Technological progress does not stand still. More advanced technologies are being introduced into literally all areas of life. This also applies to cars: both foreign-made and domestic. However, updates are not always beneficial. For example, the electronics installed in the Lada Kalina do not so much make it easier as they complicate the life of the owner. The most common malfunction in this car, caused by the operation of electronic systems, is a refusal to engage reverse gear. The reasons and solutions to this problem will be discussed further.

What is a reverse gear locking mechanism?

To move the car back in Kalina, a whole scheme is provided. The gearbox in the car is equipped with a special solenoid that helps engage reverse. However, the reverse connection mechanism has a somewhat unusual algorithm, introduced by AvtoVAZ engineers for the purpose of being on the safe side. First, the driver moves the gearshift lever toward himself and forward, gripping a special plastic ring. But what happens inside at this moment: the ring allows the magnetic switch to be activated, after which the solenoid moves to the ground of the car. This, in turn, allows the solenoid auger to move in the rearward direction.

Why the Lada Kalina stopped turning on: reasons and solutions

Some operations will require a multimeter

Failure of the locking mechanism fuse

Since this device in the Lada Kalina is of electronic origin, it is first of all worth examining the electronic systems. To do this, you need to check the condition of the corresponding relay and fuse, which are located in the mounting block. Its cover is located under the handle for turning on the dimensions. Open it and evaluate the functionality of the fuse responsible for the operation of the transmission reverse lock circuit.

The documentary designation of the required element is F21. The current rating of this component is 10A. The location can be seen in the photo below.

F21 (10) - the fuse you need

To determine the true cause, remove the fuse from its socket and carefully analyze the condition of the jumpers. If the part is damaged, the integrity of the jumper will be compromised.

Option to solve the problem: replacing the fuse with a new one is the only way.

Important! If a newly installed mechanism quickly fails, then the cause must be sought in the solenoid.

Magnetic switch failure

As a rule, such breakdowns are not so common due to the fact that the magnet itself is a fairly durable spare part and has a sufficient working life. However, if the reverse gear fails, it would not be superfluous to check it too.

The procedure is as follows:

- Remove the cover from the manual transmission lever.

Stage 1: removing the protective casing - Locate the connector that connects the lever and separate it.

- To check the operation of the reverse gear in stand-alone mode, close the contacts using a wire.

Where do you need to close the contacts? - Engage reverse gear.

But here there are possible options. If the reverse gear engages freely after completing all the manipulations, then the reason is in the magnetic switch. However, before disassembling the box and removing the magnet, it is worth analyzing the operation of the plastic ring: it should rise easily and without distortion until it clicks. Due to its wear, the ring may not move the required distance, and this may also result in reverse gear failure.

A solution to the problem: replacing the reed switch (magnet) or ring with new ones.

There is no voltage supplied by the solenoid to the manual transmission lever

This is most often the cause of malfunction of the reverse gear locking mechanism on Kalina. And here we must thank the AvtoVAZ engineers, who placed the wire supplying power from the solenoid to the lever in an unusually bad place - under the bottom of the car. He has to endure a lot: the action of reagents that are generously sprinkled on roads in winter, and water, and snow, and flying sand and gravel, and sudden temperature changes. Considering the lack of any adequate protection for this element, it is not surprising that it fails quite often. In most cases, wire rupture occurs at the point where it connects to the spar. Dirt and sand accumulate here, which act as rough abrasives, thinning the part.

Option to solve the problem: replacing the wire.

Solenoid faulty

This is evidenced by the absence of voltage at the solenoid contacts. To check the fact itself, you need to disconnect the contacts and test each of them with a multimeter. Performance indicators - 2.2 Ohms. If there is no voltage on one or the other wire and the parting shows “0”, then we are talking about a burnt-out solenoid winding. You can check this this way: switch the multimeter to ringing mode and repeat the voltage test procedure. If in this case both wires are “silent,” then it was the burnt winding that caused the failure of the reverse gear locking mechanism.

Solution to the problem: replacing the solenoid.

What to do if Kalina does not go in reverse (video)

Defects in the design of the Lada Kalina are the root cause of frequent car malfunctions, including in our region. This is eloquently evidenced by the most common cause - an unprotected wire located in the wrong place. Therefore, when repairing the reverse gear locking system, you should first pay attention to this option.

The first generation Lada Kalina is equipped with a system that prevents accidental selection of reverse gear instead of first when starting to drive. This solution, which is quite successful at first glance, quite often leads to the impossibility of reversing due to the failure of the locking solenoid for the corresponding gear.

Technical features of the gearbox

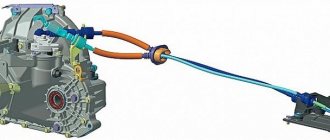

The drive gear block is engaged by the input shaft

This is important to consider when repairing a gearbox. As for the input shaft itself, a constant clutch is created for it with the front gear elements that perform similar functions

When repairing the secondary shaft, we must remember that it has a hollow structure. It is thanks to this that the oil reaches the driven gears without any problems.

The design of the gearbox is such that repairs cannot be done without the use of special circuits. In this case, the radial clearance on the roller bearings is no more than 0.07 millimeters.

