Lada Kalina is a budget Russian car. The main element of a car is the engine. The Lada Kalina engine is a completely domestic development. This is an improved power unit from the eighth model of the Lada. He passed the main test of time. The first engine was released back in 1984. True, they were smaller in volume than now.

Engine of the new Lada Kalina 2

Lada Kalina Sport 1.6 Logbook Alternator belt tightening

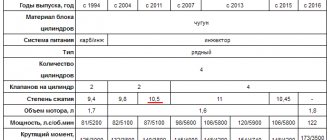

The new Lada Kalina is equipped with three engine versions: 87, 98 and 106 horsepower. All of them have 4 cylinders and a volume of 1.6 liters.

The first engine is the VAZ 21116, which is an improved version of the classic eight-valve engine.

More recently, it acquired a new connecting rod and piston group, as well as several other improvements, which increased power and torque.

This engine is significantly superior to its predecessor 11183-50 and even more so to the G8 engine (21114).

The unfortunate fact is that belt weights remain a welcome feature. It was not returned to this engine due to economic considerations - the Indian Bosch generator is cheaper than the domestic one.

Engine 21116 is installed on basic versions of Kalina together with a manual transmission 2181. The gearbox is essentially a new mechanism, which has retained only a set of gears from its predecessors, and everything else is new or updated

It is important to note that the drive from the lever to the gear selector has become a cable drive (made in Japan). This allows for increased shift clarity

No less important was the fact that reverse gear is engaged again by moving to the right and backwards.

The second engine is a 16-valve VAZ 21126. It is known from Priora and Granta with automatic transmission.

The automatic transmission was inherited by Kalina 2. Despite its archaic nature, this gearbox was liked by many car enthusiasts due to its reliability. It is worth noting that the Jatco gearbox works well in China on the Nissan Micra.

Over time, the Jatco automatic transmission will be calibrated for the latest version of the engine. The new powerful engine 21127 was presented to the public for the first time on Kalina 2. But for now Kalinas are equipped with a 106-horsepower engine only with a manual transmission.

The 27th has one feature - the length of the intake manifold can vary. At low speeds, the air moves to the cylinders along a long path, and when the speed increases, thanks to the actuation of the damper, the air comes from a small part of the receiver.

Due to the fact that air resistance is reduced in this case, greater engine responsiveness is achieved. For domestic automakers, the use of such “resonant supercharging” is a serious step forward. Although it is worth saying that three intake chambers have been used in the world for a long time.

For the first time in the history of the domestic automobile industry, truly high-quality and modern mechanisms are installed on board cars, thanks to which the ride quality reaches a completely new level.

Is it worth buying a Kalina with a VAZ-11183 8 valve engine

Details Category: Test drive Published 06/20/2019

Self-replacement of the Lada Kalina thermostat step-by-step instructions

Today we will share a review from a real owner - is it worth buying a Lada Kalina with an eight-valve 1.6 VAZ-11183 engine.

Today we will share a review from the real owner of a 2012 Lada Kalina car equipped with a VAZ-11183 engine.

The VAZ-11183 engine is the basic and simplest one that was available on first-generation Lada Kalina cars. Nowadays, a lot of such cars are sold on the secondary market, so we decided to publish a review from a real owner - is it worth buying such a car?

Minuses

11183 – 8-valve engine with a volume of 1.6 liters and a power of 82 hp. It is equipped with a distributed injection system. The design of the engine is extremely simple - there are no phase shifters, adjustable intake, etc. There are no hydraulic compensators, so valve adjustment is required periodically (usually once every 30 thousand km). This is one of the disadvantages of this engine - periodically you will have to spend time and money adjusting the valves.

Another disadvantage is the low power - 82 hp. enough for confident driving around the city, but on the highway (especially if there are several people in the cabin), it’s better to plan overtaking well - the dynamics are not enough for quick maneuvers.

Also, as a minus, one can note the significant vibration and noise load of this engine.

pros

Now about the advantages, of which there are also many. Perhaps the most important and main plus is that the VAZ-11183 engine does not bend the valve when the timing belt breaks. Considering the quality of the components, a timing belt break on Kalina is a lottery in which you cannot guess when it will happen. For example, the author of this article broke his timing belt before reaching 60 thousand km. At the same time, not a single valve was damaged - replacing the timing belt along with the roller and work at the nearest car service center cost 2,000 rubles.

The second plus is low transport tax. For example, in Tatarstan, since the engine power is less than 100 hp, the tax is 10 rubles per hp. – 820 rubles per year.

The third plus is efficiency. In city mode, you can easily meet 9 liters per 100/km; on the highway, consumption in cruising mode does not exceed 6 liters.

