The ignition module (IM) of the Niva-Chevrolet car is highly reliable and, most often, provides sparking over many tens of thousands of kilometers. However, if it fails, it is difficult to diagnose due to the lack of obvious signs. The decent cost of a module does not always allow it to be replaced with a new one, which is called “blindly”. First you need to reliably verify that the old one is faulty. Read the article about how to check the ignition module of a Niva-Chevrolet.

Check procedure

First you need to check all the contacts, both those suitable for the block and the high-voltage wires going to the spark plugs. To do this, simply disconnect the wires several times and reconnect them. If this does not bring positive results, you need to move on to the next steps.

To do this, they usually use a multimeter connected to contacts D and the second one connected to ground. The device itself is switched to 20 volt mode. In this case, the readings on it should be 12 volts. Then, using the same scheme, check contact C in ohmmeter mode. The reading should be less than 1 ohm.

Contacts A and B are checked in voltmeter mode. Their readings should not exceed 0.3 Volts. If at least one of these indicators is outside the normal range, you need to look for problems in the coil.

If you find damage to the soldering of the contacts, you can try to fix them yourself using a soldering iron. If the coil is damaged, the ignition module must be replaced.

Chevrolet Niva ignition module

After traveling through fords, another problem appeared: the engine was not running smoothly.

I changed the spark plugs and armor wires, but nothing helped. There was an assumption that the ignition module was to blame, and the contacts on it where the armor wires enter were all covered with blue powder. Clearly traces of water. My Chevrolet Niva is old, but it’s clear that the ignition module has never been changed. In the process of searching for a replacement, I looked through a lot of information. The ignition modules that came in cars from the factory lasted for a long time, more than 100 thousand km, but after replacing them, problems began. New modules traveled at most 10 thousand km, and sometimes they did not even travel 1000 km. The reason is that the Chevrolet Niva ignition module is sensitive to high temperatures, and it is mounted on the engine, where the temperature is always high. As a way out, people began to move it, for example, to the wing so that it would not get so hot. And this helped, but another problem appeared - low-quality spare parts. On the forum of Chevy Niv owners, somewhere I even came across a list of ignition modules from different manufacturers, where statistics were given on how long they last.

This problem is relevant not only for the Chevrolet Niva, but also for the VAZ 2112. Because before 2006, the Chevrolet Niva was equipped with an ignition module from the VAZ 2112, after 2006 from the VAZ 2111. The difference between them is that the ignition module from the VAZ 2112 is “smart” ”, i.e. It itself controls the process of supplying a spark, and from the VAZ 2111 this process is controlled by a computer and the module itself is essentially just ignition coils.

Naturally, I had a desire to change my module to a more reliable one from a VAZ 2111, but to do this, at a minimum, I would have to change the computer from Bosch 7.0 to Bosch 7.9.7, the latter has ignition control. This is all expensive and there is a cheaper solution from craftsmen.

On the Internet I came across a description of the “God’s Spark” system; it allows you to connect a reliable ignition module from a VAZ 2111 to a VAZ 2112 and Chevrolet Niva up to 2006. God's spark consists of an adapter cable and two modified controllers from the VAZ 2108. I didn’t quite understand why they needed to be modified, the only thing in the description was that with unfinished controllers there would be problems with ignition, which would be especially noticeable on turbocharged cars.

I ordered the “God's Spark” system before the New Year, but Russian Post took several weeks to deliver. And finally, after standing in line for a couple of hours, I got it. I bought an ignition module from a VAZ 2111 for it, a bracket for attaching it and a corner for attaching controllers.

Installation in the cold took several hours. I removed the old ignition module, its bracket and installed a new one. They are attached completely differently. Therefore, the new one, unlike the old one, is held on by one bolt, and not by three.

I secured the controllers to a corner, which I attached under the air filter mounting bolt. Having previously cleaned the metal, since the controllers require a good ground, just in case, I threw a separate ground wire to the battery. After that I connected everything and started checking.

Firstly, the car started up faster, and secondly, it began to pick up speed faster. Apparently the old ignition module was indeed faulty. By the way, I will carry it in the trunk, and I will attach the old bracket back, so if something happens to God’s spark, I can temporarily switch to it.

Ignition order for VAZ 2123 injector

1.4.

