Shock absorber struts on the VAZ-2114, like on any other car, play the role of absorbing unevenness in the road surface, and also take the load of the entire car: cargo and passengers. Therefore they must be strong. The choice of struts should be treated carefully, since it depends on them whether the car will be hard or soft, and how loud the potholes will be, of which there are plenty on our roads.

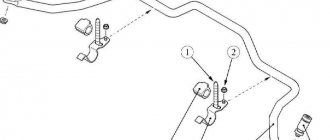

Support bearing diagram

Failure of a support bearing entails significant consequences: deterioration in controllability, extraneous crackling noises, knocking in the suspension. Failure of the support bearing - crushing of the balls, or the bearing simply crumbled or jammed.

To make sure that the support bearing is faulty, you need to check it: How to check the support bearing (support)?

Next, after making sure that it is faulty, you need to replace it: Replacing the support bearing (support)

But before you start replacing, you need to select a new bearing.

Today, bearings are available on the market from many manufacturers and of varying quality.

As a rule, factory strut supports last a maximum of 40 thousand km (and then in the best case), and more often only 20 thousand km, then they need to be changed.

Let's look at the main support market:

- "Rusich." The quality is poor, probably even worse than the factory ones.

- "Asomi." Essentially an ordinary factory bearing, besides, the bearing itself is plastic.

- Support "SS-20". Perhaps, probably the only serious unit on today's market. If you ask me to recommend props, then definitely SS-20. Just read the reviews online and see for yourself.

In appearance, these supports look monolithic and reliable; they include a sound insulator, so the suspension will be much quieter than in the stock version. The only drawback is the high price compared to competitors (almost twice as much), but the quality requires it. But there is a small rumor that, due to their strength and rigidity, weak suspension elements suffer - whether this is true or not is anyone’s guess. In any case, weak elements in the suspension will always suffer.

Why you shouldn’t delay repairs

When the OP has completely crumbled, you can continue moving. But driving with a damaged bearing dramatically accelerates the wear of other suspension parts. In addition, usually with this breakdown the geometry is disrupted - alignment and camber. This not only causes accelerated tire wear, but can significantly reduce the car's handling. This increases the risk of an accident. Therefore, it is not recommended to drive for a long time with damaged support bearings.

Every car owner needs to know this.

The supports themselves do not require maintenance and last a long time. But it is necessary to change the old support on time. A serviceable car is the key to safety on the road!

Source

Which shock absorbers are better to install on the VAZ-2114: choosing shock absorbers based on price and quality

Shock absorber struts on the VAZ-2114, like on any other car, play the role of absorbing unevenness in the road surface, and also take the load of the entire car: cargo and passengers. Therefore they must be strong. The choice of struts should be treated carefully, since it depends on them whether the car will be hard or soft, and how loud the potholes will be, of which there are plenty on our roads.

When contacting us, you can be sure of these 3 points:

Is it time to replace the engine mounts? Our car service in Ufa carries out the full range of diagnostics and repairs in a short time and at the best price.

When do you need to replace engine mounts?

The comfortable and efficient operation of a car is influenced by many factors. One and important phenomenon is sound insulation. The level of silence in the cabin depends on the condition of the road surface, the condition of the engine and the health of the suspension. The supports are responsible for reducing vibrations that are produced on the body. Like most spare parts, they are subject to wear and tear, and as a result, loss of efficiency. This is when engine mounts need to be replaced. A timely procedure will eliminate the resulting noise and eliminate further problems.

The car owner is recommended to monitor not only the condition of the supports, but also the proper operation of the car as a whole. If worn out cushions are not replaced on time, they can cause a lot of trouble to the engine, which can even lead to engine replacement. Listen carefully to the sounds of your car.

The main signs of wear are:

- Increased vibration when starting and driving,

- A previously unnoticeable roar appeared when hitting bumps,

- A characteristic metal-on-metal creaking sound.

Replacing engine mounts at the Avtodetal-Ufa car service center

The procedure for replacing engine mounts is quick and the price is quite reasonable. Therefore, if at least one point appears, we recommend calling our service and asking for advice. Delaying can lead to more serious damage and therefore increase the cost of repairs.

Our car service provides such a service as replacing engine mounts in the city of Ufa. Our specialists, having extensive experience in this field, will make the necessary diagnostics and carry out high-quality and fast repairs. Call us at the phone number listed on the website, and we will answer any questions you may have.

Our service is conveniently located near Sipailovo. While our car is being repaired, you can spend time in the rest room or in a nearby cafe. Trust your iron friend in the capable hands of our professionals!

