Today, the automotive industry is moving forward at tremendous speed. Design solutions that seemed innovative just a few years ago are now completely becoming obsolete. In addition to the rapidly developing direction in the field of automobile design, technological aspects of production are also constantly updated.

One of the goals pursued by engineers is to increase the time between overhauls. Constant work is underway to strengthen vulnerable nodes. One of the stressed vehicle systems is the exhaust system. On the one hand, it works under conditions of constant chemical aggression and high temperature, on the other hand, it is subject to mechanical loads.

Almost all modern cars have a device in the exhaust pipe for damping dynamic loads, the so-called muffler corrugation. Let's take a closer look at what this device is.

Replacing the muffler corrugation on Kalina

No matter how much Russian car enthusiasts scold the domestic auto industry, the models produced by VAZ, such as Kalina, deserve the right to flattering reviews.

Of course, with a caveat - if you notice problems in all its systems in time and replace failed devices. One of these “problem” parts is the muffler corrugation. Real reviews from Lada Kalina car owners about its exhaust system:

- For some reason, the corrugation is one of the first to burn out, and then the festival of breakdowns is picked up by the rest.

- It is no longer the system elements themselves that cause concern, but the factory welds at their connections.

- Sedans, station wagons and hatchbacks have different mufflers, but their service life in practice is the same.

- Kalina’s mufflers “destruct a long life” after only 40-50 thousand kilometers.

Why does it fail, affecting the condition of other parts, and how to replace it?

Corrugation in the VAZ exhaust system (purpose and installation)

| Russian cars cannot boast of a quiet exhaust system; vibrations and noise accompany the owners throughout their entire operation. But there are a number of ways to modify the exhaust system of a VAZ, for example, installing a corrugation in the exhaust system . |

Why is corrugation needed in the exhaust system? The engine of any car in working condition creates vibration, which in turn is transmitted to the exhaust system, and then to the body. To get rid of the noise and vibrations of the exhaust system, on foreign cars two corrugations are cut in, right at the mounting flange to the exhaust manifold.

On Russian cars the situation is somewhat different, for example, on a VAZ of the tenth family with Euro-3, the plant installed a corrugation where the catenary collector is. The Lada Kalina also has corrugation and it is similar on all trim levels. Those who got a car without the “miracle” corrugation can do a little tuning of the exhaust system by installing the corrugation themselves:

| For injection cars with Euro-2, it is possible to order a ready-made element in online stores: 'Pipe between. 2108-2110 and mod. with corrugation (instead of a catalyst) Phobos company. The price is about 800 rubles. For the carburetor, the design will no longer be dismountable. |

You can save a little and buy a vibration compensator (or corrugation - a flexible element of the muffler, which also compensates for mechanical and thermal vibrations of the exhaust system) separately for the diameter of your pipe:

|

Such corrugations are made of high-alloy stainless steel and cannot be repaired; they can only be replaced. The service life is quite long, but it is the most vulnerable link in the exhaust system. When the exhaust gases have nowhere to go, the pressure burns through and gradually breaks through the corrugation. It makes sense to buy corrugation no longer than 150mm, otherwise the structure will sag. For example, the length of the Kalina vibration compensator is 100mm.

Installing a corrugation in the exhaust system of a VAZ using welding. The corrugation is installed in the exhaust system only using electric welding (semi-automatic or argon). The process is quite simple:

- We measure the dimensions in the resonator (in front of it).

- Cut out the excess with a grinder.

- We insert the corrugation into the pipe and weld it (with an electrode, grab it with a two-piece, and scald it with a three-piece). The main thing here is to do everything smoothly.

- Installation in reverse order.

- Significantly less (virtually none) vibrations are transmitted to the body from the exhaust system (the muffler stops vibrating). At idle there is a complete feeling that the engine is not working.

- Reducing vibrations on the body entails reducing noise inside the car.

- The service life of suspension elastic bands (gingerbreads) increases.

- It becomes possible to correctly hang the exhaust system, regardless of the tolerances on the length of its components.

- Pipe rattling disappears during sudden engine acceleration and braking.

Installing a metal expansion joint using screws and sealant. High temperature sealant will be required. We clean the paint from the outer surface of the additional muffler pipe and apply a thin layer of thermosealant to it and the inner surface of the metal compensator bushing. We insert the additional muffler pipe into the corrugation sleeve and drill eight holes with a diameter of 4.2 mm around the circumference. We cut M5 threads in the holes. After applying thermal sealant to the threaded part of the screws, screw them into the holes. This is what the connection looks like.

