Replacing the rear wheel bearing of a Lada Granta

Any car enthusiast should monitor the condition of his “iron horse”.

You can check the serviceability of a particular part yourself. Let's say, to find out what condition the rear wheel bearing of a Lada Grant is in, you need to hang the wheel in a free state and rotate it by hand. Ideally, the wheel should spin evenly and smoothly without knocking or sticking.

But it happens that the car owner hears extraneous noise while driving, like a buzzing or howling, or when shaking a suspended wheel, he notices a rather significant play. In this case, we can say that the support bearing of the rear wheel hub may fail.

If we talk about the durability and reliability of the bearings of the Lada Granta car, then we must admit that many car owners, when operating their car in the first thousand kilometers, noted failure or breakage of the hub.

Perhaps in the future this error will be corrected by the manufacturers of the Lada Granta, but today we will proceed to the independent step-by-step repair and replacement of the bearing on the rear wheel hub of the Lada Granta car.

In the Lada Granta model, the front hub bearing also requires adjustment and replacement from time to time, but here for now we will talk about the rear hub bearing.

The hub is equipped with a double-row ball bearing, which, it should be noted, requires absolutely no maintenance - no lubrication, no adjustment.

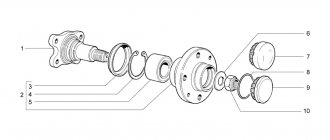

Hub configuration

The rear wheel hub of a Lada Granta car consists of:

— mud ring, — thrust washer, — lock ring, — hub fastening nut, — hub axle, — sealing ring, — Lada Granta hub bearing, — hub cap,

To repair and replace the bearing, you will need the following tools:

- universal puller, - thin chisel, - lock ring remover, - socket wrench (head) 30,

Repair and replacement of Grant rear wheel bearing

So, let's proceed directly to the bearing replacement itself:

1. Remove the protective cap.

2. Unlock nut 5 securing the hub.

3. Engage first gear and install supports for the front wheels.

4. Loosen the fastening bolts of the hub nut and wheel. As a rule, the hub nut is tightened with a large torque, and therefore, as a lever, you can take a piece of pipe for example.

5. Raise the rear of the car and place it on reliable supports.

6. First remove the wheel from the bearing side, which is being replaced, and then the brake drum.

7. Finally unscrew the hub nut and remove the thrust washer.

8. Install the puller and carefully press the hub from the axle.

9. We clamp the hub with a vice and remove the retaining ring from it.

10. Press the bearing out of the hub using a puller, clean the inside of the hub, press in a new bearing and install the retaining ring. It is imperative to make sure that the retaining ring fits completely into the groove of the hub.

11. Applying force to the inner ring of the bearing, we press the hub onto the axle, helping ourselves with the appropriate mandrel. Next we install the brake drum and wheel. Before installing the drum, the mating surfaces of the drum and hub should be thoroughly cleaned of scale and rust.

This must be done, since even the smallest foreign body, falling between these surfaces, will lead to vibration during braking and drum beating. To press in the bearing, use a mandrel of the required size. If there are none, then you can use the rings of the old bearing.

12. The final stage is to tighten the hub nut in the same way as the wheel mounting bolts, and this must be done with the car standing on the ground. A new nut or a nut from another wheel is best for this.

13. Lock the nut and install the protective cap.

14. We check the work done.

Replacing the front wheel bearing on a Lada Granta Replacing the front wheel bearing: catalog of materials

Wheel bearing failure is a common occurrence during the operation of domestic cars. Using an example, consider the Lada Granta car (Lada Granta, 2190, 2191, Sport, Liftback, Sedan) produced by VAZ, designed on the basis of the Lada Kalina, in terms of dimensions the car is classified as “C” class. The front suspension is borrowed from Kalina, but is modernized. In terms of reliability, these models are not much different. The Granta wheel bearing is replaced without specialized tools, experience and knowledge.

Following the instructions and recommendations, the replacement can be done with your own hands in a couple of hours, without the financial costs of a car service. Before reading the article, watch the video of replacing the wheel bearing on a Lada Grant.

