As the car moves, the unit that is responsible for turning the hub when the steering wheel rotates wears out. Replacing the ball joint of a VAZ 2110 is not particularly difficult. It can be done with your own hands if you have the right tools. Such work should be carried out in a timely manner, because the breakage of a part leads to serious consequences.

How to check a ball joint

For those who do not know what a ball joint is, you need to immediately clarify - this is not an inflatable ball under the seat of some person who is leaning on it, but one of the car suspension elements, made in the form of a steel ring, where One end is a ball and the other is a thread. This is a nuance, but it is important for those who want to know how to check the ball joint in case it is damaged and needs to be replaced. Some novice drivers manage to tell the mechanics at the service center that they recently fell into a hole and their ball joint was torn out, but they still managed to make it to the workshop. Although, any experienced motorist will only smile at such a statement, because if the ball joint is torn out, the car simply will not get anywhere unless it is dragged by a tow truck.

Well, God bless them, the beginners, let’s talk about this automotive element in a little more detail. So, the ball joint connects two fixed suspension elements (the lever and the steering knuckle), making them movable due to its round shape. The action is similar to the operation of any bearing. There are suspensions where there is a multi-link system and two balls are used, but this is not important, because everything is checked in the same way, only twice. The ball assembly is necessary for the car so that the driver can control it while making turns. Simply put, without a ball joint there will be no turns - if the car moves, it will only go in a straight line, until the first obstacle.

Symptoms of “disease” and damage

If while driving and, in particular, during turns, you hear a certain knocking or crunching sound in the lower part of the car, then most likely the ball joint of your car is no longer sealed and deformed. No, it is not completely broken, because you would not be able to turn the steering wheel, but something is not as intended by the designers. For example, the protective boot could be torn off and instead of oil, a decent layer of dirt from sand and dust would form in the assembly. Or, even worse, the ring could crack. In any case, if such noises occur, you need to crawl under the car and carefully inspect everything for any deviations or irregularities, because driving a faulty car is life-threatening.

By the way, for the ball joint to fail, it is not at all necessary to drive your car like crazy over potholes and bumps - a banal entry of dust, water and dirt under the boot is enough for catastrophic destruction to begin in the entire assembly. Then a slight backlash appears and driving a car becomes extremely painful and dangerous, because it can easily jam during a turn, and then disaster will follow.

Trust but check

Checking the ball is carried out in two ways.

Either by eye, visually inspect the safety of the boot and, if there are cracks, tears and other damage on it, replace it with a new one, or drive the car onto a pit, overpass, lift (underline as appropriate), and then mechanically identify possible problems. For the mechanical option, you need to crawl under the car and tug the wheel with your hands to determine the presence of play. You can equip yourself with a pry bar and a crowbar to install the pry bar between the lever and the support, and then try to push it upward. By the way, arming with iron is the best way to check for backlash. There is another option. You need to remove the balls, clamp them in a bench vice, and then check the pin play and axial play. If the finger moves very easily, then replacing the entire ball joint is really necessary. In principle, many experienced drivers have had to deal with similar things more than once. You can check it yourself. Some will even be able to replace it themselves, but for beginners, it is certainly better to go to a workshop where there are all the conditions and experienced mechanics.

Main symptoms of malfunctions

Lada Kalina Universal Logbook Replacing ball joints

1. When the car moves on a straight road, it pulls to the side, as well as deteriorates stability and controllability.

2. Increased wear of the tire is possible on the side of the faulty hinge. As a rule, the inner part of the wheel begins to wear down intensively.

3. A knocking sound may appear when driving over uneven surfaces, moving towards the lower suspension arm.

How to check the condition and serviceability of ball joints yourself.

In order to independently diagnose the condition of the rotary bearings of the steering knuckle, it is enough, first of all, to know their structure and operating principle. Namely, this will allow you to understand all the intricacies of the work.

Methods of diagnostics on your own and without a lift

1. Checking the camber angle. The ball joint of the suspension arm, more than any other part, is responsible for the camber angle of the wheel. If it fails, the wheel will fall to the side. On a completely flat area, if you look at the car from the front, you can see a wheel that is not level. For example: a ball play in a Teflon cage of 1 mm gives a wheel tilt of about 1°, which outwardly looks like a wheel displacement from the vertical of about 1-1.5 cm. Read more about self-adjustment of the camber.

