The paintwork coating (LPC) protects the car from external influences. The majority of cars have a paintwork thickness of 80-150 microns; for premium models (for example, Mercedes) this value will be in the range of 150-250 microns. Do you know how thick Vesta’s paintwork is?

The measurements were carried out using a thickness gauge ET 11S (available on AliExpress). The results are as follows:

- roof paintwork thickness – 102-128 microns ;

- doors – 139 microns ;

- front wing – 140 µm ;

- hind wing – 144 µm ;

- hood – 104 microns ;

- trunk lid – 125 microns .

The process of taking readings is also shown in the video:

Lada Vesta SW Cross has a similar thickness of paintwork:

Comparing the thickness of Vesta’s paintwork with its competitors, you can see that the values of each body element are approximately the same. The numbers 100-150 microns can be attributed to the bulk of modern cars.

The domestic auto industry is among the TOP 30 in the production of modern class B (small cars) cars. One of the models presented by the manufacturer AvtoVAZ is the well-known Lada Vesta. After reading this article, you will understand whether the car will rust and how many years it will remain untouched by corrosion. Car enthusiasts and experts often say that when developing the Lada Vesta, manufacturers clearly set the task of “jumping above their heads.” This is evidenced by innovations that AvtoVAZ did not resort to. Including improved galvanization of the Lada Vesta body. In modern road conditions, the bodies of old cars cannot withstand the load of the environment and quickly succumb to rust. Due to global warming and climate change, road workers sprinkle the asphalt with substances that affect the metal body of the car. To prevent corrosion, a zinc protective layer is applied to the metal. The presence of a protective layer prevents the car body parts from rusting.

Let's look at the types of zinc coating. Is the body of the Lada Vesta galvanized at all? Comparison of the protective layer.

There is a myth that the Lada Vesta, like most Russian cars, has a body protected only by paintwork (paint coating). It is not true. The Lada Vesta has a zinc coating, although not the best.

The paint on the roof is thicker than on the doors - we checked the eternal myth

We measured the thickness of the paintwork on several cars and are ready to share the statistics. We will also teach you how to quickly and accurately determine whether a car has been in an accident.

“It also appears that the car was given a double coat of paint, which naturally made it more durable.”

Arthur Haley, "Wheels"

Everyone knows that a thickness gauge helps a lot when choosing an “unbroken, unpainted” car.

The device allows you to measure the layer of any dielectric coating applied to metal. Moreover, good thickness gauges react both to iron-containing, “magnetic” alloys, and to aluminum-based alloys.

But in order to correctly interpret the thickness gauge readings, you need to know what general paint thicknesses are available on cars that left the factory and were not involved in accidents.

conclusions

When considering the measurement results, patterns were identified.

- If the car has not had a body repair followed by painting, then the thickness of the paint coating on all parts will not differ by more than 20–40 microns.

- Roughly, we can assume that the thickness of the paintwork on most mass-produced cars is 100–120 microns. It is not for nothing that many thickness gauges have the main, or even the only, calibration strip with a thickness of 100 microns.

- The myth that the paint layer is somewhat thicker on horizontal surfaces has been refuted

. Cunning automakers have long learned to take gravity into account and do not pour unnecessary paint. - Significant differences in the thickness of the paint on one car clearly indicate that the panel with a thicker layer has been repainted.

- If in doubt, it is advisable to check the thickness of either adjacent parts (for example, the front and rear doors are close to each other), or paired ones - for example, the right and left wings.

- Very often, a body part being repaired ends up with a double layer of paint. This happens if you painted a replaced part, but didn’t get the color right the first time and had to repaint it.

The greatest thickness of the paint coating is on cars of the Renault-Nissan alliance. The paintwork of the Arcana is especially different. Lada Largus also showed excellent results.

- How to recognize repainted body parts? All the tricks are here.

- If you see small pockets of corrosion, use the miracle rust remover ZINCOR.

Reviews

| Positive | Negative |

| “Phantom” suits Vesta very well, the car looks interesting and simply excellent. | There's nothing special about the Carthage color, but for some reason it's the most expensive. |

| As for me, the ideal colors for the cross version are “Carnelian”, “Mars” and “Glacial”. | The black color doesn't really suit this car, it's better to choose other colors. |

| I'm completely satisfied with the car, I bought a bright red SV. |

This is an inexpensive foreign car at a very competitive price and it has everything you need.

