This is the car

Very often, when turning the steering wheel on a Lada Kalina car, you hear a knock, creaking, or the steering wheel bites. The driver hears the sounds constantly or they occur after the car has been parked for a long time.

Extraneous noise may appear even if the driver constantly monitors his vehicle and promptly replaces outdated parts with new ones. Such phenomena must be taken very seriously and try to identify their cause, since they may indicate serious malfunctions in the machine mechanism. Working parts of cars often need repairs, as they become unusable and must be replaced with new ones.

Causes of knocking and creaking steering wheel

The first cause may be a worn ball joint. It should be replaced. A rupture of the support will result in the impossibility of further movement due to the wheel being twisted inward or outward. A tow truck will be needed.

The grenade may also be faulty. The load is applied to the right grenade when the steering wheel is twisted to the left, and vice versa.

The steering rack is faulty. There is a kickback and the steering wheel bites. You need to do diagnostics at a service station, tighten the rack fastenings or replace it.

If the Kalina shock absorber bushings are very worn, silicone should be used for lubrication, then the noise will disappear.

If the crankcase protection mounting bolts are loose, you need to tighten them. If the thread breaks, the bolt should be replaced.

The knocking noise may occur after changing a wheel. If the bolts are loose, they need to be tightened with a certain amount of force. If this is not done, vibration will be added to the knocking.

If the spring has burst or cracked, it will need to be replaced.

The shock absorbers are leaking or worn out, cannot support the load when turning the steering wheel to the right or left, and sag with a crash under the weight of the car - carry out diagnostics or replace spare parts.

vendor code

Standard Electric power steering VAZ 1118 (Kalina), Granta, Datsun On-Do (Mi-Do), Priora 11186-3450008-02, 1117-3450008-02

Manufacturer: Autoelectronics, Kaluga, Russia

Price 20,500 rubles

Replacing the ball joint

Tool for work:

- wrenches 17, 19;

- hammer;

- mount;

- puller;

- head for 12.

The ball joint is being replaced

The car is put on the handbrake, the bolts of the wheel from which the ball joint will be removed are loosened. Using a jack, the front part of the Lada Kalina car is raised, the bolts and wheel are removed. Use a 19 wrench to unscrew the ball pin nut. Insert the puller and twist to release the support pin.

The support fastening bolts are removed using a 12mm socket. The lever is pressed down, the support is released and removed. There is another way to dismantle the ball joint: the brake disc is placed on a rigged brick, the jack is lowered slightly to relieve the lever. At this moment the rack rises up, the ball is released.

A large amount of lubricant must be added to the new support. The pin is put in place, the nut is tightened with a torque of 66-82 Nm. If the holes of the steering knuckle and the support coincide, the bolts are tightened. The procedure requires patience and considerable effort.

Grenade change

The grenade, or CV joint, is one of the main parts of the vehicle's chassis. It ensures safe driving on the roads. The grenade is located in the drive of the drive wheels, which allow the steering wheel to move. It is rare to see this hinge on a rear-wheel drive car. The CV joint can be internal or external.

The grenade is out of order and needs to be replaced if the car starts to click and squeak when moving back and forth, and you can hear a creaking noise when you turn the steering wheel.

Tool for work:

Use a reliable jack

The car is lifted with a jack, the wheel is removed, and you need to try to knock out the steering rod with a hammer. Unscrew the lower ball nuts and use a crowbar to push the steering knuckle away. The bolts are unscrewed and the steering rod is removed. The old snap ring is discarded because it is included with the new CV joint. Lubricate the spare part with a special granite-based lubricant and put on the boot. Reassemble in reverse order.

Steering rack tightening and repair

When driving the car, you may hear a knocking noise when turning the steering wheel, especially on rough roads. The Lada Kalina steering rack is no different in its structure from parts of other VAZ car models. Disassembly and installation have some differences.

Device operation process:

- from the steering wheel through the steering column, torque movements are directed to the drive gear;

- the gear gives off energy and sets the rack in motion, they interact with each other;

- the end links are attached to the steering rack and turn the wheels.

The structure of the rack is very simple; there is no need to spend a lot of time to adjust or replace it. But there is a part that causes concern because it is difficult to see and reach. The pressure spring regulates the contact force between the device and the gear. During operation, the elasticity of the part decreases, as a result of which the functionality decreases. To restore force, the spring often needs to be tightened. It can only be seen in the inspection hole; adjustment will not be easy; this will require dismantling the rail.

