Cars of the Kalina-2 family are equipped with a steering rack similar in design to the Granta rack. This part transmits force from the steering wheel to the front suspension links. If you feel a knocking sound from the rack while driving, it needs to be adjusted (tightened) correctly. The effect described here can be observed after 10-15 thousand kilometers, and more often it makes itself felt on uneven roads. Next we consider how this problem is solved in practice. And the solution comes down to turning one nut.

The role of the steering rack in the car control system and its design

Structurally, the steering rack looks like a steel form, on one side of which there are teeth that are tightly meshed with similar elements of the drive gear. Well, the drive gear itself is driven by the driver, who rotates the steering wheel. The steering wheel and drive gear are coupled through a shaft and a small cardan.

The upper part of the steering rack has fasteners to which rods are attached, which go further to the shock absorber struts and are secured there with tips and pins.

The driver, by turning the steering wheel, sets the steering shaft in motion, thereby transmitting force through the cardan to the drive gear. In turn, the gear rotates and moves the steering rack and, accordingly, the steering rods in the required direction. This is the simplest way to drive a car.

Of course, the design of the steering rack itself is not exactly the same as we described above. To ensure reliable operation of the rack, its design also includes the following important elements:

- column housing (case);

- corrugation (protective casing) with clamps;

- ball and needle bearings of the drive gear;

- support bushing (fluoroplastic);

- thrust nut;

- emphasis;

- various plugs, boots, fastening nuts, etc.

A little theory: front suspension design

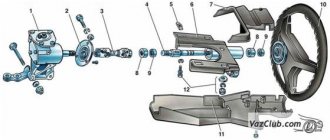

Before attempting to fix any problem, there is a tendency to look at the blueprints or repair manual. It is known that the VAZ-2192 parts catalog contains the following object:

This is what the steering rack looks like in the drawing

Whether the knock will remain in the steering rack of Kalina-2 depends on the following: how accurately element “14” is adjusted. The adjusting nut, marked “14”, looks almost invisible here. But first impressions are deceiving. In the catalog, by the way, the element is called “Stop Nut”.

It is important to know that the thrust nut has external threads. And it spins clockwise. And the words “tighten the rack” mean screwing in the specified nut, and nothing more.

Now let's move on to practice and see what the node in question looks like in reality:

If you remove the rail, it looks like this

The nut has a non-standard notch, and it can only be rotated with a special tool. By the way, the recess will be closed with a cap. In the catalog it is designated by the number “15”, and now, let’s look at the appearance of the special key:

Rack adjustment key

The thrust nut is turned at small angles. We are talking about values of 10-15 degrees. What happens if you overdo it with tightening the rack? The knocking noise will disappear, but the steering wheel will turn with difficulty. Therefore, if necessary, the nut can be pulled back.

Steering wheel play

If such a malfunction is identified, we advise you not to despair; it is likely that this problem will be resolved by carrying out minor repairs. Let's immediately figure out how to identify play and how to properly tighten the rack to get rid of this malfunction.

So, to deal with this problem, you need to open the hood and determine the installation location of the steering rack. Next, dismantle all engine elements that clearly interfere with free access to this part. Now grab the rods with both hands and try their movement to the right - to the left. If during such actions you find play, you can eliminate it by adjusting the thrust nut.

This rack adjustment is a simple process, but to carry it out you will need a special key No. 17 with an octagonal head. Without such a specific key, you don’t even have to start adjusting. Well, if the key is prepared, then move under the car and be sure to remove the engine protection. Now look around and determine how best to get to the steering rack. Now remove the existing plug from the thrust nut. Insert the wrench and start screwing this nut into the housing. We recommend that you first turn the nut about fifteen degrees and then check the change in backlash. If the need for adjustment remains, then turn the nut to the same angle. Note that it is better to tighten the nut a little at a time so as not to overtighten it, as then the steering wheel will be difficult to rotate. We also advise you to check the reliability of the fasteners on the rods. If necessary, tighten the mounting bolts.

Steering wheel tuning on Lada Granta

There are few options for upgrading the steering wheel on the Lada Granta. The most popular of them is installing a sports version. Such a steering wheel will not only make the interior more attractive, but will also increase the comfort of control, especially if it is selected correctly. You can install a multi-steering wheel, but only if the configuration is maximum, in other cases there will be nothing to control with its help.