A huge problem with colors, if you need to choose exactly for your car.If you need to tint or repaint a car or its parts, then be prepared for the fact that the shade ordered from the officials will not match. Finally, the domestic auto industry has started making normal cars. I have a Vesta model with an automatic and in classic black. I've been driving for a little over six months - there have been no problems. An excellent alternative to foreign cars. One of the first Wests that I am completely dissatisfied with. I'm not even talking about the shade, which shows all the chips, but the assembly itself was disappointing.

The cars released later after modifications turned out to be much better. The SV has a spacious interior and trunk, sensors are installed on the headlights and brushes, the engine is very quiet, you can hardly hear it. Minor disadvantages in the Vesta are different knobs and knobs. The big drawback was the creaking of the front suspension. Quiet engine, easy soft start.

The doors close easily and quietly.

Good brakes, clutch, steering.

On large bumps in wet weather, the anti-roll bar creaks. The problem turns out to be very common. Lots of passive and active safety features. ESP, which helps a lot in winter. The air conditioning and heater work great. Mounts in the trunk take up a lot of space. Stainless seat upholstery. The engine compartment is splashed through the gap under the hood.Lada Vesta paintwork thickness

Today the assumption was confirmed that there is practically no paint layer on my machine. We can assume that it simply does not exist.

Below is a photo of measurements of Kalina-1. Skoda A-7. Vesta

I am depressed. Now it becomes clear why any train adds chip after chip to Vesta’s mortal body.

The layer comparable to Kalina is only on the roof. because it is not galvanized.

Well, the Hood, Wings and everything else have a funny layer of paint, which is 10.6 times thinner than on Kalina.

Just imagine - 6 hundredths of a millimeter = only 60 microns.

Shame and disgrace - the bourgeoisie pays for everything, and we have to pay for it with our own money.

Even the Skoda has an average layer of paint on the hood, almost twice as thick as on the Vesta.

It's somehow completely unpleasant.

Was the thickness gauge calibrated before taking measurements?

You can try to officially request from AvtoVAZ the thickness of the body paint for a given color and body and then, after consulting with a lawyer, think about what to do next.

Galvanization and paintwork of Lada Vesta body

The domestic auto industry is among the TOP 30 in the production of modern class B (small cars) cars. One of the models presented by the manufacturer AvtoVAZ is the well-known Lada Vesta. After reading this article, you will understand whether the car will rust and how many years it will remain untouched by corrosion. Car enthusiasts and experts often say that when developing the Lada Vesta, manufacturers clearly set the task of “jumping above their heads.” This is evidenced by innovations that AvtoVAZ did not resort to. Including improved galvanization of the Lada Vesta body. In modern road conditions, the bodies of old cars cannot withstand the load of the environment and quickly succumb to rust. Due to global warming and climate change, road workers sprinkle the asphalt with substances that affect the metal body of the car. To prevent corrosion, a zinc protective layer is applied to the metal. The presence of a protective layer prevents the car body parts from rusting.

Let's look at the types of zinc coating. Is the body of the Lada Vesta galvanized at all? Comparison of the protective layer.

There is a myth that the Lada Vesta, like most Russian cars, has a body protected only by paintwork (paint coating). It is not true. The Lada Vesta has a zinc coating, although not the best.

Is Lada Vesta galvanized?

Following Soviet tradition, manufacturers chose a cheap galvanizing method for Lada Vesta and LADA Vesta SV Cross - cold coating. It should be noted that the cars are galvanized on the outside. This galvanization is of lower quality, but is a good option for budget cars. Double-sided galvanization typical for expensive brands Mersedes, BMW, Lexus.

AvtoVAZ gives a six-year warranty on LADA Vesta. This is due to the fact that the zinc layer covering the body is 8 microns - not bad for the domestic automobile industry.

What do we end up with?

The developers kept their promises, because the body turned out to be really strong. A six-year warranty, instead of the promised five-year period, became a balm for the soul of the owners. This figure is not impressive when compared with the warranty periods that foreign manufacturers provide for their models.

So is the body galvanized? Yes! There is galvanization, and the thickness of the metal is quite good! But for some reason the manufacturer uses the most “budget” method of applying such a coating. Body elements are processed only from the outside, with the exception of the bottom, which is coated on both sides. Another feature is that instead of liquid zinc, the plant uses the substance in powder form. This allows you to better process not only the cracks, but also all the bends present in the body. The thickness of the formed zinc layer reaches 8 microns, which was taken into account when calculating the warranty period.

