Depending on the year of manufacture, the “ten” can be equipped with a hydraulic booster (power steering) or an electric booster (electric power steering). Of course, the second option is preferable, since it makes driving the car easier and more comfortable. If your power steering is worn out or you just want to replace it, then it is recommended to choose the power steering for the VAZ 2110 as an alternative.

This material contains two instructions:

- Installation of power steering.

- Installation of an electric power steering VAZ 2110 instead of a standard power steering.

Before installation, you need to understand the structure of these units, and also find out how they differ from each other.

Detailed guide to installing electric power steering on a “Ten”

The amplifier installation procedure is as follows:

- First you need to take the purchased wires and remove the standard terminal from the connector, and then install it into the connector on the harness.

- The terminal connected to the connector is mounted where the wire was connected to the standard block. This must be done so that you have the opportunity to pass a standard cable between the bundles. It is also necessary to take into account that the wire from the blocks carries 50 amperes; accordingly, it is necessary to install the same safety element.

- The next step will be to remove the steering column trim, ignition switch, and all switches located under the steering wheel. At this stage, you need to do everything carefully, since the lining itself is fragile and can crack.

- Then the screw securing the rail is unscrewed, after which it is removed. Next, you will need to compare the length of the old and new intermediate shafts, since adjustments will need to be made to the plates and the shaft itself. The further fitting procedure is carried out by turning - it is best to perform it on a machine, this will allow you to obtain the most accurate result. We recommend that you contact specialists for this task. As for the dimensions of the plate, they are adjusted by re-drilling some holes to a greater depth. In addition, you may also need to trim the corners of the plate a little with a grinder, after which you will need to install spacers between it and the car body.

- Install the amplifier along with the rail and plate - it is possible that a standard screw will not fit for fixation, so you will have to install a shorter bolt instead. In turn, this may lead to the need to install a limiter to prevent arbitrary rotation of the shaft.

- Next, the central part of the switches is installed.

- After this, two wires are laid from the vehicle interior to the battery; it is advisable to lay the wiring through the left fender. The expansion tank of the washer system is being dismantled. You need to find a long copper wire, with its help you will push the wiring. Then open the mounting block with the safety elements and find the wires that go into the engine compartment, you will need to push the wire through the same hole. Be careful not to damage the wiring. Once the wire comes out through the left fender, attach the amplifier wires to it and push them into the engine compartment.

- Then the control panel is dismantled, having done this, you need to find the red connector. Next, the wiring from the amplifier is pushed into the space under the shield. It is necessary to disconnect the orange cable from the red connector; a block from the set of wires for the electric power steering is installed on it. This wire should be connected to the orange wiring of the installed system, and the remaining end with the terminal is mounted instead of the standard cable in the connector.

- Similar actions are carried out with the gray wire; it is also installed in the red connector. The cables routed into the engine compartment must be connected as follows: the black wire is connected to the negative, the pink wire to the positive. Actually, at this point the installation procedure can be considered complete. Now you only need to reinstall the cover and steering wheel.

Replacing hoses and oil

Power steering hoses are an important part of it. Therefore, they need an eye and an eye. But what if they still need to be replaced? Should you take your car to a service station? Of course, there is no need, because you can do all this yourself. Usually, hoses are replaced simultaneously with the power steering oil change. And it would be opportune to present joint instructions.

- First you need to lift both front wheels of the car (they should be in the air);

- We find the power steering reservoir from which the oil should be pumped out;

- Pump out the oil;

- Turn the steering wheel all the way in any direction (after this oil will appear in the tank again, which needs to be pumped out again);

- Now turn the steering wheel in the other direction and pump out the oil again;

- We remove the hose, which is the oil conductor (through it, the oil comes from the passenger compartment and enters the tank);

- Turn the steering wheel from side to side (oil should come out again);

Replacing power steering oil

- We take new power steering oil (usually about 800 ml);

- Fill it into the tank to the maximum level;

- Again, turn the steering wheel from side to side (all the way);

- We start the engine for a few seconds, turn it off;

- We turn the steering wheel again;

- Add oil;

- We pump and remove air from the system by turning the steering wheel with the car turned off ten times in each direction (we do the same number of times with the engine running).