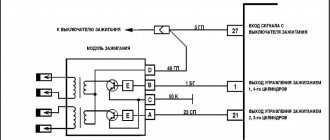

Chevrolet Niva engine ignition system (controller M7.9.7) The ignition system (Fig. 1.4-01) uses a 4-lead ignition coil, which is a block of two 2-lead ignition coils. The ignition system has no moving parts and therefore requires no maintenance or adjustment, with the exception of the spark plugs.

The current in the primary windings of the ignition coils is controlled by a controller that uses information about the engine operating mode received from the sensors of the engine control system. To switch the primary windings of the ignition coils, the controller uses two powerful transistor valves (Fig. 1.4-01).

The ignition system uses a spark distribution method called the “idle spark” method. The engine cylinders are combined in pairs 1-4 and 2-3, and sparking occurs simultaneously in two cylinders: in the cylinder in which the compression stroke ends (working spark), and in the cylinder in which the exhaust stroke occurs (idle spark).

Chevrolet Niva engine ignition coil (controller M7.9.7)

The four-terminal ignition coil (Fig. 1.4-02 and 1.4-03) has the following three circuits (see Fig. 1.4-01):

Primary winding power circuit

The vehicle's electrical system voltage is supplied from the ignition switch to contact “15” of the ignition coil.

Circuit of the primary winding of the ignition coil of cylinders 1 and 4, contact “lb”

The controller switches to ground the circuit of the primary winding of the ignition coil, which supplies high voltage to the spark plugs of cylinders 1.4.

Circuit of the primary winding of the ignition coil of cylinders 2 and 3, contact “1a”

The controller switches to ground the circuit of the primary winding of the ignition coil, which supplies high voltage to the spark plugs of cylinders 2 and 3.

If any element of the 4-terminal ignition coil malfunctions, the entire assembly must be replaced.

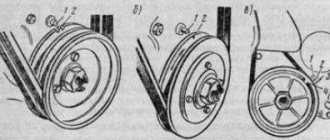

Removing the ignition coil 1. Turn off the ignition.

2. Disconnect the wiring harness block from the ignition coil.

3. Disconnect the high-voltage wiring harness.

4. Remove the ignition coil by unscrewing the mounting bolts.

ATTENTION. Dismantling of high-voltage wires should only be done using the protective cap.

Installing the ignition coil

1. Install the ignition coil on the bracket on the engine and secure with bolts, tightening to a torque of 9.6. 15.4 N • m.

2. Connect the spark plug wires.

3. Connect the high-voltage wire harness to the coil leads and spark plugs.

Dampening detonation of a Chevrolet Niva engine (controller M7.9.7)

To prevent damage to internal engine parts due to prolonged detonation, the ECM adjusts the ignition timing.

To detect detonation, the system is equipped with a knock sensor, see section 1.1.

The controller analyzes the signal from this sensor and, when detonation is detected, which is characterized by an increase in the amplitude of engine vibrations in a certain frequency range, it adjusts the ignition timing using a special algorithm*

Adjustment of the ignition timing to dampen detonation is carried out individually for the cylinders, i.e. it is determined in which cylinder detonation occurs, and the ignition timing is reduced only for this cylinder*

In the event of a malfunction of the knock sensor, the corresponding malfunction code is entered into the controller’s memory and the malfunction indicator turns on* In addition, the controller, depending on the engine operating mode, sets a reduced ignition timing, which eliminates the occurrence of detonation.

Source

Description of the camshaft sensor on Niva Chevrolet

Where is it located: in engines with a gasoline power system, the DPRV is installed on the camshaft pulley. In an engine with a diesel power system, the control system is somewhat different. Where the upper and lower position of the piston in each cylinder is fixed.

On engines with a carburetor fuel system, the role of the DPRV is played by the distributor. The design of the injector is different, the system was parallelized, injection and ignition were done in pairs.

During systematic operation, the household equipment wears out and becomes unusable. The process of self-replacement is not at all difficult. The task is feasible for a car enthusiast without technical equipment maintenance skills.

To determine which cylinder is on stroke, the electronic engine control unit controls the position of the camshaft using DPRV (SMR)

Data from the sensor is extremely important for setting and dosing fuel, sparks in the combustion chamber, and injectors. The camshaft sensor directly affects fuel consumption, acceleration dynamics, and the amount of emissions in the exhaust gases.

In cars, including Niva Chevrolet, magnetic and Hall effect sensors are preinstalled. Both types are designed to read and transmit data to the electronic engine control unit.

