A couple of days ago this situation happened to me. In the evening I washed my car at the car wash, and in the morning, as usual, it was frozen. In the morning the handbrake brake pads froze a little, but at the first pull everything fell into place and the wheels turned. I got to work, the frost did not subside during the day, it was about 9 degrees minus. And in the evening, when I was getting ready to go home, I had to drag the car 40 meters on the brakes to break off the frozen brake drum pads. The car has a Chinese ELM327 V2.1 and the Torque program on the smartphone. It initially reported PENDING FAULT C0037. I found a decoding on the Internet - an error in the rear left wheel speed sensor. I immediately thought that the frozen water had somehow damaged the ABS sensor. I went to remove the wheel. Removing the sensor is not difficult, you just need to know that the machine is assembled in such a way that the person repairing it will get a little screwed up. The ABS sensors are screwed on with a 7 bolt. In general, after reading a little about Vesta, I realized that it is better to have keys and heads of all sizes. Okay, I unscrewed the sensor, everything was fine with it at first glance, the teeth in the hole for the sensor didn’t look damaged either. I decided to check whether the problem was actually in the left sensor. To do this, it was decided to disconnect the connector of this sensor. The connector itself is located in the cabin, covered with plastic trim. You can see which one from the photo. It is fastened with two torx screws.

I disconnected the connector, the program generated another error with the same number, only this time it was CURRENT FAULT (which in the language of a potential enemy means CURRENT FAULT).

Hmm..., I said. I started the car and went to the store to find out the cost and availability of this sensor. It turned out that the cost of the original was very inhumane, only 3,600 rubles per piece. You can buy it cheaper on Tyrnet, its number is 8450006894, Exist gives the price of about 2500 rubles, but that’s not fun either. The consultant advised me to just warm up the car first, although I would have guessed this without him. The scanner did not reset the error. the word did not disappear at all, not even for one second. I think that this Chinese guy is not able to overcome his walking mistakes. When I left the store and started the engine, the error was no longer there. This is a story with a happy ending.

Modern cars are equipped with electronic assistants. One of them is the ABS system. If the ABS light on the dashboard is on, it means there is a malfunction in one of the elements of this system. It will not work; during emergency braking, your car's wheels will lock. This is fraught with the risk of the car getting into a skid; it will not be possible to go around an obstacle with locked wheels - an accident. Therefore, the functionality of this system is important for your safety.

Let's look at the reasons why the ABS light is on and what an ordinary car owner can check on his own, without resorting to the help of car services and special equipment. But the problem may be trivial, which can be solved in your garage.

Why does the ABS and ESC light come on?

ABS malfunction may be caused by:

_x000D_

- _x000D_

- failure of wheel rotation sensors; _x000D_

- malfunction of the hydraulic valve block; _x000D_

- damage to the wiring. _x000D_

_x000D_

If the ABS malfunction indicator light comes on, you must contact a service station as soon as possible for diagnostics (read error codes) and repairs.

The most common cause of ABS failure is damage to the wiring near the ABS sensor connector. It is located under the fender liner, but is still not well protected from moisture and dirt.

location of the rear ABS sensor on the Lada XRAY wiring harness of the rear ABS sensor on the Lada XRAY

As a result, the wires oxidize and break, and the ABS lamp lights up.

damaged ABS sensor wires on a Lada XRAY damaged ABS sensor wires on a Lada XRAY

Briefly about the functioning of anti-locking

Cars equipped with ABS do not lose control during any type of braking. Anti-skid system components:

- control device;

- speed sensors for each wheel;

- hydraulic pressure control unit in the brake line.

The ABS unit on Vesta receives a signal from the rotation sensors of each wheel. Based on this data, the processor issues commands to the hydraulic unit of the brake system. Until the car comes to a complete stop, directional stability is maintained, even if the driver tries to press the pedal all the way.

