Description of replacing the VAZ 2106 hub

Replacing a VAZ 2106 hub is done quite rarely, since the part lasts a long time, at least 150 thousand km. The main reason why the replacement operation is performed is wear of the bearing seats, as a result of which the bearing races begin to rotate. The fault can only be determined by removing the hub and removing the bearing races. If they rotate in their seats, then after removing the lubricant, clear marks will be visible on the inner surface.

A sign of wheel bearing wear is a hum and vibration from one of the front wheels. To accurately determine the origin of the humming sound, the car is jacked up and the wheel is rotated by hand in different directions. If a loud noise is heard, then the bearings need to be replaced. The service life of these parts averages 40-50 thousand km. Disassembling this unit on a VAZ 2106 car, removing old parts and installing new ones is a simple task and is accessible to every car enthusiast.

The device of the hub on the Lada Grant

Front

- rounded fist;

- external and internal dirt-reflective metal rings;

- front roller bearings;

- hub;

- washer;

- hub nut;

- retaining ring, plug.

Rear hub device

- hub mechanism axis;

- metal ball bearing;

- mud ring;

- retaining ring;

- washer;

- screw;

- sealing ring;

- rubber boot;

- hub cover.

Resource for replacing hub mechanism elements

The average service life of wheel joints is 80 – 85 thousand km. The indicator is average, as it depends on the following factors:

- quality of workmanship of the part;

- frequency of operation of the technical device;

- driving style;

- quality of road surface;

- aggressive environment;

- high operating temperatures;

- compliance with technical inspection intervals.

Signs that a hub needs to be replaced

- the appearance of uncharacteristic noise during wheel rotation;

- wheel runout in the steering column;

- vibrations at different speeds. Sometimes there is vibration at a certain speed;

- metallic grinding noise as the wheel rotates;

- front wheel hub play.

Diagnostics of the hub mechanism

- We place the car on a level platform, squeeze the parking brake if we are checking the front row. For the rear, we install wheel chocks.

- Let's jack up the front (rear) part.

- We turn the car wheel and carry out troubleshooting.

- We shake the wheel up and down with our hands. In good condition there should be no play. Otherwise, we dismantle and replace worn elements.

Preparing and disassembling the unit

The front rolling bearings are roller, cone type, consisting of two parts: external and internal. Good quality products are sold complete with the required amount of lubricant and two clamping nuts. The nuts differ in their thread, on one it is left-handed, on the other - right-handed, the first will fit the axis of the right axle, the second - to the left.

The manufacturer does not know which wheel will be replaced, so he completes the product with both nuts. Additionally, you need to purchase an oil seal, which is located at the rear of the hub and does not allow grease to leak out. You can carry out the work on a level surface, securing the car with the hand brake so that it does not roll away.

Before lifting the car with a jack, you need to pull out the metal boot covering the hub nut and loosen the latter with a 27 mm wrench. Then the wheel bolts are loosened, the car is jacked up and the wheel is removed. The next step is to remove the brake caliper, which is attached to the axle with 2 bolts; they need to be unscrewed, the part removed and moved to the side.

It is recommended to first remove the brake pads from the caliper, then it will be easier to put it back.

Now you can completely unscrew the nut, pull out the washer and remove the hub from the axle axle by hand. After this, you need to remove the old grease from all parts; it contains metal shavings.

Article: 00001-0040448, additional articles: 00001-0040448-718, 14044871

Order code: 040192

Thread diameter - M18*1.5 L (length) - 17 S - 27 Strength class -6

Information used: JSC "AVTONORMAL"

- Passenger cars / VAZ / VAZ-21312 drawing

» href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2131-73/kolesa-213/#part64938″>M18x1.5 self-locking nutWheels / Wheels - » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2131-73/shesterni_razdatochnoiy_korobki-176/#part64247″>M18x1.5 self-locking nut Transfer case / Transfer case gears

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_21213-731/kolesa-166/#part2011101″>Nut M18x1.5 self-lockingWheels / Wheels

- » href=»/catalog/chevrolet-125/legkovye_avtomobili-30/chevrolet_niva_1_7-1233/shesterni_razdatochnoiy_korobki-156/#part2974377″>Nut M18×1.5 with belt Transfer case / Transfer case gears