The sports version must be injury-proof, that is, in the event of an accident it must be deformed without causing damage to the driver. Among the shortcomings, it can be noted that although there is an airbag in the standard steering wheel, the sports one does not have it. You can also modify the steering wheel by installing braid. More advanced ones install a heating thread under it.

To install the sports steering wheel, you will need to carry out the following operations.

- Align the front wheels straight (you can drive a little forward and back so that the trajectory is straight).

- Disconnect the battery terminals by de-energizing the vehicle's on-board network.

- The airbag control module must be disabled (if the Granta equipment is equipped with it). If you do not turn it off when removing the factory steering wheel, it may shoot out.

- Remove the steering wheel and install a horn on the adapter. The wiring must be stored in the adapter; to do this, carefully inspect all contacts.

- Connect the adapter to the shaft, but do not secure it with a nut.

- A sports steering wheel is installed on the adapter and secured with special screws.

You cannot throw away or sell the factory product; the sports version will raise questions when passing inspection.

Removing the steering column

If adjusting the nut does not help and the play remains, you will have to completely disassemble the rack and repair it. True, first you still need to dismantle it, which is also not easy. There are two methods: with removing the steering rods and without removing them. Preferable and easier, of course, is the method without removing the steering rods, since it takes less time. Before starting dismantling, you need to jack up the front of the car. This is done in order to completely relieve the steering rods, otherwise you simply will not be able to dismantle the steering rack. So, let's start disassembling. Inside the car, where the pedal block is located, find and unscrew the steering shaft cardan bolt. Next, move to the engine compartment and there you will find the mounting bolts on the rods and unscrew them. Don't forget to bend the locking plate first. After this, unscrew the four fixing bolts that secure the steering column to the car body. All fasteners are unscrewed, carefully move the steering column and remove it through the opening under the left wheel arch.

Troubleshooting

As the car moves, the ball pins rotate in different planes and gradually wear out the crackers, which causes backlash. The following signs indicate critical wear of a tip (or several):

- a distinct dull tapping sound when driving over any uneven surfaces;

- vibration from the play of the ball pins is transmitted to the steering wheel;

- on a flat section of the road the car spontaneously leaves the straight path;

- The rotation of the steering wheel is difficult, and a creaking sound is heard from below.

When a lot of force is required to turn the steering wheel, the worn tip must be replaced immediately. The symptom indicates that the ball pin is jammed inside the housing. If measures are not taken in time, the hinge may jump out of its socket and the car will become uncontrollable.

A similar story happened to my relative. When there was literally half a kilometer left to drive to the garage, the right steering tip on the “seven” broke off. The driver showed ingenuity: he tied the end of the dropped rod to the suspension arm, leveled the wheel with his hands and slowly continued driving. When it was necessary to turn, he stopped, got out of the car and manually adjusted the wheel in the right direction. The 500 m long path was covered in 40 minutes (including the entrance to the garage).

Most often, hinges become unusable due to a torn protective cover.

Steering rods of Zhiguli cars become unusable for a number of reasons:

- Natural wear and tear. Play and knocking appear at 20-30 thousand km, depending on conditions and driving style.

- Operation with torn hinge boots. Water flows into the unit through the holes, dust and sand penetrate. Corrosion and abrasive effects quickly destroy the ball pin.

- Lack of lubrication leads to increased friction and accelerated wear. The presence of lubricant must be checked before installing the part on the car.

- Bending of the rod due to impact with a stone or other obstacle. If the outcome is successful, the element can be removed and leveled by heating it with a burner.

When the production of all tips reaches a critical limit, the front wheels have large free play in the horizontal plane. To drive straight, the driver has to “catch” the car along the entire road. How to diagnose wear on steering rods and not confuse them with suspension faults:

- Place the car on a viewing ditch or overpass and apply the handbrake.

- Go down into the hole and carefully inspect the trapezoid, especially after hitting the bottom.

- Grab the shaft near the tip with your hand and rock it up and down.

If you feel free movement, replace the worn element. Repeat the operation on all hinges. To check, the lever must be swung in a vertical plane, grasping it near the hinge

The method of developing traction during diagnosis is of great importance. There is no point in turning the lever around its own axis - this is its normal operating stroke. If the test shows a small tight play, the hinge is considered to be in good condition - the internal spring is triggered.