The fourth plus is maintainability. This engine can be serviced and repaired in almost any village, and many operations can be performed independently (changing oil, filters, spark plugs, etc.).

Conclusion

To summarize, we can say that the Lada Kalina with the VAZ-11183 engine is more suitable for a calm, measured drive. If you need more dynamics, it is better to choose a version with a 16-valve engine. It will be more interesting in motion, but the transport tax will be more expensive, and if the timing belt breaks, repairs can cost a pretty penny.

Summing up

It is quite difficult to unequivocally answer the question which engine is better.

If you are interested in power, quick acceleration and quiet driving, then it is better to choose a 16-valve engine. It consumes less gasoline and does not require valve adjustments.

If low maintenance and unpretentiousness are important to you, then your choice is an 8-valve engine . This option is better suited for those motorists who prefer to maintain and repair their car themselves.

The car is not for everyone, it seems to me that 8-kapans are an ideal option for it, in terms of reliability, at least. And the consumption of the 8 valve is less. This is essentially an engine from the Nine.

If there is high-quality gasoline in your region, then 16 valves are better. If you are far from a normal network gas station, then 8 valves are better. With 16 valves, 95 needs excellent quality, if this is not available, a cracking sound immediately starts from under the hood of Kalina when you press the gas pedal.

Source

Engine malfunctions and repairs 11194

Lada Kalina engine 1.4 16 valves 11194 is a simplified version of the Priora engine and an evolution of the well-known modified, redesigned engine 21083. It differs from the Priora engine in volume, power indicators and torque for the worse. The engine itself is an injector inline 4 cylinder with overhead camshafts, the timing belt has a belt drive. The service life of the 11194 engine, according to the manufacturer's data, has increased, relative to previous AvtoVAZ developments, by 50 thousand and is now 200 thousand km, in practice it is about that. On the technical side, the 194 engine differs from the 126 (Priora) by smaller diameter pistons (it was 82 mm became 76.5 mm), due to this the volume decreased from 1.6 liters. up to 1.4 l. and a slightly smaller combustion chamber, due to these transformations the low-end torque disappeared, the engine only starts at 2000 rpm and for normal movement it needs to be constantly turned, so the conceived idea of an economical engine did not work. In addition, the VAZ 11194 engine bends the valves, the rollers fall apart, the pump gets stuck, the timing belt falls off, and we end up with expensive repairs. In order to avoid problems, every 60 thousand km it is necessary to change the timing belt with a roller and the pump. In addition, this motor can knock and make various sounds, get warm or not warm, the speed can fluctuate, stall, etc. What is the reason and what to do in these cases, see HERE in the “Faults and Repairs” section. At the moment, engine 11194 has been discontinued and is available only for aftermarket use; it is not available on new cars.

Description of main faults

On Kalina, with regard to power units, there are a number of constant malfunctions. Why are they considered permanent? Most likely, this is due to design flaws that the designers cannot correct. So, let's look at which faults are more common than others.

The engine gets hot

The cause of this phenomenon is often the thermostat. As everyone knows, this is a common occurrence on cars produced by AvtoVAZ, starting with the “Classics”. To eliminate the problem, you need to replace the thermostat with a new one. But what to do if the reason is not in it, and the engine was heating up for another reason? It is worth determining why this is so and what the reasons are.

- Temperature sensor malfunction.

- The cooling fan has failed.

- Faulty wiring or electronic engine control unit.

Failure to comply with the temperature regime can lead to engine malfunction, and will also lead to significant malfunctions of the cylinder head and cylinder block. It is worth remembering that the recommended operating temperature of the Kalina engine is 87-103 degrees Celsius.

Bubbling and diesel engine Lada Kalina 1.6 8cl

After purchasing my Kalina two years ago, it was very unusual for me to listen to a strange sound when the engine was running, especially during sub-zero temperatures. I remember all my previous cars, there was no such problem, and so at first I thought that there was something wrong with the car. But when I listened to the sound of the other owners, I realized that all 8-valve engines on the Lada Kalina work this way.

By the way, in the summer this bubbling is not so pronounced and is noticeable only in the first minutes after starting the engine, and even then it is not a very pronounced sound. But in winter you have to listen to diesel quite often, especially in the morning in good frosts, until the engine warms up to at least 50 degrees. Then, gradually these sounds become quieter and when they reach 90 degrees, for me personally, they go away completely!

At one time, this problem was discussed on the Kalina Club forum, but there, in fact, many owners were in a panic, drove their cars to official dealers for service, asked to fix this problem under warranty, etc. But in almost all cases they were told that this is the design of this 1.6 8-valve engine and nothing can be done about it. All you have to do is get used to it, because this obviously doesn’t affect the traction and the other parameters of the power unit either! So why bother yourself with incomprehensible questions and doubts? As they say, don't stop the machine from working!