Repairing the gearbox is also a rather complicated process. Especially considering that 0.04 millimeters should not exceed the same figure, but for ball analogues.

Location of the checkpoint backstage on the Lada Kalina.

The oil sump is responsible for supplying oil. It is located in the area of the front bearing, fixed behind the output shaft. Major repairs often affect such details. If you select the desired thickness of the rings, it will be possible to adjust the tension indicator. The dimensions of the seals are easy to find in the instructions; these parts can be replaced without problems, even at home.

When repairing the gearshift knob, you must remember that the driven gear of the gearbox on this machine is attached to the differential flange. Through the saloon, the atmosphere is combined with the box itself, located at the top of the structure we are considering.

Lever repair is not the only operation that needs to be carried out from time to time. Sometimes it is necessary to replace bearings; this is done when extraneous noise appears. A gearbox repair kit must be purchased if excess noise becomes noticeable when pressing or releasing the clutch pedal.

All control drive elements of the Lada Kalina gearbox.

The repair manual says that the box is controlled using a drive, which consists of several elements:

- Switch rod.

- Spherical bearing.

- Lever arm.

According to the manual, cable structures are always equipped with jet traction, then the gears do not turn off on their own. One of the ends of the rod is connected to the lever, and the other to the motor. If the seals of the internal joints are faulty, it is necessary to carry out independent repair of the gearbox. But before replacing them, you need to completely change the oil. The front wheel drive is completely disconnected.

Three axes are present on the shift system. One axis is equipped with a three-arm lever for selecting and disengaging gears. There is no gearbox on the second axle, but there are brackets that block rotation. After every 75 thousand kilometers, this design is completely changed. Gearbox lever play should also alert you, as should failure of other parts.

How does the reverse gear lock system work in Kalina?

Reverse gear blocking in Kalina is carried out by a solenoid installed in the gearbox housing. The solenoid is an electromagnetic coil with a core, which prevents reverse gear from engaging when there is no current in the winding. Unlocking is carried out by closing the contacts by lifting the ring on the gearshift lever - the core is pulled into the coil.

One of the main features of the system is that a constant positive “hangs” on the solenoid, and the voltage supply is ensured by shorting the ground wire. In the event of a short to ground and constant stay in the “on” state, the solenoid quickly fails, which makes it impossible to unlock the reverse gear.

Relay location

The relays are in the same block as the fuses.

K1 - headlight washer

. If the washers stop working and this relay is working properly, check their nozzles. Sometimes they become clogged or damaged.

K2 - electric windows

. Check this relay together with fuse F2. See F2 for troubleshooting.

Short circuit - starter relay

. If you turn the ignition key and the starter does not turn, it may be the relay. Check its contacts and clean them if necessary. Next, you need to check the battery terminals so that there is reliable contact between them, and if necessary, clean them. Also check the contact group of the ignition switch, there may be no contact there.

K4 - additional relay, heated rear window, heater switch, wiper and washer switch.

K5 - relay-breaker for turn signals and hazard warning lights

. If the direction indicators or hazard lights do not work, check this relay together with fuses F1 and F3.

K6 - windshield wiper relay

. Check together with fuse F4.

K7 - high beam relay

. Check together with fuses F14 and F15.

K8 - sound signal

. Check together with fuse F6.

K9 - fog lights

. Check together with fuses F16 and F17.

K10 - heated rear window

. Also check relay K4 and fuses F4 and F8.

K11 - heated seats

. Also check fuse F18.

K12 - reserve

.

Checking the functionality of the reverse gear solenoid in Kalina

There are several ways to check the performance of the solenoid. The simplest and does not require additional tools is to supply 12 V voltage to its terminals directly from the battery. When the contacts of a working solenoid are closed, a characteristic click is heard, indicating that the core is being drawn into the coil. In this case, the reverse gear is usually safely unlocked.

Thanks for subscribing!

In rare cases, when voltage is applied, the core may not fully retract into the coil, still preventing reverse gear from engaging. The click is still audible, so you can certainly verify the malfunction only visually by completely unscrewing the solenoid from the gearbox housing and applying voltage to its output. In this case, you must first drain the transmission oil.

You can also check the functionality of the solenoid without removing it from the car using a tester (ohmmeter). The resistance of the working solenoid should be 13 Ohms. If the solenoid is in order, you should check whether current is supplied to it by measuring the voltage at the terminal of the block connected to it, to which the red wire goes (it should be at least 12 V). The absence of voltage indicates an open circuit of the positive wire. If the voltage is normal, but there is no ground, the switch at the gearbox is faulty or there is a break in the ground (red-yellow) wire.

The need to replace the reverse gear lock solenoid in Kalina can be determined both using a multimeter (tester) and in practice. In the latter case, it is necessary to apply voltage to its contacts directly.

The reverse speed of the Lada Kalina gearbox depends on the wiring involved when it is turned on. Check the power button itself - its travel may not be enough to close the contacts on the connector that comes from it.