Selection of racks

Tuning version of car suspension

The choice of shock absorber struts for a VAZ-2114 can often confuse the car owner, since in addition to the original there are a number of analogues that can also be installed, as well as a sports version. Let's consider which of all the racks are most suitable for installation on a car and are suitable for our rough roads.

Native racks

2108-2905001 and 2108-2905002 – original catalog numbers of front shock absorber struts for the VAZ-2114 family of cars. The average cost is about 2,000 rubles/piece.

Original shock absorber struts

Since the conversation is about which struts are better, we can conclude that original shock absorbers do not suit car owners. But why? It seems that the design engineers took everything into account when designing this spare part, but no, something is still wrong.

The first factor that puts native stands in a negative position is that their endurance leaves much to be desired. The shock absorber seal does not last its life on smooth roads , not to mention the fact that it has to constantly absorb potholes. Since the original struts are of the oil type, when accelerating over 120 km/h it begins to loosen, and at 140 km/h this becomes significantly noticeable.

It is these two problems that become the reasons that car owners begin to look for a replacement for the original part.

What's behind?

2108-2915003 and 2108-2915004 – original part numbers for the rear left and right shock absorber struts manufactured by AvtoVAZ. The average cost is 2000 rubles/piece.

Maybe analog is better?

Analogue racks are usually either a cheap replacement for the original, with the same characteristics, or an improved budget option.

In fact, many manufacturers of spare parts offer a wide range of products that have long been loved by car owners and are highly popular.

So, let's consider a possible option for installing analogues of the VAZ-2114 shock absorber.

Front struts

Shock absorber strut manufactured by Fenox

Rear pillars

Shock absorber strut manufactured by Finwhile

Particular attention should be paid to shock-absorbing struts manufactured by Monroe.

Monroe racks

As practice has shown, they cope well with the uneven roads of the country and also have high durability. Read more about the process of replacing rear shock absorbers here.

Sports and popular stands

Sports shock absorbers

Removing the engine mounts

Before you start work, you will need to go over all fasteners with a solution that removes rust. Thanks to this procedure, the VAZ engine mount will be removed much easier. When lifting the engine, make sure that other parts of the car, including wires, are not damaged.

Otherwise, you will have to pay extra money to repair once high-quality car parts. Next, the socket head breaks off the fasteners, and the process of carefully lifting the engine begins. After this, all work related to the VAZ engine support will be easier to carry out using a wrench and ratchet. The easiest way to start the replacement procedure is with a bolt that is located across the body with a support.

It is worth noting that it is thanks to him that the bracket located there is connected. After this, you can begin to gradually unscrew all the bolts that hold the cushion to the engine block. If the process went without complications, you can begin dismantling the old rubber support. Now all that remains is to directly install the new pillow in the old place.

In this case, all parts are screwed in the reverse order. When performing the work described, you should pay attention: the bolts are attached only after you are completely sure that you have assembled the entire structure correctly and the parts fit perfectly into their original place. In addition, before directly tightening it, it would be useful to additionally treat the fasteners against rust.

Features of the left support

Before starting work, keep in mind that the left engine support of the VAZ is located in such a way that in order to pick up the gearbox, you will need a cable. The left support is one of the most difficult to place cushions and is very inconvenient to replace. First of all, this occurs because the starter housing interferes with the removal of the fasteners. Since replacement still needs to be done, you can use two options:

- complete removal of the starter;

- turning out the studs.

Keep in mind that when choosing the second method, you will need to remove the mounting bracket for the airbag, located directly in the gearbox. In most cases, the studs can be unscrewed without any complications. However, if difficulties arise during operation, in order to remove the studs, use a structure of several nuts and unscrew the stud by the lower one.

After this, you only need to unscrew the bolt securing the support to the bracket. The left engine mount of the VAZ, like the others, requires careful placement of the studs in their designated places. To easily complete this procedure, jack up the transmission and install all required fasteners. After the work is completed, the box is lowered to its original place and all the bolts are carefully secured.

Replacing the rear support

Its replacement is carried out according to the same principle as when dismantling the left support. You will need to lift the gearbox using a cable and be sure to place a jack under it, which will support it from below. Now all the bolts holding the support to the engine are removed, and the unit is carefully lifted. Only after you have completed all these steps will you be able to completely remove the transmission mount.

In order for the installation of the new rubber support to be successful, you will have to adjust all the holes together using a jack. This procedure must be carried out with special care so that the installation of vertical bolts occurs without difficulty.

If they go in askew, the thread will be very damaged. And do not forget that all bolts can be tightened only after you are completely confident in the careful matching of the parts. When they are all fully tightened, you need to carefully remove the jack from under the engine and further tighten all the fasteners.

