First, let's figure out what the VAZ 2114 corrugation in the air filter is and why it is needed at all. The part is a pipe that is attached to the air filter and is responsible for drawing air into it.

Many motorists drive without it, but this is wrong. In working condition, the corrugation should take in air that passes through the gap between the hood and the radiator; if it is not there, then the air that has already passed through the radiator and cooled it is sucked in.

The temperature of such air is much higher, and as a result, the machine heats up, and its power drops, and if you also turn on the fan, then all the heat will go straight to the filter. If you drive little or it’s winter outside, then the drop in the car’s power will be less noticeable, otherwise even a novice motorist will feel the drop in engine power.

Corrugation VAZ 2114

Reviews (0)

The air filter bellows (air intake hose) are original (factory). Designed for VAZ cars of the tenth family LADA Samara and LADA Samara 2. Installed to replace the one that has become unusable.

Applicability:

- VAZ 2108

- VAZ 2109

- VAZ 21099

- VAZ 2110

- VAZ 2111

- VAZ 2112

- VAZ 2113

- VAZ 2114

- VAZ 2115

First, let's figure out what the VAZ 2114 corrugation in the air filter is and why it is needed at all. The part is a pipe that is attached to the air filter and is responsible for drawing air into it.

Many motorists drive without it, but this is wrong. In working condition, the corrugation should take in air that passes through the gap between the hood and the radiator; if it is not there, then the air that has already passed through the radiator and cooled it is sucked in.

The temperature of such air is much higher, and as a result, the machine heats up, and its power drops, and if you also turn on the fan, then all the heat will go straight to the filter. If you drive little or it’s winter outside, then the drop in the car’s power will be less noticeable, otherwise even a novice motorist will feel the drop in engine power.

What types of wheel bolts are there?

Let's look at what a VAZ 2109 wheel bolt is.

Standard fasteners have:

- hex head;

- conical clamping part;

- threaded part.

Moreover, the edges of the head turn into a cone. M12 thread with pitch 1.25 and thread length 22 - 24 mm. Thread pitch is a very important parameter. If you forcefully screw in bolts with a different pitch, you can ruin the threads in the hub, and then you will have to change it.

Such hardware is used for wheels with stamped discs. If cast (light alloy) wheels are used, then for the VAZ 2109 the wheel bolt must be longer (27 - 33 mm). Chrome plated with a conical rotating washer is often used. This washer, located under the head, protects the surface of the disc when the bolt is tightened. Its threaded part must completely fit into the hole in the hub, but no more, so that when the wheel rotates, the bolts cannot touch stationary parts.

It is worth emphasizing that you cannot put old stamping hardware on new alloy wheels. In this case, the bolts can easily unscrew under load and the wheel will fall off while driving. I don’t even want to talk about the consequences.

The clamping part of the bolt can be spherical, but it must coincide with the profiles of the holes in the wheel rim to ensure wheel alignment.

Wheel bolts for the VAZ 2109 are made with a hex head for a 17 or 19 wrench. There are also lightweight hardware with a hollow head for a hex key. There are also bolts in which the head has an internal 10-pointed star. These require a non-standard key.

To widen the vehicle track, longer bolts and spacers up to 40 mm are used.

Oil in corrugation

Experienced motorists check the presence of oil in the air filter pleat at least once every 3 months. The problem itself is oil and water collecting in the corrugation.

Water is condensation from passing air, so there is no need to worry about it, but there should be no oil in this pipe under any circumstances. It appears for two reasons: a dirty ventilation system and problems with the piston.

Actually, if you have the second option, then you will know about this not by the presence of oil, but by a host of other more pressing problems of the car, so we will not consider this option and will go straight to repairing the ventilation system.

Installing a cold intake on Lada Granta, Kalina, Priora

Cold Air Intake (CAI) is a system for supplying cold air to the engine intake manifold. Such tuning allows you to slightly increase engine power, reduces the chances of detonation in hot weather, and in some cases it can improve responsiveness to the gas pedal and slightly reduce fuel consumption. Do you know how to make such a modification yourself?

The process of installing a cold intake is shown on Lada Kalina cars. On Lada Granta and Lada Priora, all actions are performed in the same way.

