What temperature sensors are installed on the VAZ 2114

DTOZH is designed to monitor the temperature of antifreeze in the cooling system circuit of the power unit. After receiving data about the current “degree”, the ECU increases (lowers) the speed of the power unit in order to adjust the temperature.

The quality composition of the fuel mixture depends on the accuracy of the DTOZ readings. The service life of the sensor is unlimited, with the exception of mechanical damage or short circuit in the circuit.

Where it is located: the standard installation location is the outer part of the thermostat housing. The base is screwed into the thermostat body. Two power contacts are connected to the upper part for power supply from the on-board network.

- A melting element is installed inside the DTOZh base. As soon as the antifreeze degree reaches “90”, the contacts close and the on-board computer signals an error.

Next, the driver decides on the advisability of stopping the car immediately, carrying out preventive maintenance, or calling a tow truck.

Catalog articles, prices of temperature sensors for VAZ 2114:

Name Catalog item Price in rubles

| DTOZH (original), 8 valves, injector | 2115-3811053 | from 350 |

| DTNV (original) | 2115-3828210 2115-3828210-02 2115-3828210-03 | from 350 – 400 |

Which sensor to choose

Independent automotive industry experts and service workshop specialists are of the opinion that it is better to buy original spare parts or branded analogues. The latter are selected according to codes in special combination programs. The coolant temperature sensor, VAZ 2110–2112 family, has serial number 21120–3851010–00. Sometimes at the end, instead of 00, you can see: 01, 02, 03. This indicates that the device was made at one of the related AvtoVAZ enterprises.

Table 2. Price of the original DTOZH and its foreign analogues

| Manufacturer | Number | Amount, rub. |

| GM AvtoVAZ | 21120–3851010–00 | 250 |

| AvtoVAZ | 21120–3851010–82 | 165 |

| Magneti marelli | 1719 16011 150 | 355 |

| Hella | 6PT 009 107–271 | 735 |

| Eps | 1.830.098 | 1080 |

Sources: autopiter.ru, exist.ru.

Interesting fact. Some owners buy exclusively foreign spare parts for their “tens”. The same shock absorbers, struts, springs, timing belts, electrical equipment and other parts “from there” last much longer.

What signs indicate a sensor malfunction?

Car owners can independently understand that the DTS is starting to work poorly based on the following signs:

- the car fan starts working even if the VAZ-2114 engine has not completely warmed up;

- a fully warmed up engine refuses to work normally;

- fuel consumption increases several times.

Among the most common breakdowns are the following:

- contact with the temperature sensor is lost;

- the connecting contacts break and the protective insulation breaks;

- The cooling fan starts to work intermittently.

Before you start replacing the DTOZh, you need to check its operation and in no case confuse it with the coolant temperature indicator sensor, which quite often happens among car enthusiasts who carry out work without taking into account the recommendations.

Why the temperature arrow goes off scale - the main reasons!

The normal operating temperature of the engine on the instrument panel is 90 degrees. The arrow indicates the red zone of engine overheating. Learn more about the situation when the instrument panel does not show the engine temperature.

You can find out why the malfunction occurred in your garage, and you don’t have to go to a car service center. But to fix the problem, you may need outside help from professionals.

So, let's look at the main reasons why the temperature arrow on the VAZ-2114 dashboard goes up:

- Dashboard diagram.

- Temperature sensor.

- Wiring harness.

- ECU.

Solution methods

The arrow is off the charts!

When the reasons are identified, you can proceed directly to eliminating them and consider the issue in more detail. So, to begin with, it is worth noting that the motorist will need some knowledge of the design features of the car, as well as knowledge of the electrical part.

Dashboard diagram

Dashboard board

The first place to look for a problem is the dashboard. In order to eliminate the malfunction, you will have to dismantle the “tidy” and also disassemble it.

The next step is to find the motor that powers the arrow. There may be two malfunctions here. Which ones exactly:

- Due to a short circuit, the motor winding burned out.

- The wire that is soldered from the motor to the dashboard board has come unsoldered or has come off.

To eliminate this cause, it is necessary to inspect the place and determine the presence of breaks. For complete reliability, it is necessary to ring the contact wires of the motor that close the winding.

Another stage of diagnostics will be the connector that connects to the board . It is necessary to find the contact that is responsible for the temperature indicator and also ring it using a multimeter. If a connection break is detected, it must be repaired.