The front wheel bearing on the Grant is not the most vulnerable part in the suspension, but its failure is possible after a mileage of 80,000 km or due to external and internal factors. A malfunction of the front hub is determined by the following signs: - Noise from the wheel while driving (damaged ball bearing parts: rolling elements, raceways or separator); - Vibration, wheel runout, grinding noise (typical of a broken ball bearing); - Front wheel play (ball bearing) is out of order or the hub nut is not tightened with sufficient torque).

Diagnostics of the front hub bearings proceeds as follows:

- The front of the car is raised with a jack;

- Spin the wheel by hand and check for noise;

- Check the axial play (clearance) according to the instructions. #

- If you hear a noise or notice other signs, then replacing the front wheel bearing on Granta is inevitable.

- Be sure to watch the diagnostic video.

On the Lada Granta, replacing the front wheel hub bearing is divided into stages:

- Preparatory activities;

- Disassembling the unit, dismantling the old part;

- Pressing in a new product;

- Assembly, performance check.

Causes of breakdowns

Below are the 2 most common reasons for element failure:

- Loss of bearing tightness. The fact is that the product body contains a certain amount of lubricant to reduce friction between the internal elements. The lubricant is retained by special protective covers made of rubber or plastic. Accordingly, these materials deteriorate over time, which leads to a gradual loss of lubrication and failure of the hub element.

- Large production resource. No matter how carefully you operate your car, over time most components and elements become unusable. Each part has its own service life. The bearing, whose service life is about 60 thousand kilometers, is no exception. In some cases (regular or periodic driving through potholes, under conditions of increased wear), the element fails much earlier than the above indicators.

Where are the front and rear hubs on the Lada Grant? Description, purpose

The front hub joint is located on the front left (right) side of the axle shaft. The rear hinge is located in the rear left (right) suspension block.

The main purpose of the bearing is to firmly hold the hub and ensure wheel rotation. Structurally, the front (rear) hub consists of:

- outer and inner metal frame;

- a separator in which metal balls and rollers are located;

- insulating rings;

- special filler - graphite-based lubricant.

Original articles, catalog numbers

Front wheel hub bearing (No. 6)

:

- 11180-3103020-00 or 8450051118 - “VPK” CJSC Vologda

- 11180-3103020-04 or 8450051120 - “TD EPK” LLC, Moscow

Rear wheel bearing (No. 11)

:

- 21080-3104020-00 or 8450054096 - "VPK" CJSC Vologda

- 21080-3104020-02 or 8450054097 - “TD EPK” LLC, Moscow

- 21080-3104020-04 or 8450054098 - “TD EPK” LLC, Moscow

The price of the original bearing is about 1200 rubles.

The device of the hub on the Lada Grant

Front

- rounded fist;

- external and internal dirt-reflective metal rings;

- front roller bearings;

- hub;

- washer;

- hub nut;

- retaining ring, plug.

Rear hub device

- hub mechanism axis;

- metal ball bearing;

- mud ring;

- retaining ring;

- washer;

- screw;

- sealing ring;

- rubber boot;

- hub cover.

Resource for replacing hub mechanism elements

The average service life of wheel joints is 80 – 85 thousand km. The indicator is average, as it depends on the following factors:

- quality of workmanship of the part;

- frequency of operation of the technical device;

- driving style;

- quality of road surface;

- aggressive environment;

- high operating temperatures;

- compliance with technical inspection intervals.

Signs that a hub needs to be replaced

- the appearance of uncharacteristic noise during wheel rotation;

- wheel runout in the steering column;

- vibrations at different speeds. Sometimes there is vibration at a certain speed;

- metallic grinding noise as the wheel rotates;

- front wheel hub play.

Diagnostics of the hub mechanism

- We place the car on a level platform, squeeze the parking brake if we are checking the front row. For the rear, we install wheel chocks.

- Let's jack up the front (rear) part.

- We turn the car wheel and carry out troubleshooting.

- We shake the wheel up and down with our hands. In good condition there should be no play. Otherwise, we dismantle and replace worn elements.