There is no point in putting pressure on the hinge from below - you will only feel the resistance of the spring

Self-repair of the steering column of a VAZ car

As with any other work, you first need to prepare the necessary tools. To repair the steering rack, you will need two special wrenches: octagons No. 17 and No. 24, as well as special pullers for existing bearings. I would like to immediately note that repairing the steering rack involves replacing worn parts. These parts include bearings, stop, bushings, retaining rings, seals and drive gear boot. You can purchase all the necessary elements in repair kits. Thus, the automotive market currently offers three types of repair kits for the steering column:

- a minimum kit, which includes retaining rings, seals, a boot and a support sleeve;

- standard kit, which includes all elements of the minimum kit and bearings;

- complete package with all consumables and new rail.

A suitable repair kit should be purchased only after disassembling the column, as well as its complete troubleshooting.

Why do you need to change the clutch?

To replace the clutch you will need to stock up on: A 13mm wrench, and in addition to all this you will also need to take two different types of screwdrivers (Flat and Phillips in this case), and you also need to stock up on a mandrel for centering the clutch disc which in a car store it costs literally 100 rubles! (You can see what this mandrel looks like, which is discussed in the article, just below in the section: “For beginners!”)

When should you change the clutch?

During operation, the clutch of any car wears out over time, and the first signs of a worn clutch that a car will show are:

- Increased noise that begins to appear very clearly when changing gears in the car.

- Jerks can also occur when starting a car, and they can also occur while driving when you depress the clutch pedal, then engage a gear, and then when you release the pedal, the car jerks forward slightly.

- In addition to all this, if the clutch malfunctions, the effect that the clutch “slips” may occur. This is when you are driving a car and at the same time you press the gas pedal, let’s say to the floor, and your car does not accelerate, but the engine speed increases sharply and even reaches the red zone, this effect is popularly called the clutch “Slipping”.

- And in conclusion, we note one more effect, called the “Leads” clutch. The first signs of this effect are as follows: let’s say you engage first gear and at this time the clutch pedal is still fully depressed, but even despite this the car starts to roll. This effect is called the “Leads” clutch.

Disassembling the steering column

The first step in disassembling the column is to remove the protective casing; to do this you need to cut the plastic clamps. Next, take a special key No. 17 and unscrew the thrust nut, carefully remove the installed retaining rings, then the spring. After this you can knock out the rack stop. Remove the boot and the existing seal installed on the drive gears. Take the second special wrench No. 24 and unscrew the nut that holds the ball bearing - carefully remove the gear.

There is now nothing holding your rack in the housing, so you can carefully remove the right side. Having freed up some space for yourself, try to remove the drive gear bearing. This can be done using a prepared puller. Be sure to check the removed bearings for play. If there is one, then the bearings must be replaced. It is imperative to replace the support sleeve - it has a cylindrical shape and is located in the steering housing. It is quite easy to get it out - take a screwdriver and pry it off.

Steering column assembly

This process should begin by installing a new needle bearing. Before installation, generously lubricate the seat with Fiol-1 grease. Next, press the ball bearing onto the drive shaft. The next element is the support sleeve. Install it into the control unit housing. After this, you need to fill the inside of the column with lubricant and you can insert the steering rack into it.

Mount the drive gear, secure it with a nut and do not forget about the retaining ring. Put on a new boot. After this, all you have to do is install the stop in place and secure it with a locking ring and nut. OK it's all over Now. After these steps, all you have to do is adjust the entire control unit and then put on the protective cover.

Lubrication

For VAZ cars, the only steering rack lubricant recommended by the manufacturer is FIOL-1.

1. Lubrication during assembly. First, the rail and the internal cavity of the housing are lubricated.

How to adjust wheel alignment with your own hands? - there is more useful information here.

- A generous coat is then applied to the plastic sleeve.

- Lubricant is placed in the seat for the needle bearing.

- The rail is installed in the housing.

- The steering gear shaft is lubricated.

- Grease gets clogged up in the bearing.

- The stop is lubricated.

- Screws and stoppers are installed.

- The casing and anthers are put on.

2. Lubrication without removing the rack. After cutting through the plastic clamps, the side protective caps are removed.

It is through the side holes in the rack body that lubricant is pumped. It is recommended to carry out this procedure at least once every 150 thousand km.

For convenience and greater efficiency, you can use a syringe with a nozzle made of a rubber hose of such a diameter that you can insert it between the rail and the body. The hose must be pushed from the side where the rod bolts are attached.

You may be interested in this article - When and how is a wheel bearing replaced?

At this point on the bushing there is a cut through which the lubricant will pass into the space behind the bushing and lubricate the steering mechanism.

