You may know that many cars contain stabilizer bars (beams) in their design - either on the front axle or on both.

On Vesta, stabilizers (beams) of lateral stability are installed by the factory only at the front.

The stabilizer is designed to combat lateral rolls (for example, during a turn), preventing a possible rollover. With such a beam, the car has greater stability on the road, and you are less likely to lose reliable grip on the road. The stabilizer kit includes the following elements:

- Barbell

- Mounting bracket (clamp)

- Bushing (cushion)

- Rack

- Mounting bolt

The stabilizer bar for Vesta is made of spring steel, which is installed on the subframe using brackets and bushings. The rod is also attached to the front suspension shock absorbers with appropriate struts. During the lateral tilt of the machine, the stabilizer links move (one moves up, the other moves down), resulting in an even distribution of the load between the chassis parts.

In this case, the stabilizer bushings play a very important role - they allow the bar to twist around its axis during load, ensuring stabilization of the car’s position on the road.

The bushings are replaced if they are worn out. The results of wear can be:

- Extraneous sounds from the front suspension.

- Creaking occurs when driving on uneven roads or after driving through puddles.

- Reduced controllability in the speed range from 60 to 90 km/h.

The causes of wear are the aggressive action of the environment (road dirt, reagents) or poor manufacturing quality of the bushings.

Life expectancy of bushings

The wear of bushings is not regulated by manufacturers - there are recommendations for mileage, after which it is advisable to change the bushings. But the duration of operation of these units is influenced by several factors that cannot be foreseen or calculated in advance.

Let's say there are two cars released at the same time. One of them spends 90% of the mileage on rural, dirt roads, and the second - the same mileage, but on asphalt. It is clear that the bushings of a city car will “live” longer. In addition to road conditions, the performance of rubber bands is affected by driving style and driving speed. At high speeds, there are more opportunities to “yawn” a pothole or sharply turn a corner, which will cause the stabilizer to actively work.

The average service life of bushings is 70 thousand kilometers. There were cases when the bushings “nurtured” 100 thousand, and there were cases where they did not reach 35 thousand.

How to prevent the stabilizer from squeaking

Each owner tries to improve his car, eliminating the flaws made by the largest domestic manufacturer. Vesta’s owners continue the tradition. In particular, they often think about how to improve the performance of the stabilizer.

The easiest way to rid the Lada of squeaking is to thoroughly lubricate the bushings. To do this, it is permissible to use silicone compounds or even WD-40. This recommendation, by the way, is also present in the official operating manual for the machine. The problem is that this measure is not enough for a long time - sooner or later the lubricant dries out, so its layer has to be renewed regularly. Moreover, the owners note that the described measure helps only at first.

A more effective way is to replace the bushings. However, it is not very wise to use original products, because they will not last as long as their predecessors. Thus, the best way out is to use elements from foreign cars, and then the stabilizer will start working, albeit not silently, but much quieter.

Radiators (cooling, heating, air conditioning systems): Valeo brand, made in Russia

All three Vesta radiators from the French brand Valeo (a well-known component manufacturer) are distinguished by good workmanship, in no way inferior to their world analogues. During dismantling, it was difficult to suspect that the radiators were assembled in Tolyatti at Valeo’s own production site.

By the way, the competence of the employees of the hotline of the Russian representative office of Valeo (where we were transferred to answer questions) was called into question. They couldn’t say exactly what was being assembled at the Valeo site in Nizhny Novgorod, and when asked about production in Togliatti, we were told that there was no confidence that it was working at all, although the press service of AvtoVAZ firmly confirmed the opposite.

AvtoVAZ official opinion

To answer thousands of questions from car owners about stabilization problems, AvtoVAZ has the following opinion; These are design features of the model caused by the long working strokes of the struts when driving on uneven roads.

- bushing lubrication;

- installation of rubber-metal hinges, .

Point one is reminiscent of servicing the Volga GAZ-21. It recommended lubricating ten lubrication points under the car body, after rain and once a week. True, no one suggested doing interesting things like lubrication of bushings. The most unclear thing is how to smear them. Whether it is worth disassembling the stabilization unit or not is still unknown. Although old cars can still be found on the roads and nothing creaks or breaks for years.

Regarding the short operation of the stabilizer struts: They promise to bring them to normal condition. Now the problem is caused by the liner, which creates play inside the ball joint. Replacement of stabilization struts can be done free of charge at the dealer, it does not cause problems, they know about the problem with the stabilization unit and are ready to make repairs. But in this case, it’s much more profitable to learn how to change yourself. The reason for this is quite obvious. Replacing standard spare parts at a dealer does not imply the installation of spare parts or consumables from other brands of cars.

How to change the stabilizer struts yourself in 5 simple steps Replacing the stabilization struts on a Lada Vesta car comes down to a simple algorithm, but there is also preparatory work: It is necessary to hang the front wheels of the car. Firstly, this is required by safety measures. Secondly, it’s much more convenient to work this way. Let's get started:

- The stabilizer link pin nuts are cleaned;

- The nut is turned out from the top of the part, keeping the ball joint pin from turning;

- The nut is turned out from the bottom using a similar tool;

- The anti-roll bar is removed, the ball joint pin is removed from the front suspension strut and from the anti-roll bar;

- To check the anti-roll bar link, you need to pull out the top pin of the ball joint, grab it firmly with your hand and swing it up and down. The presence of a knock indicates a faulty part. Installation of the node rack is performed in the reverse order. When starting a repair, you can watch the entire process in the video.

Something happened that many car enthusiasts in our country were waiting for - AvtoVAZ created a high-quality Lada Vesta car. To expect that he will be devoid of shortcomings is, if not stupid, then naive. But I wanted them to be insignificant and not disturb too often.

It’s been 3 years since the serial production of the car and it’s safe to say that the domestic auto industry has made a big step forward. The car turned out to be not only beautiful, comfortable and affordable, but also reliable.

Among the few shortcomings of the car are poor-quality stabilizer struts, which are not able to withstand the high load of driving on damaged roads. As a rule, this part fails first.