2. Open the hood, put your hand on the stand cup and shake the car vigorously 2-3 times. The appearance of pulsed impacts in the cup will be a “bell” about possible malfunctions in the suspension. (the principle of this method is similar to listening to the rails while waiting for a train)

3. Raise the wheel with a jack until it is free, and place an additional support under the car for safety purposes. Then take the wheel with your hands in the extreme upper and lower parts and rock it in a horizontal plane (with one hand towards you and the other away from you). If you feel play or knocking in the suspension, the ball joint is most likely faulty.

!!! Be careful: wheel play in all planes may be caused by worn hub bearings, but the difference in vibrations in this case should be significantly less.

4. Remove the wheel with the car jacked up. Using a pry bar or a wide flat head screwdriver, place it where the arm attaches to the steering knuckle. Using mechanical action, very carefully check the condition of the play. If there is no play and the boot is in good condition, then the ball joint is in good condition.

Interesting fact

Diagnostics of ball joints is conveniently done at the time of off-season tire changeover, when the car is suspended on jacks; you can check the play in the supports without much effort.

Average life of ball joints

The quality of the road surface and the driving style of the motorist make a big difference in the service life of these supports. Also an important role is played by the height of the rubber profile, which has been repeatedly established. In cars with low profile tires, the service life of ball joints is on average 2-3 times shorter than in cars with medium and high profile tires, and this is mainly due to weak damping of wheels, impacts from road unevenness, which in turn are transmitted to parts and suspension units. The average statistical life of ball joints is considered to be 65-90 thousand km, and on a “low” profile, it is a rare case when it is possible to travel 35 thousand km.

A very important argument I would like to note is the fact that ball joints in the design of a car serve as one of the main safety elements in driving a vehicle. It is strongly recommended that they be diagnosed and repaired in a timely manner, using only proven and high-quality manufacturers.

Symptoms and causes of element wear

While driving, a worn ball joint manifests itself as follows:

- overcoming small bumps at medium or high speed, you will hear a dull knocking sound coming from the front suspension;

- with average wear, a knock may be heard on the steering wheel;

- In heavily worn bearings, the ball begins to wedge, causing a creaking sound when turning the steering wheel.

If you find one of these signs, you should contact a service station for diagnostics or check the functionality of the parts yourself and without a lift. The service life of ball joints on cars made in Russia, China and Korea is in the range of 20-50 thousand km.

Contrary to popular belief, the behavior of a car with worn joints when driving on a flat road changes little. The deviation from a straight line and the lateral abrasion of the rubber are so small that an inexperienced driver will not notice the changes, unless the ball joint becomes completely loose. A clear sign is a distinct knocking sound.

Accelerated wear of joints occurs for the following reasons:

- Driving fast on bad roads. Due to constant shock loads and vibration, the plastic bushings of the elements break and the ball pin begins to dangle.

- Cracks and breakthroughs of anthers. Through them, road dirt gets between the rubbing parts - the ball and the plastic bushing. The latter is inferior in hardness to metal, so it wears out faster.

- Constant overload of the vehicle, causing the supports to experience increased load.

Removing and installing a ball joint on model 2110

Maintenance

Replacing a ball joint begins with preparing the necessary tools: a special puller, a socket or socket wrench for “17” and “19”, a balloon wrench, a mounting blade or a pry bar. Start the repair by checking the ignition is turned off and the condition of the handbrake lever - it must be tightened. For safety, place chocks under the wheels.

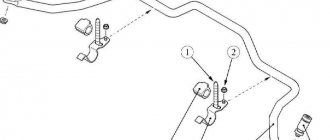

Loosen the wheel bolts on the wheel being repaired. Raise the car using a jack. Remove the wheel. Then, using a “19” wrench, unscrew the ball pin mounting nut, move the steering knuckle to the side, install the puller and uncompress the ball pin. Then use the pry bar to move the suspension arm down. The VAZ ball joint can be easily removed.

If there is no puller, unscrew the ball stud mounting nut only halfway. Then, pulling back the pin bracket with a pry bar, carefully strike the fastening element with a hammer, gradually unpressing the pin. After this, using a key set to “17”, unscrew the fasteners securing the ball joint to the steering knuckle and remove it. These bolts have spring and flat washers, which must also be removed and cleaned.