Although there are also owners who nevertheless decided to get rid of this bubbling and dismantled their engines, some at home in garages, and some in a car service center, I never heard from them later whether they managed to get rid of diesel, or everything remained in place and this strange sound did not disappear anywhere. Maybe there are drivers here who have solved this problem, many are wondering what exactly is the design flaw of this 8-valve engine? I heard an opinion that this strange sound occurs on a cold engine due to the fact that the piston stroke in the 1.6 modification has increased, and accordingly, while the oil is cold, it does not have time to properly lubricate the piston and this grunting occurs! I wonder if these are just assumptions or are there lucky people who managed to get rid of this illness from Kalina? Share your experience!

Lada Kalina 1st generation

Fuel consumption rate per 100 km

In the first two years, AvtoVAZ had to recall a number of cars back to the plant for modification and repair due to a defect in the assembly. This happened three times: due to a defect in the steering column, incorrect casting of the steering housing and a defect in the engine mounts. In the basic configuration, the standard power unit was a 1.6-liter engine producing 81 hp. The maximum speed to which such a car accelerates is 160 km/h, and its consumption is 10.2 liters in the city and 6.6 liters on the highway. Later, a 1.4 89 hp engine was added to it. and 1.6 98 hp The maximum speed of such units is 160 and 183 km/h, respectively. Consumption per 100 km in the city is 9.6-9.7 liters and on the highway 6.3-6.4 liters.

Real gas consumption

- Dmitry, Vologda. Lada (VAZ) Kalina 1.6 MT 2009 When I took the car, of course, I didn’t expect anything supernatural, since I know our auto industry quite well. But I didn’t expect such shortcomings either. During the first thousand kilometers the horn broke. The build quality couldn't be worse. And the consumption is a bit high - 10-11 liters in the city, 7 liters on the highway.

- Sergey, Kursk. I originally bought the car for my mother’s dacha, but later I got behind the wheel. Overall not bad, but too many shortcomings, although roomy. After a month and a half, the doors began to creak terribly. Now the steering rack has already started to act up. The engine is good, its consumption is 8.5 liters per 100 km. Our model is 2007 with a 1.6 MT engine.

- Valery, Moscow. 3 years after the purchase, I can say that Kalina is a good car. Especially with such a configuration for such money (1.4 MT engine, manufactured in 2011). The interior is spacious and the paint job is also good. The only bad thing is that the trunk lid closes tightly, with some effort. Plus, the rubber bands on the doors are bad - they leak when it rains. Consumption in the city is 10 liters, on the highway 6.5-7 liters.

- Alexander, Ufa. Lada Kalina 1.6 MT 2006. The car is good only in terms of engine and spaciousness. Its consumption is average - it consumes up to 7 liters per 100 km on the highway. In the city, in quiet mode, 10-10.5 liters are consumed. In terms of reliability, everything is bad here. In the first six months I stood up on the highway 5 times. I had to pull it on a rope.

- Victor, Samara. I’ve been driving my Lada Kalina I for seven years now (I bought a new one from 2006 with a 1.6 MT engine). During all this time, only the generator and reverse gear broke down. And it didn’t let me down anymore. The engine is good, pulls well. Fuel consumption per hundred is on average 8-9 liters. The bottom is also done well, although the silencer has begun to rot a little. The noise could have been done better.

- Leonid, Chelyabinsk. I like the car in every way. A lot of advantages. Kalina's engine is powerful, and the consumption is low - on the highway at 110 km/h 8 liters, in the city 10 liters (1.4 MT engine, year of manufacture - 2009). The salon and the view from it are excellent. The steering wheel holds well. Disadvantages include poor sound insulation and a battery that broke after six months. They say it was defective.

- Andrey, Tolyatti. Lada (VAZ) Kalina 1.6 MT 2009. On the highway, the Lada behaves with dignity. Plus, I went into the forest and off-road there. In general, cross-country ability is also good. But its consumption is a bit high: in winter in the city it’s 12 liters, on the highway 7-8 liters. The big drawback is the box, which began to make quite a lot of noise. Soon we'll see what the reason is.

- Sergey, Yaroslavl. For the entire time I have owned Lada Kalina I, I have only good impressions. There were no breakdowns, except that the low beam lamps burned out. Consumption is also good. For a hundred kilometers on the highway at 120 km/h no more than 7 liters, taking into account both the air conditioner and the stove. In the city within 9-10 liters. I bought a used one from 2008 with a 1.4 liter engine.