As AvtoVAZ representatives assured, the car’s suspension is reliable and can easily withstand the load of bad roads. But this turned out to be untrue, since many owners complain about the appearance of minor noise when driving on rough roads after 5-10 thousand kilometers.

In most cases, noises and knocks are associated with a malfunction of the stabilizer struts. If you contact an official dealership and have a warranty, the problem will be resolved quickly. But, as practice shows, many experienced car enthusiasts prefer to repair the suspension themselves.

Step-by-step instructions for replacing bushings

To make high-quality repairs with your own hands, you must meet some requirements: prepare the place for repairs and select the necessary tools.

Necessary tools and place of work

To perform the work, you should know the basic rule: the wheels of the car must be unloaded, that is, hanging freely in the air. The work will require a technician to be under the car, so it is better to do it on an inspection pit or a lift.

When using an inspection hole to hang the wheels, you will need a jack and stands on which the car will rest. They are not needed when working with a lift.

Tools and materials:

- M16 socket or combination wrench.

- Open-end and ring wrenches, M13 head.

- Head or combination wrench M10.

- T40 Torx key.

- A small crowbar or spudger.

- Silicone or other non-rubber-damaging lubricant.

- Rags.

Where are they installed and how to remove them

The Lada Vesta stabilizer bushings are located on the right and left sides of the front suspension subframe. They are located in front of the car's steering rack. A special feature of the Lada Vesta is that its stabilizer bar bends around the anthers of the left and right steering rods.

The lack of space for installing the stabilizer bar led to the fact that the factory designers moved its mounting points as close as possible to the steering rack. This decision greatly complicated the ability to unscrew the inner bolt securing the hub clamp. Even using a T40 wrench does not always allow you to completely unscrew this bolt.

Sequence of work when using a cut bushing:

- Place the machine on a pit or lift.

- Hang up and remove the front wheels.

- Clean the stabilizer bar from dirt along its entire length.

- Unscrew the outer bolts securing the bushing clamps.

- Unscrew the inner bolts to the maximum possible height and try to rotate the clamp around the inner bolt so that the bushing is released.

- If you cannot unscrew the inner bolt, then loosen the steering rack fastenings and lift it, or remove it completely.

- The damaged bushing is moved in any direction and simply removed if it is cut, or cut off with a sharp knife if it is not cut.

- The installation site is cleaned of possible adhering particles of rubber and dirt, wiped with a rag, and lubricated with a special lubricant.

After completing all the items on the list, the place can be considered prepared for installing a new rubber band.

Installation of new parts

If you plan to install a cut bushing, then simply put it on the rod using the cut. Then the elastic band is moved along the rod to the installation site.

Installing an uncut bushing is a little more difficult - you need to disconnect the rod from the wheel assemblies before starting work. To do this, at both ends of the rod, unscrew the nuts of the ball pins of the stabilizer struts, and, having disconnected these struts, move them to the side.

After this, you can begin installing new rubber bands. The assembly sequence is as follows:

- Lubricate the rod from the edge to the place where the bushing is installed with silicone grease.

- Place a new elastic band on the bar and slide it along the bar to the desired location.

- Close the bushings with clamps and tighten the fastening bolts (it is advisable to tighten them lightly so as not to strip the threads).

- Return the steering rack to its place.

- Stabilizer struts are attached to the edges of the rod.

It should be noted that if, when replacing the bushings for the first time, it became necessary to work with the steering rack, then in the future this need can be eliminated if the holes on the bushing clamps for the internal bolts are replaced with slots. Then to remove the clamp it will be enough to unscrew the inner bolt 2/3 of its length.

Assessment of the condition of parts after replacement

It may happen that the creaking of the bushings does not disappear in the first kilometers after repair. This is acceptable - the new rubber bands should “break in.”

Bad roads are not the best place to drive, but they provide a good way to test the quality of any repair work. If after a run of 300 km the squeak does not disappear, you should look under the car and visually evaluate the bushings. A bushing made of low-quality material, even over such a short run, will become covered with a network of cracks and, alas, will have to be replaced again.

If the appearance of the replaced bushing does not raise suspicions, then perhaps you should pay attention to the tight fit of the bushing to the stabilizer bar. The fact is that sand that gets under the rubber band “eats” not only it, but also the top layer of metal of the rod

In this case, the stabilizer bar itself must be replaced.

Can I replace it myself?

Everything you need to know about Lada Vesta tires. choose the right tires

The task is not difficult, so the owners of Lada Vesta, if there are conditions to carry out the work, can safely begin to implement it. You won’t need any special skills, but you will have to acquire a few things.

These are the tools and devices:

- lifting device or repair pit;

- socket heads in a set;

- knob;

- a set of keys, both open-end and spanner;

- "TORX" - nozzles;

- a lubricant that does not have a destructive effect on plastic and rubber.

Due to the fact that the manufacturer retains the right to make certain types of changes to the design of the car, it makes no sense to specifically indicate the size of the keys. It will not be difficult to find your way around the place.

Stabilizer bushings creaking

Causes of squeaks

Often, owners of passenger cars complain about creaking stabilizer bushings. It often occurs during frost or dry weather. However, the conditions of occurrence manifest themselves individually. The main reasons for this problem are:

- low quality of the material from which the stabilizer bushings are made;

- rubber hardening in the cold, causing it to become inelastic and squeak;

- significant wear of the bushing or its failure;

- design features of the car (for example, Lada Vesta).

Methods for solving the problem

Some car owners try to lubricate the bushings with various lubricants (including). However, as practice shows, this gives only a temporary effect

(and in some cases it doesn’t help at all). Any lubricant attracts dirt and debris, thus forming an abrasive. And this leads to a decrease in the life of the bushing and the stabilizer itself. Therefore, we do not recommend that you use any lubricants

.