ABS unit on Vesta. Photo source: https://www.drive2.ru/l/527903571115510325

The anti-lock braking system is controlled by a magnetic adjuster. Working positions of the mechanism:

- When the wheel locks, the valve stops the flow of brake fluid to the RTC.

- If rotation does not resume, then pressure is released into the outlet line.

- When rotation begins, pressure is applied to the RTC.

A magnetic device regulates the braking forces on each wheel. The valve actuation speed is up to 10 times per second. Disabling ABS does not affect the braking system, which continues to operate as normal. But without anti-lock, the stability of the car in case of emergency braking is reduced.

How to repair wiring

We remove the wheel, and then the locker (for the front wheel, turning out the fastening screws) or the protective shield (for the rear wheel, turning out the two fastening nuts “10”). Press the latch and disconnect the block with wires from the ABS sensor. We inspect the connector and make sure there is no corrosion or damage. In case of damage, we restore the integrity of the wires:

restoration of the ABS sensor wiring on the Lada XRAY restoration of the ABS sensor wiring on the Lada XRAY

We treat it with a special means for cleaning electrical contacts (for example, graphite grease) and clean the contacts from oxides. We clean the wheel speed sensor and the surface around the sensor from dirt.

Attention! Keep ABS sensors away from magnets as this may cause damage.

Is it possible to disconnect without consequences?

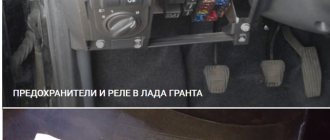

When thinking about how to disable ABS on a Grant, it is important to remember: “arbitrariness” will lead to some questions during maintenance, which will be visible to the on-board computer technicians. When contacting service during the warranty period, the fact that ABS is turned off is the reason for refusal of free repair.

How to carry out the procedure correctly?

- First, open the mounting block where the fuses are located. It is located near the battery. Sometimes you have to remove the 15-amp fuse, but the car's instructions will help clarify this issue.

- Then the ignition is turned on briefly, and it is important that the brake system and ABS lights do not go out. After the sound signal, the ignition must be turned off.

- Then comes the removal of the block with the bottom cover. The electrical wire from the fuse is cut lengthwise and its ends are stripped to about 2 cm.

The problem of how to disable ABS can be easily solved: you will need a five-pin relay, which can be purchased at any auto store. A thorough study of the contact pattern will help carry out the procedure without negative results.

Work begins with winding contacts 86 and 85. It is necessary to connect the wire going to ground to them. The second wiring is responsible for supplying the signal. The contact marked “30” should connect to the wire coming from the fuse, while 88 should connect to the ABS. The shutdown button can be placed anywhere in the cabin.

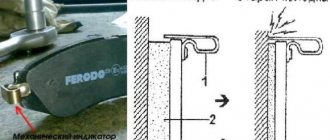

Replacing ABS sensors

If the cause of the malfunction is not in the wiring, but in the ABS sensor itself, we replace it. To do this, first unscrew the fastening screw with a Torx T30 key, and then remove the sensor wiring harness from the bracket. The photo shows a Lada Vesta car; on other Lada models the work is performed in a similar way.

Instructions for replacing the front wheel ABS sensor:

Instructions for replacing the front wheel ABS sensor Instructions for replacing the front wheel ABS sensor

Instructions for replacing the rear wheel ABS sensor:

Instructions for replacing the rear wheel ABS sensor Instructions for replacing the rear wheel ABS sensor

Generations of anti-lock braking system

It took 14 years of effort from a huge number of engineers to create the ABS system. ABS has been produced since 1978, its creator is Bosch.

The first generation of the system (1970) was called ABS-1. This electromechanical product was not reliable and durable due to the thousands of analog components that were used in the ECU. Although the main function of ABS was fulfilled, the product was not suitable for mass production.

Second generation (1978). ABS-2 from Bosch first began to be installed as an option in Mercedes-Benz S-Class cars, and after some time in BMW 7 Series limousines. The number of components was reduced to 140, and the weight of the hydraulic unit was 6.3 kg.