The latter, based on the analysis of indicators, adjusts the fuel supply, ignition timing, and spark frequency.

- The magnetic controller produces its own alternating current. The design has two contacts;

- The Hall effect controller has one contact, powered from a third-party source.

Signs of DPRV malfunction:

- Unstable engine operation at idle speed;

- After stopping, the engine starts again;

- Increased fuel consumption;

- Power reduction;

- Passive acceleration dynamics;

- On the dashboard there are system error indicators (see photo);

- The gearbox can be locked in one position until it comes to a complete stop and the ignition is turned off. Single or cyclic action;

- The car moves jerkily;

- The maximum speed of the car is limited to 65 – 85 km/h;

- Periodically the engine stalls;

- Misfires when turning on the ignition;

- Inability to restart the engine.

Frequent causes of premature wear of the controller:

- Natural factor due to long-term use;

- Mechanical damage to the controller housing;

- Open circuit;

- Short circuit of contacts;

- Sensor breakage due to impact, accident;

- Malfunctions of the electronic engine control unit.

| Name / catalog article | Price in rubles |

| Automega 150097810 | From 800 |

| JP group 1191400200 | From 800 |

| EPS 1953071 | From 800 |

| Delphi SS10814 | From 800 |

| Meyle 3148000038 | From 800 |

Also interesting: Review of standard Niva Chevrolet alarm system Preparatory stage:

- Key to "10";

- New controller;

- Rags;

- Phillips screwdriver;

- Additional lighting is optional.

Step by step guide:

- Open the hood;

- We release the metal clamp - the tie from the rubber pipe of the air duct. We extract it;

- At the top of the block we find the controller, remove the terminals, unscrew the bolt to “10”;

- We remove the sensor and replace it with a new one;

- We put on the terminals and install the air duct pipe.

The controller replacement is complete. We start the engine and check the serviceability of the equipment.

What to look for when purchasing

The spark plug design is not the only parameter that you should pay attention to when choosing such parts. Two more characteristics are important:

- overall dimensions of the candle;

- heat number.

As for the sizes, everything is simple here: a candle that is too small will simply fall into the candle well, while a large one will not fit into it. To accurately determine which spark plugs are suitable for your car, it is worth studying the recommendations from the car manufacturer. Most often, this information is in the car manual; you can also clarify this issue with the dealer or on the forums of a specific brand and model.

You can also easily find spark plug interchangeability tables

. They contain all the dimensional parameters of the candle, and there are many of them:

- thread size on the spark plug body;

- type of installation of the spark plug in the cylinder head (flat supporting surface or cone-shaped);

- wrench size (16.0 mm hexagon size, 19 mm, etc.);

- thread length on the spark plug body.

In order not to remember countless numbers and designations, it is enough to find the very interchangeability table or configurator, where you just need to enter the car make/model/engine type, and you will immediately be offered all the suitable options from all well-known manufacturers.

an important selection criterion, illustrating compression at which uncontrolled ignition occurs. Each brand has its own standards and scales for candle heat ratings. If you ignore this indicator, you can bring the engine to glow ignition

— uncontrolled combustion of fuel, provoked not by a spark, but by contact of the fuel mixture with hot engine parts or carbon deposits.

It is impossible to determine what heat rating is needed for your engine by eye - this is done by the manufacturer at the factory. The candle is marked accordingly. It illustrates the maximum permitted temperature load of the spark plug, its resistance to glow ignition and overheating.

This marking cannot be ignored, since it is almost impossible to determine by ear the line between normal ignition and glow ignition. But if the transition has taken place, the overheated pistons are destroyed in a matter of minutes, and the engine is sent for repair. Too low a temperature also has negative consequences on the engine - in this case, carbon deposits increase and engine power decreases.

New ignition module

The ignition module is a new model, as I said above, from Bosch, although unlike the flow meter that is produced in Germany, this product is made in Brazil. But Bosch, he’s Bosch in Africa too))) What did the people of Nivovodsk notice after installing these ignition modules?

- The central contacts for the spark plug wires are made a little thicker than in the Russian version and the high-voltage wires fit very tightly.

- After installation, starting is easier after cold nights and the “reception” of the engine while driving is slightly improved.