In addition, it is not recommended to lubricate the bushings due to the fact that this violates the principle of their operation. After all, they are designed to tightly hold the stabilizer. Being essentially a torsion bar, it works in torsion, creating resistance to the car's roll when cornering. Therefore, it must be securely fastened in the sleeve. And if there is lubrication, this becomes impossible, since it can still turn, making a creaking noise again.

The recommendation of most car manufacturers regarding this defect is to replace the bushings

. So, general advice for car owners who are faced with the problem of squeaking from the stabilizer is to drive with the squeaking for a certain time (one or two weeks is enough). If the bushings do not “grind in” (especially for new bushings), they will need to be replaced.

In some cases, replacing rubber bushings with polyurethane ones

. However, this depends on the machine and the bushing manufacturer. Therefore, responsibility for the decision to install polyurethane bushings lies solely with the car owner.

Stabilizer bushings must be replaced every 20-30 thousand kilometers. Look for the specific value in the manual for your car.

To solve the problem, some car owners wrap the part of the stabilizer that is inserted into the bushing with electrical tape, thin rubber (for example, a piece of a bicycle tube) or cloth. Original bushings (for example, Mitsubishi) have a fabric insert inside. This solution will allow the stabilizer to be seated more tightly in the bushing and will relieve the car owner from unpleasant sounds.

Description of the problem for specific vehicles

According to statistics, owners of the following cars most often encounter the problem of creaking stabilizer bushings: Lada Vesta, Volkswagen Polo, Skoda Rapid, Renault Megane. Let us describe their features and the replacement process:

Lada Vesta. The reason for the creaking of the stabilizer bushings on this car is a structural feature of the suspension. The fact is that Vesta’s stabilizer strut travel has become greater than that of previous VAZ models. Their struts were attached to the levers, while Vesta's were attached to the shock absorbers. Therefore, previously the stabilizer rotated less and did not cause unpleasant sounds. In addition, Vesta has large suspension travel, which causes the stabilizer to rotate more strongly. There are two ways out of this situation - shorten the suspension stroke (lower the landing of the car), or use a special lubricant (manufacturer's recommendation). It is better to use a washout-resistant silicone-based lubricant for these purposes. Do not use lubricants that are aggressive towards rubber (also do not use WD-40).

Replacing stabilizer bushings on a Volkswagen Polo

Volkswagen Polo. Replacing stabilizer bushings is not difficult. To do this, you need to remove the wheel and place the car on a support (for example, a wooden structure or a jack) to relieve stress on the stabilizer. To dismantle the bushing, unscrew the two 13mm bolts that secure the bushing mounting bracket, then remove it and take out the bushing itself. Assembly is carried out in reverse order.

Another common method that allows you to get rid of squeaks in the bushings of a Volkswagen Polo is to place a piece of an old timing belt between the body and the bushing. In this case, the belt teeth should be directed towards the bushing. In this case, it is necessary to make small reserves of area on all sides. This procedure is performed for all bushings. An original solution to the problem is to install bushings from Toyota Camry.

↑ Installation of new

Essentially, this is the reverse process of removing the old stabilizer bushings. But in reality, everything turns out to be a little more complicated: the analogues do not always match in size with the “native” parts of the Lada Vesta, it is quite possible that to adapt them you will have to use the widely known “method of modification with a file” among the people.

To do this, you need to have confidence in your own abilities, or you will have to contact specialists at the nearest service center. Searching by article number for the stabilizer bushing on the Lada Vesta will help if you have an understanding of what the part looks like in real life. There are several different options, for example, higher inserts from Chevrolet or from Kia, with a pressed-in clamp. “Nivovsky” parts are ground down to reduce their height, then a special slot is made in them.

Korean ones most often coincide in dimensions with Western ones, but may differ in the method of fastening. To avoid future problems and questions about which stabilizer bushings are suitable for the Lada Vesta, it is best to select a replacement with the removed part in hand - the method is old, reliable and time-tested. The new rubber band must fully match the dimensions of the old one, including fasteners.

Therefore, you should check with the seller in advance (especially if we are talking about expensive Korean analogues) how to secure the bushing. This smart approach will eliminate the need for repeated visits to the store, ordering additional items or exchanging purchases.

Important. Compatible spare parts can exist in 2 versions: with pressed-in eyes for installation and mounted on a clamp

Both options should be worked out in advance by talking with the salesperson at the auto parts store.

As a rule, the success or failure of the operation will quickly manifest itself: if after 1-1.5 thousand kilometers the noise does not recur, it means that the installation of new components was justified. Otherwise, you will have to start the quest again to select high-quality shock-absorbing liners.

This is why the process of initially determining compatibility (and originality) is so important: you will not need to re-purchase elastic bands and go through the hassle of installing them.

Replacing stabilizer bushings on Lada Vesta - instructions with photos and videos

Almost without exception, owners of Lada Vesta and Vesta SV Cross cars immediately after purchasing the car begin to notice a characteristic creaking of the suspension in the front part.

After searching for the sources of the squeak, it turns out that the culprit is the stabilizer bar rubber. Or rather, the material from which they are made is to blame.

Most likely, this is a design miscalculation or another attempt by AvtoVAZ to save money.

What can be done to get rid of the creaking of stabilizer bushings on the Lada Vesta?

First, you can simply lubricate the rubber bands with grease. WD-40 or any other similar lubricant will work great. However, over time, the creaking will appear again, as the lubricant will dry out or be washed out. Therefore, the procedure will have to be repeated.

Secondly, you can purchase new stabilizer bushings. But it is far from a fact that this will help or solve the problem forever, since the material itself will remain unchanged. And most likely it will also creak over time.

Thirdly, you can install rubber bands of a suitable size from another car. As practice shows, stabilizer bushings from Chevrolet Niva or Kia Rio (Hyundai Solaris) remain suitable options.

However, Nivov rubber bands do not always solve the problem, but when installing rubber bands from Kia or Hyundai, you can completely forget about the squeaking of bushings.

This is what the original stabilizer rubber bands look like in comparison with the rubber bands from the Kia Rio:

Articles for ordering: 548132K100 - bushings, 548141W000 - clamps.