- Nikolay, Kyiv. Lada (VAZ) Kalina 1.4 MT 2012. If we take all VAZ brand cars, then Kalina is the best. I really like the spacious interior and the fact that it has never broken down in three years. The engine is playful, but gluttonous, and eats a lot of oil. Gasoline consumption is also quite high - 10-11 liters in the city and 8 liters on the highway. And it's a cool car.

- Andrey, Stavropol. When choosing a car, I was guided by the price-equipment ratio. As a result, I took the first generation Kalina (2008) with a 1.6 liter engine. Pros - the design and interior of the car, fuel consumption - in the city with traffic jams 10 liters, and on the highway about 6.5 liters. The disadvantages include the box and sound insulation. In addition, after 2 months the interior began to creak.

- Sergey, Kemerovo. Lada (VAZ) Kalina 1.6 MT 2009. I have been driving my car for about 6 years. The first good thing about it is that it is inexpensive, and they will serve you anywhere. The consumption was also impressive, since it does not quite correspond to the official data - 7 liters in the city, 6 liters on the highway. The disadvantages include noise and creaks in the cabin, which indicates poor build quality.

Engine tuning 11194 1.4 16V

City tuning Kalina engine 1.4

The 11194 viburnum engine is not the best choice for tuning; boring the 11194 to 79 mm or 82 mm is fraught with the appearance of shells, and modifying a low-volume engine is ineffective. Installing sports top camshafts with a receiver means squandering the already non-existent low end. The most rational thing to do would be to start tuning by replacing the block with a Priorovsky one and build according to already proven options. But what to do if you want to slightly improve performance without major changes... let's install a 4-2-1 spider straight-through exhaust on our viburnum with 51 pipes or a 4-1 spider ( replacement of the catalyst), simple Nuzhdin 8.7 camshafts (a wider shaft will not work well on a sluggish engine), a 54 or 56 mm throttle body, a receiver and all this is properly configured, this set will provide us with up to 110 hp. at the top, at the bottom the engine will be worse than standard, which is not very convenient in the city. This problem is solved by selecting the main pair and choosing a suitable range of gearboxes. To get even greater output and at the same time tighten up the bottom end, you need to bore the cylinder head channels, install larger valves, etc., but such procedures are a waste of time on an initially non-running engine. In general, despite 16 valves, engine 11194 is unsuitable for tuning.

Compressor for Kalina 1.4 16 valves

Unlike other VAZ engines, the Kalinovsky 194 engine has a high compression ratio and it will not be possible to painlessly install a St. Petersburg compressor on a standard engine. It is necessary to reduce the compression ratio by installing a tuning piston; with such an investment, the return will not live up to expectations.

Engine Kalina turbo 1.4

By analogy with the compressor, we change the piston to a forged one with a reduction in the coolant to 9, Nuzhdin shafts 8.7 or 8.85, install a small turbine like a Garrett 17, a turbo manifold, a Walbro pump for 450 liters/hour, BOSCH 431 injectors with a capacity of 360cc, switch to DBP with DTV, blow-off, 51-pipe exhaust, intercooler and consumables. Approximately 150+ hp we will get it, but the same thing on the prior block will give a greater increase. It's up to you to do it or not.

For this car, the best tuning is to replace the block with a !

ENGINE RATING: 3+

Main characteristics of the Kalina engine

The first engine model that was installed on the Lada Kalina were conventional 8-valve units numbered 11183, with a displacement of 1.6 liters. Engine power was 82 horsepower. 13.5 seconds were enough for him to accelerate the Lada Kalina to 100 km per hour. This engine pulls great, even at low speeds.

During a long climb, the car does not slow down, but continues to pick it up. Fuel consumption is acceptable. At a speed of 80 km per hour it will be 5.5 liters per 100 km. The engine life is about 230,000 km, but looking at the statistical data, you can see that troubles can happen even at 35-45 thousand km.

The second production engine was 11194. The working volume of the power plant was reduced to 1.4 liters. But the number of valves has doubled, to 16 pieces. The engine power of the Lada Kalina has increased and amounted to 90 horses. Due to the reduction in volume, consumption also decreased. At the same 80 km per hour, less than 5 liters of fuel left the tank.

The acceleration dynamics have become much brighter. It took 12.5 seconds to accelerate to hundreds. The engine life has not changed significantly, about 200,000 km. Although there are examples that have traveled 500,000 km without major repairs, this is the exception rather than the rule.

21126 became the third model, with a displacement of 1.6 liters. Number of valves: 16 pieces. At the same time, engine power increased to 98 horsepower. Many owners carried out their own measurements, and the average figures indicated a power of 107 horsepower.