If you want to finally verify that the unit is faulty, clamp it in a vice to check the radial and axial play of the ball pin. If the finger can be moved fairly easily by hand, the support needs to be replaced. Each VAZ ball joint has a protective cover - boot. Before installation, be sure to clean it from dirt and inspect it. If the protective cover is torn, it must be replaced with a new one.

Before installing the boot, be sure to fill it halfway with lithol or grease. For reliability, seal the installed boot with a special sealant. Bolt the new assembly to the steering knuckle, then, pressing the lower suspension arm down, insert the ball pin into the eye and secure it with a nut. When the Lada is suspended on the jack, do not tighten the nuts and bolts completely.

Remove the car from the jack, rock it from side to side several times with force, then finally tighten: the ball joint nut with a force of 65-95 N.m (6.5-9.5 kgf/m), the bolts securing the ball joint to steering knuckle with a force of 50-65 N.m (5-6.5 kgf/m). After a run of 100 km, it is recommended to check the tightening torque of nuts and bolts.

Let's summarize

To independently replace the supports on the right and left, you will need no more than an hour of time, and the price of replacing a ball at a service station is from 700 to 1200 rubles.

Recently there has been a knocking sound on the right side when driving over bumps, so I took the car into the garage to check the suspension. Verdict - balls need to be replaced. On the left side it still seemed basically alive, but on the right side there was already noticeable play when checking. Well, I decided to wave both at once. The last time the ball joints were changed was after buying the car - and that was about 50 thousand km ago, if I’m not mistaken. I bought new ball joints from Belmag, and they included new fasteners:

On the advice of the seller, I removed the boots to check the amount of lubricant and this is what I saw:

Of course, there is not enough lubricant, so I mixed lithol with the transmission and refilled the balls with this mixture:

To remove the old ball joints, I hung it in front of the car and took off the wheels, unscrewed everything I needed, and then failure awaited me - the old ball joints did not want to come off at all. Neither a hammer nor a puller helped. As a result, he spat and completely removed the levers along with the ball joint - filled it with Vedashka, waited a little and knocked it out with a hammer (they also didn’t fly out the first time, they sat very tightly):

As I diagnosed, the ball joints were already tired - both fingers rotated very freely, on the left there was non-critical play, but on the right it was already strong - even a knock appeared in the hands))

PS After the replacement, the knocking noise disappeared, there is now silence in the suspension, I stretched them again after about 250 km.

At the moment I have driven about 600, everything is fine. Issue price: 700 ₽

Background. I'm driving home from work, listening to music. There are 600 songs on the flash drive, most of which I haven’t even listened to.

And suddenly one song began to put pressure on the brain, a nasty squeak. I switch the song, and whoops - something else beeps! I stop the car, open the hood - nothing beeps.

I sit down and continue driving - there is a squeaking noise from the front on the driver's side. After some googling I realized it was time to change the ball joint. I went to the store, and after 200 meters of movement the squeak disappeared.

To replace, we will need keys for “17” and “19”, and, ideally, also a puller for the ball joint. Unfortunately, I don’t have a puller, so I’ll have to suffer while pressing the rod out.

Slightly loosened pin nut. If anyone manages to knock their finger out of the lever, you're lucky! I didn’t succeed, so I used perversions, namely a jack and a crowbar. We place the jack under the nut, lift the jack, and use a crowbar to help the pin press out.

Old and new ball joint The new ball joint came with bolts and nuts; there were no problems with fastening. We install the new support in reverse order. You will have to struggle a little with installing the support back, but everything can be done alone; with an assistant, everything is done much faster.

None Issue price: 700 ₽

With frequent use of the VAZ 2110-2112 in road conditions that are far from ideal, the ball joints have to be changed almost every 50,000 km. Although, there are many owners who cannot even achieve this mileage on one set of ball joints.

If, after carrying out diagnostics, it turns out that the knocking sound of the front suspension is caused precisely by the wear of the supports, then they need to be replaced with new ones. I’ll say right away that this repair is performed on cars such as VAZ 2110, 2111 and 2112 in completely the same way, so there will be no difference. Moreover, even on the same Priora, the procedure will be the same, since the operating procedure is the same.