Reviews

| № | Positive |

| 1. | Gennady: I’ve been actively using the car for two years, there are no comments on the chassis or suspension. Once I replaced the rubber boot on the left CV joint. |

| 2. | Kirill: I have driven the car over 80,000 km, I can say that the CV joint still has service life, but it is necessary to prepare for repairs. In general, the parts are maintained within the period specified by the manufacturer. |

| 3. | Vyacheslav: the car is a year and a half old, I bought it at a dealership, no complaints. I systematically carry out technical inspections, buy original consumables, and do not skimp on preventative maintenance. |

| 4. | Dmitry: replaced the “grenades” only at 90,000 km. The service station master said that the mileage is good, not every car gets that much mileage. I believe that careful driving contributed to extending the life of the vehicle's chassis. |

| 5. | Leonid: I’m pleased with the build quality of the car, there are no complaints. Breakdowns happen, but they are insignificant, I fix them myself. |

| 6. | Vasily: if you don’t take into account minor flaws, then the car is good, better than previous generations. |

| 7. | Victor: I drove Grant for a year and a half, didn’t do any repairs, visited a service station only for diagnostics. |

| Negative | |

| 1. | Ivan: I replaced the right CV joint for the first time at 45,000 km, after which the left one needed repairs. In general, the workmanship is low, I am dissatisfied with the machine. |

| 2. | Alexander: standard CV joints are weak and poorly made. After purchasing a car, experts recommend installing foreign analogues. True, the cost is 15% more expensive than domestic ones. |

| 3. | Vladlen: after two years of active driving, I can’t say anything bad. Minor defects are present, but they can be easily fixed. |

Preparatory stage before replacing the hub mechanism

Required materials and tools:

- hydraulic (mechanical) jack;

- wooden stand;

- wheel wrench;

- screwdriver with a flat, cross-shaped bit;

- hammer;

- knob, nozzles;

- spanners;

- stationary vice;

- chisel;

- two-jaw and cup pullers. The exact dimensions of the pullers are indicated in the operating instructions;

- forceps;

- metal brush;

- lubricant type “CV joint - 4”;

- rags;

- caliper for measuring diameter;

- new wheel bearings;

- additional lighting provided that the work is carried out in the dark.

Comments

TOP materials of the week

TOP products in the store (more)

Have you contacted the dealer regarding a warranty case for Lada Kalina?

Lada.Online

Lada (“Lada”) is a brand of cars produced by JSC AVTOVAZ. Previously, it was used only for export cars, and for the domestic market, cars were produced under the Zhiguli brand. In 2004, the management of AVTOVAZ announced the transition to the Latin alphabet for the official spelling of the names of all cars produced by the plant: Lada - instead of "VAZ" and "Lada".

Lada.Online is the largest Russian-language automotive resource with a daily audience of thousands, which is dedicated primarily to cars of this brand, the domestic automotive industry and the automotive world in general.

This site is not the official LADA website.

© 2022 Lada.Online. Copying of material is permitted only with a link to the source.

Source

Replacing the front hub of Lada Granta

- We place the car within the perimeter of the repair area and provide priority safety measures.

- Let's jack up the right (left) side.

- Unscrew the bolts and remove the wheel.

- Let's unlock the hub.

- On the back side, unscrew the two bolts that guide the brake caliper.

Location of two bolts

- We remove the caliper, hang it on a wire (we fix it on the steering tip).

- Unscrew the hub nut and remove the brake disc.

Removing the hub nut

- We unscrew the two bolts - the rack clamps. If necessary, we use a liquid to remove deposits like WD-40.

- Disconnect the strut with the steering knuckle and unscrew the ball joint fasteners.

- We remove the CV joint.

Next, install the new hub assembly and assemble the structure in the reverse order.

Replacing the front wheel bearing of Lada Granta

- The front hub joint is located in the steering knuckle housing, remove it. Pre-clamp the structure in a stationary vice.

- We install the metal spacer - the head at “22” on the surface of the hub. We apply targeted blows with a hammer to press it out.

- We disconnect the inner race of the hinge and remove the separator with metal balls.

- To remove the outer part of the hinge, use pliers and remove the retaining rings.

- To dismantle the inner part of the cage we use a chisel. Gently tap with a hammer. Press-out puller

- Use a puller to press out the axle shafts.

Pressing in a new wheel bearing and assembling the unit

- We clean the surface from dirt, deposits, and rust. We remove the old grease from the hub and wipe it with a rag. We measure the diameter of the hub, it should be 35 mm.