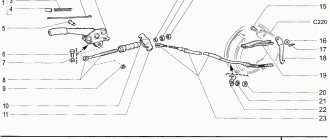

Refinement consists of several stages

:

- Using pipes with a smooth inner surface instead of corrugated pipes.

- Reducing the path to the collector.

- Organizing the intake of cooler air from outside the engine compartment.

Required

: steel inlet pipe, lower coolant pipe from Kamaz (article 54115-1303026), corrugation with a diameter of 70 mm (available in a hardware store).

Interior tuning

External tuning is of course good, but you still need to take care of yourself. Tuning the interior is also huge and great, because the exterior is made for others, and the interior is for yourself. It is necessary to approach modifications to the interior in such a way as not to sacrifice the comfort of the car.

Cases

Stylish covers help you choose any pleasant color for the interior, if you don’t like the standard colors in the Kalina’s interior. The covers also protect the seats quite well from dirt and retain their original appearance much longer.

The cost of good covers starts from 5,000 rubles.

Salon Suite

Luxury Lada cars differ from the norm not only externally, but also in the interior. The luxury version of the viburnum includes heated seats, full power accessories, a touch screen and much more.

To give your car a luxury touch in the interior, you can install heated seats and connect a full electrical package.

The steering wheel is the element most susceptible to aging and in many Lada cars, by 100 thousand km, it already falls into a sad state. To protect it or hide signs of wear, a steering wheel braid is installed.

There is a huge selection of different braids, so choosing steering wheel protection to suit your taste will not be difficult. There are two types of braids: completely covering the steering wheel and partially covering it. The most popular braids are those that partially cover the steering wheel; they are simple and quick to install. But their main drawback is that the steering wheel only partially closes.

The cost of braiding is from 300 rubles.

Currently, braids that completely cover the steering wheel have begun to gain popularity sharply, that is, they are put on around the steering wheel, sewn up with threads and protect it from all sides.

The cost of stitched braiding starts from $5 on AliExpress.

Rugs

If you decide to give your car originality in the interior of the car, then undoubtedly you will have to replace the floor mats in the cabin with more popular and attractive ones.

EVA carpets are very popular rugs. They not only add style to your car, but also help retain moisture, preventing it from getting past the carpet. One EVA mat can hold up to two liters of water.

The cost of carpets is from 2000 rubles.

Side mats

To protect the car from various dirt between the seat and the door, it is recommended to install side mats. They have a special shape and completely cover the fleecy covering of the car, preventing it from getting dirty.

The cost of such rugs starts from 500 rubles.

Improvements at the factory

The manufacturer cannot always make what will actually be effective under different operating conditions. Therefore, car enthusiasts often modify their cars on their own.

Rear shelf

In viburnum, the rear shelf is made of low-quality material, which soon leads to it being skewed. Also, if you install a speaker system in your car, then a standard shelf will not allow you to achieve good sound.

An alternative to all these problems is an acoustic shelf made of thicker materials and covered with carpet.

What drives can be installed

It is clear that any car manufacturer, just like AvtoVAZ, always recommends installing only its original sets of spare parts. But replacing a wheel rim with non-standard samples has long been considered completely commonplace.

Often such a replacement can even improve handling characteristics and reduce financial costs. The wrong approach to this issue can lead to the repair of suspension elements and the entire chassis of the car.

Owners of Grants sometimes notice that the standard set with winter tires copes with its functions worse than the less wide non-standard options. Wide wheels are prone to skidding and hydroplaning.

Regardless of the reasons why the discs are replaced, inexpensive stamped products, cast or forged options can be installed on the Lada Granta. If the stamp is made only of steel, then the material for the production of light alloy wheels can be aluminum, titanium and magnesium alloys.

Stamped wheels, despite their unattractive appearance, are in high demand due to their practicality. Firstly, this is the cheapest replacement option, and secondly, with strong impacts such a product will only bend, which can always be fixed, and the unattractive appearance can be easily hidden with inexpensive plastic caps.