It happens that you use a car, no complaints. One day you leave your Kalina in the parking lot and, when you arrive after a while, you realize that you cannot leave because the reverse gear of the Kalina’s gearbox has disappeared.

What problems happen with reverse gear on Kalina?

Before moving on to repairs, you need to figure out how reverse gear is engaged on the Kalina.

The activation mechanism consists of:

- fuse;

- solenoid (electromagnet);

- gearbox shift lever; a locking switch is located on the lever.

The reverse lock switch is located on the lever (the ring that you lift up when you engage reverse). After the connector is closed, the current is transferred to the solenoid, after which the reverse gear lock is released, which can now be engaged.

Doesn't turn on

If you put the lever in reverse and nothing happens, the problem may be in the transmission that needs to be repaired.

Reverse gear plug

The reverse speed of the Lada Kalina gearbox depends on the wiring involved when it is turned on. Check the power button itself - its travel may not be enough to close the contacts on the connector that comes from it.

Difficult to turn on or crunches when turned on

If it is difficult to engage reverse gear, pay attention to the clutch. It needs to be tightened or replaced. The same symptoms can appear when the spring in the gear selection mechanism is broken or the gearbox mount is faulty.

When you engage reverse gear, the Lada Kalina gearbox crunches - look at the condition of the plastic bushing of the gearbox. It could become unusable.

There is a low probability that dirt will get into the backstage, which will subsequently make an unpleasant sound. Severe wear on the release bearing is another reason. The speed turns on with difficulty or does not turn on at all.

Takes off

The speed may drop if the box swings strongly. This occurs as a result of wear of its supports.

The mechanical reason for the lack of reverse gear on Kalina is wear of the drive mechanism. Here you may not fully turn on the speed, so it is possible that it will go off.

Gearbox bushing "Lada Kalina"

Speed deviations are usually associated with incomplete inclusion. This can be caused by synchronizers and weakening of their springs, wear of the power forks.

Reading the instruction manual

The instructions included with the Kalina-2 hatchbacks and station wagons say the following:

According to reviews, 3 seconds will be enough. By the way, the blocking stops working not after 3 seconds, but earlier. But if you switch immediately, there is a risk of breaking the gear teeth. All this, of course, is true only for the break-in period.

As the owners themselves say, reverse gear is engaged perfectly even on a car with “zero” mileage. But the driver is required to show dexterity: having squeezed the clutch to the maximum, the pedal is then moved back a little. The handle moves to the desired position and the pedal is fully released.

Clutch pedal response zones

You can also turn it on “through neutral”. This method is the most reliable. Release the pedal when the handle is in neutral and you are guaranteed to be able to shift into any gear. Actually, the method is suitable for any car and any manual transmission. But regarding AvtoVAZ products, the advice sounds like this: take a 3-second pause.

Let’s say that when you try to engage reverse gear, the handle does not move completely to the required position. Then under no circumstances should you release the clutch pedal. Perform the switch “through neutral” and save yourself from problems in the future.

How to fix the problem

All these problems will not allow you to drive safely. Therefore, it is urgent to repair worn elements.

Repair reverse gear chain

Most problems are related specifically to the wiring, which could have a break.

Starting at the fuse box, check the voltage at fuse 21. If everything is in order, then check the connector, which is located in the shift lever, under the leather cover. To do this, be sure to close the circuit by lifting the locking ring up.

If the problem remains unresolved, check the voltage at the solenoid and at its switching chips. To do this, you will have to unwind the twist of wires that goes from the fuse to the solenoid.

Adjust the rocker drive

Sometimes, to eliminate problems with gear shifting, you just need to adjust the rocker drive.

The problem associated with selecting reverse gear is solved by loosening the rocker clamp and placing the selector lever in the reverse gear position. After this, the clamp is tightened again.

Replace the plastic bushings of the gear shift mechanism

An extraneous rattling sound in the gearbox can irritate the owner. It's all due to the plastic bushings of the scenes.

To replace it, you need to remove the soft cover from the gear shift lever and unscrew the bolt that secures the lever with the rocker. Then you should dismantle the old worn bushings and install new ones in their place. It is advisable to use fluoroplastic bushings - they are more durable compared to factory ones.

Reverse gear "Lada Kalina"

After this procedure, extraneous sounds from the scenes will disappear, and reverse gear will engage more clearly.

Adjust or replace clutch cable

If the gears no longer engage clearly, you can try adjusting or replacing the clutch cable. For this:

- Open the hood and remove the air filter housing, after first disconnecting the air flow sensor.

- Remove the clutch cable from the fork.

- Remove the driver's side front wheel. Now it is possible to remove the cable mounting bracket to the gearbox.

- To remove the bracket from the cable, unscrew the plastic adjusting nut.

- Remove the clutch pedal by removing the clamp securing it.

- Pull the clutch cable through the interior. Install the new cable in reverse order.

To adjust the cable, you need to look at the gas, brake and clutch pedals. They must be on the same level. If the clutch pedal is not level with the other pedals, then tighten the adjusting nut located on the clutch fork. Bring the pedal to the same level.

Repair the box

The problem may be hidden inside the box. This is usually due to wear on the gears and stabilizers.