Attention! If a motorist does not have experience in repairing such components, it is strongly recommended to contact professional auto electricians so as not to cause even more trouble when doing the repairs yourself. They will do everything quickly and efficiently.

temperature sensor

The temperature sensor is checked with a multimeter

If the problem was not hidden in the dashboard, then you need to contact the temperature sensor directly . It is this that serves as an indicator of the engine temperature and transmits data through the computer to the needle. Failure of the product can cause a freezing effect and the needle on the dashboard going off scale.

To determine the functionality of the sensor, it must be dismantled and “ringed” using a multimeter. If it is determined to be “dead”, then it must be replaced.

Wiring harness

Disconnecting the wiring harness from the instrument panel for inspection

If the first two reasons are eliminated, but the problem remains, then you should look for the problem in the wiring harness that goes from the engine to the dashboard. Of course, not all motorists are able to cope with this type of diagnosis, due to ignorance of wire pinout. Therefore, in this case, it is also worth contacting professional auto electricians to find out the causes and repair. Although, the reason here is quite simple and understandable - a wire break or burnout.

ECU

List of ECU errors

It is not often that the problem of the needle leaving its normal position can be caused by an electronic control unit. It is he who sets all the parameters and signals on the dashboard.

To troubleshoot the problem, you need to connect to it and check for errors related to the temperature sensor and cooling system. Thus, a simple reset of errors can lead to normal operation of the device.

Location of temperature sensors

- One of them, DTOZH, is located on the cooling system pipe running from the block head to the thermostat. It sends signals to the computer's electronic control unit so that additional cooling (fan) is turned on in a timely manner. Don't look for it on the radiator; it was located there in previous models. Has two terminals. The DTOZh removed from the car looks like this:

Appearance of DTOZH

- The second sensor is called DTUOZH, it has one terminal and sends a signal to the dashboard in the cabin, where the driver sees the temperature of the coolant (not the engine, as many people mistakenly think). It is located, as can be seen from the first figure, on the engine block under the cooling system pipe. It may have a rubber cap that protects the terminal from moisture. DTUOZH looks like this:

Appearance of DTUOZH

Factors and signals of malfunction

Service center specialists quite often encounter breakdowns of DTOZH. Many of them agree that most devices fail for natural reasons. For example, the internal contacts of the resistor break. Because of this, the ECU receives incorrect parameters, which leads to a system failure.

For example, the main controller considers a hot engine to be cold, so it sends a command to the flow meter (DMVR) to enrich the mixture, that is, reduce the air supply. As a result, the motor begins to “choke” and run rough. In addition to the natural breakdown of the DTOZh, other causes of malfunction may appear:

- The seal of the sensor housing is broken.

- There was a break in the electrical wires.

- The power supply has fallen off.

In these cases, the ECU will warn the owner by turning on the Check Engine signal on the dashboard (check engine). In addition, the driver may experience the following signs of sensor malfunction:

- difficult engine starting;

- floating speed;

- severe detonation;

- loss of power;

- the engine stalls.

The listed symptoms are accompanied by a fantastic increase in fuel consumption and the appearance of dark smoke from the exhaust pipe. So it's time to go to a car service for diagnostics. You can also check the ECU system yourself. To do this, install a special application on your smartphone and buy a Bluetooth adapter for the diagnostic block.

Signs of trouble

Typical symptoms of DTOZ failure are as follows:

- Turning on the fan when the engine is not warmed up;

- A warm engine does not start well;

- Unstable engine speed at idle;

- Unstable engine operation (triggering, lack of traction)

- Gasoline consumption increases;

If the DTUOZH fails, the engine runs stably, without interruptions, but on the dashboard you see that the liquid does not heat up or does not cool down at all. These are all signs of a faulty DTOZH on a VAZ 2114.

Possible reasons

The most common cause of such problems for DTOZH and DTUOZH are:

- Oxidation of terminals (contacts);

- Broken power wire;

- Damage to the sensor itself;

Step-by-step device check

You need to independently check the functionality of the sensor in stages:

- If, when the engine is running, the arrow on the instrument panel rises to the maximum, and the engine is cold, you need to disconnect the connecting contacts from the sensor. If the arrow drops to the minimum mark, the element will have to be replaced.

- Otherwise, if the arrow on the dashboard does not change its position, you just need to inspect the connecting contacts to make sure that a short circuit has not occurred to the vehicle ground.

- If the engine warms up normally, but the needle does not rise from “zero” or continuously changes its position, you should look for the cause of the malfunction in the fuses.