In order to perform the procedure for replacing supports with your own hands, we will need the following tool:

- Special ball or tip remover

- Mounting without a puller

- Hammer

- 17 and 19 mm wrenches

- Head 17 preferably

- A wrench or ratchet (an extension cord would help)

Replacing a VAZ 2110 ball joint, lubrication details

Checking the hub for runout

Changing the support on the ten with your own hands is quite simple. Having placed the car on the handbrake and put the gearbox in first gear, tearing off the wheel bolts, the front part is raised with a jack and installed on a stand. The wheel is removed, the pin fastening nut is unscrewed, after which the pin is pressed out of the lever using a puller. You can remove the finger without a puller; in this case, a pry bar and even tapping on the conical part will help. The support is unscrewed from the steering knuckle with two bolts; now you can install a new support, having previously coated it well.

Special attention must be paid to the lubricant, and the recipe for its preparation is special: a quarter of the transmission, a quarter of the lithol, the remaining part is the CV joint. The new support is clamped in a vice, the pin is spilled with the transmission, and after that the required composition is filled into the boot

The consistency should not be too thick, because after 5 thousand km there will be no lubricant left in the joint. If you lubricate every 45-50 thousand, the support will come off for a very long time, regardless of the brand.

We will answer your questions for FREE regarding deprivation of rights, road accidents, insurance compensation, driving into the oncoming lane, etc. Daily from 9.00 to 21.00

Moscow and Moscow region

St. Petersburg and Leningrad region

Free call within Russia 8-800-350-23-69 ext.418

How to check a ball joint yourself

Today, the most widely used suspension system is the MacPherson system. Ball joints are located only in the lower part. We will take this option for consideration.

For vehicles equipped with double wishbone suspension, the same troubleshooting algorithm should be used, with the only difference being that you will have to check not only the lower, but also the upper ball joints.

Sequencing

Checking the ball joints is carried out in the following sequence:

1. A visual inspection of the unit is first performed. Damage to the boot indicates that the part will most likely need to be replaced. To save money, you can try to get by by replacing the boot. But such repairs do not always give the desired result. Dust that gets inside the hinge is detrimental to its design. If no external signs of damage are found, proceed to the next diagnostic step.

2. Using a lift or jack, the car is lifted and a pre-prepared stop is placed under the support body. It is best to use a height-adjustable tripod stand. After this, the car is lowered down a little, creating a load on the ball joint. The wheel should be in the air and rotate freely.

3. Holding the upper and lower edges of the wheel, rock it in a vertical plane

It is best if someone carefully and smoothly turns the steering wheel. The wear can only make itself known at a certain wheel position.

If you discover a backlash, do not rush to conclusions. It can be caused by a failed or loose wheel bearing, damage to the silent blocks of the lever, or other reasons. This is just a reason to move on to the next stage of verification.

4. Inserting the flat end of the mount into the gap between the pivot pin and the lever, press on the handle and observe the parts of the ball joint. If the unit is working properly, there should be no play. Clicking or tapping when pressed, transmitted to the handle of the mount, also indicates a malfunction.

Video - how to check the ball joint and steering ends:

Final diagnosis

To finally make sure that the part has failed, you will have to disassemble the suspension by disconnecting the ball joint from the steering axle. This is done as follows:

the machine is placed on a lift or jack and raised;

the wheel is removed to provide free access to the unit;

the nut securing the support to the axle is unscrewed. There may be some difficulties with this. If the tip does not have a wrench, it may turn along with the nut. You have to insert a pry bar between the lever and the trunnion and, creating pressure, keep the tip from rotating;

Using a special puller, the cone is removed from its seat on the axle.

After the support is removed, its condition is checked by grasping the conical tip and moving it from side to side. The hinge can rotate freely, but if there is no play, this is not a reason to consider the unit to be faulty.

Video - how to check the suspension yourself:

This is especially true for elements made integral with the lever. But if there is even slight play, the unit must be replaced or, in the case of dismountable ball joints, repaired.

Having learned to determine the malfunction of ball joints, the car owner will protect himself from possible breakdowns on the road, and will be able to move on to mastering the next stage of work - replacing failed parts.

Video - replacing a ball joint on a Ford Focus 2:

May be of interest:

Scanner for self-diagnosis of a car

How to quickly get rid of scratches on a car body

How to check a used car before buying

How to apply for an MTPL policy online in 7 minutes

Diagnostics

It is important for the driver to be able to correctly assess the technical condition of the ball joints. There is some complexity here, some of the symptoms may indicate other suspension problems, so it is very important to carefully diagnose.

The first sign is a knocking sound, which is initially observed only when driving over bumps and uneven surfaces. If you do not pay attention to the suspension, then this knock will intensify, which will lead to almost continuous noise. But knocking is far from the most serious indicator; there are a number of signs by which such a problem can be diagnosed.