In subsequent generations of ABS, Bosch engineers relied on improving the system and reducing its size. So, in 1980, ABS-2E was released, in which the mass of the hydraulic unit was already 4.9 kg, and the number of components was reduced to 40. In 1995, ABS 5.3 appeared with a mass of the hydraulic unit of 2.6 kg and 25 components. In 2003, ABS 8 was released, in which there were 16 components, and the weight of the hydraulic unit was reduced to 1.6 kg. Since 2010, Bosch has been releasing the 9th generation of the ABS system, which is distinguished by its compact dimensions and hydraulic unit weighing only 1.1 kg.

How does Vesta behave on ice using ABS and ESP?

We decided to test the Lada Vesta in the winter - it’s interesting how the operation of the above systems will behave. For testing, we chose an ice testing ground with a length of 700 m. It was important for us to find out in which cases the system would perform poorly and in which cases it would perform well. For greater stability, we equipped the sample we tested with Nokian tires.

Typically, such tests begin by turning off both systems. This is not surprising - after all, it is important for us to know how a “naked” car behaves on ice. To disable ABS+ESP, you will need to remove the voltage supply - namely, remove the fuse responsible for their operation. If you don’t pull it out, then no matter how much you poke your finger at the ESP switch off button, the on-board electronics will in any case force it to turn on at speeds over 50 km/h.

So, let's start, since good studded tires help us get off the ice. We see a turn, we try to fit into it, but at the same time we feel that the car is starting to skid. The front wheels confidently hold traction, but the rear is unstable - however, nothing critical.

An experienced driver will overcome such a small skid without any particular difficulties by pressing down on the accelerator pedal - fortunately, the test site allows this. The fact that the car drives very confidently even on icy surfaces is definitely encouraging - at the same time, the quality of control does not suffer, Vesta clearly responds to the slightest rotation of the steering wheel, turns smoothly, and does not fidget while moving in an arc.

We stop and turn on the anti-lock and directional stability systems. We start it up and hit the road again - and the car practically does not suffer from loss of dynamics.

Once again, excellent wheels come to the rescue. In this case, ESP + ABS do not respond instantly to changing driving conditions.

Most likely, problems will begin only when the car completely skids. If you get into a real side drift, the electronics are unlikely to help you out. In such a situation, the driver may not be able to save the situation, because the fuel supply control will already be controlled by the on-board electronics - no matter how much you press the gas, you will not get an adequate response from the car.

Summarizing the above, we can safely say that with the exchange rate stability and anti-lock systems turned off, Vesta showed a highway completion time 8 seconds faster than when ABS and ESP were turned on. As one can easily assume, this result is due to the fact that the turned on systems in some way suppressed the driver’s actions, wasting precious time assessing the responses of various sensors. However, during an ordinary trip on an icy road, the systems, on the contrary, will only help while driving, preventing loss of course and skidding.

How to drive - with or without ASB+ESP, it's up to you to decide. Only your driving style and your driving experience influence this decision.

Characteristics of car racks, their choice for VAZ

- front, located on the front axle - ensure smooth operation when controlling the movement of the car;

- rear (photo 1), located on the rear axle - prevent sagging when the body is loaded;

- adjustable, can be installed on both the front and rear axles to adjust the characteristics of the struts - each car owner can adjust them to his car and install them on any axle.

But the service life largely depends on the operation of the car and the condition of the road surface. If the roads are in poor condition, the wear of the struts will be much faster, and if previously motorists carried out repairs by replacing seals, valves, and oil, now it is necessary to replace the struts completely.

These reasons are an indication for repairs and their elimination. If you neglect them and do not repair or replace the rear and front struts in a timely manner, then other troubles may arise. This includes failure of the front strut support bearings, increased uneven wear of tires, failure of hub bearings, increased risk of accidents due to increased braking distance, and uneven wear of brake pads.