- If upon inspection it turns out that the fuses are functioning normally, you will need to short-circuit the vehicle ground. If the needle rises to the maximum mark, the sensor will have to be changed.

About DTOZh breakdowns

- no contact with the sensor;

- loss of insulation, broken contacts;

- device failure;

- the fan does not work systemically.

- the engine is not even warmed up yet, but the fan is already running;

- a warm engine does not want to work;

- gasoline began to be consumed more.

We recommend: How to repair a driveshaft on a European truck?

Before you check the coolant temperature sensor, remember, the main thing is not to confuse it with the coolant temperature gauge sensor!

DTOZH functions in the ECU system

The injector was replaced by a carburetor, which means the “choke” disappeared from the car. The ECU is now responsible for enriching or depleting the fuel-air mixture. It reads the t°C readings from the temperature sensor and adjusts the supply of gasoline to warm up the internal combustion engine and then operate the car. The DTOZH is also responsible for turning the radiator fan on and off, preventing the coolant from boiling.

Troubleshooting steps

To identify a malfunction, experienced technicians do the following:

- They start checking with fuses, replace the burnt ones, and this can solve the problem;

- Inspection for external damage (melted plastic, insulation, chips)

- Remove the terminal by unfastening the latch and clean the contacts. If the problem is in them, then the operation of the motor will stabilize;

- Check the power circuit with a multimeter; lack of power will mean a wire break;

- Removing and checking the DTOZH;

Replacement

Before repairs, it is necessary to carry out a number of preparatory measures. First, you should choose a level area for the machine. It can be in the garage, it can be outdoors. Secondly, prepare the tool: open-end and ring wrenches (19 mm, 13 mm, 10 mm, 8 mm). You will also need a capacious medical syringe of 100–250 ml, a 15–20 cm dropper tube and a 0.5–1 liter jar (so as not to drain the antifreeze/antifreeze). The sequence of actions is as follows:

- We wait until the engine cools down completely.

- Use a syringe to pump out the coolant from the expansion tank (100–200 ml).

- Unscrew the negative terminal of the battery (10–13 mm wrench).

- Unscrew the air filter housing fasteners (8 mm wrench).

- Carefully tilt the “pan” to the right.

- Disconnect the power supply from the DTOZH.

- We unscrew the sensor (19 mm wrench).

- We clean the landing area from dirt.

- We screw in the new DTOZH.

The assembly must be done in reverse chronology. There is no need to use sealant, since the copper O-ring fits perfectly and seals the connection. Let's start the engine. We check its operation and inspect the repair area for antifreeze leaks. The entire event takes 15–20 minutes.

Removing DTOZH

But checking the coolant temperature sensor on a VAZ 2114 requires removing it from the car. It can be removed simply:

Advice: it’s safer to work on a cool engine to avoid getting burned or scalded.

- Disconnect the terminals from the battery

- Remove the air filter together with the casing; to do this, disconnect the block with the wires and loosen the clamp on the pipe;

- Disconnect the block and loosen the clamp.

- Using a 19 mm socket or wrench, unscrew the bolts securing the housing to the body;

- Unscrew the bolts that secure the housing to the body.

- Disconnect the rubber support from the bracket that is attached to the battery shelf.

- From under the hood lock rod, remove the brackets of two more supports and remove the filter housing along with the air sensor and hose;

- Partially drain the liquid from the cooling system by replacing the container. To make the process happen faster, remove the cap from the radiator or expansion tank;

- Carefully disconnect the connector from the sensor; it has a special latch;

- Use a 21 key to unscrew the sensor;

Self-removal of the sensor

Before removing the DTOZH from the VAZ-2114, you need to dismantle the air filter so that it does not interfere with operation. Next you need to do the following:

- Drain the coolant. You should definitely take into account that you only need to drain antifreeze or antifreeze from a cold engine and before work, prepare a container into which the liquid will be drained. Place the container under the bottom of the radiator, carefully unscrew the drain plug and wait about 15 minutes for the liquid to completely drain.

- The rubber protective layer is carefully removed from the sensor.

- Using a 21 key, the device is unscrewed.

- The meter markings are inspected so that the new sensor can be installed in accordance with the main system.

- A new one is installed in place of a device that has become unusable, taking into account the markings. Before installation, experts recommend applying a high-quality sealant to the threads to prevent leakage of antifreeze or antifreeze.

- Coolant is poured to the required level into the radiator and into the engine cylinder block.