Replacing stabilizer bushings Lada Vesta

If we talk about the complexity of the work, then there is nothing complicated at all in replacing the stabilizer bushings on a Lada Vesta. To do everything quickly and correctly, all you need is a little time, tools, and follow our instructions.

It is important to understand that when replacing the Lada Vesta stabilizer bushings, it is necessary to completely remove the load from them. To do this, you simply need to raise the front wheels so that they do not touch the ground. This can be done by lifting the front of the car with two jacks.

Or first lift one side and put a stop under it and then lift the second side

This can be done by lifting the front of the car with two jacks. Or first lift one side and put a stop under it and then lift the second side.

The main difficulty in replacing stabilizer bushings on a Lada Vesta is that without minimal disassembly it is almost impossible to install new bushings. But, if you cut the bushing, you can actually install it without any problems.

We move the clamp to the side, remove the old bushing (thanks to the cut on it, this is very easy to do). We install the new bushing in place. If there is no cut on it, then we make it on a new elastic band.

Then we put everything back together in reverse order.

But on the clamp, which is installed on the driver’s side, difficulties arise in dismantling one of the bolts. The fact is that it is completely impossible to unscrew it without dismantling the protective screen. This is not the easiest or fastest activity.

Therefore, we will proceed as follows. We unscrew one bolt completely. We do not unscrew the second bolt completely, but about 2/3. This will give us the opportunity to rotate the clamp 180 degrees to remove the bushing and install a new one.

Then we stretch the clamp. At this point, the replacement of the Lada Vesta stabilizer bushings can be considered complete. Now no creaks or extraneous sounds will disturb you, and your Lada Vesta will go over all bumps very quietly and smoothly.

Replacing stabilizer bushings Lada Vesta video

In order to make the process of replacing the Lada Vesta stabilizer bushings more understandable, we will leave here a video in which everything is clearly shown.

And here is another video that we found on the Internet:

Independent work

In this case, there are several ways:

- Bushing lubrication;

- Replacement with analogues.

Bushing lubrication

If you choose this option, everything is done exactly the same as when contacting a dealership. However, car owners choose the lubricant themselves. Some people buy regular mastic, others use foreign lubricants, for example, Japanese ones.

Owners buy different lubricants

Be that as it may, these are only temporary measures, since mastic and other lubricants are still quickly washed out. It may last a little longer, but that doesn't solve the problem.

Replacement with analogues

According to reviews from owners, most often either bushings from Chevrolet Niva or components from KIA are used.

Bushings from Chevrolet Niva

Elements from this model are suitable for Lada Vesta, which can be bought at almost any car store. In addition, they can be ordered online using the following article numbers:

Stabilizer bushings from Chevrolet Niva

The second type of product has larger dimensions, so it is used more often. The price of bushings from Chevrolet Niva is about 150 rubles per pair. However, there are also polyurethane products on sale, which are often painted in bright colors (yellow, red, etc.). The price of polyurethane products reaches 250 rubles per piece.

You can purchase products from one of the resources below:

- https://www.autopiter.ru/goods/21232906046/rossiya/ >However, Vest owners note that elements from the Chevy Niva also often creak, and it doesn’t make much difference what material they are made of - rubber or polyurethane.

Bushings from KIA

These are more expensive components, which can be purchased under article number KSBSOULF or 54813-2K100. The price for such products is significantly higher than for similar ones from ChevyNiva. Usually the cost varies between 400-650 rubles, but the price can reach 850 rubles per piece. Therefore, it is recommended to monitor offers from various suppliers before purchasing. In this case, you need to buy only original products. Purchasing a non-original one is fraught with the same creaking noise, which is extremely unpleasant, because bushings from a Korean manufacturer are not cheap.

You can purchase them on one of the following sites:

- https://koreanaparts.ru/product/548132K100/730

- https://www.autodoc.ru/part/hyundai-kia—647/548132k100/

- https://www.autopiter.ru/goods/548132k100/hyundai-kia/id11105217

- https://plentycar.ru/autopart/1981834

In addition, it is worth taking into account the configuration of parts from HYUNDAI-KIA, which differs significantly from that of the Lada Vesta. For this reason, along with the bushings, you need to buy brackets for them, which are sold under article number 54814-1G000. The price tag for them ranges from 300 to 500 rubles per piece.

Loose wheel bolts

The situation when the fastening bolts of one or several wheels have become loose is typical not only for Lada Vesta, but occurs frequently. There can be many reasons - from inattention during tire fitting to an unsuccessful attempt to steal a wheel.

If a knocking sound occurs while driving, the first thing you need to do is stop the car and check the tightness of the wheel bolts, since a tire that falls off while turning can cause the car to roll over with unpredictable consequences. In this case, diagnostics is inseparable from troubleshooting.

After tightening the bolts or making sure that the reason for the knocking is not their tightening, you can continue driving. If the problem is not solved, you should not put off diagnosis for a long time. In order not to aggravate the situation when one malfunction causes another, it is strongly recommended to contact an authorized dealer as soon as possible for qualified diagnosis and elimination of the causes of knocking or other abnormal suspension noises performed on a car raised by a lift.

Independent repair of a car before the expiration of the warranty period may be classified by the dealer as a violation of contractual obligations by the consumer and become grounds for premature termination of warranty service.

Comments

Guests cannot leave comments on the site, please log in.

Products for LADA at the best price

A selection of accessories for LADA from AliExpress

- https://xn--80aal0a.xn--80asehdb/do-my-self/repair/repair-lada-vesta/1329-zamena-vtulok-stabilizatora-poperechnoy-ustoychivosti-na-lada-vesta.html

- https://carfrance.ru/zamena-vtulki-stabilizatora-lada-vesta/

- https://autobann.su/zamena-vtulok-stabilizatora-lada-vesta.html

- https://xn--80aal0a.xn--80asehdb/do-my-self/tuning/tuning-lada-vesta/1674-kakie-vtulki-stabilizatora-podhodyat-na-lada-vesta.html

Lada Vesta suspension diagnostics

Before starting repairs, be sure to carry out diagnostics. This is necessary to assess the condition of the machine, identify breakdowns, and correctly calculate spare parts and consumables.