- According to their adaptation, the results are as follows. It breaks through a gap of up to 2 cm with a spark. The domestic product takes the bar to only 1 cm, after which the engine already starts running on 3 cylinders.

I classified the ignition module in the “children’s tuning” section, although by and large, it is just an ordinary high-quality spare part with the characteristics that were included in the “standard” engine.

Frequently asked question: ignition modules are quite similar, how can you determine what is on the car?

Answer: Look at the module input connector. If there are 4 wires coming to it, you have the old version. If there are 3 wires - new.

Common causes of malfunctions

It is rare to encounter a situation where both coils fail at once. The engine can be started even if the module is only partially faulty.

But when the following signs appear, it becomes easier to identify the problem:

- jerking while moving;

- the so-called “triple” of the engine;

- idling with “floating” indicators;

- “working” speed is gained by the engine more slowly than we would like.

However, these problems often appear when other parts of the engine break down. The main thing is to carry out correct diagnostics and figure out how to check the ignition module itself.

Types of breakdowns

The ignition module is highly durable and reliable. But there are problems that arise immediately or after some time during active use.

For example, when the ignition system is used with inappropriate components

It is important to select high-voltage wires depending on the characteristics of specific devices. Malfunctions occur if the voltage is too low or too high

Poor assembly, the use of defective parts and low-quality structures also lead to problems. For this reason, entire systems and other components fail.

First signs of trouble

The signs by which a problem can be identified have already been written about. If two cylinders do not fire at once, the problem is definitely in the ignition module. For example, cylinders 1 and 4, or cylinders 2 and 3 fail. Or misfires are shown in all cylinders during diagnostics.

Main types of faults.

Often the cause of problems with the Niva Chevrolet ignition module are breaks in the second winding, because it is this that generates the high voltage pulse. This mainly happens due to the fault of car owners:

- in case of untimely replacement of failed high-voltage wires

- installing spark plugs that do not match the car model.

- moisture ingress due to improper washing

Also, the cause of burnout may be delamination of the solder due to increased vibration during frequent use of the engine at high speeds or during frequent temperature exposure - engine overheating.

Also, if the integrity of the winding of high-voltage wires is violated, extinguishing occurs due to the secondary winding. The charge finds the nearest exit point and enters the place where the wires are thinnest, leading to their destruction.

Problems with the ignition module can be determined in advance, since two coils do not fail at the same time, so car owners will still have the engine start, but with some difficulties:

- it takes a long time to gain working momentum

- floating idle speed

- excessive engine vibration

- jerking while driving

But these problems may be associated not only with the ignition module, so before replacing it is recommended to check its condition

How to check and identify faults in the ignition coil of a Niva Chevrolet

Let’s try to figure out how to diagnose and identify faults further:

- First of all, you need to disconnect the battery, then remove the plastic casing of the power device from under the hood of the car.

- Having previously studied the order of the wires (if necessary), we turn off the high-voltage ones, disconnecting them from the spark plugs.

- To fully perform the diagnostics, you will need a multimeter (first we measure the resistance of the secondary winding); To do this, the device is connected to high-voltage wires. If the indicators exceed the permissible standards, the coil must be replaced.

- In a similar way, you can check the resistance of the primary winding. The readings should be around 1-2 ohms. When the indicators differ, the coil can be replaced.

When the need arises to change the ignition coil, it is not necessary to immediately go to a service station and pay money for it. You can do this kind of work yourself in your garage without spending too much time on it.

Disconnect the battery and remove the protection from the motor. Having disconnected the high-voltage wires and the block from the output of the coil itself, we unscrew the fixing nuts and dismantle the mechanism. Next, you should pay attention to the brand of the reel. When buying a new one, you need to buy a similar brand. For more convenient installation, you can try removing the holder, which is secured with three screws

The entire installation procedure is performed in reverse order.

The ignition module on the Niva Chevrolet and other domestic cars is nothing more than a pulsed high-voltage supply source. It happens that sometimes these devices break down and require partial repairs or complete replacement. In this article we will analyze in detail how to check this device in order to determine the fact of a possible malfunction.