Checking at home

After removal, it remains to make sure that the sensor is faulty. To do this, you need to know how to check the coolant temperature sensor on a VAZ 2114 yourself. It is necessary to measure its resistance in a cold state and after placing it in boiling water:

- The resistance at the terminals of the device unscrewed from the car is about 3500 ohms;

- The resistance, after immersing it in a glass of boiling water, should be below 200 Ohms;

- Getting intermediate values is not so important;

If the readings are very different, then the DTOZH should be replaced. Look at its markings and purchase the same sensor. Then screw it in place of the old one and connect the connector to it. Don't forget to fill the system with antifreeze. Now you know how to check the DTO on a VAZ 2114.

How to check DTOZH

First of all, you need to remember that in order to correctly display the temperature of the coolant, the sensor must be immersed in this liquid. Therefore, regularly check the presence of refrigerant and its level in the system. This is probably the first thing to do if you suspect that this meter is not working properly.

If the level of antifreeze in the cooling system is in perfect order, the contacts may have oxidized or there are other irregularities in the connection of the coolant temperature sensor. You can check its connection yourself. Typically, but not always, this sensor is installed next to the thermostat. In some engines, not only DTOZH. Therefore, check the correct number of sensors and their locations for your vehicle. When you find the coolant temperature sensor and determine that everything is in order with its connection, you need to check the device itself. To do this, the DTOZh must be disassembled, since it must be checked by immersion in a glass of boiling water.

And then take the sensor, dip it in a glass of boiling water and measure the output resistance. In general, there are no common indicators of changes in resistance. Sensors for different machines from different manufacturers will show different differences in resistance. The correct values at certain temperatures specific to your sensor must be found online.

As a result, if the sensor resistance values and the reference values coincide or have a minimal error, the coolant temperature sensor is in good condition. Well, if the resistance values differ, the sensor needs to be replaced. In fact, its design itself, as well as the principle of operation, does not provide for any repairs. Therefore, there are simply no other alternatives.

See also: Signs of a bad knock sensor.

Sensor check

Your VAZ 2114 engine overheats, or other signs of DTOZh failure appear. This suggests that you should check this element first.

There are two verification methods, each of which we will introduce you to.

First method

Removal

- Start the car, look at the dashboard. The gauge is at maximum, but the engine is still cold. Disconnect the contacts from the meter. If after this the arrow falls as far as possible, this indicates the need to replace the coolant temperature sensor on the VAZ 2114.

- If the arrow remains at the top, at the maximum level, take a closer look at the DTOZh contacts. Often they simply short circuit to the vehicle's ground.

- The engine may heat up normally, evenly, but the gauge needle jumps in different directions. Most likely the fuses have failed.

- If the fuses are good, close the contact to ground. If the arrow immediately jumps up, then the temperature sensor has failed.

Method two

- Take a multimeter and turn it on in ohmmeter mode.

- Arm yourself with a thermometer with notches over 100 degrees Celsius.

- Prepare heat-resistant containers that will not deform due to hot coolant.

- Connect the probes of the device to the sensor terminal and the housing.

- Having connected the DTOZH, place it in a container with coolant and begin heating.

- Monitor the ohmmeter and thermometer readings at the same time.

The table shows readings that correspond to a working, serviceable sensor. Using this method, you can check the condition of the new sensor before installing it in place of the old one.

| Temperature, C | Resistance, Ohm |

| 30 | 1350-1880 |

| 50 | 585-820 |

| 70 | 280-390 |

| 90 | 155-196 |

| 110 | 87-109 |

How to remove the coolant temperature gauge sensor?

Before removing the coolant sensor, remove the air filter, it will interfere with its unscrewing. And first of all, drain the antifreeze (antifreeze). We will merge as follows:

- The engine must be cool.

- You will need spanners for 8, 13, 17.

- Prepare a container for the coolant to drain!

- We remove the engine protection, use a wrench to unscrew the radiator mounts

- We set the heater to maximum, then open the heater tap and the cap of the expansion tank.

- We place the container under the radiator and SLOWLY (if you do it quickly, you will flood the generator) unscrew the drain plug.

- Let him run away for about 10 minutes.

- Let's move on to the engine itself: similarly, we place the container under it and unscrew the plug (under the ignition module) on the cylinder block.

- Let it flow again for 10 minutes.

Before closing all the plugs, wipe the neck of each of the holes!