Diagnostics of EMURU without a scanner

In the absence of a scanning device, fault codes for the electric power steering can be read using the “paperclip” method. To do this, you will need to perform the following steps: 1. Turn off the ignition; 2. Close contacts No. 6 and 7 at the 8-pin connector of the control unit (control unit), which is located next to the power connector. 3. Turn on the ignition. You will be able to “read” the codes by the flashing diagnostic light. Which contacts need to be closed? Look at the control unit connector from the wire side (we remind you that it is 8-pin, black). We consider the first contact to be the one located at the top right and count from right to left: 1. Ignition switch (+12V) – blue. 2. Tachometer – red-brown. 3. Car speed – gray. 4. EMURU control lamp – white and pink. 5. K-line – black and yellow. 6. L-line – empty contact. 7. Mass – brown. 8. Empty contact. If you are planning to independently repair the Lada Kalina electric power steering, you need to remember, or better yet, write down the following data: Light code parameters (temporary): 1. Initial pause - duration 2 seconds; 2. Long signal – 2 seconds; 3. Short signal – 0.5 sec; 4. Pause between signals – 0.5 seconds; 5. Pause between codes – 2 seconds. Decoding the light code of faults: 1. “11” - the system is working; 2. “12” - there is no engine speed signal; 3. “13” - torque sensor; 4. “14” - EMUR engine; 5. “15” — sensor PRV (steering shaft position); 6. “16”—PRD sensor (engine rotor position); 7. “17” — on-board network; 8. “18” - control unit; 9. “19” - vehicle speed sensor. That's all the basic information you need to know on this issue. We hope that you understand - if the electric power steering of the Lada Kalina does not work, there is no need to panic and run to a car repair shop; repairing the device is quite possible even for a non-professional. We are confident that this information will provide you with significant assistance in operating and maintaining your vehicle.

Electric power steering is a component used to provide more comfortable driving. Not so long ago, domestically produced cars began to be equipped with EUR, in particular, in this article we will talk about Lada Kalinas. What malfunctions can occur with the Kalina EUR and what troubleshooting methods are there? Find answers to these and other questions below.

Causes of EUR failure

Dismantling and disassembling the electric amplifier

How to tighten the electric power steering rack?

Photo gallery “Adjusting the steering rack”

How can I lubricate and adjust the EUR?

Electric power steering connection diagram with icons

Video “Guide to repairing an electric booster in a garage”

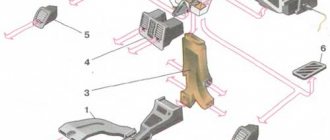

Removing the steering rack from the car

The rear wheels are fixed by rolling back, the front wheels are lifted with a jack. Inside the car, on the driver's seat side, the column spline bolt is unscrewed. The difficulty in disconnecting is that it is located where the pedals are grouped.

After removing the front wheels, the cam nuts are removed and the space under the hood is prepared. The terminals from the battery and the battery itself are removed, along with the mounting plane and the heat reflector. The body mount of the rack is removed with a nut, it is released and placed on a flat surface for further work with it.

Diagnostics for the presence of play is carried out as follows: the rack casing is clamped in a vice and swung with force from side to side. If you feel any play, you should try to tighten the spring nut no more than 10 degrees. Check the play again, and so on until the problem is resolved. Tightening is prohibited, as the steering wheel will become very difficult to rotate, even if an electric booster is installed.

A steering rack repair kit can be purchased at any automotive store. But before you use it, you need to examine the old spare part. If this is not done, the part may need to be removed again.

Electric power steering for Kalina

Some drivers have learned to make adjustments without removing the rack. This method helps save time and effort. To perform this type of work, the car is placed in a pit and the location of the part in the front part is determined. The spare part is pulled clockwise if you can only get to it from below. If you can feel it from above, then the tightening goes counterclockwise. Actions are carried out in the sequence described above.

It must be remembered that replacement does not always solve the problem; the rack continues to make noise and squeak when turning the steering wheel. To double the service life of the steering rack of a power-assisted vehicle, constant oil monitoring, checking the technical condition of the steering rod boots and their timely replacement are important.