Replacement of support bearings VAZ-2113, 2114, 2115

The support bearing, to the inner part of which the front strut is attached, and the body rests on the outer part, serves to movably connect the front strut and the body, softening all kinds of shocks and vibrations coming from the shock absorber. A timely replaced bearing will eliminate the problems of overhauling the entire chassis. When the hood is open, the support bearings are visible above the wheels on both sides.

A little about the design of the car suspension

Let's talk about the suspension design

— almost all mass-produced cars now use the so-called MacPherson suspension, named after its inventor. An important element of the suspension are shock absorber struts.

MacPherson strut is also called the “swinging candle”

due to its design features. The device contains a spring, a damper and a shock absorber on one axis, which absorbs the energy of vertical vibrations of the car, ensuring a smooth ride.

The upper part of the rack is attached to the body

car using a special rubber bushing - the upper support. These undercarriage components transfer variable vertical load from the wheels to the body during operation.

In the front supports

In addition, a rolling element is required, a strut bearing, which allows the strut to rotate. Therefore, the design of the support in the front of the car differs from the rear in that a strut bearing is installed there.

Basic faults

Wear of the VAZ-2114 bearing is the main reason for replacing it. A knock in the suspension, which is heard when driving on a bumpy road or when turning, should alert the driver. Checking the bearing is simple: you need to grab it with your hand and rock the car; a knock that may appear indicates the need for repairs.

The dirt that is abundant on the roads is one of the causes of defects in the mechanism. The support is practically not protected from it.

It is worth checking the condition of the supports at least after 20,000 km.

If the knocking does not go away, then think about this: a completely worn bearing can break completely, and this will lead to the strut breaking through the hood. Repair costs will be completely different.

What is this?

It’s not uncommon for owners of the domestic “fourteenth” VAZ model to notice that a knocking noise

. The reason for its appearance is failed support bearings.

But you don’t need to start replacing right away. The first priority is to check the condition of the support. And only then take appropriate actions.

The support bearing is an element of the shock absorber strut located in the front suspension structure. Its job is to maintain the mobility of the connection between the body and the shock absorber of your car. If the bearing turns out to be faulty, mobility is impaired and a knocking noise occurs, which is difficult not to notice. Especially when it comes to bad roads.

There are several types of supports:

- A bearing with an integrated inner or outer ring. No clamping flanges are required for its installation. There are corresponding holes for installation;

- With detachable outer ring;

- With detachable inner ring;

- Finishing and cutting structure, the characteristic feature of which is its strong rigidity.

The name of the support bearing speaks for itself. This is something like a strut support on the front shock absorber, which is located in the area where it connects to the body. This arrangement indicates the axial loads that the support must withstand.

Replacement

- spanners;

- spring tie;

- jack;

- hammer;

- mount;

- a device for removing the nuts securing the stand;

- mechanism for removing the steering tip.

Work order

- You need to remove the hub cap and rip off the CV joint nut while an assistant presses the brake using a wrench or socket.

- Raise the car using a jack and remove the wheel. The factory stand should also secure the vehicle.

- With the steering wheel turned in the opposite direction from the support being repaired, you need to release the cotter pin. To do this, use a hammer, a pry bar and a steering rod puller.

- Remove the 2 ball joint mounting bolts.

- The brake hose is removed from the holder.

- Next, the 2 caliper bolts are also loosened. It must not be allowed to hang on the brake hose; it must be taken to the side and hung on a wire.

- To make it more comfortable to work with the stand removed, the nut needs to be removed, but there is no need to unscrew it completely. Then the 3 support nuts are unscrewed.

- Unscrew the CV joint nut completely and simultaneously remove both the CV joint and the strut.

- Use the device to compress the spring evenly on both sides.

- You can easily disconnect the support from the compressed spring. A new support is installed.

- Assembly is carried out in reverse order.

ESSENTIAL TOOL

A high-quality replacement of support bearings on a VAZ 2114 with your own hands requires a minimum set of tools to perform these tasks:

- Standard set of open-end and ring wrenches size 12-24;

- Steering rod puller;

- Standard auto jack;

- Coupler for shock absorber springs;

- A “19” wrench is used to remove the strut rod nut.

Unscrewing the nut

Which shock absorbers are better to install on the VAZ-2114: choosing shock absorbers based on price and quality

Shock absorber struts on the VAZ-2114, like on any other car, play the role of absorbing unevenness in the road surface, and also take the load of the entire car: cargo and passengers. Therefore they must be strong. The choice of struts should be treated carefully, since it depends on them whether the car will be hard or soft, and how loud the potholes will be, of which there are plenty on our roads.