But their high weight reduces the dynamics of vehicle acceleration and increases fuel consumption, which often tips the scales towards the purchase of cast and forged wheels, which, due to their lightness and high thermal conductivity, improve dynamics and contribute to faster cooling of the brake elements. Products made from titanium alloy have the most attractive appearance and have the best strength, but they are also the most expensive of this product segment.

Their aluminum counterparts are more popular. They are not as expensive as titanium, but in terms of strength they meet all safety requirements, and, moreover, they look great. The disadvantages of cast wheels include their worse strength characteristics than stamped steel options and high cost. A strong blow can permanently damage the disk.

TOP products in the store

Lada.Online

- about the project

- ·

- Rules

- ·

- Confidential Policy

- ·

- Contacts

- ·

- mobile version

- ·

- LADA concepts

- ·

Lada (“Lada”) is a brand of cars produced by JSC AVTOVAZ. Previously, it was used only for export cars, and for the domestic market, cars were produced under the Zhiguli brand. In 2004, the management of AVTOVAZ announced the transition to the Latin alphabet for the official spelling of the names of all cars produced by the plant: Lada - instead of "VAZ" and "Lada".

Lada.Online is the largest Russian-language automotive resource with a daily audience of thousands, which is dedicated primarily to cars of this brand, the domestic automotive industry and the automotive world in general.

This site is not the official LADA website.

© 2022 Lada.Online. Copying of material is permitted only with a link to the source.

Types of fasteners

Here are the types of fasteners needed for alloy wheels:

- Bolts are metal rods with a screw thread at the end. Used to connect detachable elements.

- Nuts are round-shaped parts designed to fasten elements by screwing a metal die onto threaded rods.

Steel, aluminum or titanium alloys are used to produce products.

Titanium bolts are distinguished by high quality indicators. Black bolts for alloy wheels are made from steel with the addition of molybdenum or steel with a chrome or nickel coating.

Locking bolts for alloy wheels

Secret bolts for alloy wheels are another subtype. If you install locks, car tires will be protected from theft. You won't be able to remove the wheel with a regular wrench. To unwind the secrets, you will need a key that comes with them in one set.

When selecting fasteners for wheels, you should remember that cast products are relatively thick. Accordingly, longer bolts are selected for them than for stamped discs.

Corrosion protection

For reliable operation of the chassis, everything is important: the bolt pattern, the dimensions of all components, the alignment/camber settings, and even the protection of the arches from corrosion. It is the arches that are more susceptible to adverse factors than other parts of the body - from ordinary moisture during rain to reagents on winter roads

To ensure reliable protection of the arches, it is best to install lockers (fender liners) on the VAZ 2110. Such protection will cost much less than subsequent repairs of rusted arches

It is important to choose the correct size of the lockers and ensure their tight fit in the area of the arches

We hope that by completing all the repair work yourself, you will provide your VAZ 2110 with many years of trouble-free service on the road.

Selection principles

The selection of wheels is made taking into account the design features of the vehicle and operating conditions, assessing the impact of many factors.

A car with 15 rims looks beautiful, but requires the use of low-profile tires, otherwise the tires will rub against the wheel arch protection. Operation in off-road conditions, maximum loading of the trunk with this option is fraught with negative consequences.

Wide wheels with a long offset increase stability, but tend to heavily pollute the car in bad weather conditions. The large curb weight of the car leads to friction between the tires and the fender liners.

Choosing non-standard wheels means replacing car tires. It is necessary to take into account the acceptable tire sizes for the VAZ-2107 recommended by experts:

- diameter 13-15 inches;

- width 165-185 mm;

- tire profile – 55-80%.

Characteristics of bolts and nuts

Bolts and nuts differ in design features, so the choice is determined by the type of disk. The stamped disc is made from a durable type of steel. Moreover, it has a small thickness at the point of attachment to the central part of the rotating part. For an optimal connection, the bolt and nut must have a flat surface. The composition of cast wheels includes relatively light alloys. They have reduced reliability characteristics. The fastening system of the products is made in the form of a cone.

Thread

When purchasing bolts, you should pay attention to the threaded part. Not all elements have the same thread pitch. More often there are hardware with a thread pitch of 1.25 and 1.5 mm with a diameter of 12 or 14 mm. It is recommended to purchase new wheel bolts complete with rims or take into account the requirements of the car manufacturer's instructions.