Advantages and disadvantages of corrugations in a car exhaust system Pros:

No cons found.

Conclusion This modification of the exhaust system can be classified as a 'Must have been there from the start' category. The only difficulty that may arise is the lack of electric welding. By the way, do you know how to tune the exhaust system?

What will tell you that the muffler corrugation on Kalina needs to be replaced?

You don’t need to be an auto mechanic to understand that the muffler corrugation on Kalina needs to be replaced when the element is no longer suitable for use.

They will tell you about this:

- The smell of burning. Exhaust gases can penetrate into the cabin, causing nausea and fatigue of the driver and passengers, and if inhaled for a long time - loss of consciousness and tragic consequences (from fatal poisoning to an accident).

- Claps. They come from underneath. Such sounds not only cause discomfort to the owner of Kalina; for violating the noise level in neighborhoods, the traffic police inspector has the right to impose a fine on him.

- Engine noises. It can operate louder than usual, while producing sounds similar to gurgling.

When failure and replacement of Kalina corrugation

An experienced craftsman will name the reasons for the failure of the corrugation after only briefly examining it.

Dents, punctures, gaps in the housing with rupture of the outer layers of the braid - most likely, the corrugation received mechanical damage during movement. The body can be torn open by a stone, a bump, a hole in the road, or anything that the bottom of a car can run into.

Rust, breaks at the joints of the part with the manifold and pipe. The joints, as motorists have already warned, are the weak side of the muffler corrugation on Kalina. It itself is made of stainless steel, but welds that are not coated with anti-corrosion material, from dirt, dust, moisture, reagents, etc., crumble quickly.

Traces of burning through the corrugation. Due to constant exhaust pressure at high temperatures, the braid layers may someday burn out. This almost always happens if the honeycomb of the catalytic converter is clogged, when the pressure increases many times. The body bristles with brittle and torn layers of braiding and loses its seal.

Violation of corrugation fixation. The clamps can simply rot, and part of the weight of the pipe will be distributed onto the corrugation, which will lead to its rupture.

Not a repair, but a replacement of the Kalina muffler corrugation

It is not worth shifting all the sins onto the manufacturer due to breakdowns of individual parts. Much depends on the driver - any master will tell the owner of Kalina. Imported muffler elements will also not last forever for two reasons:

- Constant thermal impact on the corrugation. Since the part is an integral link in the exhaust system chain, gases with an unquenched temperature pass through it, and the wave will create internal pressure on the walls.

- Constant mechanical impact on the corrugation. As soon as the driver starts the engine, vibrations and vibrations are transmitted to this part, which, due to its plasticity, compensates for them, thereby protecting other parts of the system from rapid wear.

Most popular manufacturers

There are three types of corrugations on the market:

- single-layer, consisting of a metal hose and outer braid;

- three-layer (the most popular) - a corrugated two-layer metal hose, an additional rolled inner sleeve and an outer braid.

two-layer, consisting of a metal hose, outer and inner braid;

If we approach the choice of corrugation from the perspective of the manufacturer’s demand, we can distinguish three main companies whose products are present in our car markets:

Hydra

A German manufacturer offering the most durable vibration compensators, characterized by high quality damping of resonant vibrations.

The part has a high level of elasticity, which ensures smooth deformation in any direction vector. This corrugation is often used on German-made cars and on Korean cars with a V-type engine.

Interlock

Polish company with assembly shops in China. Produces three-layer high-quality corrugations that can protect the exhaust system even from sudden jerks. The part has a good safety margin and a long service life.

The material is stainless steel, which is difficult to compress.

Excellent for vehicles with an in-line number of cylinders.

Innerbraid

In fact, corrugations produced by Innerbra >

Where to buy a new muffler corrugation for Lada Kalina

Unlike the muffler, which is produced for Kalina only at VAZ, the corrugation can be selected from a very wide range. The defining factors here will be:

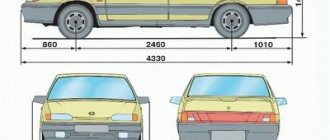

- Dimensions. The length and internal diameter are taken into account, taking into account the application of welding seams. Measurements can be made using the old corrugation removed.

- Type. Instead of corrugation with a two-layer braid, you can install it with a three-layer one. It will be about one and a half times more expensive, but will last longer. With one condition - the welds will be applied as evenly as possible.

- Manufacturer. There is a choice of imported corrugations of suitable sizes. World brands guarantee quality, but the price of their parts is higher than domestic ones. Although the corrugations produced in Russia by manufacturers with less famous names are not inferior to them in all respects, and cost significantly less.