Another sign of problems with the ball joint is decreased controllability. This occurs due to a decrease in the reliability of the joint between the wheel and the lever. As a result, the wheel becomes less sensitive to steering input, and the driver experiences a slight “yaw” on the road. But, here it is worth remembering that a similar problem can occur with other problems with the steering and chassis.

Also, with high wear of the ball joints, the wheel alignment angles are violated. This leads to a tire problem. They wear out much faster, so if you notice increased wear on the rubber on your wheels

, then it is worth checking the condition of the ball joints.

If there is any suspicion of a ball joint malfunction, it is important to conduct a detailed inspection of the part. Often the problem occurs due to damage to the anthers, in which case the problem will be visible visually. If the boot is damaged, then replacing the part is simply inevitable. If this part has no visual defects, it is worth checking for play

. To do this, we try to move the levers with a pry bar; if the ball joint is working properly, this will not work; if there is visible play, then you should think about repairing the suspension.

Ball joint design 2110

The service life of the suspension of front-wheel drive cars, as in the photo, depends on operating conditions

True, in the VAZ 2110 and other front-wheel drive models the unit no longer has such strategic importance as on the classics, where a loose support could lead to complete destruction of the suspension, and fives and kopecks lying teeth on the asphalt with the wheels turned out were constant attributes of bad roads. You still need to be able to bring the suspension to this state. In both front-wheel drive and classic models, the task of the support is simple - to provide an articulated rotary connection between the knuckle and the upper or lower arm, and the design of the unit has remained virtually unchanged, except for the landing planes.

A ball joint is a cone-shaped pin with a ball or mushroom-shaped end that can rotate and change angle through the range of operation of the suspension. The ball is placed in a plastic liner and pressed on both sides with a metal case with a top and bottom cover. At one time they produced supports with a collapsible body, but later this idea was abandoned. There were too many factors influencing the wear of the support - here was the quality of assembly during repairs, the quality of the liners, and the quality of lubrication. And the unit had quite a strong influence on traffic safety, and besides, it was more profitable to sell the entire support than to just replace the pins and bushings. Therefore, collapsible supports are practically never found. They are all welded, assembled at the factory, and lubricated there with lubricant, which, however, must be added immediately when installing a new part.

Video on replacing a ball joint on VAZ family cars

The quality of the support depends not only on the design. It just doesn't differ in variety. The support can be of only two types - with a metal-ceramic bearing, they are used as lower supports, and a filler one. The latter are installed on the upper arms of the front suspension and work only on compression, so there is little demand for them. And the main load falls on the lower supports with a metal-ceramic plain bearing. Visually, they differ in the shape of the hole for the finger and the shape of the boot, which protects the sliding bearing from dirt and moisture.

Causes of failure

During operation, these supports experience severe loads. Depending on the location of their installation and the design of the suspension, the supports carry most of the total weight of the car, and also withstand constant systematic impacts when driving on uneven roads.

The main reason for the disruption of the correct operation of the ball joint is wear of the contacting surfaces; it leads to an increased gap in the gap from the body to the pin. As a result, the finger begins not only to rotate, but also to dangle in the body.

If the wear is too severe, the loads on the support may cause the pin to break out of the housing. As a consequence of all this, it turns out that the support is not able to hold the wheel, and the car collapses onto the asphalt.

An increase in the gap occurs due to the following factors:

- natural wear and tear combined with obsolete materials,

- dynamic loads increase while driving at high speeds on uneven roads,

- the protective cover or boot breaks, as a result of this, water and all kinds of dirt get into the gap, and they in their time increase corrosion, and even abrasive wear,

- lack of lubricant in the hinge (if necessary).

Here are a few main signs of wear on ball joints:

- When you drive on an uneven road at low speed and you hear a knocking sound.

- If the force on the steering wheel is increased, and when you turn it, you hear a creaking noise from the front of the car.

- Because the front wheels are wobbling, your car is moving unsteadily in a straight line.

- The tires on the wheels are worn unevenly.

Ball joint life 2110

Replacing the VAZ 2110 ball joint, oddly enough, becomes relevant only after 150-200 thousand mileage. Not 15-20, but precisely 150 thousand. That's how long a quality support for ten goes. Another thing is that buying one is not so easy. The supports are falling like leaves in October, and the producers are multiplying. Therefore, choosing a human support becomes increasingly difficult. But it is possible. To do this, you need, without paying attention to the boxes and colored packaging, just carefully examine the support, and the scorched part will show itself.