Video about checking the ignition module:

Moneybox of knowledge

All ignition coils are a step-up transformer (Ruhmkorff coil). That is, constant 12 volts turn into 15,000 volts and higher. When the piston of a certain cylinder approaches TDC, the primary circuit opens and an impulse arises in the secondary winding, which reaches the spark plug through high-voltage wires. In carburetor cars, the “breaker” was a distributor; in injection cars, there were transistor or thyristor switches located in the computer. Now technology has certainly come a long way, but nevertheless, modern reels, like their predecessors, also do not like overheating and vibration. In German literature, I came across a recommendation not to keep the ignition key in the first position for a long time, with the engine not running, because the ignition coil suffers the most (overheating).

Procedure for checking the ignition module on a Chevrolet Niva

Before proceeding with dismantling the module, you need to make sure that the cause of unstable operation is not a simple lack of power contact. To do this, we “move” or turn on and off the connected block of wires several times. If such a procedure does not bring any results, then the functionality should be checked on a dismantled device.

The values on the multimeter are normal.

- When the element is removed, we prepare the multimeter for use and check the integrity and cleanliness of the sockets on the terminals (A, B, C, D - approx.).

- First of all, connect the red probe to contact – D, the second one to ground. We turn the multimeter into voltmeter mode - 20 volts, and if the socket is working, then the readings on the tester should be 12 volts.

- Next, go to contact – C, the second again to ground. We switch the multimeter to the ohmmeter mode and look at the readings of the device, and if it is less than 1 ohm, then the socket is normal.

- We check contacts A and B one by one, but in the same order. We connect the multimeter in voltmeter mode and if the readings do not exceed 0.3 volts, then the device can be considered fully working.

If any measurement shows results that do not meet the standards, then you should look for problems immediately in the coil circuit.

Transferring the ignition module

The ignition module has been moved higher

As already written above, for better operation of the ignition module, it is recommended to move it higher in the engine compartment.

Candle making options:

To increase productivity when creating these products, some technological features are used, which in theory can increase productivity, and as a result, the highest quality fuel combustion:

- Platinum coating. Allows you to increase the service life up to 50 thousand kilometers due to the fact that the surface becomes more resistant to the combustion products of the fuel mixture.

- Multi-contact spark plugs. Typically used in cars that are operated in regions with predominantly low temperatures. Such products make it possible to improve the starting of a cold car in the morning. In summer, it is recommended to replace them with regular ones.

Methods for diagnosing device performance

The simplest method that will help determine the performance of the coil is to replace it with a similar working device. This is possible if there is somewhere to get it. Please note that the module must match the parameters of the device under test. If the engine with a working coil works as before the breakdown, the ignition module is definitely faulty.

The main testing method involves using a multimeter. It consists in determining the resistance of the secondary windings of the coils built into the ignition module. The method is simple and does not require additional skills. The device does not need to be removed for testing. The check is done with the engine turned off.

This is how you check the resistance of the secondary winding with a multimeter

- High-voltage wires are removed from the module sockets.

- The tester switch is set to the 20 kOhm position.

- The multimeter rods are placed in turn in the recesses of the corresponding contact pairs (1 and 4, 2 and 3).

- With an intact secondary winding, the performance in both cases is the same. Normally, the resistance should be about 5.4 kOhm (in some models the indicators differ, which needs to be clarified). If the resistance is much greater, then there is a winding break. The resistance is much lower - a breakdown. The coil is faulty and cannot be repaired.

Fines for crossing the stop line and speeding will no longer bother you!

Spark plug.

On the Niva Chevrolet, the spark plugs are closely related to the previous device. And if they malfunction, all the same problems as described above are possible. Spark plugs fail especially often in winter. This is due to the fact that the car is not used so often and mainly for short trips. Due to the low ambient temperature, the candles do not warm up to the maximum temperature at which they self-clean from carbon deposits.

If problems occur, it is necessary to replace the spark plugs in a timely manner so that this does not affect the performance of other system components. Spark plugs for Chevrolet Niva must be purchased special for eight-valve injection engines

When purchasing, you should pay attention to the gap between the electrodes. It should be no more than 1.5 mm

If this distance is greater, this will affect the duration of the candle.

Varieties

During its production, Shniva was equipped with two types of modules.

- MZ from a VAZ 2112 car. Installed until 2006. It includes a spark control system.

- The module is from a VAZ 2111. It is controlled by signals from the ECU, therefore, in essence, it is a regular ignition coil.

Please note that the modules are not interchangeable. This is due to their different designs. You can determine which ignition module on a Niva-Chevrolet by its appearance. The old one has large dimensions and weight, and most importantly, unlike the new one, there are not three, but four contacts on the primary winding connector. At the same time, the process of checking the Niva-Chevrolet ignition module will be considered using the example of a new module.