The process is not at all complicated, you can do it on your own. If you encounter any difficulties with installation, please read the instructions and watch video tutorials on the Internet.

- We drive the car into the inspection hole, fix the rear row of wheels with boots to avoid any arbitrary rollback;

- Jack up the side and remove the wheel;

- From under the bottom we press on the stabilizer bar, check for play, deformation, cracks;

- Additionally, we inspect the condition of adjacent parts, levers, and mechanisms.

To check the tightness of the fit, we use a metal pry bar. We summarize, analyze the received data, and calculate the number of necessary spare parts.

Finally, we check the brake pads, disc, and cylinder. If the actual thickness of the pads is less than 17.0 mm, they must be replaced with new ones. Subsequent operation of the vehicle is unsafe.

Reviews

| № | Positive |

| 1. | Vasily , 34 years old (drive2.ru) Sverdlovsk: for the first time the seals creaked at 20,000 km, I went to the service station under warranty, the guys lubricated it with a metal-rubber aerosol. A year has passed - silence. |

| 2. | Petrovich , 44 years old (prom.ua), Krasnodar: the car is in its third year, no complaints, the suspension is working as normal. I've heard drivers complain about the crunching noise, but I didn't have that problem. |

| 3. | Alexander , 35 years old (autotoday.com), Omsk: I’m happy with the purchase of the Lada Vesta, I regularly visit the service station, I drive carefully, the speed limit is medium. |

| 4. | Ivanovich , 45 years old (rozetka.ua), Rostov-on-Don: my positive review of the Lada Vesta car in general. Good build quality, relatively cheap spare parts, developed network of car services. |

| 5. | Vyacheslavovich , 43 years old, Kursk (avtoflit.com): my first car was a Lada Priora, after which I bought a Vesta. The difference is noticeable in quality, assembly, and service life. Undoubtedly Lada Vesta is better. |

| 6. | Valery , 33 years old, Voronezh (autotoday.com): in three years of using the car, I visited a service station once to replace stabilizer bushings, not counting scheduled technical inspections. |

| 7. | Vasilievich , 46 years old, Ufa (drive2.ru): I take care of the equipment, periodically go to the inspection pit, check the fastenings and components. Over the course of three years, I lubricated the stabilizer bushings several times. I didn't do any more work on the suspension. |

| 8. | Semenych , 38 years old, Bashkortostan (drive2.ru): The Lada Vesta is well assembled, I’m pleased with the quality. I fix minor damage myself. Even when operating on rough terrain, the suspension absorbs bumps perfectly. |

| Negative | |

| 9. | Dmitrievich , 49 years old (prom.ua), Saratov: Vesta disappointed me, after 30,000 km the stabilizer seals creaked. I visited a service station, the guys lubricated it with an aerosol, and after 5000 km the situation with the “sound” repeated itself again. |

| 10. | Alexey , 46 years old, Moscow (avtoflit.com): in two years of using the car, I went to the workshop three times for suspension maintenance. Constant squeaks and crunches. The quality is raw, the machine has shortcomings that the manufacturer must eliminate. |

| 11. | Filippovich , 39 years old, Voronezh (drive2.ru): my opinion is that the Lada Priora was made with better quality than the Vesta. I bought it a year ago and now I regret it. There are a lot of shortcomings, defects, and expensive spare parts. |

| 12. | Valentin , 37 years old, Pskov (autotoday.com): if you are choosing a car between Lada Vesta and Renault Logan, then consider buying a French brand. |

Replacing stabilizer bushings on Lada Vesta

When removing elements, it is extremely important to do this when the load on the stabilizer is completely removed. This can be achieved using a lift, which will relieve the load on both front wheels. The second option is to jack up one wheel, install a reliable stop, and move on to the next one.

Or use two jacks. The wheels are raised, let's start replacing. It will be the same for any of the selected options.

The second option is to jack up one wheel, install a reliable stop, and move on to the next one. Or use two jacks. The wheels are raised, let's start replacing. It will be the same for any of the selected options.

Required Tools

- open-end wrench 10×12;

- ratchet bit or L-shaped Torx T40 wrench (star-shaped with six rays);

- socket wrench 13;

- knife to cut new pillows.

Dismantling sequence

We carefully clean the bottom of the car from dirt, paying special attention to the stabilizer bars and mounting bolts so that all the debris does not fall on your head. We take a key with a T40 bit and completely unscrew only one bolt securing the rod of the first bracket. We turn the second one out almost to the end so that you can release the bracket and turn it 180 0, using the remaining fasteners to fix it

We remove the creaking pillow, do the same with the second bushing

We turn the second one out almost to the end so that you can release the bracket and turn it 180 0, using the remaining fasteners to fix it. We remove the creaking pillow, and do the same with the second bushing.

Unscrew the bolts securing the bracket rod.

In fact, it would not be possible to unscrew the bolts that are located on the steering wheel side, since the clamps will not allow this to be done. The fact that we have weakened it by at least 2/3 is quite enough. Provided that you want to change new bolts, the operation will be a little costly in time and effort. Dismantling the protection alone is not enough. You will need to slightly unscrew the bolts on the steering rack, lift it up, and remove the stabilizer pad brackets to the end. In some cases you have to completely remove the rail.

You can try one more method, but very carefully, so as not to violate the main principle of medicine - “do no harm.” Using a little effort, move the anthers a little, as they are, together with the clamps. Our simple method of turning the staple together with the rubber band should work exactly.

Installation and assembly of unit bushings

Half the battle is done. We take new elements and use a knife to cut each one according to the marks made on the pillows. The material is very hard and will require some effort. Then everything is simple, we install the spare parts in place of the unsuitable ones, reassembling them in the reverse order. We tighten all the bolts tightly, and there is no need for additional lubrication.