The steering rack does not like driving through deep holes without braking. The steering wheel does not need to be turned all the way, so as not to create increased pressure in the hydraulic booster, otherwise the seals will quickly wear out.

Pump failure

The saddest situation for the owner is when the steering wheel with power steering is difficult to rotate, and the culprit is a broken power steering pump. A pump breakdown can be detected by the characteristic sound it makes during operation. Also, in the most advanced cases, looking into the fluid reservoir, you can detect a lack of circulation.

“Turn the wheel”, “steer”, “be behind the wheel”: everyone certainly understands what stands behind these words, phraseological units and phrases. The steering wheel has long become synonymous with driving and not only with a car. And if you remember the catchphrase from the film “Prisoner of the Caucasus”: “Cursed be the day when I got behind the wheel of this vacuum cleaner,” then everyone will understand that the steering wheel in a car may not be the most important part, but it is certainly a system-forming one. Over more than a hundred years of development of the automobile industry, the steering wheel has changed a lot. Today it is not just a tool for turning a car right or left; in a modern car, the steering wheel is actually the point of contact between the human nervous system and the iron horse. And if suddenly the steering wheel becomes harder to turn, then problems will definitely arise in this contact.

How to remove the steering wheel from a Lada Kalina

When the steering wheel on Kalina sticks, you need to disconnect the negative terminal of the battery and wait about 10 minutes for the airbag activation capacitor to discharge. The two latches and cushion latches should be released.

There are holes on the sides of the steering wheel. If the steering wheel was not removed, they are sealed. After removing the seal, use a flat tool to find a stop with a spring in the vacated opening. Squeeze the latch with one hand and pull the pillow toward you with the other until it clicks. If the cushion does not return to its place, the latch has become loose. Do the same on the other side.

The released cushion should be moved slightly. A pair of audio signal wires are disconnected by using a flat object, maybe a knife, to pry off the small yellow clip from the orange connector of the airbag. It is moved forward, the connector is removed, the pillow is released and set aside.

Error codes

c1044 - incorrect sequence of the rotor position sensor (RPS)

c1621 - incorrect voltage 5V

c1622 - speed signal circuit failure

New Lada: How to change the backlight bulbs of the Lada Kalina stove

c1011 - car engine speed signal circuit, no signal - the signal from the idle sensor (or the standard tachometer through a voltage limiter) is divided by 4 and applied to the tachometer input,

c1022 - error, voltage of the main output of the torque sensor - it is possible that the shaft cover has rubbed the insulation and the middle, green wire shorts to ground

Nuances of troubleshooting on Kalina

Sometimes applying lubricant to the shock absorber bushings does not bring positive results; a squeak accompanies the driver when driving on uneven roads. The reason is improper installation of the part, wear of rubber bushings, cushions, and oil leakage.

With such problems, the shock absorber will move freely. Worn bushings must be replaced, installation errors can be corrected by tightening the fastening bolts and nuts. When oil leaks, stains mixed with dirt appear on the shock absorber. It is necessary to simultaneously replace parts on the left and right.

Sometimes it is necessary to remove the crankcase guard to replace the gasket and tighten the bolts. To do this, you need to dismantle the engine splash guard, drain the residual oil, unscrew three bolts, remove the lower clutch housing cover and the engine sump. Then you should replace the gasket and bolts, while tightening them from the middle to the edges.

To eliminate the damage, the steering wheel is completely disassembled

To prevent noise from disturbing the driver, you need to know the correct tightening pattern for the wheel bolts. To ensure even tightening and to avoid figure eight, the bolts are tightened clockwise in the following order:

- 4 bolts - “hourglass”, pattern: 1-3-4-2;

- 5 bolts - “pioneer star”, scheme: 1-4-2-5-3;

- 6 bolts - “radiation”, scheme: 1-4-5-2-3-6.

You need to tighten the bolts by hand, first using a can with a short lever, then with a long one.

A dull knock when turning the steering wheel may come from the front wheels. Springs and shock absorbers are best replaced in pairs. If the driver wants to change the springs because of their age, this is not always reasonable. Ground-in old springs make the suspension soft, and they should be changed if the car owner is not satisfied with the ground clearance, which is measured in the front of the car.

When replacing a spring, trouble may arise.

- The new part will burst.

- A creaking and crunching sound will appear in the CV joint.