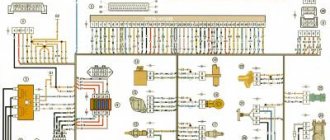

Ignition system harness

The ignition system ensures the formation of a spark in the cylinders according to the power strokes. In modern engines, wires are connected to sensors that monitor ignition, engine temperature and other parameters.

The ignition system harness 2123 (commonly called “braid”) is indicated in blue in the figure.

In the cabin, it connects to the controller (“brains”), instrument panel, ground and wire from the rear harness. Exiting into the engine compartment, it is divided into two wires.

The largest one is directed to the radiator and along the way it is connected to the mass air flow sensor, crankshaft sensor, resistor, and electric fans.

Throwing over the power steering pump, wires extend from the core to the phase sensors, idle speed, throttle valve, detonation and injectors. This wiring controls the operation of the engine and ensures its smooth functioning.

The second wire runs upward and is divided into two: wires go to the right to the plus and minus of the battery, and to the left to the adsorber, fuel pressure sensor and oxygen sensor.

On models with air conditioning, a branch goes from this harness to its fuse.

If at least one wire in the “braid” is short-circuited, there is a big risk that you will not be able to start the engine. The controller simply will not see information about its temperature, fuel supply to the injectors or throttle position.

In this case, it is better to immediately replace the entire harness than to contact a diagnostician, look for one wire and replace it if the result is questionable.

Connecting high voltage wires

The sequence of connecting the high-voltage wires plays a huge role, since the spark in the cylinder is supplied in a certain order, which is indicated by the crankshaft position sensor. As soon as the piston reaches TDC, a spark is supplied to it to ignite the air-fuel mixture.

Below is a diagram of how to connect high-voltage wires on a Niva.

Transferring the ignition module

In order for the ignition module to work better, it is moved to the engine compartment higher than it was originally located.

Before moving and installing additional parts, it is important to ensure that there are no foreign objects nearby. The wires are disconnected from the system only when the ignition is turned off

The main thing is not to touch them with your hands without any additional protection. The same goes for completely disconnecting the batteries when the need arises. Transfers are classified as simple operations.

Installation is carried out in the reverse order compared to dismantling. Bending the standard bracket is the main solution that is used in such situations. Each master decides for himself which way is best to weld the bracket - you can easily achieve the effect when all its parts remain even.

Purpose and design of the part

The purpose of this sensor is one thing - to supply a reliable spark to the combustion chamber of the car through high-voltage wires and a spark plug. To be more precise, the ignition module does not supply a spark, but only the voltage necessary to form a spark on the spark plug.

The design of the part is made of heat-resistant plastic, in which two coils are placed. Each of the coils is responsible for the operation of two cylinders. The coils have a primary and secondary winding in which high voltage is generated.

Module differences

There are two types of ignition modules for Niva. The first type was installed on Niva until 2006, and it migrated to the Lada 4x4 from the VAZ 2112.

VAZ 2112 module

The Niva received a new type of module from the VAZ 2111.

VAZ 2111 module

Visually, these two details are quite difficult to confuse. They differ from each other in weight and dimensions; the weight of the MZ from the VAZ 2112 is much greater than from the VAZ 2111.

Why does the MH break down?

The ignition module fails due to the use of low-quality spark plugs, as well as due to the use of old high-voltage wires whose insulation has lost its properties.

If the MZ gets wet, for example, by driving a Niva along a ford, then the likelihood of it breaking is quite high.

In order for the ignition module to work much longer, it is necessary to change the spark plugs and high-voltage wires on time.

How to check the ignition module, ignition coil and armored wires?!

I change the wires, pray, start it - it starts. No problem, everything is fine. Since I saw oxides inside one old wire, I decided that now the problem was definitely solved. Tomorrow we are planning to go to my mother-in-law's, a kilometer away, so it was still a good idea, what if there were no wires? There is nothing to do, we are taking risks. We leave in the morning, we drove 20 kilometers, everything is fine, I am already relaxed, it’s good that we are still driving through populated areas.

Resistance between the high-voltage terminals of the KILLED ignition module.

In Vakhrushi - again, according to the classics - traction disappears, the car jerks. The likelihood of both breaking down is very high, I hope, of course, to get by with little damage and only change the sensor.

