to the side when driving in a straight line.

But it is impossible to diagnose only a ball joint based on these signs, since these same symptoms may indicate problems with the shock absorber strut, wheel bearing or suspension arms. There are a number of methods for independently identifying faults that are not very complicated.

Diagnostic methods

| Options | Performance |

| The first and most accessible is a hearing test. | To do this, it is better to use the help of a second person. The engine must be turned off and the vehicle placed on a level surface. Have a helper rock the car. At this time, you need to listen to identify any extraneous sounds coming from the ball joint. Unfortunately, despite the simplicity of the method, it will not be informative for inexperienced car enthusiasts, since it is difficult for a beginner to localize the source of knocking and squeaking. |

| The second method is similar to determining whether a wheel bearing is faulty. | To do this, you need to check the wheel play using the rolling method. First you need to hang the desired wheel using a jack. Next, holding the lower and upper points of the wheel, you need to swing it in different directions with your hands. Ideally there should be no backlash. If there is play, this may indicate trouble with the ball. On the other hand, play may indicate problems with the wheel bearing. |

| The third method involves diagnosis by touch. | To do this, you need to place your palm on the support so that your palm simultaneously rests on both the body and the ball-shaped tip. At this time, the assistant should swing the wheel hanging on the jack; in this situation, you can easily feel the degree of play of the ball joint. |

It should be taken into account that on non-original supports there are special diagnostic holes that allow you to determine how worn the tip is. In addition, you can find out about problems with the ball by looking at the condition of the protective boot. Even small cracks can cause grease to leak and dirt and dust to enter. As a result, this results in accelerated wear of the unit and a significant reduction in service life.

Causes of ball joint malfunctions

Among the most common are mechanical damage and natural wear and tear, which can be significantly accelerated by a number of factors.

Boot rupture

This is one of the most common reasons for ball joint failure. A working boot should protect internal working elements from moisture, dirt, dust, etc. As a result, the lubricant ceases to perform its functions and increased wear of parts begins. The boot is made of rubber. This means that in the summer and at low temperatures in winter, the protective boot is susceptible to destruction.

Off-road

When driving on uneven surfaces most of the time, the ball joint wears out much more intensely. This is especially true for Russia, where the problem with roads is familiar to every motorist. Based on this, you should not rely on the service life indicated by European auto parts manufacturers. Usually it is better to change much earlier, because foreign brands do not take into account the condition of our roads.

Inadequate or absent lubrication

If there is heavy wear, it should be added in a timely manner, otherwise increased friction of the metal parts will lead to heating and rapid wear of the ball. Typically, this situation leads to severe grinding of the ball-tip pin, resulting in an increased gap and the pin dangling in the socket.

When the car starts to move off-road or on uneven surfaces, the pin may jump out of the housing (clip) with increased clearance. This is usually accompanied by a characteristic knock (knocking from one of the wheels) in the front suspension.

When is it worth checking?

It is necessary to check the ball joint when there is a suspicion of a problem.

Let's list the most common ones:

Knock - if a knock is heard from the front wheels while driving off-road.

Wobbling - if there is a kind of “wobbling” of the car when driving on a flat surface.

Creak - if the driver hears strange creaks when turning the steering wheel.

Wear - if it was noticed that the front tires wear unevenly, namely, the wheel with a faulty ball joint is subject to greater wear.

If at least one of these signs of malfunction is detected, we recommend checking the balls. This should be done as quickly as possible, since malfunctions pose a threat to passengers.

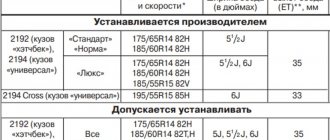

Selection of ball joints for Lada Kalina

Its front suspension is not much different from previous VAZ models, for example, Priora, Samara, etc. The chassis of different generations of Kalina itself does not stand out fundamentally. On the first generation and on Lada Kalina cars of 2 different modifications, ball joints with catalog number 21100-2904192-82 are installed, and for supports with a set of fasteners, catalog number 21100-2904192-86.