When changing the oil, be sure to look at all hoses and pipes. If oil is leaking, this is a sign of a torn or faulty hose that will need to be replaced. Hoses are replaced only after the oil has been completely pumped out. You will need to unscrew the clamps and remove the hoses from the pump. As for installation, new hoses and pipes should be tightened with clamps and not overdo it (hoses easily burst, if anything happens).

Electric booster for VAZ 2107

An easier way to make the 7 easy to drive is to install electric power steering. Structurally, the VAZ 2107 is ready for such a procedure; moreover, due to the absence of oil containers, installation will be easier and faster.

The electric power steering wheel copes well with loads; in terms of operating efficiency, it is practically no different from the effectiveness of hydraulic power steering. At the same time, the electric mechanism does not require maintenance or constant monitoring.

The most affordable version of the EUR for the VAZ 2107 is the “Aviaagregat” mechanism from a domestic manufacturer. The mounting location for this device is the location of the standard steering column. The design of the electric amplifier includes a relatively small number of parts:

- the amplifier itself;

- bracket for its fixation;

- intermediate value cardan;

- casing, wiring and fastening elements.

A device for facilitating the steering of a vehicle without the use of hydraulic force.

In terms of cost, the EUR is inferior to the power steering, so VAZ 2107 owners often prefer to install “electrics” rather than “hydraulics”.

Installation of EUR

Required Tools

Let's say you purchased an EUR kit - it could be from a VAZ 2110 or from another model, for example, from a Priora. Prepare the following tools:

- Drill together with a metal drill.

- Set of screwdrivers, grinder.

- Long ruler.

All is ready? Let's move on to installation.

Step-by-step instruction

- You need to remove the standard terminal from the block and place it in the block on the harness. We find the standard drive, which is attached to the block. A free terminal must be installed in its place. Now the wire can be placed between the fasteners.

Adjustment

After assembly, you will need to straighten the steering wheel if it is installed crooked. Separately install the sensor that came with the EUR. If the column casing is cracked, it is better to immediately replace it with a good one. There may be gaps between the front panel and the casing - they must be removed.

Approximate prices

A new hydraulic booster for VAZ 2110 and 2112 cars can be purchased for 20,000-32,000 rubles .

Approximate prices for power steering depending on the generation of the car:

- VAZ 2110 - from 21,000 to 32,000 rubles .

- VAZ 2112 - from 20,000 to 28,000 rubles .

Approximate prices for parts from different companies:

- ZF LENKSYSTEME - about 32,000 rubles .

- AvtoVAZ - from 28,000 rubles .

- TRIALLI – from 20,000 rubles .

An old spare part will cost less - 3,000-9,000 rubles .

Operating principle of EUR and power steering

Power steering VAZ 2110 is a system consisting of many elements. The power steering pump in this case is driven by the crankshaft - it pumps oil, as a result of which, through pressure, it allows rotation of the steering wheel.

The electric power steering is a modular design that is built into the steering column; the module itself consists of:

- synchronous type electric motor;

- torsion bar;

- several sensors;

- control module.

EUR device for a VAZ car

The principle of operation is as follows - the torsion bar is twisted, the sensor reads the torque, and the electric motor transmits a small force to the output shaft.

Varieties

All power steering can be divided into two types:

- Electrical. The system is represented by an electric motor, a control mechanism and a mechanical transmission. The peculiarity of this type of device is the creation of additional force when turning the steering wheel using a special electric drive. Provides perfect handling at all speeds and during sharp turns. If a malfunction occurs in the control units, the electrical device may suddenly turn off.

- Electrohydraulic. The hydraulic pump is started by an electric motor, which is powered by a generating device. In terms of fuel economy, the electro-hydraulic booster is more preferable. The spare part is efficient and informative.

You can pick up the spare part at the place of purchase:

- At the car market.

- In the auto parts store for VAZ cars.

- At the transport dismantling point.

- In the online store.

- According to the advertisement.

Differences between EUR and power steering

These are completely different units. To understand the main differences, it is enough to study the hydraulic booster. Its main component is a pump driven by the crankshaft, it is integrated with other parts. The operating principle of the hydraulic booster is based on hydraulics.