We make a cut in the bottom of the new pillows and put them on the bar.

All is ready. Our Lada Vesta doesn’t care about potholes, speed bumps or other obstacles. Now there will be no more creaking or nervous tapping. The trip will bring you joy and a sense of inner peace.

How to correctly change the Lada Vesta SPU airbags?

The technology for performing repair work on changing the rubber pads of the stabilizer bar is simple and accessible to the vast majority of motorists. Of course, if the car is under warranty, then this should be done by the mechanics of the dealer's car service center.

Preparatory activities

To carry out repair procedures, you do not even need to remove the engine protective apron. However, no one has canceled the availability of a small set of tools; for work you will need:

- Torx key T40.

- Ring wrench “16”.

- Socket wrench “13”.

- Driver, extension and 10mm socket.

- Silicone Grease.

For a comfortable and high-quality replacement of faulty stabilizer bushings on a Lada Vesta car, you need at least an inspection hole or overpass, and in the best case, a lift. Before putting the car in for repairs, it is worth washing it thoroughly, especially in the area where the work is being carried out.

Technology system

It is important to remember one important detail - you need to start changing the SPU rubber cushion only when the stabilization bar is in a relaxed state. This happens when the front wheels are suspended or the entire mass of the car is loaded evenly on an overpass or pit. After this condition is met, the process proceeds according to the following scheme:

- Using a wrench, an extension and a 10mm socket, unscrew the five bolts securing the steering gear protective cover.

- Unscrew the two rear bolts securing the mounting brackets for the cushion and the rod using a 13mm spanner.

- Using a Torx T40 ratchet wrench, unscrew the two front bolts on the brackets (on the steering rack side).

- Dismantle the bracket and remove the old bushings.

- Make a cut in the bottom of the new cushions.

- Treat the inner surface of the holes in the pads with silicone grease and put them on the bar.

- Tighten the fastening nuts in the reverse order, tightening torque – 1.8-2.4 kgf.m.

Order of Operations

Important! You can begin repairs if the stabilizer bar is not tense. To do this, the front wheels need to be suspended or the weight of the car is evenly distributed - on a viewing hole or overpass. The place where the work will be performed must be washed

The place where the work will be performed must be washed.

So, the car is lifted with two jacks or driven into a pit, now you can start working:

- Clean the stabilizer bar fasteners from dirt.

- Completely unscrew the stabilizer link fixing nut and move it to the side. The same procedure must be performed on the other side of the machine.

- There is a cover on the steering system casing that protects it from contamination. It needs to be removed. To do this, five bolts are removed.

- Now you can unscrew the two bolts securing the brackets.

- The bracket or clamp is removed from its place.

- Now you can remove the bushing.

- The rod must be thoroughly wiped, and particles from the old bushing must be removed, especially at the fastening points. The operation is repeated for the second element.

- The rod needs to be rubbed with lubricant so that the new parts can easily fit on it and move easily.

- A new element is installed on the rack.

- The bushing moves along the rod to the installation site.

- On site, you need to accurately align the bushing along the axis of rotation and fit.

- The same procedure will be repeated with the second bushing.

- Next you need to do the assembly. It is performed in reverse order.

On a note! The manufacturer recommends carrying out routine maintenance every 25-30 thousand kilometers, but Russian climatic and road conditions make significant adjustments to the condition of car parts. Practice shows that bushings are changed much more often. If there is only a suspicion, you need to inspect the part. If defects are found, replace them immediately, since the car’s handling and road safety depend on it.

Power steering reservoir with cap 8200005185 for VAZ Largus

A sign of air in the system is the steering wheel jamming when you try to turn it sharply.

In addition, the pump makes increased noise when the steering wheel is turned, and the fluid in the reservoir usually foams.

Brake the vehicle with the parking brake and place wheel chocks (“chocks”) under the rear wheels.

Raise the front of the vehicle and place it on secure supports so that the front wheels do not touch the ground. If you have a lift, you can lift the entire car.

Fill the hydraulic booster system with hydraulic fluid up to the “MAX” mark.

Without starting the engine, turn the steering wheel five to six times left and right until it stops.

Start the engine and turn the steering wheel all the way in one direction. Do not increase engine speed above idle speed.

Do not hold the steering wheel in the extreme position for more than 5 seconds.

Turn the steering wheel all the way in the opposite direction.

Return the steering wheel to the center position and turn off the engine

Check the fluid level in the power steering reservoir and add fluid if necessary.

The level of working fluid in the tank should be no higher than the “MAX” mark when the engine is warm, and no lower than the “MIN” mark when the engine is cold.

Repeat operations 4-7 until the fluid level in the tank stops decreasing when you turn the steering wheel and air bubbles no longer appear in the fluid.

Add the required amount of working fluid. Do not pour liquid above the “MAX” mark.

Lower the front wheels to the ground.

Start the engine and make several full turns of the steering wheel from one extreme position to the other.

Make sure that the difference in fluid levels in the reservoir when turning the steering wheel left and right is insignificant.

Make sure that the difference between the fluid level when the engine is running and the level after the engine is stopped is within 5 mm.

If the difference in levels reaches 5 mm or more, it means that air has not been completely removed from the system and bleeding should be repeated.

Reinstall the reservoir cap and wipe away any fluid spills.

The noise of the power steering when the front wheels are turned to the limit is not a malfunction

Which bushings should I choose for replacement?

As we found out, the original products are not of decent quality, so you will need to look for analogues. And the main thing is to decide which bushings are suitable.

Here we look at some options for resolving the issue:

- many small manufacturers already produce stabilizer bushings, the material of which is polyurethane (it is less prone to mechanical and chemical stress compared to rubber);

- purchase stabilizer bushings for Kia; the parts fit perfectly in size and have a sufficient level of quality, and it doesn’t matter whether these are original stabilizer bushings or analogues.

What's the matter?