The process of replacing rear and front struts on a VAZ 2110 begins with the question: which ones to choose? According to the data, the owners of this brand of car preferred two (Kayaba) and SS 20. For fans of a comfortable ride with a moderate driving style, the most suitable parts will be the SS 20, and for speed lovers - Kayaba. There are others (“Asomi”, “Hola”, “Bilstein”, “Delphi”), about whose products there will definitely be reviews from car owners. You can choose the appropriate option for your car only on the basis of practical experience. The manufacturer of collapsible racks for the VAZ 2110 is (Belarus). Their advantage is considered to be maintainability. When replacing struts, it is more practical to replace all four at once. It is preferable that the rear and front ones are of the same type, i.e. gas-oil or oil. You can replace the front and rear struts on a VAZ 2110 yourself.

Cuvette test Lada Vesta with and without ESP

The winter road promises many hidden dangers. Often the right side of the roadside looks like a snow-covered, flat surface. However, a very large number of motorists who, for one reason or another, have to drive onto it, annoyedly (and, alas, belatedly) end up in a real ditch, covered with a seemingly horizontal layer of snow.

Our new test of the Lada Vesta is designed to find out what advantages the ESP system provides, specifically designed to control the distribution of vehicle forces in difficult situations. For greater clarity, we decided to drive into a ditch and try to get out of it, first without the exchange rate stabilization system, and then using it.

Let's say right away that the car had to work hard. Almost in a dangling state, its two wheels balanced on the edges of the ditch - in this case, as a rule, it is almost impossible to do without outside help. But we dare to assure you that the factory electronics did not let us down. The on-board “brains” accurately dosed the injection of gasoline, allowing not only to let the car stand up straight, but also to climb onto the opposite side of the ditch, returning to the roadway.

Let us remind you that we performed all the above maneuvers with the ESP system engaged.

Next we disabled ESP. In this case, no attempts or tricks to move the car from an awkward position were successful. The wheels of the front axle only bit into the snow and ice harder and harder. In such a situation, leaving the ditch is possible only with great luck or with outside help.

The test results revealed a clear benefit provided by the ESP system on the Lada Vesta. This applies to both smooth road surfaces and roads with poor traffic. In general, the presence of an electronic stability control system will be an excellent help for both beginners and experienced drivers - after all, when they want to help you, is it worth refusing?

Comparison of injection units

The VAZ 21103 operating manual indicates the following engine characteristics.

| Aspects | Options |

| Volume | 1.5 l |

| Maximum power | 94 l. With. (achieved when the crankshaft reaches 5600 rpm.) |

| Limit torque | 130 Nm (possible at 3600 rpm) |

| Number of cylinders | 4 (in-line arrangement) |

| Number of valves | 16 |

| Fuel supply system | Injection |

| Gasoline injection | Distributed |

| Compression ratio | 9,8 |

| Cylinder diameter | 82 mm |

| Piston stroke | 71 mm |

The VAZ 21104 operating manual prescribes parameters slightly different from the above. The engine volume is 100 ml larger and is 1.6 liters. Peak power is 98 hp. With. and is possible already at 5000 rpm. Torque is increased by 1 Nm, but to achieve it, the rotation speed must be increased by 100 rpm. more. The piston stroke has been increased by 4.6 mm, and accordingly the compression ratio has become 0.5 more.

Both the Lada 1103 model and the 1104 version are equipped with 16-valve injection engines.

Lada Vesta test video:

How does Vesta behave on ice using ABS and ESP?:

Cuvette test Lada Vesta with and without ESP:

Lada Vesta hill climb test:

Currently, all LADA models ( Lada XRAY , Vesta, Largus, Granta, Kalina, Priora, Niva 4×4) without exception are equipped with ABS (anti-lock braking system).

During the operation of the car, many owners notice that the ABS and ESC lamps (if this system is available) light up on the instrument panel. Let's figure out how to solve this problem and improve the design.