ECU

This is another popular problem when Kalina does not start. ECUs are the “brains” of the car; they themselves are quite reliable, and if you don’t touch them, then no problems will happen. However, most often the ECU is flooded.

This often happens when antifreeze leaks. This has already been discussed in the section on the immobilizer. When installing an alarm system or when pulling car wires, they forget to install the plugs - water gets into the ECU. Repairing an electronic unit is a futile exercise.

In the new generation, this problem was solved, and now the ECU is located in a different location. However, now another problem has appeared - if the drain hole, which is located next to the cabin filter, is clogged, then water can enter the computer through the holes.

Why does reverse gear not engage in automatic and manual transmission?

If the car is equipped with an automatic transmission or manual transmission, and the reverse gear of the Kalina gearbox still disappears, the problem is in the electronic control unit. An automatic machine is a complex unit equipped with electronic systems. It will not operate correctly if the oil level is low.

Monitor the technical condition of your car - this will protect you from expensive repairs.

As usual, at the most inopportune moment, the reverse gear stopped engaging. I'm parked in front and can't put it in reverse. But you need to leave. I had to suffer a couple of times without reverse gear)))

For those who don’t know, the Kalina has a reverse speed locking solenoid, unlike the tens. The locking is turned off by lifting the special ring on the gearbox cluster.

I go over all the events of this day in my head. Just half an hour ago I was backing out of the parking lot, then I encountered a large and long-lasting puddle.

Temporary solution to the problem

It’s good that I carry a multimeter with me. I turned the steering wheel to the left, I looked at the solenoid, the wiring was all wet. I took off the pad and cleaned it. I put it back.

We remove the block in the cabin, measure the voltage at the connector bypassing the reed switch on the gearshift handle.

The block is in its original condition. Raise and fix the switch. We measure the voltage that comes to the solenoid in the gearbox. The measurement showed 1.2V instead of 12V. By the way, I also measured the winding of the solenoid that is installed in the gearbox itself. The result is 0.2 Ohm. Conclusion: the winding is intact, the solenoid is working.

Place your hand up to your elbow in the motor, remove the block from the speed sensor and remove the wiring. We measure the voltage on each contact relative to the negative (positive) terminal of the battery. I identified the jamb wire.

I took it out of the corrugation and found a broken wire in the area where the plastic clip was attached, approximately 13 cm from the block. The tension remained on him due to the dampness. We twist the damaged wiring and check the operation of the reverse speed. As expected, everything worked.

Reworking the twist in the wiring

I assume that many Kalinovods had a similar situation at a distance of about 10-15 cm from the block to the solenoid.

We solder new wires, extended by 15 cm.

We disassemble the connector, bend the plastic retainer with a nail and remove the remains of the wire with the terminal.

Solder the extended wires to the connector contacts.

The result was such an elongated tourniquet. Minimum costs for restoring reverse gear functionality. But in my case, many people buy: the solenoid itself (price about 1 thousand rubles), a switch for the gearshift knob (price about 500 rubles)

I wish you all successful diagnosis of problems and their solutions with a minimum of costs)))

At the same time I carried out maintenance of the rear view mirrors. Well, this is certainly a loud statement.

The mirror elements are removed carefully by hooking the 8 latches.

Now the mirrors are better adjustable. I think the rattling of the right mirror has disappeared (I’ll have to check)

You need to lift the cover. We lift the cover on the gearshift lever and see the feature.

If after closing the contacts the rear one turns on, the magnetic switch on the lever is faulty.

If there is no voltage at the contacts, check the wiring to the solenoid in the box.

The wiring running from the gearshift lever to the solenoid is located on the Lada Kalina near the left side member under the bottom. Because of this, it is affected by water, snow, and reagents from the roads also affect its condition.

To see the solenoid, you need to unscrew the wheel all the way.

The photo shows the solenoid contact connectors.

Long-term use of the car leads to rotting of the wire. The presence of voltage at the solenoid output is checked. If it is, then the wiring is broken, you need to inspect it for damage.

To check, we pull out the wiring into the engine compartment.

We replace the damaged wires with new ones and hide them in the corrugation.

After replacing the wiring with the name of the circuit - everything is normal!

After the previous check, there may be a different result - there will be no voltage at the output. If the fuse is intact, it remains to ensure the integrity of the winding inside the solenoid.

For diagnostics, all wires are disconnected from the element and the voltage on them is checked. If so, the solenoid has burned out. Otherwise, the problem lies in the power supply in the area from the fuse to the lever.

A common problem is a broken solenoid plug when driving off-road.

This can be solved by installing a protective bracket made of thick metal.

To find out why there may be no reverse gear on a VAZ car, you need to understand what kind of design it is, what parts and assemblies it consists of. The reverse gears themselves are located inside the gearbox, in the housing, just like the speed selection mechanism, located outside the crankcase:

- two scenes (jet thrust);

- shift lever (RP);

- solenoid blocking the gearbox, screwed into the gearbox housing from the outside;

- locking ring located on the lever rod;

- switch located in the gearshift knob.