After 150,000 km on the “ten” you need to think about replacing the ball joint

To buy the right support, you need to conduct a detailed inspection and do several tests right at the point of sale:

- Anther quality. No matter what they say on the packaging, the boot should be rubber, elastic and remain that way for a long time. If it still shows microcracks in the store and its design is primitive, one cannot expect good things from such a support. The boot must have a metal ring filled with rubber on the finger side and a clip for shrinking onto the body.

- The finger must have a high class of machining accuracy and in no case should show traces of machining on a lathe. 80% of all supports have just such fingers, which simply gnaw out the liner after 10 thousand km due to poor quality treatment of the ball surface. The thread on the finger should be rolled, not threaded, the finger itself should be forged, no paint should be used.

- The body must be made of hardened steel halves. The three welding points should be clearly visible, the lower half should be cylindrical, without a cone, and a grease nipple can be screwed into the lid.

- The finger can be turned with difficulty, but must be turned by hand. Moreover, it turns without jerking, evenly. If your finger is standing like a stake, this is not a support that will last long. There is a possibility that it will simply tear out part of the lever.

Once again, we emphasize that the price and brand do not matter, because Tracks and Crafts can be made in a garage around the corner, and the hologram and packaging also say little

Identifying Symptoms of Problems

Replacing the VAZ 2110 ball joint is necessary when the main signs of malfunctions begin to appear.

They are as follows:

- While driving over hilly terrain at low speed, a sound is heard from the front of the vehicle. This is a sign of a malfunction of the ball joint of the VAZ 2110. Perhaps there is no lubrication in it or a large hole has formed.

- If, while moving, the car sways in different directions, this indicates the presence of a large backlash. There is a risk that the wheel will turn out and the car will fall to one side. In this case, the VAZ 2110 ball joint must be replaced as soon as possible.

- If the surface of the tires on a VAZ 2110 wears unevenly, replacing the ball joint can eliminate this problem.

- The need for great effort and the steering wheel squeaks when turning.

How to check a ball joint with your own hands video

A ball joint is available on any car - both front-wheel drive with MacPherson strut suspension and rear-wheel drive. This is a suspension element with which the front wheel hub rotates relative to the body. For example, on old VAZs of the classic series there are two ball joints - on the upper and lower arms. A hub is installed between them, to which the steering rods are attached. The appearance of this part is quite simple - the lower part is made in the form of a thick steel washer with a spherical thickening in the center. The inside of this thickening is hollow, so a tip is placed there during the manufacturing process of the support. On one side it has the shape of a ball, on the other it has a cone and a thread on the edge.

Now try to imagine an unpleasant picture - the ball joint breaks into two parts. What will happen then? Nothing good, since the wheel will not stand strictly vertically, but at an angle to the surface and rest against the body. And if someone suddenly tells you a story that after the ball joint fell apart, he arrived safely at the repair site, then do not believe this person. Only the service of a tow truck or replacing the unit in the field will help. If there is, of course, it is in stock or there is a store with auto parts within sight. But in order to avoid getting into such trouble, it is necessary to monitor the condition of the suspension and promptly identify shortcomings

It is very important to know how to check the ball joint yourself

First signs of breakdown

Exterior view of a car's ball joint

When the car is moving, a slight crunching or light tapping noise is heard - this is the first sign of a malfunction. It is especially noticeable when cornering. Very often, too light a steering wheel or increased play is accompanied by a knocking sound. The main thing is not to confuse it with a broken CV joint, because when the steering wheel is turned all the way at the beginning of movement, they also emit an unpleasant crunch. If you believe the books, then ball joints last forever (provided that they always have lubrication and are operated under normal conditions). Probably, this mode of operation is lying on the counter in a store.

In fact, during operation, the integrity of the anther is compromised. The rubber from which it is made is constantly exposed to dirt and water. Over time, the surface of the boot dries out, it becomes covered with microcracks, which then turn into full-fledged holes. And then small particles fall inside the ball, gradually breaking the metal. As a result, you will hear unpleasant crunching and tapping sounds. In fact, nothing more is needed for the ball to fail; constant exposure to dirt and dust is enough. And the result of such a breakdown is an increase in backlash and the likelihood of jamming. In the latter case, you will not be able to turn the steering wheel, no matter how much force you apply to it.