We remember where the coolant temperature sensor is located on the VAZ 2114, and begin to remove it:

- found it, removed the protective rubber layer;

- we look at the body, look for the markings (on one of its 6-sided parts), remember it, so that later we can put everything in accordance with the system;

- unscrew the meter with the twenty-first key;

- install a new one.

How to change the temperature sensor on a VAZ 2114:

- bought a new one;

- Using the same key number 21, we turn the new one into its rightful place;

- remember the markings;

- add a little heat sealant to the threads just to be sure;

- pour coolant (antifreeze or antifreeze) back into the heating system (radiator) and the engine cylinder block.

If the VAZ 2114 coolant temperature sensor still does not work, then carefully check the following:

- Its quality may be defective (take it to the store and ask for a replacement), therefore, always keep the receipt for any spare parts purchase. parts!

- There may be a coolant leak, or perhaps you have splashed the generator after all.

- You just might not have refilled the antifreeze.

- The sensor is not screwed in tightly enough

We checked everything, but the meter still does not show the temperature of the VAZ 2114 engine. Then you should contact a service center. As with any vehicle, everything in the fourteenth is interconnected. The system may fail for a related reason: for example, when you removed the DTOZH, you decided to remove the ignition module so as not to interfere. The decision is correct, however, removing the module and putting it in its place is also an art.

The second point related to the temperature sensor: coolant level. It may be unstable, it may be that the meter for this level (also a sensor) has failed, and so on. Keep an eye on the antifreeze and save your nerves and your coolant temperature meter.

The service will replace the sensor for you and guarantee a high-quality replacement with proper high-quality assembly of all parts in their places. Naturally, you can buy a coolant temperature sensor on the spot, and the cost of replacement work will be twice the cost of the device.

How much a VAZ 2114 coolant temperature sensor costs should be judged based on geographic location: from 80 to 400 rubles in any store that sells auto parts . The pleasure, in principle, is not expensive, but, given the fact of fairly frequent breakdowns (the car stopped being produced in 2013, breakdowns are a natural process), it is still expensive. Therefore, you should not bother with the service, you need to try to figure out the situation yourself. Moreover, now the Internet is saturated with all sorts of useful links, forums, photographs, diagrams and even videos on replacing one or another auto part.

How to replace it yourself

Preparatory stage:

- Open-end wrench set to “19”;

- Rags;

- Additional lighting as needed;

- New "measuring device".

Replacement algorithm:

- We install the VAZ 2114 in the perimeter of the repair area;

- We turn off the engine, open the hood;

- We provide priority safety measures: block the rear row of wheels with wheel chocks, squeeze the parking brake;

- Remove the terminals from the DTOZH, unscrew the sensor with a key;

- We replace the device with a new one, screw it in, and put on the power terminals again.

We turn the key in the ignition, activate it, and check the functionality of the equipment. Add the missing amount of antifreeze as needed.

We recommend: Repair and assembly of VAZ 2105 engine

Sensor operation

Before you familiarize yourself with the technology of how to check the idle speed sensor, oil pressure, temperature and other types of control devices, you need to consider the features of their operation.

The main devices of this type monitor the functioning of the motor and related systems. It is the engine that needs precise control of the operation of its elements and systems. Its failure entails the need for major repairs. To avoid large financial costs, it is recommended to check the functionality of the sensors.

Control devices are responsible for testing the heating level of the system and coolant. They provide measurement of the condition of various components during idling, in normal mode, etc. Every car owner should know how to check the temperature, air, oil pressure and other similar devices.

Replacement instructions

On the VAZ 2114 model, the element we need is installed in the engine block, and not in the radiator block!

To check the coolant temperature thermistor with your own hands, you must first remove it. With model 2114 this is not very difficult to do. To do this you will have to:

- Remove the air filter, because the sensor itself is located on the inlet pipe of the cooling jacket of the cylinder head;

- Remove the negative charge cable from the battery;

- Drain the coolant (coolant) from the radiator. If you have good repair experience, then you can do without this item, but it is recommended for beginners to perform this item;

- Disconnect all contacts. Using a deep socket, unscrew the sensor;

- After this, you can unscrew the sensor. If the bolts are too tight, use a wrench.

Unscrewing the DTOZH should occur carefully and gradually

Where is DTOZH located?

All front-wheel drive VAZ cars received a transverse internal combustion engine. If you look down, between the cylinder head and the air filter housing, you can see the location of the DTOZH. It is built into the coolant flange pipe and looks in the direction of travel, that is, towards the radiator. A block with two wires fits into it. (A little lower, directly in the block, there is another coolant temperature sensor. Thanks to it, we can see the t°C level on the dashboard. 1 white-green wire goes to the device).