Perhaps this was a deliberate understatement of the specifications by the manufacturer in order to protect the buyer from excessively paying transport tax. It is known that after passing the 100 hp mark. With. transport tax increases 3 times.

Consumption remained at 5 liters per 100 km. And the acceleration dynamics dropped another half a second when accelerating to hundreds. The traction performance has worsened when compared with its 8-valve counterpart. When climbing, you will definitely have to switch to a lower gear. Resource about 250,000 km

Pros and cons of power units of different models of the family

Each Lada Kalina engine has its own immediate advantages and disadvantages. Positive aspects of model 11183:

- a time-tested engine (problems can be fixed at any car service center, spare parts are widely available);

- excellent traction, even when climbing uphill;

- A broken timing belt does not threaten the need to replace pistons and valves.

Negative aspects of model 11183:

- valve adjustment must be carried out with enviable regularity;

- the factory does not install air conditioners on this model;

- noise and vibration (hum, like from a diesel unit).

Motor with serial number 11194

Motor with serial number 11194. Pros:

- silent operation;

- the most economical gasoline consumption;

- there is no need to adjust valves, change oil and filters on schedule;

- good dynamics indicators.

Disadvantages of series 11194 motors:

- after 50,000 km the oil begins to be consumed;

- replacement of valves and pistons when the timing belt breaks (the piston system is quite scarce).

And finally, the last contender. Power unit number 21126. Advantages:

- silent operation;

- the best dynamics, the most powerful engine;

- There is no need to adjust the valves, only routine maintenance.

There is only one drawback: repair of valves and pistons in the event of a broken timing belt. Rarely is there continuity from the 11194 series in excessive oil consumption after 3-4 years of service.

Technical Standards and Troubleshooting

All power units of the Lada Kalina are installed together with a 5-speed manual transmission. For the 8-valve Kalina engine, an oil change is provided after 15,000 km. The timing belt, according to technical documentation, should be replaced every 60,000 km. But in order not to run the risk of replacing the belt in the field, it is recommended to change it every 50,000 miles.

In general, chronic deficiencies do not need to be eliminated, but, as with any mechanism, breakdowns are inevitable. As practice shows, any part can fail. From the cylinder head to the offset of the liners. The 16-valve Kalina engine often has problems with the gearbox. Its technical capabilities reach zero after a mileage of about 100,000 km.

When passing the 25-30 thousand mark

km, special attention should be paid to the clutch disc. More than 60% of owners replace it during this period

If your family budget allows it, then it is best to install an imported analogue. In 95% of cases, it will last much longer than its original VAZ.

If the Lada Kalina was purchased secondhand, then it is necessary to check the entire engine compartment. It is necessary to make sure that the compression is uniform in all cylinders in the Kalina engine. Otherwise, the protection of the power unit may be at risk. The steering rack should also be checked. This is Kalina’s weak point; such a “chronic disease” is inherent in cars produced before 2006.

One of the signals to seriously think about repairs (possibly overhaul) in the Kalina engine is the exponentially increasing oil consumption. This can happen either at 40 or 140 thousand km. More than half a liter of oil per 1000 km is a critical signal.

Be prepared that the cost of repairs may approach 20,000 rubles. The main elements that require replacement and repair may be: the piston camshaft (the clearance may already be critical), the cylinder block (boring will be required). Changing the engine oil yourself will help you save a lot of money. To do this you need to complete 6 steps.

- We warm up the engine to operating temperature, soot and sludge will be better washed out.

- We put the car on the handbrake and determine where the drain plug points.

- Drain the engine oil and replace the oil filter.

- Install a new filter.

- Pour in new oil and check the level.

- We make a test drive and check the level again.

Description of the Kalina engine design

Cross section of the engine : 1 - drain plug; 2 — engine sump; 3 - oil filter; 4 — coolant pump; 5 — catalytic collector; 6 — oxygen concentration sensor; 7 — inlet pipe; 8 — fuel injector; 9 — fuel rail; 10 - receiver; 11 — cylinder head cover; 12 — camshaft bearing cover; 13 - camshaft; 14 — lower crankcase ventilation hose; 15 — valve adjusting washer; 16 - crackers; 17 — pusher; 18 — valve springs; 19 — oil deflector cap; 20 — valve guide; 21 - valve; 22 — spark plug; 23 — cylinder head; 24 - piston; 25 — compression rings; 26 — oil scraper ring; 27 — piston pin; 28 — cylinder block; 29 — connecting rod; 30 - crankshaft; 31 — connecting rod cover; 32 — oil level indicator; 33 - oil receiver.

general description

The VAZ-21114 engine is a gasoline, four-stroke, four-cylinder, in-line, eight-valve, with an overhead camshaft.