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_4x4_urban-1885/d400__povorotnye_kulaki_i_stupicy-175/#part4208102″>Nut M18x1.5 with beltWheel / D400. Steering knuckles and hubs

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/shevrole_niva_1_7-2404/povorotnye_kulaki_i_stupicy-249/#part5436771″>Nut Suspension / Steering knuckles and hubs

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2102-4/kulak_povorotnyiy-156/#part7986″>Nut M18x1.5 self-locking Front axle / Steering knuckle

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2104-5/kulak_povorotnyiy-122/#part14827″>Nut M18x1.5 self-locking Front axle / Steering knuckle

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2106-7/kulaki_povorotnye-132/#part21159″>Nut M18x1.5 self-locking Front axle / Steering knuckles

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2120__nadejda_-245/kolesa-135/#part56903″>Nut M18x1.5 self-lockingWheels / Wheels

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2123-315/shesterni_razdatochnoiy_korobki-123/#part977860″>Nut M18x1.5 self-locking Transfer case / Transfer case gears

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_21213_214i-1240/povorotnye_kulaki_i_stupicy-216/#part2990392″>Nut M18x1.5 self-locking Suspension / Steering knuckles and hubs

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_4x4_m-1456/povorotnye_kulaki_i_stupicy-181/#part3241807″>Nut M18x1.5 with belt Suspension / Steering knuckles and hubs

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/lada_4x4-1887/d400__povorotnye_kulaki_i_stupicy-202/#part4215533″>Nut M18x1.5 with beltWheel / D400. Steering knuckles and hubs

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2101-3/kulak_povorotnyiy-156/#part3502″>Nut M18x1.5 self-locking Front axle / Steering knuckle

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2103-106/kulak_povorotnyiy-122/#part11543″>Nut M18x1.5 self-locking Front axle / Steering knuckle

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2105-6/kulak_povorotnyiy-122/#part17933″>Nut M18x1.5 self-locking Front axle / Steering knuckle

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2107-8/kulaki_povorotnye-171/#part25382″>Nut M18x1.5 left self-locking Front axle / Steering knuckles

- » href=»/catalog/vaz-3/legkovye_avtomobili-30/vaz_2121-13/kolesa-125/#part60062″>Nut M18x1.5 self-lockingWheels / Wheels

Installation and adjustment of new parts

The insides of the outer bearing are removed, and the old grease is removed from the opened hole. To get to the insides of the second part, you will need to pull out the oil seal by prying it with a mounting spatula or a powerful flat-head screwdriver. It is recommended to wash the inner surface of the hub together with the remaining clips in it with gasoline or diesel fuel. Sequence of further work.

- Place the hub on 2 wooden boards and attach a punch or other metal rod with a pointed end to the holder from the inside. Lightly tapping with a hammer, knock the part out. During the process, the punch needs to be moved so that the clip comes out evenly. Turn the hub over and perform the same operation on the other side.

- Now you need to study the condition of the surface of the hub seats. If traces of turning the clips are visible, you should think about replacing it. It is possible to somewhat extend the “life” of the hub, for this they use the old antiquated method. Small notches should be made on the surface of the seats with a core or chisel. After pressing the clips, they will sit tightly on these bumps and will not turn for some time.

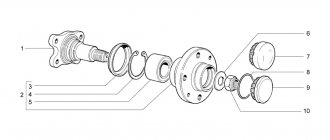

Hub diagram: 1. Outer ring cage with rollers and inner ring 2. Outer bearing outer race 3. Hub 4. Inner bearing outer race 5. Inner bearing cage with rollers and inner ring 6. Oil seal

- Coat the new clips with a thin layer of thick lubricant, then insert one of them into the hole without distortion. Place an old part of the same size on top and, with light blows of a hammer, press the clip flat into the seat. Repeat the operation on the other side of the hub.

- After carefully lubricating the rollers, place the bearing into the pressed race. You need to start from the inside of the hub. Next, install the oil seal in the same way as described in paragraph 3. Thoroughly lubricate and insert the second bearing; coat both parts generously with thick grease. Wipe both working surfaces of the brake disc from grease and place the hub on the axle axle. Tighten the fastening nut and lightly tighten it with a wrench.