Varieties of corrugation

In order for a vibration compensator to serve for a long time, it must have two main characteristics:

- elasticity (expressed in the optimal combination of the tightness of the corrugated material, the density of the braid and the quality of tension of the cylindrical part);

- long working life (depends mainly on the quality of the material used).

There are two types of vibration compensators used in the automotive industry. When selecting a part to replace one that has become unusable, you should definitely understand what type of corrugation was installed on this car model:

- Vertically installed corrugation.

The vibration compensator is mounted under the exhaust manifold of the vehicle exhaust system. During engine operation, it is deformed by straightening and compression. The length of such a vibration compensator is less than 15 cm, and its internal diameter does not exceed 6.5 cm.

- Horizontally installed corrugation.

This type of vibration compensator is predominantly deformed by bending. The part is attached after the 1st elbow of the receiver pipe, counting from the engine. With the same diameter of 6.5 cm, the length of this type of corrugation reaches 40 cm.

What is needed to replace the muffler corrugation for Kalina

To replace the corrugation quickly and efficiently you will need:

- Conditions for the procedure. The street and the jack are not the best combination for such a case. When the muffler pipe is removed, the old one is dismantled with a grinder and a new corrugation is installed by welding, it is better to use a lift or inspection hole, and carry out the work in a dry and warm room with sufficient lighting and compliance with safety regulations.

- Equipment. Any test benches, etc. It is not necessary to replace the muffler corrugation. But at a minimum, you need a cutter and a welding machine.

- Tool. The minimum set is open-end wrenches, screwdrivers, a hammer, that is, everything that is included in a standard repair kit.

- Additional details. You will need WD-40 lubricant, anti-corrosion agents, new gaskets, O-rings, clamps, and replacement bolts.

- Experience in welding work, as well as experience in replacing corrugations. Without it, it is better not to try to experiment - in the best case, you will soon have to install a new corrugation again, in the worst case, you will have to change the entire muffler and resonator.

Algorithm of actions when replacing a muffler corrugation

A simplified procedure for replacing the corrugation looks like this:

- The muffler is removed.

- The old corrugation is cut down.

- On the new corrugation, cuts are made at the joints (if necessary), and the old seams on the pipe are cleaned.

- The new part is installed in place of the old one.

- Welding is carried out (first spot welding to fix the part, then full welding around the entire circumference).

- The weld seam is treated with an anti-corrosion agent.

- The muffler is installed in place and secured with hangers.

Choosing in a car store - what to look for

If there is a need to purchase corrugation in an auto store that does not have products from reputable manufacturers, you will have to choose based on inspection and analysis of the offered assortment. Most corrugations on the domestic market come from China. However, this does not mean that all of them are necessarily of poor quality - different Chinese manufacturers offer parts with very different characteristics.

Choice

The choice of corrugation for Lada Kalina depends on the parameters, design and manufacturer. Regarding the sizes, it is recommended to purchase a product 230/45 mm - such a corrugation is more than twice as long as the standard one, so there is no need to worry about vibrations.

As for the design and manufacturer, there are a lot of options.

Products differ in manufacturing method:

- 2-layer;

- 3-layer;

- 4-layer;

- Made of stainless steel;

- Reinforced, etc.

The choice of brands is also very extensive:

- ARD;

- Ehler;

- Interlock;

- Hydra;

- POLMOSTROW;

- bosal;

- Vibrant Performance and others

In most cases, the price of corrugation varies between 500 - 2,500 rubles.

Replacement

The cost of replacing the Lada Kalina muffler corrugation depends on the amount of work performed. Making a replacement from an authorized dealer can be problematic, since it is a minor job and you may get a refusal. This is why, and also because of the price, most owners order work done at a third-party service station.

Typically, the price of work ranges from 500 to 2,000 rubles, although some stations may charge up to 4,000 rubles. If you only need to cut and weld a new corrugation, you can get by with minimal costs. But sometimes the exhaust pipe already has time to rust, and then, along with the corrugation, part of the pipe also has to be replaced, which naturally affects the final cost.

Spare part price

The cost directly depends on the size, model of the car and corrugation parameters. For many low-price cars, the price will be 200–400 rubles. The cost of a unit for more expensive cars reaches 1200, and sometimes exceeds 1500 rubles. During the purchasing process, you should buy 2 gaskets; they are useful for connecting the flange parts to the corrugation. When dismantling the old structure, it is impossible to maintain sufficient quality of the old gaskets; it is better to replace them.