During the design and creation process, designers carefully consider the aerodynamics of the car, since it has a significant impact on the technical performance of the model.

When a car moves, most of the power of the power plant is spent on overcoming the resistance created by the air. And properly created aerodynamics of the car allows you to reduce this resistance, which means that you will need to spend less power and, accordingly, less fuel to combat the resistance of the oncoming air flow.

Vehicle aerodynamics measurements are used to study the forces created by air flow on the vehicle. And there are several such forces - lifting and lateral, as well as drag.

Drag and coefficient Cx

For the most part, all work on a car body is aimed at overcoming drag, since this force is the most significant.

Air flow movement

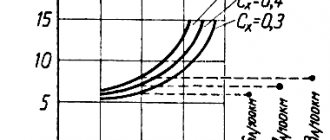

The calculations are based on the force of air resistance. To calculate the result, data such as air density, the transverse projection area of the car, and the aerodynamic drag coefficient (Cx) are used - this is the most important indicator in the aerodynamics of the car. At the same time, the resistance force is also significantly influenced by the speed of movement. So, doubling the speed will be accompanied by a 4-fold increase in resistance. Speed is one of the most powerful factors in increasing consumption.

For example, for a well-streamlined car with a projection area of 2 m2 and a coefficient of 0.3 when driving at a speed of 60 km/h, 2.4 hp are needed to overcome air resistance, and at a speed of 120 km/h already 19.1 hp. With. The difference in fuel consumption under such conditions reaches 30% per 100 km.

If you currently require maximum fuel economy, you need to maintain a constant speed of about 60 km/h. In this driving mode, consumption will be minimal even for a car with a large Cx.

Let's look at everything in a simple way. Air has its own density, and a considerable one. When moving, the car has to pass through the existing air masses, which creates a flow that flows around the body. And the easier it is for a car to “cut” the air mass, the less energy it will spend on it.

But it's not that simple. While driving, an area of increased pressure is created in front of the car (the car compresses the air mass), that is, an invisible barrier is formed in front, complicating the “cutting” of the air mass.

Also, after flowing around the body, the air flow separates from the surface, which causes turbulence and vacuum behind the car. In combination with increased pressure, the resulting vacuum further increases resistance.

Since it is impossible to influence air density, designers can only make adjustments to two other calculated components - the area of the car and the aerodynamic drag coefficient.

But it doesn’t seem particularly possible to reduce the projection of a car without compromising the useful spaces of the body (it’s simply impossible to make a car smaller than it is), so all that remains is to change the Cx coefficient.

This coefficient is established experimentally (in a wind tunnel) and characterizes the ratio of drag to velocity pressure and cross-sectional area of the body. Its size is dimensionless.

Aerodynamic tube

A drop-shaped body has the lowest aerodynamic drag coefficient. When moving in an air mass, such a body smoothly spreads the flow in front of itself, without creating an area of high pressure, and the existing “tail” allows the flow to close behind itself without breaks or turbulence, that is, there is also no vacuum. It turns out that the air simply flows around the body, creating minimal resistance. For such a body, the coefficient Cx is only 0.05.

Designers, working with the aerodynamics of the car, have not yet been able to achieve such indicators. And all because when moving, resistance is created by several factors:

- Body shape;

- Friction of the flow on the surface during flow;

- Flow entering the engine compartment and interior.

Therefore, for modern cars, the aerodynamic drag coefficient is considered excellent if its value is below 0.3. For example, the Peugeot 308 has a coefficient of 0.29, the Audi A2 has a coefficient of 0.25, and the Toyota Prius has a coefficient of 0.26. But it is worth noting that these are estimates under ideal conditions. In practice, while driving, a car is affected by many different factors that negatively affect the resistance of the body.

It is noteworthy that the coefficient is most influenced not by the front of the car, but by its rear. And the reason for this is the creation of vacuum and turbulence as a result of flow separation from the body. Therefore, designers for the most part are engaged in giving the necessary shape to the rear part.

The drag coefficient of the Volkswagen XL1 is only 0.19

The Cx coefficient can also be reduced by reducing the number of protruding parts, everywhere on the car (sides, roof, bottom, front), and those elements that cannot be removed from the surface are given the maximum possible streamlined shape.

Citroën GS

Here is another car that, at first glance, also does not inspire confidence in the aerodynamic miracle - this is the Citroën GS. At its premiere in 1970, the manufacturer announced that the car had an air resistance coefficient of only 0.31 cd.

The family sedan had a lot of space in a comfortable cabin and was equipped with hydropneumatic suspension. More than 2.5 million cars were produced. Production continued until 1986.