How to lubricate the steering rack in the absence of FIOL:

- Litol. It is the most suitable lubricant to replace the recommended one. Has good lubricating properties and durability.

- Solid oil. Not recommended due to its tendency to dry out over time and lose its lubricating properties.

- Graphite grease. For the same reason as grease, it is not entirely suitable for lubricating the rack.

Replacing the steering rack

In some cases, although very rare, the usual replacement of consumables is not enough. The steering rack, although made of reliable steel, still does not last forever and can wear out a lot over time. Often, the culprits in the rapid wear of the steering rack are the owners themselves, who do not monitor the condition of the steering mechanism. In addition, the steering rack may require replacement in a car after a traffic accident. Replacing the rack in a VAZ car occurs according to the scheme described above, only taking into account the fact that you will have to buy a complete repair kit, which includes a new rack.

Lyrical digression

Suzuki Grand Vitara 2.4 manual, color ZMA Logbook Replacing the steering rack oil seal, without removing the rack. And not only Part-1

In Lada Kalina, the steering rack never makes a knock when we are talking about a new car. This is also true for the break-in period. Let's say in your case this is not done. Then, do not try to repair anything, but go straight to the dealer. According to reviews, the defect in question is covered under warranty, and most car dealers do this: the steering rack assembly is replaced with a new one.

This is what the replacement unit looks like, the rack assembly

There is a logic here. At the factory, adjustments are made correctly (this is true in 99.9% of cases). If a defect appears, the dealer replaces the assembly without expecting that adjustment will solve the problem. The owner does not need to hope for this either. The choice is yours.

Useful tips for motorists

In conclusion, I would like to give a few tips that will help the steering rack and other elements of the control system serve you for a long time and reliably:

- visit a service station once every three months or check the condition of the steering yourself;

- constantly monitor the condition of the protective casing installed on the steering rack;

- try to drive on road irregularities to a minimum, especially when driving at high speed;

- do not wear out the steering rack by sudden starts with the wheels turned all the way;

- If play appears, make adjustments immediately;

- If you notice signs of malfunction, carry out repairs immediately, without waiting for the condition of the steering system to deteriorate.

What is the function of the steering rack?

Steering racks can be driven by hydraulic, electric or mechanical. Most vehicles are equipped with hydraulic racks. This design ensures fast and accurate steering at high speeds, optimal entry and exit from parking lots, and also allows you to make turns in limited areas. To reduce the forces exerted on the drive wheel, the mechanism is equipped with a hydraulic booster.

As is already clear from the examples given, the steering is also responsible for the convenience and even safety of driving, along with other vehicle systems. It is in our interests to keep it in working order and listen to problems. All steering rack repair work is carried out using special equipment that allows for optimal restoration and adjustment. Let's figure out what can expect us?

Quick Guide

The main reason for tapping is the formation of a gap in the joints. In the steering system, there may be knocking on the tips, ball joints of the rods, the rack, the “cardan” in the column, the steering wheel on the shaft, or the auto-folding system in case of an accident. The metallic sound is distinct and can be heard in place when rocking the steering wheel.

It is quite possible to mistake problems in the suspension for problems in the steering, since the initial stages of wear of bearings and supports only make themselves felt when cornering at speed. In the suspension part, the cause of the knock should be sought in the wheel bearings, ball joints and “supports”.

How to tighten the steering rack and is it possible to prevent play?

Most often, steering rack malfunctions occur as a result of regular driving on dusty and uneven roads. Speed bumps, which are not always installed according to technology, have especially become a pressing problem in urban conditions; sometimes the entry to them is sharp, sometimes the height is high, and the car suffers. The longer this mode of operation continues, the faster the rack knocking will occur. This is the most pronounced symptom indicating its malfunction.

In order to repair the steering as little as possible, it is necessary to slow down if irregularities are clearly visible on the road. You should drive through them at very low speed.

Other causes of malfunctions are frequent collisions with curbs, a sharp increase in speed when the steering wheel is in the extreme position. In this regard, the load on the gearbox and other components of the steering rack increases. Under such conditions, even the car’s power steering can fail. Rack malfunctions are very similar to other breakdowns, so in some cases it requires complete disassembly for accurate diagnosis.

Analysis of typical complaints

The advice given at the beginning, to understand when the tapping occurs, makes it somewhat easier to find the cause. But this recommendation is effective only with a comprehensive diagnosis. For example, the mere fact of clanking in the pits is not enough; you need to listen to what is happening when the wheels are turned and whether there are any sounds in place.