Meters behind me I saw a VAZ auto parts store, I walked there and warmed up. First I take the sensor, it costs rubles. I change things there a little, unscrew a couple of small bolts, pull out the connector and change the sensor. But, damn it, the bolts stuck, one was unscrewed, and the other began to roll, since you can’t really get to it, you need a screwdriver with a flexible shaft type. There is nothing to do - I stupidly broke off the sensor with pliers, only after that I managed to crawl up and unscrew the boiling bolt with pliers.

I change the engine control valve, start it up, and again it’s a dog. Ignition module All hope is that by changing the ignition module, the car will drive and we will still get to mother-in-law Shuruya back to the store and buy an ignition module from MZ, it is not cheap - it costs rubles, domestic. Changing it is quite easy, the MZ is attached to the engine with 3 bolts, and explosive wires go from it to the engine itself.

And also the cause of the malfunction may be a soldering failure; this usually happens due to frequent vibration. Or moisture formed during washing or condensation.

More details about breakdowns Armored wires are marked with arrows. The same high-voltage pulse that occurs on the secondary winding must be fully used, that is, if this does not happen when the integrity of the wire is violated - approx. The first signs of a malfunction As a rule, two coils do not fail at once, therefore, it will still be possible to start the engine even with a partially faulty module. But an experienced car owner should immediately suspect a problem, and it is accompanied by the following: Jerking may be observed while driving.

All of the above reasons can also be observed during other breakdowns, so it is necessary to diagnose it correctly, and for this you need to know how to check the ignition module with your own hands.

Tags: speakers, rear, replacement, Corolla, Toyota

« Previous entry

Ignition system in the field: self-replacement and ignition adjustment

As you know, engine performance is largely determined by the state of operation of the ignition system. Problems in the functioning of the latter can lead to the motor starting to work intermittently. From this material you can learn how to remove the ignition switch on a Niva with your own hands and adjust it, as well as what needs to be taken into account during this process.

Ignition system module for Niva

Before removing the ignition module on a VAZ 21213 carburetor or injector, it is necessary to diagnose the ignition coil, distributor and spark plugs. As practice shows, spark plugs are often the cause of incorrect operation of the internal combustion engine. If you are sure that the problem lies in the fault, then the installed device will need to be changed.

Also interesting: How to open the trunk door on a Chevrolet Niva - Auto repair school

How to replace the Niva ignition switch:

- First, the battery is disconnected and the steering column is removed.

- You need to mark the wires that are connected to the contact part of the VAZ ignition switch and disconnect them. Using a flat-head screwdriver, remove the bolt securing the system switch to the steering column bracket. You will also need to unscrew the screw that is located below, on the right side of the first one.

- Next, on Niva 21213 you need to turn the key to position 0, after which you need to use a screwdriver to slightly recess the device lock through the hole. The hole itself is located on the side of the steering column. Do not touch the exposed key.

- Before removing the ignition switch on the Niva, you need to pull it slightly towards you, after which the device is dismantled. In accordance with the connection diagram, the contact part of the device is replaced; to do this, you need to pry it off with a screwdriver and remove the retaining ring.

- Next, the contact part of the assembly is removed and changed if necessary. During installation, the rotating part must be turned counterclockwise using a screwdriver. Remove the key from the structure and install the contact part so that its wide protrusion can coincide with the wide cavity of the housing. Further assembly of the unit is carried out in reverse order.

1. Unscrew the 3Z mounting bolts. 2. Remove the assembly from its installation location. 3. Remove the contact part and replace it.

Briefly about the design

The main purpose of any MZ is to convert a low-voltage signal into a high voltage sufficient for normal sparking in the cylinders. Therefore, structurally, the Niva-Chevrolet ignition module is a pulse transformer. A signal from the electronic control unit (ECU) is supplied to its input, and a voltage of about 20 - 30 kV is removed from the output. The module has a connector for connecting the low-voltage part and four sockets into which the so-called armored wires are inserted.

High voltage is supplied to two cylinders at once. In this case, 90% of the energy is spent on the formation of a spark where the compression stroke ends. The working mixture in it is under high pressure, which means it has high conductivity. Thus, the module consists of two independent ignition coils.