Thread length

To select a bolt of the required length, the easiest way is to try it on site. This technique does not work if the bolt is coated with a coating that is difficult to scratch. Then another option will do; you will need to count the number of revolutions when unscrewing the old bolt. Next, the length of the threaded pin is divided by the resulting figure. The result will be the required length of the fastener.

By size, fasteners are divided into:

- short - used for fixing stamped disk products;

- long - used for tire mounting of alloy wheels.

Pressing surface

In accordance with the classification by landing zone, fasteners are distinguished:

- with a spherical connecting part;

- with a cone-shaped clamping part. Models are produced with and without gaps in the pressure zone. The size of the headrests is 1.3 millimeters.

Many motorists wonder what would be most suitable - a cone or a sphere. In each individual case, in order to select bolts for alloy wheels, it is recommended to seek help from a professional. He will advise what will be better.

Coating

Bolts and nuts are chrome and zinc plated. The surface layer does not protect against corrosion processes. Models with decorative coating retain their visually attractive appearance for no more than a year. Fasteners with a protective and decorative shell are more expensive.

Tightening fasteners on alloy wheels

Before installing the bolts into the mounting recesses, it is recommended to treat the hardware with graphite lubricant. As a result, when it comes into contact with the disk, the head of the bolt or nut will rotate and make full contact. This will prevent blocking during starting power due to friction between the disc and the mounting system. Bolts are produced that compensate for minimal deviations in fastener dimensions. A loose connection will lead to cyclical failures in the fastening system; the bolts and nuts will begin to unscrew themselves.

Appearance and service life

When choosing, most motorists tend to choose chrome-plated wheel bolts. However, no type of topcoat provides guaranteed protection against corrosion. It all depends on the operating conditions and quality of care. Molybdenum and nickel-plated screws are not inferior in performance.

The only objective advantage is the spectacular and aesthetic appearance of the chrome coating

The service life depends on the strength class, which is recognized as a quality mark. The higher this indicator, the longer the product can be used before corrosion occurs. The existing fittings are produced at Russian, European and Chinese factories. Russian-made mounts are suitable for domestic cars. For Volkswagen and other auto industry giants, you should choose Italian models created specifically for European cars. There are special catalogs for them with a number and article number.

Purchasing bolts for caps can sometimes be the only solution to the problem. For example, deficiencies in PCD readings between holes can be corrected using eccentrics. In addition to the main function, this part plays the role of an accessory that transforms the appearance of the car. To confidently move on the roads, you should determine what type of accessories will suit a particular vehicle.

Are stamping bolts suitable for casting? VAZ Classic.

How to measure yourself

Measurements must be as accurate as possible, since the indicators differ in close values with a distance of a couple of millimeters, for example, 98 and 100 or 110 and 112, and they are not interchangeable. To eliminate errors, it is recommended to use a caliper or ruler.

Adjacent holes

Here's how to determine the distance between bolt holes. The dimensions of the circle on which the holes are located are taken. The diameter is determined using compatibility tables or by measuring using a ruler. The resulting distance between adjacent fasteners should be multiplied by a factor that depends on the number of holes. The circumference of a VAZ is 9.8 cm, and that of passenger cars is 139.7 millimeters.

Yamaha diversion 600 reviews

Pros Excellent ergonomics. Acceptable acceleration dynamics. Good brakes. Excellent handling at all speeds. Small price. Cons Noisy clutch operation. The motorcycle was produced only for European and…

The appearance of the car, among other things, depends on the wheels installed on it. Stylish alloy wheels can transform the simplest and most unprepossessing car, giving it originality. VAZ car owners have access to a wide variety of rims:

For each type you have to buy suitable bolts to securely fix the wheel. These fasteners are made from numerous materials:

- black metals;

- nickel alloys;

- metals with the addition of zinc or chromium;

- alloys with molybdenum, etc.

When choosing wheel bolts, be guided not only by their appearance and strength, but also by their dimensions: length, head type, thread size and pitch.