We advise you to read our articles

Model 21103 - “new” line 110

The VAZ 211103 model is the third modification of the 110 line. The oldest “brother” of this model is the first version of the Lada 2110 with an 8-valve carburetor engine, launched into production in 1996. Then, in the same 1996, the country saw the second modification of the VAZ 21102, which was designed to introduce injection engines into the line. But the number of valves still remained 8. And in 1997, the VAZ 21103 car with a sixteen-valve injection power unit was released.

In addition to the engine, version 21103 has the following innovations compared to its predecessors:

- ABS system;

- air conditioner;

- power steering.

Galvanized body, ventilated brakes, new gasoline vapor recovery system and air-conditioned interior. All these opportunities are real know-how for the Russian automotive industry in 1997. Additional trim levels also included power windows, metallic paint, 14-inch alloy wheels, and even an on-board computer.

WHY IS THE ABS AND ESC LIGHT ON LADA?

ABS malfunction may be caused by:

- failure of wheel rotation sensors;

- malfunction of the hydraulic valve block;

- damage to the wiring.

If the ABS malfunction indicator light comes on, you must contact a service station as soon as possible for diagnostics (read error codes) and repairs.

The most common cause of ABS failure is damage to the wiring near the ABS sensor connector. It is located under the fender liner, but is still not well protected from moisture and dirt.

As a result, the wires oxidize and break, and the ABS lamp lights up.

Decoding Vesta errors related to the data bus (U)

- 0001 – pin failure at the physical level;

- 0002 – block wiring is damaged;

- 0009 – short circuit of lines touching the on-board circuit or body;

- 0073 – diagnostic output disabled;

- 0121 – there is no signal from the ABS unit;

- 0122 – ESP controller does not respond to the request;

- 0155 – open circuit of the control panel;

- 0167 – the immobilizer does not respond to the diagnostic scanner request;

- 0415 – standard error of ABS Vesta;

- 0416 – similar for the ESP system;

- 0426 – the immobilizer transmits incorrect information to the on-board computer system.

HOW TO REPAIR LADA WIRING

We remove the wheel, and then the locker (for the front wheel, turning out the fastening screws) or the protective shield (for the rear wheel, turning out the two fastening nuts “10”). Press the latch and disconnect the block with wires from the ABS sensor. We inspect the connector and make sure there is no corrosion or damage. In case of damage, we restore the integrity of the wires:

We treat it with a special means for cleaning electrical contacts (for example, graphite grease) and clean the contacts from oxides. We clean the wheel speed sensor and the surface around the sensor from dirt.

Attention! Keep ABS sensors away from magnets as this may cause damage.

Articles about Lada X Ray Cross

HOW TO IMPROVE THE LADA DESIGN

To protect the wiring harness from the environment, you can use a D-shaped seal. We lay the wires in it and wrap it with electrical tape. We put everything in the corrugation. We glue the cover covering the ABS sensor connector around the perimeter with the same sealant. This will prevent moisture and dirt from entering the area where the sensor and connector are located.

Attention! If the ABS fails, the brakes remain operational, but the braking efficiency is reduced, which is especially dangerous on some surfaces.

What is this device?

Despite its importance, the temperature sensor is relatively simple; it monitors the condition of the coolant in the cylinder block jacket. It reports changes in temperature, transmitting this information to the electronic control unit

The device is a thermistor, whose electrical resistance decreases as the temperature increases. The temperature sensor readings affect many engine systems and engine performance. Therefore, it is necessary to constantly monitor the health of the sensor and, if any faults are detected, replace it immediately. A faulty sensor distorts the information supplied to the electronic control unit, which can lead to big troubles. There may be problems with the car's controllability when the engine is cold, emissions, fuel consumption may increase or the composition of exhaust gases may deteriorate.

Note. Often the sensor is replaced only when it breaks. But it is recommended to change it in advance, for example, when repairing or replacing an engine, because the sensor may wear out and the readings may be inaccurate.

DTOZH, as the coolant temperature sensor is also briefly called, is a device whose readings affect the operation of the engine itself. This should not be forgotten. A small but remote device closely monitors the car’s engine systems, acting as a kind of watchman.