- You will have to do the alignment several times.

If the cause of the knocking is due to metal fatigue of the spring, it needs to be replaced. Otherwise, the racks will quickly break, the supports and balls will fail, the Kalina springs will bend sideways and will not allow the installation of other racks.

It is advisable to replace it if the stand begins to hit the rubber bumper too much.

Types of generators

Based on current strength, generating devices for Kalina are available in the following types:

- 85 A.

- 90 A.

- 100 A.

- 115 A.

- 120 A.

- 135 A.

By power there are units:

- 12 V.

- 24 V.

The higher the performance characteristics of the device, the higher the price is set for it.

There are new units:

- New.

- Used.

New devices naturally cost more.

Generators for Kalina are produced by different manufacturers. So, you can buy a device from the company:

- ISKRA (Slovenia).

- LKD (China).

- BATE (Belarus).

- Eldix (Bulgaria).

- StartVOLT.

- KZATE.

- Pramo.

- Bosch.

Products from Eldix, Bosch, and BATE are more valued. Products from the Chinese company LKD are cheaper.

You can purchase a generator at the place of purchase:

The most expensive units are sold in specialized stores, the cheapest - in the car market and through advertisements.

Reasons for shutdown

The main reason lies in the electric power steering. When ignited, the system performs a self-diagnosis and if the mechanism does not pass it, a signal is turned on indicating a malfunction. The color of the signal indicates the degree of danger. The light turns red, the problem needs to be fixed urgently. If the color is yellow, the vehicle can be operated, but safety precautions should be taken. There may be several reasons why the electric power steering on Kalina does not work:

- speed sensor malfunction;

- torque sensor malfunction;

- speed exceeds 60 km/h;

- engine speed is less than 400 per minute;

- failure in the control unit;

- poorly soldered contacts;

- insufficient tension.

Software shutdown

- The electric power steering on Kalina turns off after 60 km/h. Therefore, keep this point in mind; it is set in the system unit and is not a breakdown. The Priora's electric power steering is switched off at a speed of 110 km/h.

- Also, the EUR does not work at low engine speeds. If the value is less than 400 rpm, it is not active.

This is software planned inactivity. It is needed to give information to the steering wheel at high speed and reduce wear of the mechanism.

Electrical booster malfunctions

In the event that it is impossible to immediately check the cause of failure of the electric power steering on Kalina, you need to remove the fuse from the block. This is necessary to prevent sudden activation of the mechanism, which leads to emergency situations.

A direct indicator of a malfunction of the speed sensor in Kalina's electric power steering is a non-working speedometer, as well as a lit-up exclamation mark on the dashboard. It may not work for several reasons. Check the appearance of the sensor; if it is covered with dirt, simply clean it. See if any metal shavings have become magnetized and remove those as well.

If this does not help, then the sensor is probably faulty. Such sensors are now inexpensive and can be found in many auto parts stores. We do the same for the torque sensor. But where is the speed sensor? It is usually located in the gearbox housing, see photo on the left.

Another cause of malfunction of Kalina’s electric power steering is the generator. The control unit requires a voltage of 13.6 V to operate; if you have less, change the voltage regulator (chocolate) on it.

Also, the contacts could simply become disconnected due to poor-quality soldering. You can either disassemble and solder the contacts or send it to service.

If the problem is in the control unit, it is difficult to solve this problem yourself; the service will either solder it or you will have to buy a new one.

Drive belt

If the steering wheel in a car begins to rotate tightly, not sharply, but gradually over a month or more, then the cause of this trouble is the slipping of the drive belt and, as a result, the power steering pump not performing its functions.

To diagnose this malfunction, it is necessary to visually inspect the belt with the car turned off and running.

When inspecting the car with the car turned off, it is necessary to check the belt tension, the absence of oil leaks, cracks, wear and unevenness. When the engine is running, there should be no whistling or slipping from the power steering pump drive belt.

If the belt wears out too quickly, you need to pay attention to the condition of the pump. With the drive belt removed, you must rotate the pulley by hand. Rotation should be easy and smooth without jamming.

Fuse box

The weak link of the electric power steering on Kalina is the fuse box; if something doesn’t work, it’s worth checking them. To get to them, you need to open the dashboard, to the left of the steering wheel. To do this, pull the top part towards you and the latch will open.