Can be used for installation on VAZ Lada Kalina, VAZ 2108, 21083, 2109, 21093, 21099, 2113, 2114, 2115, 2110, 2111, 2112 cars and their modifications.

The cylinder operating order is 1-3-4-2, counting from the crankshaft pulley.

Power system - distributed fuel injection (emission standards Euro-2 or Euro-3).

The engine, gearbox and clutch form the power unit - a single unit mounted in the engine compartment on three elastic rubber-metal supports. The front right support is attached to the bracket on the cylinder block, and the front left and rear ones are attached to the brackets on the gearbox housing. The front right and left supports of the power unit, although externally similar, are not interchangeable.

On the right (along the direction of the car) on the engine there are: a drive for the gas distribution mechanism and a coolant pump (by a toothed belt), a generator drive (by a serpentine belt), an oil pump, and a crankshaft position sensor.

On the left are: thermostat, camshaft position sensor, coolant temperature sensor, coolant temperature indicator sensor, starter (on the clutch housing).

Front: spark plugs and high voltage wires, ignition coil, knock sensor, oil level indicator, lower crankcase ventilation hose, generator.

Rear: receiver with throttle assembly, fuel rail with injectors, intake pipe and catifold, oil filter, oil pressure sensor.

The air filter housing with mass air flow sensor is mounted on brackets to the left of the engine.

Cylinder block

Cast from cast iron, the cylinders are bored directly into the block. The nominal diameter of the cylinder is 82.00 mm with a tolerance of +0.05 mm. The calculated gap between the piston and cylinder (for new parts) should be 0.025-0.045 mm. It is defined as the difference in size between the minimum cylinder diameter and the maximum piston diameter and is ensured by installing a piston of the same class as the cylinder into the cylinder. Depending on the dimensions (diameters) obtained during machining, cylinders and pistons are divided into five classes. The class of each cylinder in accordance with its diameter is marked in Latin letters on the lower plane of the cylinder block:

A - 82.00-82.01 B - 82.01-82.02 C - 82.02-82.03 D - 82.03-82.04 E - 82.04-82.05 (mm).

The maximum permissible cylinder wear is 0.15 mm per diameter. During repairs, the cylinder diameter can be increased by boring by 0.4 or 0.8 mm to accommodate pistons of increased diameter.

Engine (view from the right along the vehicle) : 1 - oil pan; 2 - oil filter; 3 — catalytic collector; 4 — right support bracket of the intake pipe; 5 — coolant pump pipe; 6 — inlet pipe; 7 - receiver; 8 — fuel rail with injectors; 9 — front cover of the gas distribution mechanism drive; 10 — lower crankcase ventilation hose; 11 - generator; 12 — generator drive belt; 13 — tension roller of the generator belt; 14 — bracket for the front right support of the power unit; 15 — generator drive pulley.

At the bottom of the cylinder block there are five crankshaft main bearing supports with removable caps, which are attached to the block with special bolts. The holes in the cylinder block for the bearings are machined with the covers installed, so the covers are not interchangeable and, to distinguish them, are marked with marks on the outer surface, more details here.

On the end surfaces of the middle support of the cylinder block there are slots for thrust half-rings that prevent axial movement of the crankshaft. The half rings must face the grooves (an anti-friction coating is applied to this surface) towards the thrust surfaces of the crankshaft. Half rings are available in nominal and 0.127 mm thicker sizes. If the axial clearance (play) of the crankshaft exceeds 0.35 mm, then replace one or both half rings (nominal clearance 0.06-0.26 mm).

Main and connecting rod bearing shells

Thin-walled steel-aluminium. The upper main bearing shells (installed in the cylinder block) have a groove on the inner surface. The lower main bearing shells are made without a groove, as are the connecting rod bearing shells. Repair liners are produced for crankshaft journals, reduced by 0.25, 0.50, 0.75 and 1.00 mm.

Crankshaft

Made of high-strength cast iron, with five main and four connecting rod journals. The shaft is equipped with eight counterweights cast integrally with it. To supply oil from the main journals to the connecting rods, there are channels whose outlet holes are closed with pressed-in plugs. At the same time, the channels also participate in oil purification: under the influence of centrifugal force, solid particles and resins passing through the filter are thrown back to the plugs. Therefore, during any dismantling of the shaft, it is advisable (and when balancing the shaft, it is mandatory) to clean the channels from accumulated deposits. The plugs cannot be reused - they are replaced with new ones.