The principle of operation of the ignition module on a Chevrolet Niva

Ignition modules are structures equipped with both secondary and primary windings. Additionally, there is a commutator, inside which the current switches from one coil to another. The work is carried out from the computer or vehicle control unit. Analysis and collection of information is also performed using the specified blocks. This check gives an accurate result.

The ignition module has four sockets for connecting high-voltage wires. They then move on to the spark plugs.

Varieties

Over the entire period of production of these cars, manufacturers equipped them with two main groups of devices:

- MZ from a VAZ 2112 car. Mounted until 2006. It is equipped with a system responsible for controlling the sparking system.

- The module is from a VAZ 2111. It is controlled by signals from the ECU. In fact, this is an ordinary modern ignition coil.

The indicated modules are not classified as interchangeable parts. Their design is different, so it is impossible to replace one type with another. By appearance it is easy to determine which part is used in a particular case. The old Niva Chevrolet ignition module has increased dimensions and weight.

Module design

Converting low voltage signals to high voltage is the main purpose of any module. It is based on the process of spark formation inside the cylinders. The design of the module is similar to a pulse transformer. The signal from the electronic control unit is supplied to the input of the device. In this case, the voltage is removed from the output to 20-30 kW. This means that each wire works stably.

The module has a connector to connect the low-voltage part and four additional sockets. So-called armored wires are inserted into them.

High voltage is supplied to two cylinders at once. The formation of a spark takes up to 90% of the total energy of the device. The conductivity of the mixture is associated with high pressure, which is maintained on a constant basis. The module has only two independent coils.

Where is the ignition module located?

The part is fixed to the bottom of the cylinder block. For this reason, the ignition module is constantly exposed not only to corrosion, but also to high temperatures. The second factor for this system can be called the most critical. Therefore, owners often move the structure themselves to another place where the conditions are not so problematic.

Where is the Ministry of Health located?

The location of the Niva-Chevrolet ignition module was not chosen very well. It is attached to the bottom of the cylinder block. Thus, the module is exposed to two negative factors at once:

- Corrosion. This is facilitated by the low location. During operation, moisture often gets into the MH.

- High temperature. Mounting the module on the cylinder block forces it to operate at temperatures close to 100 degrees.

The second factor is the most critical for MH. The manufacturer guarantees normal operation of the device up to 120 C°. This kind of temperature under the hood is rare. But constant exposure, even to lower values, significantly reduces the service life of the MH. Therefore, conscientious owners move the module to a place with more benign conditions. Most often, on the partition of the engine compartment.

Door harnesses

There are wires running through the interior that connect to the door wiring. They ensure the operation of power windows, speakers, alarms, heated rear windows, etc. Each line has a socket, thanks to which the door can be easily removed and replaced.

Let's note some features:

- each harness has wires going to the central locking moderator; in more advanced models, the rear doors have wires for the interior lighting and the window regulator;

- the driver's door harness goes to the buttons for the two power windows of yours and the passenger's;

- in the front doors there are wires going to the speakers that are located in them;

- The rear door harness is one of the most complex - it includes wires for the heated glass, wiper and washer gear, rear brake light, central locking and ground wires.

You can see door wiring diagrams in the picture. They all originate from the rear harness, which goes to the taillights.

Niva ignition module, old model

To be really technically precise, it is the old version that is called the ignition module, since it contains transistor switches for opening the primary circuit. Differs in size and mass characteristics. The module has a four-wire connector. The factory spare part was quite reliable, but if it suddenly failed, then it was a pure lottery. Therefore, after suffering a little, I began to install German spare parts on cars. Manufacturer Huco. If my memory serves me correctly, not a single module came for return. Everything fits and is secured in its regular places and mounting plate. Of the alternatives known to me, this is the ignition module from the Daewoo Nexia. But in this case you will have to “collective farm”. The connector is original (after all, original from GM), but you have to make your own mounting plate. But the reviews about reliability were the most positive.

Factors determining the price level

On Chevrolet Niva, ignition modules are sold at different prices. The purchase price of such a spare part is influenced by the following characteristics:

- Technical condition.

- Quality.

- Design features.

- Company manufacturer.

The need for delivery makes the purchase more expensive. The cost also depends on the place where the spare part was purchased, the seller’s pricing policy (availability of discounts), and the need for delivery (which makes the purchase more expensive). In the capital, as a rule, prices for car parts are higher.

BOSCH F 000 ZS0 211, price - 3730 rub.