Check if the fuse is working, if it fails, replace it. It is very easy to check, check the integrity of the thread inside the fuse. Changing a 50 amp relay to a 30 amp one will also help.

Newer versions of Kalina are equipped with electric amplifiers from Hyundai, which has a positive effect on its reliability. However, there are still thousands of cars with the domestic version, which malfunctions and breaks down from time to time. Now it will be easier for you to repair the electric power steering on Kalina yourself. The main thing to remember is that not every amplifier shutdown is a breakdown. And you can find the problem yourself and fix it, but somewhere you will have to go to a service center.

Low oil level

If the steering wheel is difficult to turn, the reason may be a low fluid level in the power steering reservoir. This situation could arise for three reasons:

- The oil was not changed in a timely manner.

- Gradual wear of power steering elements.

- Damage to any element of the power steering on the road.

If the first situation occurs, you simply need to replace the fluid with a new one, filling the tank to the maximum mark.

If the second situation occurs and a slight leak of fluid is detected, then it is necessary to add fluid and inspect the system elements in the near future.

If the oil leakage is significant, since the hydraulic system has recently received serious damage, you cannot drive with power steering. Most power steering pumps in modern cars will suffer serious scuffing and damage if they continue to be used without oil.

In order to continue driving the vehicle, it is necessary to dismantle the drive belt of the power steering pump or call a tow truck.

About the principle of operation of a car generator

The operation of the Lada Kalina generator unit is based on the following principle: an alternating current is induced in the stator winding, which is subsequently transformed into direct current through a rectifier module located on the body of the unit. The generator cover is also equipped with an electronic voltage regulator and a brush holder. The rotor of the device receives torque from the crankshaft pulley. The transmission link is a poly V-belt.

The basic characteristics of the generator set include the following parameters:

- maximum generated current – 85-90 Amperes;

- operating range of on-board voltage – 14.4-15.1 Volts;

- rotation ratio of the motor and rotor – 1:2.4;

- right-hand direction of rotation.

The housing of the unit is held together by pins that tighten the stator with the covers. The mounting sockets of the indicated covers contain bearings, which ensure the ability of the rotor to rotate. The rear bearing is installed inside the cover with a minimum gap. The front element is equipped with the ability to slide along the surface of the rotor shaft. It is fixed inside the front cover with a slight interference fit, and a pressure plate covers it from the outside. The back of the device is protected by a plastic casing.

Let's move on to the switching diagram of the generator with the on-board network. The connection diagram is very simple. After turning on the ignition, power begins to flow to the voltage regulator through the battery discharge lamp circuit. When the motor starts, the excitation winding is supplied with supply voltage from three diodes mounted in the rectifier unit.

Using the indicated signal lamp, the generator unit can be checked. If the device is working properly, the lamp lights up when the ignition is on. It goes out when the engine starts. When this phenomenon is not observed and the lamp continues to shine, the generator set should be diagnosed for the presence of malfunctions. In some cases, replacement is required, and many are interested in how to remove the generator?

Operating principle

The basic principle of operation of the generator is as follows: a three-phase alternating current is induced in the stator winding, which is converted into direct current using a rectifier unit attached to the cover of the device. On the cover there is a unit consisting of an electronic voltage regulator and a brush holder. The rotor rotates from the crankshaft of the car engine via a serpentine belt.

The Lada Kalina generator has the following characteristics:

- maximum output current - 85-90 A;

- voltage - 14.4-15.1 V;

- engine-generator gear ratio - 1:2.4;

- direction of rotation is right.

4 bolts secure the stator and covers of the device. The covers contain bearings in which the rotor shaft rotates. The rear bearing is located on the rotor shaft; it is mounted in the rear cover with a small gap. The front bearing, which slides along the rotor shaft, is installed in the front cover with a slight interference fit and covered with a pressure plate. The device is covered at the back by a plastic casing.

The generator connection diagram is quite simple. When the car's ignition is turned on, voltage is supplied to the voltage regulator through the low battery warning light. When the engine is started, the field winding receives power from 3 diodes that are installed on the rectifier block.

Typically, checking the alternator is easily done using the battery charging warning light. If the device is working properly, this lamp should light up when the ignition is turned on, and when the engine starts, it should go out. If the lamp burns brightly or at full intensity, then the generator needs to be replaced or repaired because it is faulty.