As for the electric power steering, it is driven by an electric motor. Its design also includes an electronic control unit, a steering shaft with a torsion element and sensors. The EUR works according to a different scheme:

- When the steering wheel rotates, the torsion shaft twists;

- Special sensors record changes in the position of the shaft and send data to the electronic control unit;

- After analyzing the information, the unit sends commands to the electric motor;

- As a result, the unit creates the necessary force or facilitates turning the steering wheel.

Car enthusiasts often argue which option is preferable for the “ten”. In fact, power steering is an obsolete unit that is being actively removed from modern passenger cars. The electric booster works even when the engine is turned off and weighs less than the power steering. The main advantage over “hydraulics” is reliability - the electric unit requires virtually no maintenance. There is less load on the engine, and as a result, less fuel is also needed. The EUR is also good for our conditions because it functions well at low temperatures.

But the electric booster also has its drawbacks. Its design is more complex than that of “hydraulics”, hence the high price. Sometimes the electronic control unit sends incorrect commands, this was especially felt by the owners of the first generation Kalina. If you drive for a long time on a poor-quality road surface (or lack thereof), the EUR may turn off for several minutes due to overheating.

Characteristic

At the moment, almost all budget cars are equipped with such an amplifier. However, owners of old cars have a desire to retrofit their car with power steering. This is a very useful option. Even with a large diameter steering wheel, the effort required to control the car will be several times less. This is especially noticeable when parking in densely populated cities. The power steering itself is part of the car's steering system and runs on hydraulic fluid pumped by a pump. This also includes the steering column. The usual factory one does not fit here. There are many advantages of this system.

The first is the comfort of control, because you no longer need to turn the steering wheel as much as before. The second is reliability. The hydraulic booster practically does not fail. The third advantage is ease of maintenance. You will not have any difficulties when operating such a car. Even if the amplifier breaks, you can fix it with your own hands. Moreover, it is quite possible to get to the garage with such a breakdown. The only thing that will happen is that the ease of control will deteriorate. The steering wheel will become “heavy”. By the way, for the first time such an amplifier was installed on Gorky’s “Chaika”. GAZ-13 was the first car with power steering.

( 2 ratings, average 4.5 out of 5 )

Source

Is repair possible?

The VAZ 2110 steering rack with power steering is a fairly reliable unit, but even it can fail if the car is used incorrectly.

Repairing the steering mechanism may involve the following steps:

- Repair of power steering rack. In this case, the repair procedure consists of replacing parts from the repair kit. This kit includes sealing elements for the piston and shaft, oil seals, bushings, as well as inserts for pressing the shaft. During this task, the surface of the shaft may be machined.

- Switchgear repair. This procedure involves replacing the upper and inner oil seals, sealing elements and grinding the shaft. If the distributor shows signs of ring wear, the housing will also need to be lined.

- Repair of the rack with restoration of the shaft. In this case, all the steps described above are performed, but in addition to this, you will also need to restore the shaft by building up the babbitt. You will also need to coat it with chrome and grind it.

- If we are talking about a major overhaul, then you will need to perform all the steps described above, as well as completely replace the transverse shaft, its (side) clamp, along with the nuts and distributor. In addition, it may be necessary to replace the high-pressure lines along with the steering rods.

Price issue

The cost of a new EUR today is about 13-18 thousand rubles. On the secondary market you can buy a set for 2-6 thousand. The price for a complete set of power steering is on average about 20 thousand rubles.

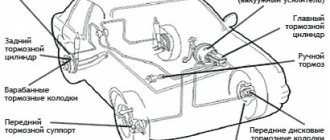

Power steering device

We can say that the “seven” is equipped with the simplest type of power steering. It contains several basic elements that make it easier to control the car:

- Hydraulic pump mechanism. It is through the cavities of the pump that an uninterrupted supply of working fluid is carried out and the necessary pressure is created.

- Steering gearbox with distributor. This device is designed to ensure the passage of air flow. The air directs the oil in two directions: into the cylinder cavity or in the return direction - from the cylinder to the tank containing the working fluid.