At the front end (toe) of the crankshaft, a toothed camshaft drive pulley and a generator drive pulley are installed on a segment key, which simultaneously serves as a damper for torsional vibrations of the crankshaft (due to the elastic element between the central and outer parts of the pulley). The generator drive pulley has a toothed ring for the crankshaft position sensor. Two teeth out of 60 are missing (forming a cavity) - this is necessary for the controller to determine the top dead center (TDC) of the piston of the first cylinder.

At the rear end of the crankshaft, a flywheel is secured with six bolts (the bolts are installed using sealant) through a common washer. It is cast from cast iron and has a pressed steel gear ring, which is used to start the engine with a starter. The flywheel is installed so that the cone-shaped hole located near its crown is opposite the connecting rod journal of the 4th cylinder. This is necessary to determine the TDC of the piston of the first cylinder after engine assembly.

Connecting rods

Steel, I-section, are processed together with covers. To avoid mixing up the caps during assembly, they, like the connecting rods, are marked with the cylinder number (it should be on the same side of the connecting rod and the cap). A steel-bronze bushing is pressed into the upper head of the connecting rod. Based on the diameter of the hole in the bushing for the piston pin, connecting rods are divided into three classes with a pitch of 0.004 mm. The class number is stamped on the connecting rod cover. Also, connecting rods are divided into classes based on weight, which is marked with paint or a letter on the connecting rod cover. All engine connecting rods must be of the same weight class.

Piston pin

Steel, tubular cross-section, floating type (rotates freely in the piston bosses), secured from falling out by two retaining spring rings located in the grooves of the piston bosses. Based on the outer diameter, three classes of fingers are distinguished (every 0.004 mm): 1 - with a blue mark (smallest diameter), 2 - with green, 3 - with red.

Piston

Made of aluminum alloy. The piston skirt has a complex shape: barrel-shaped in the longitudinal section, oval in the transverse section. In the upper part of the piston there are three grooves machined for piston rings. The oil ring groove has drillings that go into the bosses. Through these drillings, the oil collected by the ring from the cylinder walls flows to the piston pin. The hole for the piston pin is offset by 1.2 mm from the center plane of the piston, so when installing it, you must follow the arrow stamped on the bottom: it should be directed towards the generator drive pulley.

Engine (front view along the vehicle) : 1 — bracket for the front right support of the power unit; 2 - generator; 3 — front timing drive cover; 4 — cylinder head cover; 5 — oil level indicator; 6 - receiver; 7 — oil filler cap; 8 — cylinder head plug; 9 — thermostat housing; 10 — thermostat cover; 11 — cylinder head; 12 - flywheel; 13 — ignition coil; 14 — cylinder block; 15 - spark plugs.

Pistons according to their outer diameter (measured in a plane perpendicular to the piston pin, at a distance of 55 mm from the piston bottom), like cylinders, are divided into five classes (markings are on the piston bottom). Piston diameter by class (nominal size):

A - 81.965-81.975 B - 81.975-81.985 C - 81.985-81.995 D - 81.995-82.005 E - 82.005-82.015 (mm).

Spare parts include pistons of classes A, C and E (nominal and repair sizes), which is quite sufficient for selecting a piston to a cylinder. At the same time, it is not recommended to install a new piston into a worn cylinder without boring it: the groove under the upper piston ring in the new piston may be slightly higher than in the old one, and the ring may break on the “step” formed in the upper part of the cylinder when it wears out. For pistons of repair sizes, a triangle (+0.4 mm) or a square (+0.8 mm) is knocked out on the bottom.

Based on the diameter of the hole for the piston pin, pistons are divided into three classes:

- 21.978-21.982 - 21.982-21.986 - 21.986-21.990 (mm).

The piston class based on the diameter of the hole for the piston pin is also stamped on the piston bottom. The piston and pin must be of the same class.

To reduce the imbalance of the crank mechanism, the pistons of one engine are selected by weight. Pistons that differ in weight by 5 g are sorted into three groups. The groups correspond to markings on the piston bottom: “G”, “+” and “-”. All pistons on the engine must be of the same group.

The piston rings are located in the grooves of the piston. The top two rings are compression rings. They prevent gases from breaking through into the engine crankcase and help remove heat from the piston to the cylinder. To improve wear resistance, the upper compression ring has a chrome-plated barrel-shaped surface. The lower compression ring is of the scraper type (also serves as an oil scraper ring). An oil scraper ring with chrome-plated working edges and an expansion coil spring (expander) is installed in the lower groove of the piston.

The nominal height gap between the piston ring and the groove in the piston should be:

— for the upper compression ring — 0.04-0.075 mm; — for the lower one — 0.03-0.065 mm; — for oil scraper — 0.02-0.055 mm.

The maximum permissible wear gap is 0.15 mm.