Interesting! In the history of domestic serial production of cars, the Lada Vesta model was the first to receive zinc treatment of the body, with the exception of the roof surface.

Wanting to provide adequate protection for the body of his brainchild, the manufacturer focused on cataphoresis primer. The essence of the process is to immerse the body frame in a special container. The anode electrode is connected to the body itself, and the so-called cathode is connected to the bath. This procedure allows the positively charged soil to settle on the surface of the metal, which has a negative charge. Thus, the metal surface is covered with an appropriate film, which subsequently has a protective function.

Is the Lada Vesta's paintwork reliable?

Everything is fine here. The producers outdid themselves and coped with the task. The car has passed many tests carried out by painters and ordinary car enthusiasts. This time AvtoVAZ produced a high-quality painted car. The paintwork applied to the galvanized finished Vesta body has no factory defects, underpainting or abrasions of the coating. Which pleasantly surprised fans of the VAZ manufacturer. The only thing that consumers may have questions about is the thickness of the paintwork. The point here is the established eco-standards, which provide for a small thickness of the paintwork applied to the body. Experts say this is enough. Having a coat of paint on a car like Vesta has, the owner can count on at least 7-8 years of quiet life, without fear of rust. If you look at the latest inexpensive models from Volkswagen, Ford, Skoda - all of them, having paintwork thickness that meets eco-standards, keep their shape, do not rust, and do not crumble. The same durability can be expected from the galvanized body of LADA Vesta.

Does Lada Vesta need additional anti-corrosion treatment?

Above, we have already examined the strengths of paintwork and the presence of galvanization. To answer more precisely, you need to understand what the car body is made of. Low carbon sheet steel is a component that makes up the body. Steel is prone to corrosion. If we add that the body is not completely galvanized, but is protected only from the outside, the conclusion suggests itself - factory galvanization is not enough.

During one of the test drives conducted by Russian auto experts in the first months after the release of Vesta, it was noticed that the inside of the car and especially the bottom were galvanized somehow. The car is well made, but if you look deeper, you can feel the manufacturer’s signature. There are several types of application of additional primer, which are used depending on the primary galvanizing method.

A good option would be the ML method. It involves spraying chemical compounds into car parts that form a reliable anticorrosive agent. If the machine is used carefully and minor cosmetic damage is eliminated, the machine with additional treatment will not rust for 10-12 years.

What to look for

Every year, technologies are improved, and the guarantee for body protection against rust increases, and AvtoVAZ is no exception (the thickness of Vesta’s paintwork is at the level of its competitors, 100-150 microns). Pay more attention to the presence of this guarantee than to dubious information about body galvanization from the media and advertising.

At the moment, AvtoVAZ provides a 6-year . Depending on the operating conditions of the vehicle and the quality of the body treatment with anti-corrosion agents, its service life can vary greatly (see survey). If rust appears during the warranty period, do not hesitate to contact your dealer.

How do you evaluate the anti-corrosion treatment of Lada car bodies? Is it necessary to additionally treat weak points or is the factory version sufficient? Let us remind you that you can get acquainted in more detail with modern AvtoVAZ cars by content in the context of models (Vesta, Granta, Priora, Kalina, Largus, Niva 4x4 and XRAY). The VK survey is being conducted among Vesta owners.

Technology for applying a protective coating to the Lada Vesta body

Considering the method used for galvanizing, a type of additional treatment suitable for the car is cataphoresis priming. This is a complex process consisting of several stages.

- Removing protective covers from the machine body;

- Removing fats from metal;

- The body is immersed in a bath of cataphoresis solution;

- Washing off the remaining solution;

- Drying cataphoretic soil.

After passing the last stage, the body has a new, tight-fitting primer layer that protects the outer parts of the body and the internal cavity.

Does cold galvanizing protect

Galvanizing cars manually When carrying out a crash test, good results were obtained.

The painted part (car hood) was scratched and placed in a room with a high humidity saline solution. They stood for some time, which in real conditions corresponds to four years of operation. The test revealed no corrosion damage. The manufacturer has achieved good results when painting cars, but for better preservation of the paintwork, it is additionally coated with cataphoresis primer, which has good adhesion to zinc.

Painting Lada Vesta

Painting of the car begins after the application of primer has been completed. Step by step, the car is prepared for the painting procedure. Since painting is done with an aerosol in several layers, robot labor is used. A solution is applied to the surface, strengthening the seams and protecting the body from corrosion. Then noise-insulating mastic is used, which adds silence to the car on the roads.