The reason for the dissatisfaction of many Newsmakers is the creaking. It is no secret that the stabilizer bushings of the domestic model very soon begin to creak, and sometimes this happens almost immediately after purchase. There have been cases when the car did not have time to travel even 1,500 km, and some manage to drive without making noise for less than 1,000 km. As for the frequency of squeaking, surveys show that this happens in approximately 60% of cars.

Creaking is typical for many Vestas

This creak can be clearly heard in the video.

It is also worth noting that such a squeak is rarely heard constantly. Usually it appears and then disappears. In this case, the problem is extremely clear - the quality of the material or the manufacturing of the components is not high enough.

In this case, there are two solutions:

- Contacting the dealer;

- Independent work.

In general, both options are working, however, both the first and second have certain disadvantages.

Replacing stabilizer bushings on Lada Vesta - 14 repair steps

It's time to replace this unit. The car needs to be put on a lift. You can carry out repairs from a pit, but during the work you need to hang the front wheels. This must be done carefully. Because then you need to remove the front wheels. To prevent the car from rolling backwards without the front wheels and falling over, it must be secured in this state. The further repair process is completely simple. The chronology of the analysis is as follows:

Dismantling sequence

- Prepare a set of tools. Prepare a spanner wrench size 13;

- Unscrew the oil pan protection;

- Unscrew the lower bolts securing the stabilizers;

- Release the racks of the unit;

- Unscrew the bolts securing the fixing brackets;

- Remove the stabilizer;

- Remove old parts. To simplify the dismantling process, you can simply cut them off with a well-sharpened knife. Clean the stabilizing part from dirt.

Assembling the unit bushings

Assembly occurs in reverse order. To facilitate the process of putting new bushings on the lever, they can be lubricated on the inside with automobile oil. For those who are doing this procedure for the first time, it is recommended to watch a video about replacing this unit.

Principle of operation

The stabilizer is a metal pipe that is attached to the front wheels using rubber cylinders, each of which is called a stabilizer bushing. It provides the ability to rotate the stabilizing unit itself relative to the vehicle. The suspension of the Lada Vesta car was taken by the developers from the famous Renault, which has proven itself quite well on our roads. Therefore, the Vesta suspension design does not represent some new and unknown mechanism.

After some time during the operation of a new car, the owner may hear extra noise from below the bottom. The fastening elements of the car's suspension began to gradually fail. This occurs either due to the quality of the material from which they are made, or due to constant lubrication of the suspension bushings with sand, water and dirt. This contact is detrimental to this node. The driver begins to hear the bushings creaking; they have simply gradually become unusable. It is very rare for the stabilizer itself to fail, but you need to try hard. The repair comes down to replacing worn bushings on the Lada Vesta. This type of repair is very important for the safe operation of the vehicle.

Replacing anti-roll bar bushings on Lada Vesta

Many owners of the Lada Vesta sedan experience creaking in the suspension. If a squeak appears in the front of the car after overcoming uneven roads, then most likely the source of extraneous noise is the anti-roll bar cushions (bushings). Let's figure out how to replace them with your own hands.

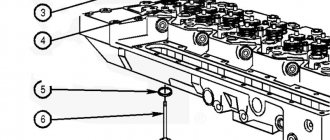

Attention! The stabilizer pads should be replaced only when the stabilizer is in a relaxed state (both front wheels are suspended or evenly loaded with the weight of the vehicle). The diagram shows the Vesta front suspension subframe assembly. The anti-roll bar is marked in red, the bushings or cushions are in green, and the white arrows indicate the location of the bolts that hold the bushings using brackets

The anti-roll bar is marked in red, the bushings or cushions are in green, and the white arrows indicate the location of the bolts that hold the bushings using brackets

The diagram shows the Vesta front suspension subframe assembly. The anti-roll bar is marked in red, the bushings or cushions are in green, and the white arrows indicate the location of the bolts that hold the bushings in place with brackets.

- Drive Vesta onto a pit or overpass;

- Clean the bolts securing the stabilizer bar from the bottom of the car;

- Completely unscrew one bolt securing the stabilizer bar mounting bracket. We unscrew the second fastening bolt, which is closer to the steering rack, as far as possible (Torx T40 wrench);

- Move the bracket to the side and remove the stabilizer bushing.

The bolts located on the steering rack side cannot be completely unscrewed, because they rest against the steering rack boot clamps. If there is a need to unscrew them completely, then you can do one of the following:

- Turn the anthers themselves together with the clamps;

- Turn the airbag mounting clamp in a circle;

- Remove the steering rack protection, then loosen the steering rack mounting bolts and lift it up. Or remove the steering rack completely.

Installing a new pillow is done in the reverse order; if necessary, make a cut in the lower part of the pillow. We tighten the fastening bolts to a torque of 180 km. Now all that remains is to change the second stabilizer cushion in the same way. The replacement process is also shown in the video:

By the way, if you modify the mounting brackets, you can replace the bushings faster.

There is a problem on the Lada Vesta car: the stabilizer bushings (struts) make a squeaking noise. Needless to say, on modern cars, besides the Lada Vesta, even on expensive ones, the problem of rubber bands is noticeable. The Lada Vesta stabilizer bushings begin to creak well and the struts quickly make themselves known. Creaking, knocking, non-functioning stabilizer bars appear so often on the Lada Vesta car - that AvtoVAZ even answered the question: why Vesta creaks so early. The price for such stabilizer struts and bushings is not high, but the sensations are not pleasant. By the way, the dealer changes the bushings under warranty. What to replace with: as an analogue, stabilizer bars from Kia Rio and Avensis are suitable for Lada Vesta - but this is after warranty. Polyurethane stabilizer bushings have proven themselves better - you can install them. Replacing components with your own hands takes 14 steps, more on them later in the article. The maximum weight of the Lada Vesta is 1670 kg. The Vesta is equipped with MacPherson strut suspension, a suspension that has been tested over years of operation on different types of vehicles. There is an opinion that the car is simply too heavy; for such stabilizers, they should be more powerful. On the Lada Vesta suspension, the stabilizer bushings are simply not slightly modified to accommodate the weight of the car. To understand the problem, let’s understand the principle of operation of the stabilization system of modern cars. There is nothing complicated about this. Everything works on the principle of a lever, which was invented by Archimedes at the beginning of the last millennium, read the article and find out about it

Installation

In general, the algorithm for replacing standard stabilizer bushings with an analogue one is simple and, by and large, the same for components from the Chevrolet Niva and for parts from KIA. The only difference is that, in the case of parts from KIA, you will have to install the purchased bracket.