The modern auto parts market offers customers different types of supports. The first are original (welded from several parts), and the second are stamped and reinforced. Structurally, all these hinges are arranged identically. The only differences are in the manufacturing technology and quality of the steel used, as well as its thickness. This determines the strength of the products, their durability and, of course, cost. In terms of size and principle of operation, they are no different from each other. From this we can conclude that the question of choice is not fundamental and depends on the personal preferences of the car owner.

Experienced car enthusiasts, as well as auto mechanics, recommend using exclusively original components. Only by choosing the original, you can be guaranteed to obtain the declared quality, reliability and long service life. However, as practice shows, original spare parts are sometimes much more expensive than analogues, so most car enthusiasts prefer to use the second option.

When choosing analogues, you need to approach the issue carefully and responsibly. You should not choose very cheap spare parts from an unknown manufacturer, and you should also not take components from markets, unknown points, or simply from your hands. Before purchasing, you should carefully inspect the components. There should be no visible welds on them; the surface should be gray, which indicates heat treatment of the part.

The components must have an emblem and a quality mark. As a rule, fakes do not have this.

Indirectly, quality is indicated by holograms on the case or packaging of components, as well as an additional set of fasteners. The cost of a ball joint for Kalina usually does not exceed 500 rubles. It's inexpensive, but it's worth considering that purchasing units for tuning can be significantly more expensive. For example, those from Pasker are valued tens of times higher.

Replacing a ball joint on a Lada Kalina

The instructions for carrying out work on the first generation Lada Kalina and the “two” are no different. This does not depend on the modification, for example, sedan, station wagon or hatchback (cross). You can do everything yourself. To do this you will need the following set of tools:

- wrenches or socket heads 17 and 19;

- TORX E12 head;

- special puller for ball joints.

You may also need a torque wrench to ensure optimal tightening of nuts and bolts, a pry bar, and a hammer to knock out the pin. As for the TORX E12 key, it can become useful when working with a ball joint on Kalina 2, where this fastener is used for fastening to the steering knuckle, and not a 17 bolt, as on Kalina 1st generation.

Rules for removing the ball joint

Before starting work, you should raise the parking brake lever all the way and use the jack to hang the desired wheel. The further process is as follows.

- Using a socket or a 19 mm wrench, unscrew the fastening nut, thanks to which the ball end is mounted on the wishbone.

- Use a special puller to remove the conical pin from its seat in the body.

- Using a 17 wrench (on Kalina 2, a TORX wrench), unscrew the fastening bolts that secure the ball to the hub knuckle.

- Using a pry bar, lower the lever lower. This will give you access to remove the ball joint.

To make the task easier, you can pre-treat the bolts and nuts with VD 40 or any similar liquid. This is true in some cases, but usually there are no problems with unscrewing nuts and bolts. If there is no puller for ball joints, you can remove the pin in another way:

- loosen the nut and leave it on the tip;

- Use a mounting spatula to press the lever from top to bottom;

- Use a hammer to knock the pin out of the body, thereby pressing it out of the seat.

If desired, the ball can be visually inspected and tested for compliance. To do this, the assembly is clamped in a vice. And with movements in different directions, the axial and other play of the finger in the socket is checked. The play should not exceed 0.7 mm; if there are large deviations in this indicator, the unit should be replaced; the ball joint cannot be repaired. If it is in order, but the rubber boot is damaged, you can only get by by replacing it. To do this, the support is dismantled and the boot is removed from it; before installing the cover, it should be filled with a suitable lubricant and fixed to the support.

Layout of front suspension parts

1 — anti-roll bar; 2 — rubber-metal joint of the transverse arm; 3 — shock absorber strut; 4 - stretching; 5 — extension bracket; 6 — nut for fastening the extension to the bracket; 7 — ball support of the shock absorber strut; 8 — joint of the anti-roll bar; 9 — wishbone; 10 — bracket for securing the stabilizer bar.