- Hydraulic cylinder. It is this mechanism that converts oil pressure into movements of the piston and rod, which reduces physical force when applying pressure to the steering wheel.

- Working fluid (oil). Oil is necessary for the stable operation of the entire power steering system, since it not only transmits movement from the pump to the hydraulic cylinder, but also simultaneously lubricates all components. Oil is poured into a special container and supplied through high-pressure hoses.

It will be necessary to add 6 more main power steering components to the steering wheel design

Typical equipment of the VAZ 2107 implies two schemes for the operation of the hydraulic booster: transmission of movement to the steering rack or to the steering shaft.

Nuances of installing power steering

Every car owner who installs a hydraulic booster must follow the instructions, otherwise the installation of the system may be carried out with errors. And this, in turn, will lead to incorrect operation of the power steering.

So, how to install power steering on the “Ten”:

- First, the timing case is removed and the bracket is installed with three screws. There are corresponding holes in the interior, so there is no need to drill anything additional. Next, the stud is installed, on which the roller will subsequently be mounted. There are no holes for the stud, so you will have to drill them. After installing the roller, the bracket is installed and fixed.

- The generator unit, as well as both of its clamps, must be dismantled; similar actions are performed with the column. The shaft will need to be trimmed a little, about 3.5 cm. If you have an angle grinder with a welding machine, then you can do this step yourself; if not, contact a specialist.

- Then part of the bracket is sawed off, after which it will be possible to securely attach the pump to it and close it with a pillow. The resulting structure is mounted on the power unit, or rather, in the place where the generator unit bracket was installed.

- Now you need to find the adsorber and install a bracket for the expansion tank under it. To do this, unscrew the screw securing the engine mount, and then lift the engine. The power steering strap is installed in the resulting hole; it should be securely fastened to the roller.

- Now all you have to do is replace the standard installed rack with a new one from the hydraulic booster. Remove the pole of screws and complete the assembly procedure of the device. Connect the hoses and fill the expansion tank with working fluid; to pump it, turn the steering wheel to the extreme right and left positions with the engine off and running.

The part marked in red will need to be sawed off

How to install?

To do this you need to remove the steering wheel. Here you will need not just a set of keys, but a puller. You can't just remove the steering wheel. This puller looks like this:

It will be impossible to remove the wheel with your bare hands - this will only damage the steering column. After removing the steering wheel, the column must also be removed. The universal joint and the nut securing the steering rod bipod are removed. Next, unscrew the three nuts of the steering element. After this, a new set of bipods is installed on the column shaft with power steering. The latter must be connected to the steering rod and secured with cotter pins. When installing a new column “under the power steering,” the old mount will interfere with us. It is cut using a grinder. Next, install a plastic protective casing on the column. The screws for fastening are old ones. Next, a rubber ring, castle nut and washer are put on the casing. The penultimate one is secured with stepladders.

A small driveshaft is installed between the steering mechanism and the column, which will connect both elements and reliably transmit force. Drive a wedge into a wide hole (using a hammer, light blows). Two washers are mounted on the wedge thread - spring and regular. As a result, the length to the hinge should be 300 millimeters. Next, tighten the castle nut and mount the steering wheel. The power steering steering column (UAZ-469 is a tuning object) has been successfully installed. But that is not all. We need to secure the remaining parts of the mechanism.

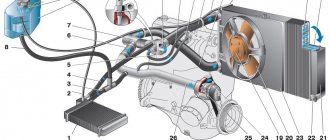

Alternator and power steering belt

Generator on a VAZ 2110 car with power steering

What, does the owner of a VAZ 21103 have a hydraulic booster? As you know, if a VAZ 2110 is equipped with power steering, which, it is worth noting, completely eliminates vibrations typical of front-wheel drive cars, replacing the alternator belt is carried out completely differently than is customary. As a rule, the alternator belt is replaced after 45-60 thousand kilometers, and cracks on it are a direct sign of replacement. A normal replacement of this part takes no more than 10 minutes, but on cars with power steering it takes more time, and the belt cannot be found in its usual place. In this place, if power steering is installed, the pump described above is placed. The generator itself is located higher.