- Apply a thin layer of graphite grease to the surface. Press in the new bearing.

- We press the hinge until the retaining ring comes into contact with the edge of the part.

- We insert the hub into the hole using a vice.

Product added to bookmarks!

- Description

- Reviews

Front wheel bearing "VBF".

APPLICABILITY: VAZ 1117, 1118, 1119 (Lada-Kalina), VAZ 2170, 2171, 2172 (Lada-Priora), VAZ 2190, 2191 (Lada-Granta), VAZ 2192, 2194 (Lada-Kalina 2), DATSUN on- DO, mi-DO.

Closed joint-stock company "Vologda Bearing Plant" is the largest enterprise in the Russian bearing industry, founded in 1967. The plant produces about 20% of the total volume of commercial products produced by bearing enterprises in Russia. The plant's product range includes more than 1,700 standard sizes of ball and roller bearings: radial, angular contact, thrust radial and thrust, bicycle.

The company's products are supplied to various industries - automotive, electrical engineering, machine tool building, metallurgy, agricultural engineering, military-industrial and fuel and energy complex.

The plant is the main supplier of bearings for such enterprises as AvtoVAZ, GAZ, Avtodetal-Service OJSC, KamAZ, MAZ, ZAZ. Vologda bearings are used in almost all car models produced by these enterprises. Products are also exported to such well-known enterprises as “Uz-DAEWOO”, “John Deere”, “Polaris”, “Eaton”, “Tean Industries”.

The plant has a network of trading houses "Vologda Bearings" . Now trading houses operate in Moscow, Vologda, Voronezh, Dnepropetrovsk, Yekaterinburg, Krasnoyarsk, Samara, St. Petersburg, Saratov, Togliatti, Ust-Labinsk (Krasnodar Territory), Kharkov, Chelyabinsk, Perm, Izhevsk, Nizhny Novgorod, Minsk, Zaporozhye.

CJSC VPZ has the ability to produce 36 million bearings per year.

The property of the company is a gas-fired boiler house. Its capacity for producing hot water and steam not only fully covers production needs, but also largely allows them to be used to supply the city with hot water and heat. Owned water supply system facilities allow the use of process water for production purposes, while reducing the cost of manufactured products.

- ✅ Contents of the article:

- 1. Diagnostics of the front wheel bearing

- 2. Preparatory activities before repair

- 3. Removing the old Granta wheel bearing

- 4. Replacing the wheel bearing with a new one

- 5. Features of bearing selection

- 6. Recommendations and advice from experts

Replacing the rear wheel hub of a Lada Granta

- We place the car within the perimeter of the repair area and secure the front row of wheels with wheel chocks.

- Using a wheel wrench, we tear off the mounting nuts, jack up the car, and remove the wheel.

- We unscrew the screws securing the brake drum to the structure.

- Remove the hub cap and remove the axle shaft from the splines.

- We fix the structure in a stationary vice. Gently tap the outer edge with a chisel.

- If necessary, use WD-40 liquid to remove deposits and rust.

- We dismantle the hinge and use a vice, although some craftsmen use special pullers. In general, whatever is more convenient for you.

- Using a metal mandrel, we knock out the inner ring.

- To finally press out the hinge, use a hammer and chisel and gently tap along the outer perimeter of the frame.

Recommended lubricants

What can be used to protect the bearing not only from high temperatures, but also from corrosion, and to ensure a minimum coefficient of friction? There are a number of well-proven formulations.

Disulfite-molybdenum agents

Considered one of the best. The lubricant contains molybdenum salt, which reduces the coefficient of friction. In addition, the material is capable of forming a dense protective film that “saves” the assembly from corrosion

There is another important advantage: the service life of the lubricant coincides with the service life of the bearing itself, i.e.

trouble-free operation of the hub for 100 thousand kilometers is guaranteed. There is also a minus - relatively rapid contamination. But if you don't allow the hub to depressurize, everything will be fine. There is one more point: it is worth checking the condition of the lubricant regularly if you constantly move at high speed. A signal for replacement will be a bluish tint to the product. Among the manufacturers of the composition, the most famous companies are Mobil, Castrol (British Petroleum), ESSO, Liqui Moly. Among the Russian brands, it is worth highlighting “Fiol” and the more expensive “ShRUS-4”.