The design of the cooling system on the VAZ-2114

Coolant temperature sensor location

Before proceeding directly to the replacement process, it is necessary to understand the design of the cooling system and the location of the sensor in the main power unit:

Everything here is trivial

1 – element in the form of a plug for the expansion tank; 2 – expansion tank; 3 – hose for draining liquid from the pipe; 4 – hose passing between the radiator and the expansion tank; 5 – hose leading from the radiator; 6 – tank to the left of the radiator; 7 – aluminum tube; 8 – plug systems; 9 – tank to the right of the radiator; 10 – drain plug; 11 – middle of the radiator; 12 – casing for electric fan; 13 – plastic wings of the electric fan; 14 – electric motor; 15 – toothed pump pulley; 16 – pump impeller; 17 – camshaft drive belt; 18 – engine block; 19 – pump pipe; 20 – radiator hose with supply function; 21 – heater radiator hose with drain function; 22 – hose supplying coolant to the throttle pipe; 23 – exhaust pipe; 24 – hose for refilling; 25 – heater radiator hose with supply function; 26 – thermostat; 27 – coolant temperature sensor; 28 – coolant level indicator sensor.

The process of replacing the sensor (DTOZH)

As mentioned earlier, the replacement process is too simple and will only take 10-15 minutes.

Therefore, as practice shows, motorists carry out the operation with their own hands. So, let's look at the sequence of actions aimed at replacing the coolant sensor:

- Remove the terminal from the battery.

We dismantle the battery terminal

- Unscrew and remove the air filter. This is necessary in order to ensure maximum access to the sensor.

In order to get to the sensor you need to remove the air filter

- Disconnect the wires that power the element.

- Disconnect the sensor power supply connector

- Coolant temperature sensor with removed chip

- Using a 19 key, we dismantle the product.

- Dismantling of DTOZH

- Using a 19mm wrench, unscrew the sensor.

- Assembly proceeds in reverse order.

Product selection

The choice of product should be approached carefully, since its quality will directly depend on its service life, as well as engine operating modes. So, let's consider all the options for purchasing a coolant temperature sensor for the VAZ-2114.

Original

Original view of the coolant sensor produced by AvtoVAZ

2101-3808600 – original catalog number of the part, which is installed on almost all cars of the Lada family. This product is produced at the AvtoVAZ plant. The cost is 300 rubles. Installed in a standard mounting location and does not require modifications.

Analogs

In addition to the original part, there are a number of analogues that can be installed on a car. Some of them are much better quality than the original.

It was not the original sensor

So, let's consider all the analogue options for the coolant temperature sensor:

Manufacturer's name Catalog number Cost, in rubles

| Fenox | TSN22101 | 210 |

| LUZAR | LS 0101 | 240 |

| Fenox | TSN22101O7 | 240 |

| Vernet | 2509 | 250 |

| Patron | PE13059 | 300 |

| Intermotor | 52400 | 300 |

| Era | 330082 | 350 |

| Facet | 7.3000 | 350 |

| Eps | 1.830.000 | 400 |

| KW | 530.000 | 550 |

| H+B Elparts | 70511515 | 600 |

| Cargo | 180804 | 700 |

| Hella | 6PT 009 107-151 | 750 |

Coolant sensor made by Hella

Consequences of untimely sensor replacement

Not many car enthusiasts know that a malfunction of the coolant temperature sensor affects the operation of the engine as a whole. Let's consider the main consequences of a malfunction of this unit for a car:

- Incorrect operation of the electronic engine control unit . Thus, the sensor does not provide reliable data to the ECU, which in hot weather may not turn on the cooling fan in time. So, in turn, the consequence will be that the car will boil. This can lead to the fact that in the worst case, it can cause deformation and sagging of the head.

- Due to incorrect operation of the sensor, the following functions may be impaired: engine performance, driving dynamics, thermostat operation .

- Other consequences to which the sensor is indirectly linked.

Causes of malfunction

Arrow stuck on dashboard

It’s probably no secret to anyone that the arrows hanging on the dashboard are inextricably linked with the electrical circuits in the car. To troubleshoot the problem, the car enthusiast will need some knowledge of auto electrics, as well as design knowledge of the VAZ-2114.

As practice shows, most motorists, when such a breakdown occurs, turn to a car service center, but this problem can be eliminated on their own. But, first of all, it is necessary to find the immediate cause of the effect.