Selection of racks

Tuning version of car suspension

The choice of shock absorber struts for a VAZ-2114 can often confuse the car owner, since in addition to the original there are a number of analogues that can also be installed, as well as a sports version. Let's consider which of all the racks are most suitable for installation on a car and are suitable for our rough roads.

Native racks

2108-2905001 and 2108-2905002 – original catalog numbers of front shock absorber struts for the VAZ-2114 family of cars. The average cost is about 2,000 rubles/piece.

Original shock absorber struts

Since the conversation is about which struts are better, we can conclude that original shock absorbers do not suit car owners. But why? It seems that the design engineers took everything into account when designing this spare part, but no, something is still wrong.

The first factor that puts native stands in a negative position is that their endurance leaves much to be desired. The shock absorber seal does not last its life on smooth roads , not to mention the fact that it has to constantly absorb potholes. Since the original struts are of the oil type, when accelerating over 120 km/h it begins to loosen, and at 140 km/h this becomes significantly noticeable.

It is these two problems that become the reasons that car owners begin to look for a replacement for the original part.

What's behind?

2108-2915003 and 2108-2915004 – original part numbers for the rear left and right shock absorber struts manufactured by AvtoVAZ. The average cost is 2000 rubles/piece.

Maybe analog is better?

Analogue racks are usually either a cheap replacement for the original, with the same characteristics, or an improved budget option.

In fact, many manufacturers of spare parts offer a wide range of products that have long been loved by car owners and are highly popular.

So, let's consider a possible option for installing analogues of the VAZ-2114 shock absorber.

Front struts

Shock absorber strut manufactured by Fenox

Rear pillars

Shock absorber strut manufactured by Finwhile

Particular attention should be paid to shock-absorbing struts manufactured by Monroe.

Monroe racks

As practice has shown, they cope well with the uneven roads of the country and also have high durability. Read more about the process of replacing rear shock absorbers here.

Sports and popular stands

Sports shock absorbers

As you know, many car enthusiasts install sports and semi-sports shock absorber struts on their cars to achieve maximum effect on the roads and maximum stability. They are more durable and absorb road imperfections much better than stock or analog struts.

There are a number of manufacturers who have proven over many years of work that parts can be not only high-quality, but also durable. So, let's look at which spare parts manufacturers offer high-quality sports shock absorber struts.

Popular solution - Kayaba

Shock absorber struts manufactured by Kayaba

“Kayaba” are legendary stands that have earned worldwide recognition. They are famous for their quality and durability. At the same time, the automobile spare parts market is filled with counterfeits of this manufacturer. Let's look at what racks the manufacturer offers for 2114:

- EXCEL-G is a gas strut that is filled with nitrogen. Mainly intended for everyday driving, without special loads.

- Ultra SR and Ultra GR are sporty shock absorber struts with increased stability.

- Premium is a new generation of hydraulically driven shock absorbers. High-quality production material increases long-term use.

ProSport - CIS is not lagging behind!

Racks produced by ProSport

A legendary CIS company that has long been making sports versions of parts for domestically produced cars. There are two options for installation on a car - gas (sports) and gas-oil (semi-sports).

SS20 - forward domestic manufacturer

Racks manufactured by SS20

Popular manufacturer of domestic origin. The main specialization is the creation of tuning parts for cars produced in the CIS. For the VAZ-2114 there are 4 options for shock absorber struts from this manufacturer:

- Highway . Rigid struts that maximize cornering when accelerating.

- Standard . This option becomes ideal for those who live in harsh regions. They tolerate extreme heat and frost very well.

- Comfort . A universal version of racks, and therefore they are highly popular among car enthusiasts. The design features are such that they grip the road surface properly and work well with any driving style.

- Sports . These are the toughest racks. This option is intended for tracks, as it ideally holds the car during sharp maneuvers at high speed.

conclusions

Of course, the best option for installation on a VAZ-2114 are sports racks, since they are durable and have many advantages over the original ones. It is worth noting that several analogues have also earned their name because they have a price-quality ratio. So, if you know your driving style, the characteristics of the region and some characteristics of the struts, you can choose the best option for your car.