The reverse gear lock (RP) protects the gearbox from accidental engagement, and to engage the RG, you need to lift the locking ring up, first move the lever all the way to the left, and then move it forward. But sometimes it happens that even with the switch raised, the ZP refuses to work; the RP stubbornly refuses to take the desired position.

So, why doesn't reverse gear engage:

- there are defects on the gears of the gearbox;

- there is no normal clutch release;

- the spring on the axis in the speed selection mechanism broke;

- solenoid does not work;

- The sensor contacts do not close;

- there was a break in the wire supplying power to the blocker;

- fuse F21, responsible for the operation of the blocking device, has burned out.

The gearbox may not yet turn on if the link (thrust) is not adjusted, but in this case problems will also arise when trying to turn on some other speed (for example, first or fifth). That is why, whenever removing a manual transmission, it is recommended to put marks on the slide so that during reassembly it can be installed in exactly the same position.

Another reason for the malfunction of the gearbox is an unadjusted or poor clutch, but here, too, other gears either do not engage or shift with a crunch. The travel of the clutch pedal on Kalina is adjusted by decreasing or increasing the length of the cable; when the disc is worn out, the car begins to drive with slipping and does not pick up speed well.

Related articles:

- Front spar of the VAZ-2109 - replacement, repair, cost of work The VAZ-2109 is a car that is not distinguished by a strong body; iron corrodes quite quickly, and almost all body parts rust. Replacement of the front side member is required […]

- Self-repair of the underbody of a VAZ-2110 car The car body corrodes over the years, and it begins to rust especially quickly if you do not take care of it and do not apply an anti-corrosion coating. How soon do they begin to cover […]

- Features of replacing the rear side members of the VAZ-2109, the cost of repairs in a car service Cars of the VAZ-2108-09 family are not distinguished by a strong body, durable body iron, the metal rusts especially quickly if it is not treated with anticorrosive. Over time, on the metal […]

Why is this happening

Usually the speed is not fast on a new car. If the speed in the Lada Kalina gearbox has stalled, the car has traveled many kilometers - the transmission and its individual elements are worn out. There are several reasons for gear snagging at the gearbox:

- failure of the clutch drive or the clutch itself;

- deformation or disconnection of jet thrust (scenes);

- failure of the manual transmission gear selection mechanism;

- transmission gear jamming;

- violation of the control unit of a robotic or automatic transmission;

- failure of the actuator or gear selection solenoid.

Broken gear selection cable

The gear selection cable may be broken.

The clutch or its drive has failed

On Kalina with a manual transmission, a mechanical clutch drive is installed, which goes from the pedal to the clutch itself. On a robotic gearbox, the clutch drive is controlled by an actuator - a servo drive, which receives a command from the control unit. The clutch cable can be purchased under article number 1118-1602210 for 600-800 rubles.

List of components:

| vendor code | Name | Price, rubles |

| 1111-1601182 | Pressure bearing | 500 |

| 2110-1601180 | Clutch assembly | 700 |

| 11186-1601130 | Clutch disc | 1700 |

The clutch on a car also fails over time. This happens especially quickly among those who like to drive fast. It can break if it was originally made poorly. Replace this unit and try to work with it carefully in the future.

Clutch kit VAZ Kalina

You should not start at high speeds, drop the clutch or hold it depressed while driving. Harbingers of an imminent breakdown may be:

- increased noise;

- vibrations;

- tremors;

- incomplete disengagement of the clutch.

The cable broke

Like all cables, over time it stretches and breaks. If this is the case, you will have to change it. Cable article number 21902-1703114-00. The price is about 2500 rubles.

Torque rod (link) is bent or disconnected

The rocker on a manual transmission moves hundreds of times a day when the driver changes gear.

At approximately 100 thousand kilometers, problems begin with the rocker and it needs attention.

In our case, it either became disconnected or failed. In the first case, you need to put it in place, and in the second, replace it.

Gearbox slide

Backstage article number – 1118-1703300. The price is about 1300 rubles.

The gear selection mechanism inside the manual transmission is damaged

Like the rocker, the mechanism is constantly used and therefore wears out over time. Replacing the gear selection mechanism requires repair knowledge, space, and equipment. If you don’t have all this, it’s better to contact a car service. Article 11190-1703050-01. Costs about 3000 rubles.

Gear jammed

Jamming of the transmission gear can occur due to low-quality metal used in manufacturing, or subsequent poor testing of finished products for defects.

Gears suffer during aggressive shifting.

The reason may also be the oil, which has not been changed for a long time. When the gears rub against each other, tiny metal shavings get into the oil, which accumulate over time and can lead to jamming of the mechanism. Sometimes it bites, and because of this it is impossible to switch to neutral.

Transmission gear

As with the selector mechanism, you will have to remove and disassemble the transmission to replace the gears. Similarly, it is better to entrust this work to professionals and have it replaced in a good service. Spare parts are much cheaper than for a foreign car.

The AMT or automatic transmission control unit has switched off or the contacts of the gear selection device have oxidized

If the electronic control unit malfunctions, it will have to be disassembled and checked. Take a good look at the PCB. There should be no traces of liquid, oxidation, or soldering defects. If any of this is present, the board can be cleaned and soldered. If you don’t understand this, take the unit to a car electrician or someone who repairs electronics.