The initial check of the ball can be carried out practically with bare hands.

Diagnosis of support

There are two verification methods - visual and mechanical. In the first case, only an inspection is sufficient. During this process, you identify cracks and holes on the boot and assess the condition. If there is damage, the rubber boot must be replaced. Only mechanical diagnostics can provide more complete information about the condition of the suspension. To do this you will have to use a pit, a lift or an overpass. First, try to pull the wheel with your hands, holding it by the top and bottom. For a more accurate diagnosis, you will need the help of a pry bar - install it between the hub and the suspension arm. If there is any play, you will feel it immediately.

The consequences of a ball joint failure, especially at speed, can be quite disastrous.

You can remove the hub from the ball joint pin and check the play. If there are problems, then the finger will easily rotate around its axis and from side to side. In this case, it is best to replace it, and do not even think of using old boots on the new part. Replacing and checking the ball joint is simple; no one should have any difficulties. But if you have never encountered such a procedure, then it is better to visit a service station for the first time or ask an experienced friend to help. Look carefully at how this work is done, what tools and devices need to be used. But next time you can do this yourself.

Interesting on the topic:

loading…

Verification methods

How to check a ball joint? In fact, testing is much easier than replacing. So, for diagnostics at home we need:

- Drive the car onto an inspection hole or overpass. A flat surface is possible, but access to the bottom of the car is desirable;

There is another way to check:

Climbing under the front of the car, armed with a caliper or depth gauge, take measurements in the middle of the ball joint between the end of the pin and the hole in the middle of the ball joint.

Replacement

Even a novice car enthusiast can replace the lower ball joint of the front suspension. Let's consider the replacement process using VAZ cars as an example.

Getting ready for work

For work we will need:

- wheel wrench;

- metal brush;

- jack;

- VD-40;

- socket and ring wrenches 13;

- open-end wrench 22;

- sliding pliers;

- ball joint remover.

ATTENTION! A ball joint remover is not cheap, but it greatly simplifies and speeds up the replacement process.

Experts recommend using ball joints, Belmag, Belebey, Kedr, Trek TRS Sport, which are sold complete with or without fasteners. A set with fasteners is more expensive, but it is also more convenient to work with. This kit, in addition to the ball joint, includes a ball stud nut and three bolts with nuts and engravers.

REFERENCE. The upper and lower reinforced ball joints are very similar in appearance. Therefore, manufacturers stamp on them the letters “B” - upper and “H” - lower

Before installation, it is necessary to check the presence of grease under the support boot. If it is not there, add it, but without fanaticism, since excess lubricant can quickly tear the boot.

Progress

We place anti-roll stops under the rear wheels, put the car in gear and the handbrake. Loosen the wheel bolts, lift the car with a jack, finally unscrew the bolts and remove the wheel. We install insurance under the car body; a removed wheel or a wooden block is suitable for this.

If we change the left support, then we twist the steering wheel to the extreme left position, if we change the right support, then to the right. Now we take a metal brush, clean the ball brush and treat it with WD-40 or brake fluid.

We take the 22mm wrench in our hands and unscrew the ball pin nut. Due to the design of the steering knuckle, it will not be possible to completely unscrew the nut. Using VD-40 we process the threads of the ball stud and the nut. Tighten the nut and treat it again with WD-40. We repeat the cycles “unscrewed - poured WD-40 - tightened” until the nut begins to unscrew without effort.

If the replacement is made without a puller for ball joints, then take a soft metal attachment, a sledgehammer and begin to hit the steering knuckle eye with force. As a rule, a few strong blows are enough to loosen the ball joint. If unpressing does not occur, you need to patiently tap the eyelet until the efforts are crowned with success. If you have a puller, dismantling the lower ball joint is greatly simplified and accelerated.

After unpressing the pin, unscrew the fastening nut. If the nut is difficult to unscrew, we use the “Unscrew it, pour it with WD-40, and tighten it.” After the nut is removed, we arm ourselves with 13mm wrenches and unscrew the bolts with which the ball is attached to the lever. We remove the support.

We clean the lower arm from dirt, inspect the place where the support fits on the arm for breaks and cracks. If the lever is damaged, it should be replaced. If everything is in order, then we install a new support, lubricate the finger with lithol, nigrol or motor oil and assemble the parts in the reverse order.