Lithium greases

They are characterized by high resistance to friction, which guarantees an extended service life. Also, lithium products have a long service life: the product does not lose its qualities even after the car has driven 110 thousand km. Among the negative aspects, it is worth noting the average resistance to corrosion processes when compared with lubricants on a different basis. Another disadvantage is the substance’s ability to dissolve some polymers, this is due to the fact that the composition contains organic acid. Therefore, before using lithium grease, read the car manufacturer’s recommendations about the permissibility of using such a product.

Lithium grease is produced by several foreign companies, the most famous of which are Renolit, British Petroleum, Very Lube. But you can also use the Russian analogue, known on the market under the brand “Litol 24”. This is a composition that successfully copes with elevated temperatures, friction and actively fights corrosion. Another serious plus is the affordable price.

Replacing the rear wheel bearing of a Lada Granta with your own hands

Note to the driver. Before starting installation work, clean the surface from debris and dirt. Apply a thin layer of oil and be sure to lubricate the outer race of the hinge.

- We install the new hinge and lightly press it into the cavity.

- Evenly tighten the hinge until it touches the outer edge.

- We fix the retaining ring and install the hub in its original place.

Installation in a regular place. Assembly of the structure

- Apply a thin layer of graphite grease, put the assembly on the shaft, and secure it with a nut.

- We complete the tightening with a torque wrench (tightening torque 30 Nm).

- Use a chisel to counter the nut and put on the cap.

This completes the disassembly, assembly, and replacement of the rear wheel bearing.

Note to the driver. The Lada Granta Sport modification has a rear hub with a pre-installed ABS sensor.

It often happens that during the process of dismantling the hub mechanism, a bolt or pin breaks. The reasons for this are different, ranging from the old age of the metal to manufacturing defects.

So, how to remove a broken bolt. We carry out the work in several stages:

- mark the center of the stud;

- drill with a drill to 2.5, after 5.5, 9.5 mm;

- scroll with a bolt with a diameter of 9.5 - 10.0 mm;

- remove remaining metal and shavings.

What lubricants should you avoid?

Not every lubricant provides reliable protection against friction under operating conditions of a car hub. The ongoing processes are influenced by a fairly large number of external and internal factors. Rotation occurs at high circular speed under high temperature conditions. Such operational features largely lead to the rejection of lubricants containing synthetic hydrocarbons. Their destruction often occurs already at temperatures of 45-65 C. The group includes vaseline or silicone materials, presented in a large assortment on the shelves of specialized domestic stores.

The use of lubricants containing sodium and calcium can damage wheel bearings. They effectively combat the friction process, but are powerless in confronting the corrosive effects. However, the operation of the unit is associated with difficult conditions, and it cannot be left completely without lubrication.

To a greater extent, these materials are used for low-moving joints or applied to springs to protect them from rust. The average output of a unit with the addition of graphite-containing substances is reduced to 20-30 thousand kilometers, in comparison with the use of materials recommended by auto companies, which give an operating time of 100-120 thousand kilometers.

Review of manufacturer prices for front and rear hinges

How to choose and buy quality parts

Service center specialists strongly recommend purchasing consumables and components exclusively from specialized stores, representative offices, and official dealers.

To a lesser extent, you need to use the services of unverified suppliers who sell spare parts at an unusually low cost.

When purchasing, check the catalog numbers with the actual data specified in the operating instructions for the technical device. If such a brochure is not available, consult a specialist.

Analogs

- AUTO DETAIL

- VPZ

- GPZ

- RUSSIA

- AT

- AUTORAM

- BAUTLER

- BZAK

- GALLANT

- GAMMA

- HOLA

- LGR

- PILENGA

- SS20

- QML

- STARNER

- METACO

- TRIALLI

- STELLOX

- ZOMMER

Determine the best wheel bearing

by voting. Leave feedback in the comments, in which you can indicate:

- Which brand of wheel bearing did you choose and why?

- What was the service life of the factory wheel bearing?

Share on social networks:

Found an error? Select it and press Ctrl+Enter..