When applying primer coating with robots, many hard-to-reach places remain and have to be processed manually. The inner sides of the pillars, the edges of the roof covered with doors, are finished manually. The primer comes in two tones: light or dark. Choose depending on the color of the car.

Once the priming stages are completed, the car is sent to the next conveyor for developing the secondary layer. Here, specialists eliminate paint coating application defects and coat the seams with brushes and paste. After all the procedures, specialists, with the help of robots, proceed directly to painting the car. The paint application process is not complicated. A common aerosol spray that motorists have dealt with. A layer of varnish is applied over the paint, and the finished painted and varnished body is sent to dry, which takes an hour. The entire painting procedure lasts no more than four hours.

When the body is dried and the varnish is applied, there are a few final steps left, after which we get the product in the form in which it ends up on the market. The final touches are polishing and applying anti-corrosion. The result is a durable, galvanized body of the Lada Vesta. Let us remind you that the thickness of the car’s paintwork is higher than that of other parts of the car, which makes it reliable and resistant to changing weather conditions.

4 ways to coat metal with a layer of zinc in production

Hot method – used for LUX class. When hot galvanizing, the entire finished car body is immersed in a tank with liquid zinc heated to +500 degrees. This expensive method is used by brands: PORSHE, Jaguar, Bentley, Ferrari, etc.

Cold method - Using an aerosol, a layer of powder containing zinc is applied. The process is similar to painting. This method is common; brands use it: KIA, Mitsubisi, TOYOTA, Skoda.

Galvanic method - using the application of electrically active solutions. Microparticles of zinc settle on the body under voltage. Inexpensive way.

Zinc metal is a method more often used in the production of Asian car brands, such as KIA. Two plastic zinc layers are applied to the body. Suitable for class C cars.

Vesta paintwork thickness

- On average 100-150 Microns throughout the bodywork;

- The thickness of the roof paintwork is 102 - 128 Microns;

- Doors 139 Micron;

- Front wing 140;

- Rear wing 144;

- Hood 104;

- Trunk lid 125.

Conclusion. Drawing conclusions let's say:

— Vesta has durable and well-protected body elements. In production, they use the cold galvanizing method, which is not the most reliable, but is used by European and Asian brands. Lada Vesta has a good layer of enamel, compared to cars produced by the AvtoVAZ plant previously. The presence of a good warranty period confirms the well-done work of the manufacturer.

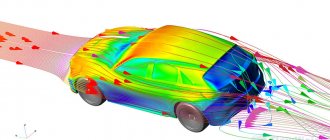

Painting Lada Vesta and X-Ray at the factory - all the details of the process

It is not for nothing that the paintwork of a car body is considered one of the most important production stages. After all, not only the safety and commercial success of the model largely depends on its quality. As you know, people greet you by their clothes...

That is why the traditional hosts of the Lada Drive program, Stanislav Bereziy and Yanina Pavlova, visited the AvtoVAZ paint shop to see with their own eyes how everything is done there.

The body painting of Lada Vesta and X-Ray takes place in a special workshop. All work is carried out by robots, which apply layers of paint to the metal while the bodies move around the workshop.

By the way, bumpers are painted separately. They are installed on special frames and also pass through the workshop.

Quality checking

Thickness

It is precisely checking the thickness of the paintwork on Lada Vesta and X-Ray that is perhaps the most important aspect, because many buyers pay attention to the thickness of the coating. Therefore, at AvtoVAZ, inspection of this indicator is carried out daily on all parts. For this, a special tool is used - a thickness gauge.

Transmission

- Lada Vesta is offered to customers with three different gearboxes, two of which are mechanical and one robotic. A Russian-made robot differs from foreign analogues in its more precise operation and reliability. If necessary, it can easily be switched to mechanical mode, and the car becomes manually controlled. One of the manual transmissions (VAZ-2180) is Russian-made, and the second (JH3101) was produced and developed in France. Both mechanics are five-speed.

- Volkswagen is equipped with two different gearboxes. The five-speed manual transmission developed by Volkswagen has an impeccable reputation around the world. It contains optimal transmission speeds and the shortest lever stroke. The Volkswagen automatic has 6 shift ranges. The box is designed according to the canons of modern automotive industry, it works accurately and in a timely manner.

The Lada Vesta gearbox looks rather weak against Polo gearboxes. In terms of comfort, the robot is unable to fully compete with a branded German machine gun. The mechanics in the Lada Vesta are made at a high level, but still German quality wins this debate by a small margin.