The difficulty of replacement in this case is characterized by the fact that the belt rotates around the left motor support, which forces you to unscrew the support, lift the engine and only then remove the belt. Specificity is also observed in the case of alternator belt tension. In particular, the angle of the alternator pulley belt in the case of power steering is quite small and the usually accepted tension of 1 cm up and down does not work here. The belt begins to slip. This means that the power steering belt tension must be stronger.

As you can see, power steering also means unnecessary troubles associated with repairs. But if you learn to do everything yourself, problems can be avoided. In addition, you can save a lot on repairs, the price of which increases every time at the service station. The instructions presented above are an introductory version for owners of a VAZ 2110 with power steering. A complete step-by-step manual for replacing the power steering, repairing it, etc. can be found in other articles, through video or photo materials.

We install EUR and power steering on a VAZ 2110 on our own

Based on the year of manufacture, the “ten” can be equipped with a hydraulic booster (power steering), also called an electric power steering (EPS). They are appreciated by women; the second option is preferable, because it is easier and more comfortable to drive a car with a child. If your power steering has worn out differently and you just want to change it, then it is recommended to choose the power steering for the VAZ 2110 as a candidate.

This material contains two annotations:

- Installation of power steering.

- Installing electric power steering on a VAZ 2110 instead of the standard power steering.

Well before installation, you need to understand the structure of these units and also find out how they are different.

Lada 2111 › Logbook › Power steering for 2110 8 cells. Part 1

The topic is old and hackneyed, but I still want to share my experience.

I would like to immediately answer frequently asked questions: Why power steering? After all, the EUR is better/simpler/more reliable/doesn’t take power away from the engine

1. Because the power steering rack has 2.7 turns from lock to lock, and all other 2110/Priora/Kalina racks have 4.2 turns. The only exception is the viburnum sprat rack with 3.1 2. I like it when the steering becomes stronger at speed 3. IMHO the hydraulic rack dampens impacts on the wheels better and allows you not to feel a slip during acceleration. Again, these are just my feelings 4. In principle, I like the idea of a hydraulic booster better. This can be considered religious beliefs

How expensive?

Within 10-12 sput

How difficult and how long does it take to install?

1 full day, nothing complicated, a minimum set of tools required

Components

This is what the most complete set of power steering looks like:

If you remove the set of priors with your own hands, then you will not have any problems, you will be able to get everything and see how it stands, but if you assemble it in parts... Particularly difficult to find is the boot installed in the engine shield, at the entry point of the steering slats in the interior:

Bleeding the brakes of a VAZ 2112. How to do it correctly

In the list of diagnostic measures, bleeding the brakes of the VAZ 2112 is one of the first places. It’s good when car enthusiasts understand this and take it quite seriously. It’s not for nothing that they say: “Why do you need a gas pedal if the brakes don’t work?” Bleeding the VAZ 2112 brakes is primarily necessary to remove air layers from the communications and equipment of the brake system, which lead to malfunctions of the entire well-functioning automotive mechanism. The most critical consequence of the presence of air in the system is its complete failure, when when you press the brake pedal, it falls to the floor without effort and remains in that position. Why and when is bleeding performed? The process, which drivers call “bleeding,” is based on the purpose of removing from the cylinder and underwater hoses of the braking system the layers of air that have penetrated into it. One can object by pointing out that the system is hermetically sealed and only thanks to this technological feature it functions. However, under the influence of constant mechanical loads, as well as material fatigue, the tightness may be broken. Carrying out a daily visual inspection of the car before driving on the road in rare cases may reveal signs of hidden depressurization, which is a consequence of:

- Loose fluid supply hoses;

- Microcracks in tubes, fittings or in the cylinder.

Bleeding must be carried out as one of the stages of work when replacing any equipment included in the functionality of the system. With rare exceptions, when the pads are replaced, however, even such a simple process can also be completed by preventative blowing of the hoses. Stages of work To carry out this type of restoration work, a set of the following tools, materials and auxiliary equipment is required:

- Capacity, preferably a clean bottle of at least 1.5 liters;

- Rubber tube from a medical IV or from a blood transfusion set;

- Clean rags;

- Wrench for 8 and 10, open-end or “bleeder”, which has a special slot;

- Steel brush for cleaning metal surfaces;

- A can of WD-40 to remove traces of dirt and rust;

- New fluid for the system.