Features of the node

The function of the ball joint is to connect the wheel hub and the suspension arm. Thanks to this design, it is possible to significantly reduce the pressure on the lever when the car is moving. Structurally, this is a ball joint that performs the function of freely articulating suspension parts.

It is worth remembering that the ball joint is filled with lubricant from the inside. It is this moment that allows you to avoid rapid wear of the part. The support is attached to the lever using three bolts; this fastening allows the most optimal placement of the load on the part. The hinge ends with a threaded pin; it is to this that the hub eye is attached.

It is possible to add lubricant to the ball joint housing, this can significantly increase the service life of the part. But this work should be done in advance, without waiting for the active manifestation of the shortage. It is worth remembering that this malfunction can lead to an emergency.

Rules for choosing ball joints

The operational period with which the ball will work is largely influenced by the following parameters:

- part design,

- its manufacturing technology,

- quality of materials used in production.

The issue of choosing high-quality automobile spare parts is always relevant for car owners - repairing a VAZ 2107 using cheap counterfeits is impractical. It is clear that replacing a ball joint requires careful selection of components. When purchasing replacement parts, you will need to check the ball joints. It is clear that first of all you should examine the packaging of the product offered to you and abandon unknown Chinese products in favor of domestic ones. However, you should not limit yourself to studying the packaging - the ball joint should also be carefully considered.

In this case, the main part of the support is considered to be the finger. The best option is considered to be one when the finger is made of high-alloy steel (for example, the specifications for VAZ models provide for 38KhGNM steel in this case). Cold heading followed by heat treatment is recognized as the best manufacturing technology. However, it should be noted that such a technological process is only “possible” for large industrial enterprises with appropriate production capacities. Smaller competitors in this industry use cross-wedge rolling to make pins. This manufacturing method results in less reliable products.

Ideally, replacing ball joints should be done very rarely - a high-quality product can “go through” tens of thousands of kilometers. To ensure this durability, the bearing is coated with a hardening surface layer and the ball pin and housing are hardened. It is clear that, say, it makes no sense to repair a gearbox using components whose quality no one can vouch for. The same applies to ball joints. At the same time, the realities of the modern market are such that there are many unscrupulous sellers on it. The main distinguishing feature of a fake is its price. At the same time, a careful visual inspection of the product will allow you to avoid “running into” a fake. Thus, a finger produced by the cold heading method does not have edges processed by cutting. The color of such a detail is very nondescript, dirty gray and uneven.

Replacing ball joints on a VAZ 2107 - instructions

It is clear that when deciding a number of operational issues - for example, how to replace the front wheel bearing, you must first of all decide on the necessary list of tools and the sequence of actions. As for operations such as replacing the upper ball on a VAZ 2107 and replacing the lower ball, the sequence is as follows:

- a wheel is removed from a car,

- the fastening elements of the ball joint are cleaned of dirt,

- the nut of the upper ball joint pin is loosened,

- the finger is pressed out from the steering knuckle. In this case, you should use a ball joint remover,

- the nut securing the ball pin is unscrewed, after which it is removed,

- loosen the nuts securing the ball joint to the lever,

- the upper ball joint is removed along with the cover and the pressure plate (the sequence of operations is identical for both the upper and lower ball joints),

- replacement parts are installed. First of all, check that there is a sufficient amount of lubricant in the case.

Assembly is carried out in reverse order. Upon completion of assembly work, it is necessary to check the alignment angles of the front wheels.

How to carry out repairs correctly?

To carry out repairs, it is necessary to raise the side of the car being serviced. First hang the wheel, then remove it. After this, place the car on a reliable support - never leave it on a jack alone. The risk of the car falling is very high. Using a 22mm wrench, unscrew the nut that secures the pin. Further replacement of the ball joint on a VAZ-2110 with your own hands will be done very quickly if you have all the necessary tools. Then, using a 17mm wrench, unscrew the two bolts that secure the cage to the hub. Please note that for convenience you can turn the steering wheel to the side.

Now the small matter is small: you need to install a ball puller on the finger. First, tighten its bolt by hand, then tighten it a little with a wrench, holding it by the body. After this, take a 17mm wrench, preferably a ring one. It is more convenient to use one with a long handle. Otherwise, install a small piece of pipe to increase leverage. Tighten the bolt until the pin comes out of the hub. That's all, now the new ball is lubricated and the boot is installed. Installation is carried out in reverse order.