Further assembly is carried out in the reverse order; after completion, the front hub of the VAZ 2106 is tightened with a nut with little force. You can check the correct adjustment by pulling the suspended wheel with your hands on its upper and lower parts.

Checking status

Checking the condition of the front wheel bearing is not that difficult. You just need to jack up the front wheel, where the bearing is supposed to be worn out. If the car is front-wheel drive, you need to set the gearbox to neutral, put chocks under the rear wheels and put the car on the handbrake. Rear-wheel drive cars use both a gearbox (1st gear is installed) and a handbrake.

You need to grab the jacked wheel with your hands at the top and bottom, and check for play with rocking movements. In a bearing in normal condition there should not be any play, not even the slightest.

Additionally, you need to spin the wheel around the axle. The wheel should rotate easily; the presence of any jamming, as well as a slight crunch or noise, will indicate that the front wheel bearing needs to be replaced.

Video: Diagnostics of the VAZ front wheel bearing.

If you have the appropriate equipment, you can make a replacement in a garage, but you must first purchase a new bearing, as well as related spare parts (hub nut, oil seal, retaining rings).

As for the bearings themselves, they differ on different cars. For example, the VAZ-2106 has two tapered roller bearings at the front, but the Chevrolet Aveo has a double-row angular contact ball bearing.

Due to the differences in these elements used, work to replace them is carried out slightly differently. Therefore, let’s look at how to replace the front wheel bearing on the above models.

Replacing the front wheel bearings of a VAZ 2106

To replace the front wheel bearings on a VAZ 2106, you first need to remove the front wheels and remove the hub with the brake disc from the steering knuckle.

We take out the brake pads and remove the caliper. We hang the caliper in the wheel well so that the brake fluid supply hose is not strained.

Unscrew the hub nut and remove the washer and inner race of the outer bearing. If necessary, if the outer bearing cage is damaged along the way, we do not press out the outer ring of the bearing, but replace only its inner part. However, at the first opportunity we install a completely new bearing

Carefully, trying not to damage the cuff, remove the hub together with the brake disc from the steering knuckle axis

Using a 12mm wrench, unscrew the two guide pins

Remove the brake disc and spacer from the hub. We clean the internal cavity of the VAZ 2106 hub from old lubricant, wash all parts with kerosene and add fresh lubricant

To remove the outer race of the outer bearing, secure the hub in a vice. Using a beard, trying not to damage the hub, we strike along the perimeter of the outer ring of the bearing

We take out the hub cuff by prying it off with a screwdriver

A spacer bushing is installed under the cuff. We remove the inner bearing from the hub in the same way as the outer one.

We press the outer rings of the bearings in a vice, using the corresponding rings from old bearings. The old rings should be oriented with a smaller cone diameter inside the hub to facilitate their removal after pressing in the new rings.

Using caution, the inner races of the bearings can be pressed in with light hammer blows through the spacer.

We put about 40 g of Litol-24 lubricant in the separator of the internal bearing and the internal cavity of the hub. We cover the new cuff with the same lubricant. Install the inner bearing into the hub. We install the spacer bushing.

Carefully press in the new cuff using a hammer and a suitable tool (installation blade). Trying not to damage the cuff, install the hub on the steering knuckle. We lubricate and install the inner ring of the outer bearing of the VAZ 2106, the washer and tighten the hub nut. We adjust the clearance in the VAZ 2106 hub bearings and install a protective cap. Before installing it, put Litol-24 lubricant in the hub cap. Replacement of the front wheel bearings on the VAZ 2106 has been completed.

Source

What tools will you need?

Description of replacing the timing belt on a Daewoo Nexia car, with a Sons 8-valve engine, with photographs and videos.

Before replacing the rear wheel bearing of a VAZ-2108, you will need the following tool:

- A 30" head and a knob, as well as a piece of pipe. You can even use a spanner wrench, but it must be strongly curved to make it easier to install into the hub hole on the nut.

- Punch or thin chisel. It is advisable to sharpen the chisel in advance. This tool is needed to straighten a jammed edge on a nut.

- It is advisable to have three-legged and two-legged pullers. The first is necessary to dismantle the wheel hub, and the second to remove the inner race of the bearing.

- Pliers for removing and installing retaining rings.

- It is advisable to have a puller on hand to remove and install the bearing into the hub.