If the contacts are oxidized, you can simply clean them. The problem will be solved.

The actuator or gear selection solenoid is burnt out

Actuator – servo drive in a robotic box. He is the one who presses the clutch. It receives current from the control unit, causing it to move. Like any electronics, it can burn out over time and need to be replaced. It is quite expensive. Article – 21820160901201. Price 10 thousand or more.

The solenoid is an analogue of the actuator in an automatic transmission. It is an electromechanical valve that receives signals from the control unit. It opens and closes channels, controlling the flow of fluid.

Training video: The 2181 gearbox can actually work perfectly

On Lada Kalina cars there is an insidious reason that leads to the inability to engage reverse gear. It is interesting that this reason is purely electrical and has nothing to do with mechanics.

Reverse gear on Kalina is engaged by moving the gearshift lever towards you and forward. In this case, you need to lift the plastic ring on the lever. This ring protects the driver from accidentally engaging reverse gear instead of first gear, as often happens on “tens”. This is done using an electric drive - a solenoid.

The solenoid is installed in the transmission and blocks reverse gear from being engaged until the ring on the gear shift lever is lifted. When raised, the reed switch (sealed magnetic switch) in the lever is activated, connects the solenoid power circuit to ground, the solenoid rod is recessed, and the stroke of the gear selection mechanism increases - you can engage the reverse gear.

We will not talk about the advantages and disadvantages of this system. There are two camps of “Kalinovodov”, who are both “for” and “against”. Here we will look at the reasons why problems with electrical locking may arise.

Lockout fuse blown

As always with electrical breakdowns, the first thing we look at is the fuse. Fuse F21, rated 10 A, is responsible for the operation of the reverse locking system in Kalina. It is installed in the main mounting block. If the fuse is intact, then move on to the gear lever. If the fuse jumper is broken, replace it with a new one and see what happens. We try to engage reverse gear. If the fuse blows again, it indicates that there is a short circuit in the solenoid power supply circuit. By

Algorithm for determining and debugging the blocking system

Proper engine running-in after overhaul

Before you start solving the question of why the reverse gear on the Lada “Kalina” does not engage, you should learn a little about the theory of the functioning of the locking system.

Power to the solenoid wiring is supplied through a special switch ring located on the gearshift handle. The principle of operation is as follows: the driver lifts the switch, which activates the solenoids, then the rod is pulled inward. Such actions lead to the fact that the reverse gear is unlocked.

After carrying out such manipulations, the car owner is able to switch the reverse gear; to do this, it is necessary to move the shift knob. Then the “limit switch”, which is located on the box, is activated, and the reverse signals light up, emitting a characteristic sound in the cabin.

To fix the problem you will need the following tools:

- copper wire and soldering iron;

- tester;

- insulating tape (heat shrink);

- wrench marked “36”.

Connection diagram on Kalina The control circuit for the locking mechanism looks like this - a current of 12 volts passes through a special fuse. It is supplied to the solenoids, after which the circuit is closed using a switch on the lever. Then the solenoid coil starts up.

The debugging procedure occurs according to the following steps:

- the required fuse is located on the safety block on the left side, it is the eighth in the list. You need to get it out and diagnose it using a special tester. If the unit malfunctions, it will need to be replaced;

- We check the switch itself directly. To do this, you will need to lift the cover on the gearbox. Below it is a connector connected to the switch. Unplug slowly and carefully;

- short the contacts using a paper clip. After this, you should try to switch to reverse gear. If the actions lead to the desired result, then the obstacle is a malfunction of the switch. If the rear one does not work, continue to determine the reasons;

- Remove the plug from the solenoid and place 2 pins inside. Next, using diagnostic equipment, measure the voltage. The device should provide information that the voltage level is 12 volts. When connected to a 5-watt light bulb, a light signal should appear. If there are no changes, it means that there are breaks in the wires somewhere. In such a situation, the voltage is due to the resistance generated by the copper oxide. Most often, breaks and refractions are located in the section of the harness where the torpedo is located;

Voltage level measurement

- remove the clamp. To do this, you need to squeeze the latch at the bottom;

- Next you will need to disconnect the plug from the switch. After performing these manipulations, it is possible to pull out the tourniquet completely. Remove the insulating tape from the corrugation and analyze the wiring. If there are breaks or refractions, you will note visual signs;

- damaged wires are removed using wire cutters, and in their place place new ones with the same cross-section and diameter. We recommend soldering the twisted area and applying insulation using heat shrink. If you wish, replace the corrugation with another one. Make sure that moisture does not get on the wiring;

- After connecting all connectors, you can check the functioning of the system.

A broken solenoid is not a common problem. To determine this malfunction, you must connect a tester. When the device operates correctly, it will show 2.2 Ohm data. If the parameters do not match, you will need to drain the car oil from the gearbox.

There is an alternative option without removing the oil, but it requires certain skills and abilities. In such a situation, it is necessary to quickly close the hole through which the substance is escaping and place a new part. After installing the new solenoid, we recommend applying a sealant compound to the threaded area. If you skip this step, the substance will soon begin to flow through the threads.