Lift and downforce

As a result of uneven air flow around the car from different sides, a difference in the speed of its movement occurs.

Effective lift and downforce

The car moves and cuts through the air flow, while part of this flow goes under the car and passes under the bottom, that is, it moves almost in a straight line. But the upper part of the flow has to follow the shape of the body, and it has to travel a greater distance. Because of this, a difference in air speed occurs - the upper part moves faster than the lower part, passing under the car. And since an increase in speed is accompanied by a decrease in pressure, a zone of increased pressure is formed under the bottom, which lifts the car.

Frontal resistance also adds problems. The area of high pressure of the air mass in front of the car presses the front end to the road, while the vacuum and turbulence behind, on the contrary, contribute to raising the body. Lift, like drag, increases with increasing speed.

A negative factor from the impact of such force is the deterioration of the car's stability with increasing speed and an increase in the likelihood of skidding.

But this force can also have a positive effect. By making adjustments to the design of the car, it is possible to convert the lift force into downforce, which will provide better traction, stability of the car, and its handling at high speeds.

At the same time, no separate solutions are required to obtain downforce. All developments aimed at reducing the Cx coefficient also affect the clamping force. For example, optimizing the shape of the rear end leads to a reduction in turbulence and vacuum, which also reduces lift and increases downforce. Installing the rear spoiler works in the same way.

Reducing turbulence when installing a spoiler

When establishing the aerodynamics of a car, lateral forces are not particularly taken into account, due to the fact that they are not constant and do not have a significant impact on the performance of the car.

But this is all the theory of car aerodynamics. In practice, everything can be explained in one sentence - the worse the aerodynamics, the higher the fuel consumption.

Why is this necessary?

Everyone knows why a car needs aerodynamics. The more streamlined its body, the lower the resistance to movement and fuel consumption. Such a car will not only save your money, but will also emit less rubbish into the environment. The answer is simple, but far from complete. Aerodynamics specialists, fine-tuning the body of the new model, also:

- calculate the distribution of lift force along the axes, which is very important given the considerable speeds of modern cars,

- provide air access for cooling the engine and brake mechanisms,

- think over the places of air intake and outlet for the interior ventilation system,

- strive to reduce noise levels in the cabin,

- optimize the shape of body parts to reduce contamination of glass, mirrors and lighting equipment.

Moreover, the solution to one task often contradicts the implementation of another. For example, reducing the drag coefficient improves streamlining, but at the same time worsens the vehicle's resistance to crosswind gusts. Therefore, specialists must seek a reasonable compromise.

What else affects aerodynamics?

Of course, designers are trying to reduce the car's drag as much as possible when driving and increase downforce. But the peculiarities of car operation and car owners’ views on the external features of the car make their own adjustments, and in some cases, significant ones.

Aerodynamic drag of different cars depending on speed

For example, installing a roof rack, even with an aerodynamic shape, increases the transverse projection of the car and greatly affects the streamlining, which immediately affects fuel consumption.

Also, consumption increases from driving with the windows and sunroof open, the use of protective and decorative body kits, transportation of oversized cargo protruding from the car, violation of the position of structural elements located under the bottom, and increased ground clearance.

But the car owner can also make adjustments that will positively affect the aerodynamics of the car. These include the use of aerodynamic body kits, installation of a spoiler, and reduction of ground clearance.

Citroen DS

First unveiled at the Paris Motor Show in 1955, the Citroën DS looked to many visitors like an alien spaceship landing on Earth.

To confirm the uniqueness of the car, in addition to innovative technology (the car had hydropneumatic suspension!), the designers created a futuristic aerodynamic design for the model, the air resistance coefficient of which was 0.37. This is an outstanding result compared to competitors of the time.

EV1 General Motors

Although General Motors did not officially sell its EV1 model, but only leased it, this car wrote its own history in the auto industry. This car contained both disappointments (the project was crude and the car was unreliable) and positives. This car, starting in 1996, became the first electric car in the auto industry. A total of 1,000 cars were produced.

See also: 11 GIF photos that demonstrate how aerodynamics works in cars

The machine was equipped with simple lead or nickel-metal hydride batteries. But despite this, the range of the electric vehicle was amazing - 230 km. And all this thanks to the body design, which had an incredible coefficient of air resistance of only 0.19 cd.

Mercedes-Benz A-Class sedan

By the end of this decade (for now), the most aerodynamic car on the market is the Mercedes A-Class Sedan (model range 2022) with exceptional aerodynamics (0.22 cd).