- You will also need any type of keys for “12”, “13”, “14”.

- You can't do without a hammer and wooden spacers.

Be sure to buy a good bearing, it is advisable to also buy a nut. It is not recommended to use the old one. You can purchase an assembled VAZ-2108 rear hub, this will greatly facilitate repairs, but will hit your wallet hard.

Front hub VAZ 2106

One of the important elements of the VAZ 2106 chassis is the hub. This part allows the wheel to rotate. To do this, a wheel disk is screwed onto the hub, and the rotation itself is carried out thanks to a pair of wheel bearings. The main functions assigned to the hub are:

- connection of the wheel disk with the steering knuckle;

- ensuring a high-quality stopping of the car, since the brake disc is fixed to the hub.

To know how hub malfunctions manifest themselves, as well as how to make repairs, you need to familiarize yourself with the structure of this element. Despite the fact that the part is designed to perform complex functions, it is structurally quite simple. The main parts of the hub are the housing and bearings. The body of the part is cast, made of durable alloy and processed on turning equipment. The hub fails quite rarely. The main malfunction of the product is the wear and tear of the outer bearing races at the installation sites.

What bearings to put

Changing the front wheel bearing on a Lada Kalina with your own hands

When a wheel bearing requires replacement, the question immediately arises of which part to install. Many people advise using original components. However, today the quality of parts leaves much to be desired and the issue of choice remains quite relevant.

Table: type, installation location, and size of bearings

| Installation location | Bearing type | Size, mm | Quantity |

| Front wheel hub (outer support) | Roller, conical, single row | 19,5*45,3*15,5 | 2 |

| Front wheel hub (inner support) | Roller, conical, single row | 26*57,2*17,5 | 2 |

| Rear axle shaft | Ball, radial, single row | 30*72*19 | 2 |

Manufacturer's choice

When choosing a manufacturer of a wheel bearing for a VAZ “Seven”, we can recommend SKF, SNR, FAG, NTN, Koyo, INA, NSK. The companies listed have many locations around the world. These products are of high quality and meet the most stringent requirements.

Among the domestic manufacturers that supply bearings for cars of the Togliatti plant, we can highlight:

- CJSC "LADA Image" - manufactures and sells original Lada wheel bearings through secondary markets;

- Saratov plant - produces parts under the SPZ brand;

- Volzhsky Plant - uses the Volzhsky Standard brand;

- Vologda plant - sells products under the VBF brand;

- Samara plant SPZ-9.

Rounded fist

An equally important element of the six's chassis is the steering knuckle. Force is transmitted to it from the steering linkage through the lever, resulting in the rotation of the wheels of the front axle. In addition, ball joints (upper and lower) are attached to the assembly through the corresponding eyes. On the reverse side of the steering knuckle there is an axis on which the hub with bearings is placed. The hub element is fixed to the axle with a nut. The left trunnion uses a nut with a right-hand thread, and the right one uses a left-hand thread . This was done in order to prevent the bearings from being tightened while moving and to avoid overheating and jamming.

An additional function of the steering knuckle is to limit the rotation of the wheels, while the part rests against the levers with special protrusions.

Malfunctions

The resource of the steering knuckle is practically unlimited, if you do not take into account the quality of roads and neglect of adjusting the wheel bearings. Sometimes a product can travel 200 thousand km. The part is made of cast iron and can withstand heavy loads. However, if it fails, the owners of Zhiguli cars often replace it along with the bearings and hub. It is necessary to pay attention to the steering knuckle when the following symptoms appear:

- the car began to pull to the sides, and the problem is not eliminated by adjusting the wheel alignment;

- It was noticed that the wheels turned out at a smaller angle. The cause may be problems with both the steering knuckle and the ball joint;

- wheel break. This happens due to the breaking of the threaded part of the steering knuckle or the ball joint pin, which happens relatively often on Zhiguli cars;

- unadjustable play. If the wheel bearings were adjusted untimely or incorrectly, then in the places where they are installed, the steering knuckle axis will gradually wear out, which will lead to the appearance of play, which cannot be eliminated by adjustment.

Primary shaft of the VAZ 2107 gearbox

In total, the design of the “seven” gearbox has three shafts:

- primary;

- secondary;

- intermediate (through which the first two shafts interact).