If the test is done, go through common complaints.

- The noise only appears when the steering wheel is turned. If nothing is transmitted to the steering wheel, then see “ball” in more detail. Perhaps it is not tightly attached to the steering knuckle or lever. For example, bolts are often forgotten to be tightened during wheel alignment.

- The knock comes from the steering wheel. This is either a rack or a cardan on the shaft. If this only occurs on washboards and other irregularities, inspect the control shaft telescopic connection. Pay attention to the rack and pinion mechanism - the nuts securing it to the subframe or body may be loose.

- The rattle is only on the straight line, quiet in turns. Rack, cardan, ball joints.

Adjusting the steering rack - how to do it in your garage?

Very often the question arises of how to tighten the steering rack yourself and make other adjustments. In this case, it should be remembered that simply tightening it may not completely solve the backlash problem or not solve it at all. This is due to the fact that the transmission pair, which includes a rack and pinion, has a degree of wear that is unknown to anyone in advance. The adjustment work itself is not particularly difficult and can be done by any driver who knows how to handle the tool.

The unknown degree of wear does not allow an accurate diagnosis to be made without opening the steering rack. In this case, you will have to contact specialists. For regular adjustments and tightening, you will need a partner, a garage with a pit and a wrench to adjust the steering rack. After preparation, you must perform the following actions in compliance with certain rules:

- Before you begin tightening, the vehicle must be securely secured and the wheels must be straight. Using a backlash meter (a special mechanical device for determining the gap), it is necessary to measure the backlash of the front wheel (if it is responsible for steering), which should not be more than 10 degrees.

- To tighten it, there is an adjusting screw located in the end cover of the steering mechanism, find it. If you have to look for it for the first time, then arm yourself with the car’s passport, because the location of the screw is different for each model. He should pull himself up slowly. It is necessary to constantly check the steering wheel travel, the amount of play and the presence of knocking in the column.

After adjustment, it is necessary to carry out sea trials. If the drive wheel travel is heavy, the adjusting screw will need to be loosened a little. Thus, steering rack adjustment work will be considered successful when the knocking or play has completely disappeared and the wheel freely returns to its normal center position.

Power steering and power steering: do-it-yourself installation

The electric booster first appeared on Kalina, then on Grant and on the new Priora. You can drive a car without an ESD. But if a car owner previously owned a car equipped with a hydraulic or electric booster, then, at a minimum, he will experience great inconvenience. On the Lada Granta in the minimum configuration, the manufacturer does not install electric power steering, so many owners of such cars decide to install the power steering themselves. This procedure is not the easiest, and the unit is not cheap. But its presence means a comfortable ride, maneuverability and safety.

Installation does not require any special knowledge or skills; minimal experience and a set of tools are sufficient. If, nevertheless, the question arose about installing electric power steering on the Lada Granta, then when purchasing an electric power steering unit, you should pay attention to its number.

The set of numbers contains a definition of the place of production, these are the last two digits:

- 00 – made in Makhachkala (not the highest quality, has many negative reviews);

- 04 – Korean amplifier, you can buy it in a store, a rare copy at auto wrecking yards;

- 02 – made in Kaluga, a good medium option.

To install the amplifier you will need a set of wrenches, screwdrivers and an angle grinder (grinder). Before proceeding with installation, the steering wheel, all steering column switches, the ignition switch, and the steering column with cardan must be removed. The further algorithm of actions is as follows.

- Knock out the bolts from the removed bracket in the form of a plate and cut off about 3 cm from the top with a grinder.

- Drill holes in the plate to mount the electric amplifier.

- Fix the cardan to the EUR.

- Place washers under the bracket (where the electric booster is mounted), and you can use them to adjust the steering wheel.

- Attach the electric booster, and then install the cardan into the rack.

After this, all that remains is to connect the EUR to the wiring according to the electrical diagram supplied with the amplifier. Using washers you need to adjust the steering wheel deflection in different positions. No further maintenance of the electric amplifier is required. Those who decided to replace the electric power steering with a hydraulic booster should understand that this idea is pointless. Firstly, the power steering is much more technologically advanced and modern, and secondly, installing the power steering on the Grant is a labor-intensive and expensive process that has no practical advantage.

The steering mechanism of the Lada Granta is reliable and simple to use. With timely diagnosis of faults and periodic maintenance of mechanisms, the rack and other components will last a long time without any serious problems.