This became possible thanks to comprehensive sealing of the car body (including sealing of headlights), including complete sealing of the underbody of the car. Including a completely isolated engine compartment, rear suspension parts and much more. The wheel spoilers at the rear and front have been specially optimized to allow the wheels to rotate with minimal loss.

ALFA 40-60 HP Aerodinamica Castagna

The first show car in history and the first attempt to apply the principles of aerodynamics to cars was the ALFA aerodynamic car, released in 1914 (in those years the brand was not yet called Alfa Romeo).

See also: Unusual cars that came for inspection

The car was created by the Italian company Carrozzeria Castagna for Count Mario Ricotti. The car body was made in the form of a drop and rested on a classic frame.

Thanks to the aluminum body and the absence of a hood, the maximum speed of this concept was 120 km/h. When the car went into serial production, the speed was already 139 km/h. Unfortunately, the exact value of the aerodynamic air resistance of this car is unknown.

Rival of the wind

This is the kind of enemy the car is dealing with.

Let's lower the window, put our palm in the wind - does it feel a noticeable pressure? If you change the angle at which your palm hits the wind, you can also detect a vertical force - like on an airplane wing. The vertical and lateral forces that destabilize the machine are no less important than the resistance. Who would like a car that gets out of control at 250 km/h! It must be stable, not yaw, not “slide” in turns, when there are gusts of side winds, when passing an oncoming car, entering a tunnel, etc. Moreover, it must have a spacious interior with small dimensions and at the same time meet the aesthetic requirements of designers! Unfortunately, it is impossible to fully calculate its streamlining and link everything in advance. The car is refined in a wind tunnel, spending a lot of money.

Meanwhile, fashion forces people to buy dubious “gadgets” that affect aerodynamics. The cross-section of a pseudowing is often completely different from the wing profile: the designer who drew it was thinking only about the grace of the lines! Fortunately, most “victims of advertising” do not drive faster than 160–180 km/h - and the effect of some illiterate “wing” is hardly noticeable. If the car is faster, careless games with aerodynamic objects are fraught with dire consequences.

Even serious companies are not immune from mistakes. Remember the first steps of the Audi TT? It wasn’t long before he was “taught” to hold on to the road tightly. But such a company has more opportunities to eliminate mistakes than a private owner - he may have life on his list of “consumables”.

Calculating the downforce of a wing is not easy: without knowing the basics of this science, motorists sometimes argue until the roosters blow. Therefore, we will give a simple example from a parallel field of technology. The B-1B bomber has a wing area of 181 m2. Take-off weight - 216 tons. The plane is supersonic, but takes off at a speed of less than 300 km/h. This means that each square meter of the wing carries a load of 1.2 tons. But some sports cars go faster, so engineers “finish” their fairings, spoilers, and wings very meticulously. A good wing with an area of only a third of a square meter can create a downforce of four centners, or even more.

But another “racer” may buy a high-performance wing, but install it incorrectly - for example, it will carry it too far back. At high speeds, the front axle of the car is unloaded, and the car may become uncontrollable. The consolation is that often the “wing” is placed in the stall zone (“aerodynamic shadow” of the body), where it practically does not work.

Fortunately for the mysterious Russian soul, we have few cars that can do 300 km/h. But there are enough of those who can handle 180–200. And the thought that a “wet” car at such a speed may not obey the steering wheel never crosses the minds of many. Was it in vain that the money was paid to the envy of the neighbors!

Streamlining punctures make themselves known loudly only at high speeds. Air resistance forces increase in proportion to the square of the flow velocity - V2. After all, by slowing down the flow (for example, with a flat shield, as in Fig. 2), we convert its kinetic energy into additional static pressure. With an air density of 1.3 kg/m3, the increase in pressure from flow deceleration (“velocity pressure”) will be 1.3.V2/2=0.65V2 N/m2.

To determine the force of flow pressure on the shield (that is, aerodynamic drag), all that remains is to multiply the resulting pressure by the shield area S.

Let's say S=1.8 m2 (frontal drag area of the Zhiguli). Then speeds of 50, 100, 150 and 200 km/h correspond to resistance forces of 226, 903, 2031 and 3611 N - the “square” law. By doubling the speed, we quadruple the strength.

By the way, determining the value of S (Fig. 1) is not the easiest task. This is done with very high accuracy on a laser stand.

The quadratic dependence of the aerodynamic force on the flow speed sometimes misleads us. For example, after driving a round trip at a speed of 90 km/h, you forget about the weak (20 km/h) wind blowing along the route. But in one case the flow hits the car at a speed of 70 km/h, and in the other - 110 km/h! The drag forces are proportional to the square of the speed, and the power at the drive wheels is proportional to the cube. As a result, the average fuel consumption is higher than at a speed of 90 km/h in a calm environment. No matter what - gasoline blown away by the wind!