However, the leading role is assigned to the primary one, since it is through it that the interaction of all the gears in the machine on other shafts begins.

The input shaft of the VAZ 2107 gearbox is manufactured together with a constant mesh gear. This element has oblique splines, which allows it to cling to the shaft teeth as clearly as possible. In addition, in addition to four gears, a synchronizer is also installed on the shaft, which allows the shaft to move simultaneously with the helical gear.

There are splines on the front of the product - it is on them that the clutch disc is located. To allow the input shaft to rotate easily, it is equipped with two roller bearings:

- front - at the end of the crankshaft;

- rear - in the front wall of the gearbox housing.

The input shaft of the VAZ 2107 has strictly verified dimensions:

- total length of the cylinder - 160 mm;

- shaft length to spline disk - 87 mm;

- diameter - 25 mm.

Front wheel bearing "six"

The main purpose of wheel bearings is to ensure uniform rotation of the wheels. Each hub uses two single-row roller bearings.

Table: parameters of VAZ 2106 wheel bearings

| Wheel bearing | Options | ||

| internal diameter, mm | outer diameter, mm | width, mm | |

| outer | 19.06 | 45.25 | 15.49 |

| interior | 26 | 57.15 | 17.46 |

The hub bearings last about 40–50 thousand km. When installing new parts, they are lubricated for their entire service life.

Malfunctions

A broken wheel bearing can cause an accident. Therefore, their condition must be periodically monitored and any extraneous sounds or unusual behavior of the machine must be responded to in a timely manner. If play is detected, the elements need adjustment or replacement. The main symptoms indicating problems with the wheel bearings are:

- Crunch. Due to the destruction of the separator, the rollers inside the device roll unevenly, which leads to the appearance of a metallic crunch. The part must be replaced.

- Vibration. If the bearing wears too much, vibrations are transmitted to both the body and the steering wheel. Excessive wear and tear may cause the product to jam.

- Pulling the car to the side. The malfunction is somewhat similar to incorrect wheel alignment adjustment, which is caused by the bearing getting wedged.

How to check a bearing

If you suspect that the wheel bearing on one side of your car is faulty, you should follow these steps to check its functionality:

- Raise the front wheel.

- We place a stop, for example, a stump, under the lower arm, and then lower the jack.

- We grab the wheel with both hands at the top and bottom and try to tilt it towards and away from us. If the part is working properly, then there should be no knocking or play.

Video: checking the wheel bearing on the “six”

How to adjust

If increased clearances are found in the bearings, they need to be adjusted. Tools you will need:

- jack;

- chisel;

- torque wrench;

- head at 27;

- hammer.

The sequence of adjustment actions is as follows:

- Raise the front of the car and remove the wheel.

- Using a hammer and chisel, knock the decorative cap off the hub.

It is recommended to replace the hub nut with a new one when adjusting the bearing, since the fasteners may end up in the same place and it will be impossible to lock it from turning.

Bearing replacement

During the operation of the bearings, the cage, rollers and the races themselves wear out, so the part must only be replaced. To do this, you will need the same list of tools as when adjusting the clearance in the bearings, plus you also need to prepare:

- key for 12 and 27;

- beard;

- head at 17;

- knob;

- flat screwdriver;

- Litol-24 lubricant.

We carry out the work as follows:

- Raise the front of the car and remove the wheel.

- We remove the brake pads and caliper. We fix the latter in the wheel well to prevent tension on the brake hoses.

Video: replacing the wheel bearing

Which to choose

Owners of classic Zhiguli cars, sooner or later, have to deal with replacing wheel bearings and the issue of choosing a manufacturer. Today there are many companies that produce products of this type. But it is better to give preference to the following brands:

The products of these manufacturers are characterized by high quality and meet the most stringent requirements.

If we consider domestic manufacturers of bearings, then they also exist. Bearings are supplied to AvtoVAZ by:

- CJSC "LADA Image" is a supplier of original Lada wheel bearings on the secondary market;

- SPZ (Saratov Bearing Plant);

- Volzhsky Standard (Volzhsky Plant);

- VBF (Vologda Bearing Plant);

- SPZ-9 (Samara plant).

About adjusting the hub nut.

And the dynamo key is not needed there