What are the options?

So, let's look at the possible options for the engine temperature indicator arrow to hang on the dashboard:

- The magnetic motor of the pointer drive is broken.

- Breaks and disturbances in the operation of the electrical circuits of the dashboard.

- Short circuit in the circuit board of the device itself.

- Freeze related to temperature sensor.

- Problems with the ECU.

Elimination methods

Once the root causes have been identified, you can move directly to methods to resolve the problem.

To carry out repair and diagnostic operations, you will need some tools, namely: a multimeter, an OBD II cable, a tablet or laptop, as well as a set of keys and screwdrivers for dismantling the main and auxiliary components.

So, now that the motorist is fully armed, you can proceed directly to the diagnostic and repair process.

The magnetic motor of the arrow drive is broken

The process of repairing and disassembling the dashboard

The most common problem with the arrow hanging or not responding on the instrument panel is a breakdown of the drive motor . To diagnose this device, you need to use a multimeter to close the winding contacts to an electrical circuit or resistance.

If the tester does not show anything, then most likely the winding is burned out or there is a break in contact with the board.

To troubleshoot the problem, of course, it is recommended to contact an auto electrician, who will do everything quickly and efficiently, but if the car enthusiast has the necessary skills and abilities in repairing such equipment, then he will be able to independently replace the motor and solder the necessary contacts.

Breaks and disturbances in the operation of the electrical circuits of the dashboard

Wiring related fault determination

Another common reason for a stuck sensor is a break in the electrical circuit from the coolant sensor to the dashboard . It is quite simple to identify this; you need to remove the ground wire from the sensor and connect it to any other “minus” so that the electrical circuit is closed.

If the wire is not broken, then the arrow will begin to move; if not, then according to the electrical diagram it is necessary to find the wire in which the break occurred and eliminate the fault. As practice shows, motorists do not change the wire, but simply connect and insulate the contacts at the break point.

Short circuit in the board of the device itself

Detection of short circuits on the instrument board

There have been numerous cases when a short circuit in the instrument panel board caused the needle to freeze.

But, in this case, an indirect sign is that nearby signs also fail. So, the tachometer and other indicators may not show. Here, troubleshooting is to replace the instrument panel assembly.

Freeze due to temperature sensor

Temperature sensor location

A frozen temperature arrow on the instrument panel will be associated with a faulty temperature sensor. So, its diagnosis can be carried out by analogy with a wiring break, or checked using a tester. If, as a result of diagnostic operations, it turns out that the coolant sensor is faulty, it must be replaced.

Problems with the computer

The process of identifying ECU errors and eliminating them

It is extremely rare that the needle freezes due to a malfunction in the electronic engine control unit.

In this case, using the appropriate cable, you need to connect to the “brains” of the car and see if there are any errors. If there are too many of them, then you need to reset them.

Of course, if this procedure does not help, then it is recommended to reset the software. It is recommended to trust this procedure to professionals who will not only fix the problem, but also set the motor to optimal operating mode.

Checking the thermistor for functionality

When the result of our work is already in front of us, we can check all the functionality and correctness of the readings. You can do this using:

- Thermometer.

- Containers with water.

- Ohmmeter.

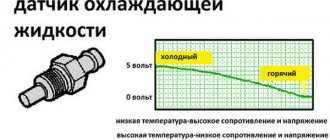

- Tables of heat versus electrical resistance. The operation of the element is based on the principle of measuring resistance depending on temperature.

If the DTO readings of your VAZ 2114 differ from those presented below, then this element must be replaced. After all, it is almost impossible to repair the device. At twenty degrees the electrical resistance should be at 3520 Ohms, at forty degrees - 1459 Ohms, and with boiling water - 177 Ohms. If everything is in order, then the problem may lie somewhere else, like a thermostat.

Why do you need DTOZH?

The coolant temperature sensor, or simply DTOZH, is one of the most important measuring instruments. It is located in the engine compartment and is responsible for measuring the temperature of the coolant (coolant) in the system. As a measuring element, a pointer, a resistor, is installed in a part called a thermistor, which changes the current resistance depending on the engine temperature. This information is needed to configure engine parameters:

- The crankshaft is working.

- Composition of the combustible mixture.

- Warm up the engine quickly when starting.

- Maintains stability in all modes.

Despite the importance of such a device for the VAZ 2114, the principle of its operation is relatively simple. It informs us about changes in coolant temperature and transmits the necessary information to the electronic control unit (ECU).