When driving a car, it is difficult to objectively assess the strength and direction of the wind blowing over the road. The general rule is that a headwind takes away more than a tailwind of the same force “gives.”

NOT ONLY "CE-IX"

Is the aerodynamic force determined only by the velocity pressure? It turns out not! The shape of the body exposed to the flow plays a huge role (Fig. 2). Having encountered a shield, the air will not endlessly accumulate in front of it (a) - it will go around the obstacle, forming vortices behind it (b). Additional movements of the jets require energy expenditure, and the aerodynamic resistance of the flat shield is much (about 17%) greater than that provided by complete braking of the flow! This means that to obtain the true resistance forces, you should multiply the previously obtained values by 1.17. This coefficient, which takes into account the shape of the body, is called the aerodynamic drag coefficient - Cx. One of the most streamlined bodies is an elongated “drop”, for which Cx = 0.04.

What is the Cx of a real car? Even the most unassuming people of the early twentieth century have about 0.8. The symbol of the Soviet era, the Zhiguli, does better: 0.52–0.53. Too much for today.

And here are the results of blowing in the wind tunnel of the Scientific and Technical Center VAZ of cars of the “tenth” family: 2110 - 0.33, 2111 - 0.36, 2112 - 0.34. This is at the level of very decent foreign cars of this class. True, some people don’t like “remnants”. But the laws of air movement are the same everywhere! Taking them into account, it is not easy to create an outwardly original car. What if you don’t really take it into account?

Cars from the Samara family are still popular in Russia. After the “classic” VAZs, it seemed that the fast-moving “eight” and “nine” were a huge step forward. In fact, the revolution did not work out. Although Cx = 0.47 is still less than 0.52, it is much higher than what small golf-class cars have today. Even the most “sophisticated” of the Samaras, the VAZ 2115, has not advanced aerodynamically: Cx = 0.435. However, technology is developing: more and more cars are appearing that combine excellent aerodynamics with a striking appearance.

If anyone is curious why we remembered the Cx, note: the actual resistance of the “ten” (even taking into account the larger frontal area than that of the “classic”) at the same speeds is 33–34% lower than that of the “Zhiguli” . Hence the improvement in speed and dynamic performance.

What does the value Cx consist of?

The first is pressure or shape resistance. Sometimes this is up to 60% of the total aerodynamic losses. The flow hitting the car's forehead becomes somewhat denser, then the jets diverge. Behind them they will not immediately “merge” - here you can see a zone of general disruption with small air turbulences. The movement of the machine is hampered by increased air pressure at the front and low air pressure at the rear.

In some cases, powerful vortex “tubes” are induced along the edges of the bevel of the rear part of the body (Fig. 3): they further reduce the static pressure and significantly increase losses. Making a smoothly descending “stern” (in imitation of a wing profile) is unrealistic, especially for small class cars. One way to combat harmful vortices is to deliberately disrupt the flow, for example with a small spoiler (as in photos 1, 2 and Fig. 4). The stall plume (the dark “bag” in the photo) takes less energy than powerful vortices. On small cars this technique is used especially often.

Shape resistance includes losses when flowing around protruding parts - mirrors, mudguards, an ajar hatch, etc. By hanging fashionable bells and whistles on the car, putting it in wide tires, etc., it won’t take long to increase Cx by 15 percent.

Having some viscosity, the air “sticks” to all surfaces of the machine - and this thin layer partially slows down the neighboring ones, etc. As a result, losses from air friction can reach 20% of the total. This is true, at least for cars with small Cx - especially unwashed ones. But owners of a UAZ, KamAZ, or Hummer can rest assured: this vehicle is indifferent to dirt.

Finally, there are internal losses caused by the need to cool the engine, brakes, ventilate and heat the body.

Aerodynamicists study many other issues as well. For example, how does a car behave in conditions of oblique blowing (with a side wind): how stable, controllable, etc. It is also important what forces act on the body in the vertical direction, what moments about the axes they create. At no speed should the lifting force of the body unload the wheels - a car is not an airplane, its task is to move reliably along the road. Therefore, they strive to streamline the air flows from below the car (up to 15% of the total resistance depends on them). You can’t do without aerodynamics when fine-tuning a car in terms of efficiency, when choosing transmission gear ratios, and so on. Science also does not shy away from minor issues such as the correct operation of wipers, rational drainage of rainwater, reducing noise from racks, seals, etc. The list of tasks can be continued.

Rice. 1. The drag area S is the same as the area of projection of the car onto the transverse plane.