As for the Chevy Niva, the bushings from it will need to be modified - it is necessary to make a slot on the side, and then grind the sides down to the same size as on Vesta.

The replacement process itself begins with installing the Lada Vesta on the overpass, after which you need to thoroughly clean the bolts that secure the stabilizer bar from dirt. Next, you need to arm yourself with a wrench and a Torx T40 bit, with which one bolt from the bracket is completely unscrewed (located further from the steering rack). The second bolt is also unscrewed, but not completely, but enough so that the mounting bracket can be moved to the side.

When the bolts are unscrewed, all that remains is to move the bracket and remove the bushing itself. A pre-prepared bushing is placed in its place, and the bolts are tightened. The second element changes similarly.

This method works provided that components from ChevyNiva are used. If you decide to install bushings from KIA, you will have to completely remove the brackets. In this case, simply unscrewing the bolts will not work, since the screw, which is located closer to the steering rack, rests on the clamp that secures the rack boot.

It can be seen that it will not be possible to unscrew both bolts

In this situation there are 4 options:

- Turn the clamp itself;

- Rotate the boot (together with the clamp, of course);

- Remove the rack protection, then loosen its fastening bolts and slightly lift the rack up;

- Remove the rail completely.

Bushing from Kia

This will allow you to replace the bracket along with the bushing.

And also the bracket from it

As you can see, there are several options for getting rid of creaking Lada Vesta bushings, which differ strikingly in both the effort involved and the financial and time costs.

This form provides general recommendations for eliminating squeaks.

Let's sum it up

We made sure that replacing bushings with your own hands is not considered a complex job. If the entire list of manipulations is performed correctly, then the products are guaranteed to withstand the declared service life or even exceed its value if driven carefully.

When operating the Lada Vesta, it is important to periodically inspect the products and clean them of any dirt that has fallen on the rubber surface. Rubber and polyurethane bushings tend to be particularly sensitive to the effects of engine oil or transmission lubricant.

If there is a leakage factor in the units, then its elimination is guaranteed to protect the bushings from premature wear and destruction

It is also important to pay attention to the creaking

Let's sum up the results

As a result, we received a new solution from AvtoVAZ related to the rigid fixation of the stabilizer bushings on the bar. Now, having installed such a new rod, we lose the opportunity to experiment with bushings.

Stabilizer bushing after 15 thousand mileage

If earlier replacing bushings cost a penny and for this you did not need to disassemble half of the front end, now to replace bushings you need to change them together with the bar ($50) and, most likely, with the stabilizer struts, which is another $50. Therefore, before replacing the barbell with a new model, it is worth considering whether there is another use for this hundred dollars.

Spare parts for Lada / VAZ Largus steering from 2021

Application in complete sets: KS015-41/KSOY5-42/RS015-41/RSOY5-42/FS015-40/FS015-41.

| Item no. | Detail number | Applicability | Quantity | Name |

| 1 | 490019371R | with power steering | 1 | Steering mechanism assembly with hydraulic booster |

| 2 | 8200849701 | without power steering | 1 | Steering mechanism assembly |

Steering gear covers and heat shield

Application in complete sets: KS015-41/KSOY5-42/RS015-41/RSOY5-42/FS015-40/FS015-41.

| Item no. | Detail number | Applicability | Quantity | Name |

| 1 | 6001547607 | 1 | Protective covers | |

| 2 | 7703602196 | 1 | Hex bolt with collar | |

| 3 | 6001548872 | 1 | Thermal screen | |

| 4 | 7703002929 | 1 | Hex bolt with collar | |

| 5 | 7703044165 | 1 | Helical union nut |

Power steering

Application in complete sets: KS015-41/KSOY5-42/RS015-41/RSOY5-42/FS015-40/FS015-41.

| Item no. | Detail number | Applicability | Quantity | Name |

| 1 | 491100699R | with power steering, without air conditioning | 1 | Power steering pump |

| 2 | 8200849632 | without air conditioning | 1 | Power steering pump high pressure pipe |

| 3 | 497257535R | with power steering | 1 | Low pressure return hose for power steering reservoir |

| 4 | 8200742060 | with power steering, without air conditioning | 1 | Low pressure hose for power steering pump |

| 5 | 8200005185 | with power steering, without air conditioning | 1 | Power steering oil tank, with plug |

| 6 | 7700816919 | with power steering | 1 | Power steering tank plug |

| 7 | 6001550688 | with power steering, without air conditioning | 1 | Power steering oil tank bracket |

| 8 | 7703008162 | with power steering | 1 | Power steering oil tank bracket |

| 9 | 7703083470 | with power steering | 1 | Spring clamp Ø1 |

| 10 | 7703602226 | with power steering | 1 | Hex bolt with collar |

| 11 | 7703001241 | with power steering | 1 | Hex Bolt 8x80 |

| 12 | 7703033206 | with power steering | 1 | Hexagon nut with collar |

| 13 | 7703179080 | with power steering | 1 | Mounting bracket |

| 14 | 7703101447 | with power steering | 1 | Hex bolt with washer |

| 15 | 7703083469 | with power steering | 1 | Mounting clamp |

| 16 | 497610324R | with power steering | 1 | Power steering pressure sensor |

| 17 | 7703065106 | with power steering | 1 | Seal 7.6×10.8×1.6 |

| 18 | 7703065243 | with power steering | 1 | Seal 9.5×12.3-1.4 |

Power steering

Application in complete sets: KS015-41/KSOY5-42/RS015-41/RSOY5-42/FS015-40/FS015-41.

Source