Locking fuse

Scheme for Kalina.

Fuse - F21 in the main unit, rating - 10A. A intact fuse indicates that there is no voltage at the solenoid.

If the fuse is blown, a new one is installed, then the gearshift lever is moved to the reverse gear position. If the jumper burns out again, the problem must be looked for in a short circuit in the solenoid power supply path.

Reverse gear of Lada Kalina is not blocked

A break in the wire of the switch on the Lada Kalina car occurs quite often, this is due to the fact that the switch often changes its position, and accordingly, the wiring is not at rest. Checking whether the solenoid itself is working is quite simple; here you need to:

- Carefully pry off the gearshift lever housing with a screwdriver and lift it up;

- disconnect the plug located inside the console;

- take a metal paper clip and insert its ends into the connector going to the blocker;

- lower the cover and try to engage reverse gear.

If a fault appears, it means that everything is in order with the switch itself and the manual transmission, it’s all a matter of electrical wiring or poor contact of the plug. After such a diagnosis, the paperclip will need to be removed; driving constantly with the contacts closed on the connector is highly not recommended.

In some cases, a break is detected immediately after lifting the gearbox cover, but often the wires fall off in the area of the locking device solenoid. To carry out diagnostics, you should install the VAZ Kalina on a pit or a car lift and conduct a visual inspection. Most often, a break occurs in the immediate vicinity of the sensor, since this place is not protected by anything - dirt and moisture, crushed stone and pebbles fly from the road.

When the wiring is still in the factory braid, it is sometimes difficult to detect any damage. The contact may periodically disappear and then appear again, the defect turns out to be floating, in which case it is necessary to open the insulating protection.

It is also worth noting that such a defect is common on Kalina and is typical for this car; such a breakdown can occur even on a car with a relatively low mileage (40-50 thousand kilometers). The problem occurs because:

- the wires are too short, they should be made a few centimeters longer;

- The insulation is of poor quality and often cracks in the cold.

So, before looking for faults in the mechanical part, you need to check the electrical part.

Another malfunction is exactly the opposite of the one described above, in this case the locking does not work, and reverse gear is engaged in any case, regardless of whether the ring is raised or not. Driving a car without a gearbox lock is not very comfortable; there is a risk of ruining the gearbox (especially for beginners) by engaging reverse gear while driving instead of the lowering first gear. There are also several reasons for the problem:

- the button contacts inside the manual transmission handle are stuck;

- there is a short circuit in the wires going from the box to the lever;

- The solenoid is stuck.

Checking the condition of the push-button contacts of the blocker is quite simple: lift the cover of the gearshift lever and disconnect the plug. If the guess turned out to be correct, it will be impossible to turn on the ZH.

Spark plug

If everything is in order with the electronic filling, you should look for the problem in the candles. Often, and especially in winter, it floods.

Compression in the engine in cold weather does not meet the standards, so the engine may not start immediately. Often flooding of spark plugs occurs due to a discharged battery, which is unable to produce a normal spark. If not, the reasons may also be in the wiring or the spark plugs themselves. The easiest way to dry the spark plugs is to press the gas to the floor and crank the engine with the starter two or more times. Often, after this the car will start. If this does not help, then for more thorough drying you should dismantle the spark plugs, then clean them, check the gap, and then dry them with a hairdryer or in the oven.

Why reverse gear does not engage on Kalina: causes and solutions

In total, 4 malfunctions can be identified related to the problem of engaging reverse gear on the Lada Kalina. Below we will describe each of them in detail. To identify some problems we will need a multimeter.

The locking mechanism fuse has blown

First of all, pay attention to the car’s electronic systems; you should carefully check them for functionality. If reverse gear on Kalina does not engage, the cause of the problem may be the fuse of the locking device.

The fuse itself, together with the relay, is located in the mounting block inside the car. Finding it is quite simple, it is standard for most passenger cars - it is located under the steering wheel or next to it. Regarding this VAZ car, the cover of the electrical system module is located directly under the handle for turning on the side lights.

After you open it, you can check the serviceability of the fuse, which supplies voltage to the electrical part of the reverse gear locking system in the gearbox. In the documents this element is designated as “F21”. The current strength of this component should be equal to 10 Amperes. You can see the location of this fuse in the picture below.

When checking the fuse, carefully remove it from its socket and carefully examine the condition of the jumpers. If the part breaks, you will immediately see it, the jumper will be damaged, just replace the fuse with another, serviceable version to solve this problem.

You need to understand that this part itself rarely burns out. If in the near future the reverse gear on Kalina stops engaging again, the fuse will burn out again, and the solenoid will still be the cause of the problem.

Damage to the wire coming from the solenoid to the gearbox lever

The most common cause of malfunction of the reverse gear mechanism on Kalina is the lack of voltage supply from the solenoid to the gear lever. This trouble, as a rule, arises due to the fact that the engineers responsible for the development of this car laid the power wire from the solenoid to the lever in a rather unfortunate place, namely under the bottom of the car.