Also, to carry out the work conveniently and quickly, you need an assistant who will bleed the brake pedal from the passenger compartment - from this manipulation the whole procedure got its name. At the first stage, air is removed from the discharge cylinder. To do this, the pedal builds up pressure and, alternately unscrewing the fittings on the cylinder, air bubbles are released from them. Prefaces these manipulations by adding fluid to the tank to the maximum possible level. Only after this do they begin to work with the wheel fittings. Bleeding the wheels on VAZ cars is carried out in the following sequence:

- Rear right;

- Front left;

- Rear left;

- Front right;

- *The sequence of processing wheels on VAZ models is determined by their distance from the cylinder, and therefore by the length of the connecting hoses.

However, in the case of the VAZ 2112, this is not critical, since on this model the system is multi-circuit and the sequential wheels do not matter in this matter. The procedure is similar to that done with the central cylinder, only there is only one fitting on the wheel. Even if no repair work has been carried out on the system, the VAZ 2112 brakes should be bled either once every 3 years, or every 4,000-5,000 thousand kilometers. Bleeding is required if the liquid becomes dark, which indicates a loss of its performance characteristics. AutoFlit.ru

- Why do you need an absorber for a VAZ 2114?

- What is the VAZ 2110 gravity valve for?

- Why do you need an adsorber for VAZ 2112?

- VAZ 2110 starter repair kit

- VAZ 2114 how to find out the color of a car by VIN code

- RDT VAZ 2114 signs of malfunction

- VAZ 2110 signs of malfunction

- DMRV VAZ 2114 signs of malfunction

- Dpkv vaz 2114 signs of malfunction

- Signs of a malfunction of the DPD on a VAZ 2112

- VAZ 2114 signs of injector malfunction

The need for power steering

VAZ 2112 cars coming off the factory assembly line do not contain power steering. This fact may indicate that the machine simply does not need such a device. However, you can find power steering on sale and install it yourself. Before buying anything, spending time and effort, it would be wise to weigh all the facts.

Arguments in favor of hydraulic booster

Aspects that indicate the need to install this device are as follows:

- Facilitation of parking;

- Reduced effort on long turns;

- Increased ease of control on the road.

As you can see from the list, there are few arguments. But for some drivers they are very important.

Ease of parking

The main purpose of the VAZ 2112 power steering is to reduce the effort when turning the wheels. In winter, when the surface is slippery, turning the wheel of a stationary car is quite simple. But if you imagine that there is asphalt under the car with small stones sticking out and digging into the tire, then you will have to make a lot of effort to perform the desired maneuver.

At such moments, it is best to start turning the wheels immediately after starting to move, as this helps reduce the load on the steering mechanism. If the parking process causes a lot of inconvenience to the driver, then you should think about installing power steering. This is often typical for female drivers.

Reduced effort in movement

Moving along a straight path and a flat surface, driving the VAZ 2112 does not cause much trouble. But when entering a sharp turn, changing the trajectory of the car requires effort.

This is due to the fact that it is affected by centripetal acceleration, the vector of which is directed perpendicular to the car. At such moments, power steering will be very useful.

Arguments against the amplifier

After analyzing the positive factors, the driver will immediately want to install an amplifier for himself. But besides the positive, there are also negative aspects. These include:

- Repair costs;

- Labor intensive installation process;

- Changes in body design.

The power steering mechanism of the VAZ 2112 has significant shortcomings. The degree of their significance for the driver determines the further decision. The existing aspects should be assessed as objectively as possible.

Repair costs

Over time, any mechanism wears out and needs repair. It is clear that an increase in the number of mechanisms inevitably leads to increased costs for their maintenance and repair.

When installing the amplifier, the following malfunctions may occur:

- Loss of system tightness;

- Broken or loose pump belt;

- Malfunction of the distributor;

- Destruction of rubber parts;

- System clogged.

- Wear and failure of the working cylinder.

Depending on the malfunction, there is a need for certain purchases and associated costs. Not only monetary expenses, but also time will be needed in such situations.