DTOZH transmits readings to the electronic control unit (ECU), which, using a temperature sensor on the instrument cluster, informs the driver.

Monitoring the temperature indicator on the instrument panel

In order to prevent such a malfunction in advance, it is necessary to monitor the indicator on the instrument panel, because it will be the first to signal a problem, moving the arrow to the red zone. Below we will tell you how to check the coolant temperature sensor on a VAZ-2114 with your own hands.

Where can I find the temperature sensor?

The VAZ-2114 is equipped with a liquid-type engine cooling system, that is, the whole process occurs due to the circulation of antifreeze or antifreeze inside the system.

Pay attention to this article in order to find out what is better antifreeze or antifreeze!

Cooling system VAZ-2114

The entire system includes the following elements: cooling and heating radiator, radiator fan, thermostat, pump (pump - approx.), expansion tank, various pipes and finally, a coolant temperature sensor.

The sensor is easy to find under the hood.

The coolant temperature sensor is located in the area between the cylinder head and the thermostat, that is, on the engine block itself.

Its body has edges (for a wrench - approx.), for the greatest ease of dismantling, and connection is made by connecting a block with two wires.

Design

The design of the sensor can be compared to a conventional resistor, which changes its resistance parameters depending on the degree of engine heating.

Where is the device showing the antifreeze temperature in the VAZ 2114 located?

At the beginning, I would like to remind you of the following: the cooling system itself on cars comes in three types: mixed, air and liquid. In the machine we are interested in, the CO runs on antifreeze, that is, on a liquid product. The whole scheme includes several clearly important components:

- radiator fan;

- radiator for heating the interior;

- radiator for the cooling system;

- CO shirts;

- pump and expansion tank;

- pipes connecting the nodes;

- coolant temperature sensor.

The VAZ 2114 sensor, unlike other VAZ car models, is located on the engine block.

Recommendations for care and maintenance of sensors

- Strictly follow the manufacturer's recommendations regarding vehicle maintenance schedules;

- Buy parts with original catalog numbers. The exact data is indicated in the instruction manual for your technical device;

- When the first signs of engine malfunction appear, contact a service station;

- Do not buy a temperature sensor from other technical means, since the full functionality of the equipment is not guaranteed;

- Carefully compare the catalog numbers on parts and spare parts with the actual markings indicated in the instruction manual.

Major sensor failures

There are not many reasons why the coolant temperature sensor may fail, because due to the simplicity of its design, there is nothing to break there. And if it does break, you should pay attention to the following:

- There is no contact with the sensor - the cause of such a problem can be a simple break, or deformation of the wire due to the effects of corrosion on it.

- The device has failed due to the expiration of its service life.

conclusions

If necessary, it is easy to replace the sensor yourself, because performing such work in a service center will cost much more than the spare part itself.

The average price in most stores is about 200 rubles, and despite the fact that it is small, they fail with enviable frequency, so the issue of choosing a device should be approached with all seriousness and responsibility.

Sources

- https://zapchasti.expert/datchiki/datchik-temperatury/datchik-temperatury-vaz-2114.html

- https://ladaautos.ru/vaz-2114/osnovnye-priznaki-neispravnosti-dtozh-vaz-2114.html

- https://vaz-2114.info/priznaki-neispravnosti-dtozh-na-vaz-2114/

- https://ladafakt.ru/dtozh-vaz-2114-priznaki-neispravnosti.html

- https://luxvaz.ru/vaz-2114/78-datchik-temperatury-ohlazhdayuschey-zhidkosti.html

- https://remontvazov.com/datchik-temperatury-vaz-2114

- https://carfrance.ru/zamena-datchika-temperatury-oxlazhdayushhej-zhidkosti-vaz-2114-svoimi-rukami-naglyadnoe-posobie/

- https://remontvazov.com/datchik-urovnya-ohlazhdayushhey-zhidkosti-vaz-2114

- https://carfrance.ru/kak-proverit-datchik-temperatury-oxlazhdayushhej-zhidkosti/

Symptoms of a problem

If you have problems with the operation of the fan (it turns on when the car is cold), problems with starting a “hot” engine, or too much fuel consumption, then the problem may lie precisely in the DTOZH.

You can easily check the performance of the part yourself by performing simple steps. Before replacing a part, you must first check the fuses. If everything is fine with them and current flows to the sensor, then there is only one diagnosis: replacement of the unit.