Naturally, this wire experiences the harmful effects of various aggressive environments, temperature changes, and even mechanical stress. The situation is aggravated by the fact that the VAZ designers did not even bother to properly protect the wire from all these unfavorable conditions in which it is located. As a result of all the circumstances, this element quickly becomes unusable.

Most often, damage or breakage of the wiring occurs at the point of contact of the wire with the spar. Over time, sand and dirt inevitably accumulate there, which act as an abrasive, wearing it out. To restore the functionality of the reverse speed, the wire will have to be replaced or restored.

Failure of the magnetic switch

Such a breakdown is quite rare, since the magnet itself is very durable and boasts a long working life. However, as we all know, even the most reliable part can fail. Therefore, if the rear speed fails in Kalina, then it makes sense to check it too.

To check the switch you will need to do the following:

- Remove the housing from the gear lever.

- The next step is to search for the connector for connecting the lever and then disconnect it.

- Then it will be necessary to close the contacts using wire. These steps will allow you to check the serviceability of engaging reverse gear in manual mode.

- After this, try turning into reverse gear.

If, after performing all the above steps, the reverse gear begins to engage freely, then the problem is most likely in the magnetic switch. However, there is one more link that is worth checking to make sure that it is the magnet - this is the plastic ring.

Also check out

- Using a paper clip, we close the contacts of the connector from which the wires are lowered under the floor of the car. Try to engage reverse gear. If this works, the switch is broken.

- Disconnect the connector from the solenoid and install 2 pins into it. Use a tester to change the voltage. The device readings should be 12 Volts. It is worth charging it with a light bulb (5 Watt or 12 Watt). If it does not light up, then there is an open circuit, and the voltage arises due to resistance formed due to copper oxide. Very often, breaks and fractures occur on the harness in the place where the clamp is located on the pallet.

- Remove the clamp by pressing its fastenings at the bottom.

- Disconnect the connector from the stop switch and remove the harness. Remove the electrical tape from the corrugation, after which you can remove the wires. In the event of a break or breakage, characteristic signs will be noticeable.

- Use wire cutters to disconnect the wires and connect them of similar cross-section and diameter. The twist should be soldered and insulated (you can use heat shrink). If necessary, put on a new corrugation. This is done so that moisture does not penetrate inside, otherwise it is possible that all the troubles will happen again. The harness should be secured with a plastic clamp.

- Connect the connectors and check the operation of the solenoid. Failure of this element is quite rare. To check it you need to connect a tester. The resistance should be 2.2 Ohm. If the cause of the malfunction lies there, you will need to drain the oil from the box. One option is to quickly block the hole with something and install a new solenoid. In this case, it is important to apply sealant to the threads so that oil does not ooze down the threads during operation.

Mechanical problems

When the electrics are checked, it's time to move on to the mechanics. The first step is to check the gear oil: level, viscosity, color. The liquid is changed if it does not meet the standards.

Wear of the internal parts of the manual transmission is diagnosed when disassembling the unit. On the Lada Kalina in the “box” the following may break:

- synchronizer,

- rear bearing,

- reverse gear, chips on the reverse gear teeth.

- fork.

The decision to replace parts is made after the “opening”.

Clutch

Car enthusiasts often experience problems with the operation of the “box” after the clutch fails. A malfunction occurs when switching to any gear, sometimes the process is accompanied by a crashing noise.

If other possible faults are excluded, the clutch assembly is replaced.

Immobilizer

If the car refuses to start, then this is one of the possible reasons. You can notice problems in the operation of this system yourself. If the corresponding icon blinks and a characteristic beeping sound is heard, then you should read the operating instructions. If the Lada Kalina does not start, the immobilizer is a common problem. The problem is not easy to fix. In the instructions for the car, the manufacturer indicates the decoding of sounds and blinking lights - the car owner needs to count the time between flashes, the number of buzzer signals, and then read what the manufacturer writes about this.

In winter, it often happens that the car starts normally after about the sixth time. In most cases, this problem can be solved by retraining the key - after this procedure, problems with starting should not appear.

Oil

The gearbox, just like the engine, contains oil. Its viscosity is thicker than motor oil. On domestic cars, the manufacturer recommends changing the fluid at least once every 60 thousand kilometers. If the reverse gear on the Lada Kalina does not engage, check the lubricant level in the box. If the mileage of the car is more than 60 thousand, drain the old fluid and use new one.

Running in the “2181” gearbox: engage the “R” gear correctly

The Kalina cars of the first family used a manual transmission equipped with a reverse gear lock solenoid. If reverse gear did not engage, it was usually caused by electrical problems. Then the blocking was simply turned off and performance was restored. The new VAZ box, designated “2181,” uses a different locking method – mechanical. But not only a faulty lock, but also incorrect actions by the owner can prevent the reverse gear from engaging. How to operate the “2181” box will be discussed further, and we will talk about the break-in period. It is precisely with this that most of the problems are connected.

- We study the design of the VAZ-2181 gearbox

- Reading the instruction manual

- A couple of practical tips

- Training video: The 2181 gearbox can actually work perfectly