Complexity of the installation process

As the amplifier is introduced, there will be difficulties associated with changing the body, so you need to be prepared for this. The necessary elements are purchased independently. The installation process will be accompanied by the addition of a pump with its mount and belt, a reservoir for working fluid, a distributor, hoses, tubes, and an actuator. All parts must be properly secured. ATF is often used as a working fluid. But there are other options, including those indicated in the instructions accompanying the purchased parts

The desire for additional amenities leads to the complication of the car. And this, in turn, is fraught with a decrease in reliability and costs. In addition, people become weaker physically.

When we want to simplify our life in some way, it turns out that, on the contrary, we make it more difficult. Installing a hydraulic booster on a VAZ 2112 is advisable when there is a genuine need for it; in all other cases it will only be an additional convenience.

Liquid leakage from the system along the way will lead to failure of the amplifier. In winter, due to low temperatures, noise may occur during operation of the device. This brings some discomfort, as the process of driving a car may be disrupted.

DIY steering rack repair video

To understand the process in more detail, it is recommended to watch the video:

I often heard noises, a friend said that it was a problem with the steering rack. Under the guidance of the video, they corrected it.

Steering mechanism of a VAZ 2112 car

An important part for controlling the movement of a car is the steering mechanism. Its main unit, the steering rack, transmits the force that the driver applies to the steering wheel through tips and rods to the steering levers, connected through axles to the steered wheels.

How safe the vehicle will be on the roads depends on the good condition of all its elements. Therefore, it is very important to timely repair the VAZ steering rack. This article suggests that you familiarize yourself with the causes of malfunctions and how to fix them yourself.

Disassembling the steering rack

- Remove the support and protective cap from both sides of the mechanism.

- Release the protective covers.

- Remove the stop nut using a special wrench.

Remove the stop nut

Removing the drive gear with bearing

Remove the support sleeve

Next, you need to replace all the elements that are included in the steering rack repair kit, check the product for play and conduct a visual inspection.

After disassembling the rack, special attention should be paid to the worm gear mechanism and the support sleeve. Also, if the anthers are damaged, then corrosion of some parts of the mechanism may occur.

Everything here needs to be cleaned and rinsed, and also generously lubricated.

It is necessary to change the retaining ring and the rack stop. These parts are subject to the most wear and tear.

Power steering pump

The pump of this mechanism deserves a separate discussion. It costs about 3 thousand Russian rubles and is often repaired rather than replaced. But if repairs don’t help, you’ll have to spend money. As for high-quality repairs, you can again do it yourself, thereby saving your money.

Typically, a ZF brand pump is installed on the VAZ 2110 power steering, which is also used on the Audi A6, Volkswagen and other cars. But this pump model is not dismountable and there are no retaining rings or covers on it. This does not mean that it is impossible to restore the operation of such a pump. Below are instructions for removing and disassembling the power steering pump:

- Remove the clamp;

- Disconnect the return hose (do it carefully so as not to spill oil);

- Disconnect the connector;

- Remove the DJ (sensor) from the fitting bolt.

- We disconnect the discharge tube, first removing the union bolt;

- Remove the power steering drive belt;

- Now it's time to start removing the pump itself;

- Loosen the first bolt securing the pump;

- We completely unscrew the second bolt securing the pump;

- Remove the pump assembly.

We clean the pump from dirt and visually inspect it. If a development is found on the inner wall of the housing, resembling steps, then they need to be removed using a special nozzle and a drill.

What does the price depend on?

Different service stations set different prices for power steering repairs. The price is formed under the influence of such factors:

- Model and make of the car.

- The number of elements that have failed.

- The need to replace (repair) other parts.

- Purchase price of new power steering components.

- Difficulty restoring power steering functionality.

- Urgency of order fulfillment.

- Availability of a valid warranty for the vehicle.

- Master qualification level.

- Car service pricing policy.

The more complex the breakdown, the more time and effort it takes to repair, and the more expensive the mechanic’s work will cost. For urgency, calling a specialist to the location of the car you will have to pay more. If the car is under warranty, it will be repaired free of charge. The more prestigious the service station, the higher the prices for restoring the machine’s functionality will be.