2 years have passed, and…another suspension repair! And again, the culprit for the repair was the front strut supports... I remembered for a long time that I had installed them there 2 years ago... in the end I took them off and realized that they were BZAK Belebey supports... they lasted even less than similar Sevi ones... and extraneous noises, crunching noises appeared... etc. ...unlike the second ones, which betrayed themselves by the presence of play... and on the same support... But both died... probably even at the same time), not the first, not the second supports do not deserve to talk about survivability, etc., reliability... considering what We have roads... let's not swear at them too much))))). Both competitors ran approximately 25 thousand km, Bzak, in my opinion, 20 thousand km.

We draw a conclusion and forget similar products regarding suspension strut supports...

What did I buy and install today... Demfi, front strut supports for VAZ 2108-15, the choice was unexpected, I was about to take the factory... Lada, the price of which is 400 rubles per piece, but I decided to see what the market offers us, and came across the following supports... SITEK, the price is 1000 r set, they say you can install it... the bearing is modified... supposedly better than the factory one, although Sitek is also a factory according to the seller... sold in the original spare parts department... then we came across AMT supports, the price is 1100... or 1200, for a set, you can try them, and now DEMFY supports, Togliatti, the price varies, I took it for 1100 for a set, they say they are good, moreover, all these supports are sold in tuning departments... goodies, so to speak... without hesitation... the price is not too bad... I bought it. I installed it in the evening! Of course, I don’t really believe that the supports will be more reliable than the previous ones, but there is Hope... and time will tell... At the same time, I bought 6 new nuts for the supports, and I advise everyone to replace the old fasteners with new ones... 24 rubles for 6 nuts...

I’ll try it, I don’t know the feeling yet, I haven’t driven it... tomorrow I plan to do an alignment, but before that I need to replace one steering tip, the boot is torn, although the tip itself is working... so I could change the boot and it’s beautiful... (when I installed them, I had only one on the right it was oriented a little not horizontally, and the boot was touching the stand... rubbing where the tip itself is inserted...) so it was apparently damaged... I have Belmag Comfort... very good tips... I've been skating for over a year... so far so good... now I'm deciding to change both or one…

Failure of the strut support bearing on cars is very common. Many owners of these cars immediately go to a service station, where they have to pay a lot of money and waste time for a replacement. If you have the necessary tools, do all the work without asking for outside help.

Support bearing diagram

Failure of a support bearing entails significant consequences: deterioration in controllability, extraneous crackling noises, knocking in the suspension. Failure of the support bearing - crushing of the balls, or the bearing simply crumbled or jammed.

To make sure that the support bearing is faulty, you need to check it: How to check the support bearing (support)?

Next, after making sure that it is faulty, you need to replace it: Replacing the support bearing (support)

But before you start replacing, you need to select a new bearing.

Today, bearings are available on the market from many manufacturers and of varying quality.

As a rule, factory strut supports last a maximum of 40 thousand km (and then in the best case), and more often only 20 thousand km, then they need to be changed.

Let's look at the main support market:

- "Rusich." The quality is poor, probably even worse than the factory ones.

- "Asomi." Essentially an ordinary factory bearing, besides, the bearing itself is plastic.

- Support "SS-20". Perhaps, probably the only serious unit on today's market. If you ask me to recommend props, then definitely SS-20. Just read the reviews online and see for yourself.

In appearance, these supports look monolithic and reliable; they include a sound insulator, so the suspension will be much quieter than in the stock version. The only drawback is the high price compared to competitors (almost twice as much), but the quality requires it. But there is a small rumor that, due to their strength and rigidity, weak suspension elements suffer - whether this is true or not is anyone’s guess. In any case, weak elements in the suspension will always suffer.

We check the quality of the work performed

When doing the replacement yourself, some skill deficiencies may appear. Somewhere a nut was not tightened or any of the elements of the rack were installed much crookedly. In order to avoid getting into an unpleasant situation on the road in the future, it is necessary to check the functionality of all the mechanisms that you touched when replacing the support bearing.

First, let's rock the car and check it for extraneous knocks. Be sure to check the operation of the brakes, since the caliper was removed during replacement. If everything is normal, you can start operating, not forgetting to check the wheel alignment settings, since it is also very easy to knock them down. The support bearing on VAZ 2108-2115 vehicles is replaced on average once every 40 thousand km. If you do not want to endanger the machine racks, replacement must be done for preventive purposes.

Taking into account the quality of Russian roads, coupled with the build quality of domestic cars, you need to be prepared for constantly occurring breakdowns in car parts. Even if you are lucky and your car is indeed equipped with high-quality parts combined with excellent assembly, natural shock absorption has not been canceled.

Nowadays, a car's suspension includes a huge variety of different parts: shock absorbers, springs, bearings and much more. Each part is responsible for certain functions, but safety is guaranteed only through the quality of the installed mechanisms and their proper operation.