Cylinder head

Made of aluminum alloy, common to all four cylinders. It is centered on the block with two bushings and secured with ten screws. A non-shrinkable metal-reinforced gasket is installed between the block and the head. Its reuse is not permitted.

There are five camshaft bearings located at the top of the cylinder head. The supports are made detachable, and the holes in them are machined together with two bearing housings. Therefore, the bearing housings should be replaced together with the cylinder head. During assembly, an oil- and petrol-resistant sealant is applied to the surface of the cylinder head, in the area of the outer camshaft supports.

Camshaft

Cast, cast iron, five-support. Driven by a toothed belt from the crankshaft. The valve seats and guides are pressed into the cylinder head. The holes in the bushings are finally machined after pressing. On the inner surface of the bushings, grooves resembling threads are made for lubrication: for the intake valve bushings - for the entire length, for the exhaust valves - up to half the length of the hole. Oil deflector caps made of oil-resistant rubber are placed on top of the bushings.

Valves

Steel, outlet - with a head made of heat-resistant steel with a welded chamfer. They are arranged in a row, inclined to the plane passing through the cylinder axes. The intake valve plate is larger than the exhaust valve plate. The clearance in the valve drive is adjusted by selecting the thickness of a special adjusting washer installed in the pusher socket. Spare parts are supplied with washers with a thickness of 3.00 to 4.50 mm with a pitch of 0.05 mm. The washers are made of 20X steel; their surface is nitrocarburized to increase wear resistance.

Engine (REAR VIEW DISTINGUISHING THE CAR) : 1 — flywheel; 2 — left support bracket of the intake pipe; 3 — coolant pump pipe; 4 - hose that drains coolant from the throttle body; 5 — thermostat cover; 6 — hose supplying coolant to the throttle body; 7 — throttle assembly; 8 - receiver; 9 — cylinder head cover; 10 — front timing drive cover; 11 - eye; 12 — cylinder head; 13 - pulley; 14 — oil filter; 15 — right support bracket of the intake pipe; 16 — oil pan; 17 — oil drain plug; 18 — catalytic collector; 19 - cylinder block.

Pushers

Cylindrical cups that move in the holes of the cylinder head and rest on the ends of the valve stems. To increase wear resistance, the surface of the pusher in contact with the valve is cemented. When the engine is running, the pushers rotate due to the displacement of the cam axis relative to the pusher axis by 1 mm, which contributes to their more uniform wear. The valve closes under the action of two springs. Their lower ends rest on the washer, and the upper plate is held in place by two crackers. The folded crackers have the shape of a truncated cone on the outside, and on the inside they are equipped with three persistent flanges that fit into the grooves on the valve stem.

Engine lubrication

Combined. The main and connecting rod bearings and the support-camshaft journal pairs are lubricated under pressure. Oil is sprayed onto the cylinder walls (further to the piston rings and pins), to the camshaft cam-pushrod pairs and to the valve stems. The remaining components are lubricated by gravity.

Oil pump

Gear-type, with internal gears and a pressure reducing valve. The drive is carried out from the toe of the crankshaft. The drive gear (smaller diameter) is mounted on two flats on the front end of the crankshaft. The maximum diameter of the socket for the driven (large) gear when worn should not exceed 75.10 mm, the minimum width of the segment on the body separating the drive and driven gears is 3.40 mm. The axial clearance should not exceed 0.12 mm for the drive gear and 0.15 mm for the driven gear. The oil receiver is bolted to the second main bearing cap and pump housing.

Oil filter

Full-flow, with a steel body, non-separable, with bypass and anti-drainage valves.

Crankcase ventilation system

Closed type with gases exhausted through an oil separator (in the cylinder head cover) into the engine intake system without entering the atmosphere. Crankcase gas from the lower part of the engine crankcase enters the cylinder head cover through the lower hose and is then discharged through two circuits: the main circuit and the idle circuit.

Through the main circuit, crankcase gas is discharged at partial and full load modes into the space in front of the throttle valve. Through the idle circuit, crankcase gas is diverted into the space behind the throttle valve both in partial and full load modes, and in idle mode. To reduce the vacuum in the engine crankcase to a normal value, a nozzle with a 1.7 mm hole is installed in the idle circuit.

The article is missing:

- High-quality photos

Source: https://wiki.zr.ru/69-3_Repair_Kalina

Engine 11194 characteristics

Years of production – (2004 – today) Cylinder block material – cast iron Power system – injector Type – in-line Number of cylinders – 4 Valves per cylinder – 4 Piston stroke – 75.6 mm Cylinder diameter – 76.5 mm Compression ratio – 10.8 Engine capacity – 1390 cm3. Power – 89 hp /5250 rpm Torque - 127 Nm / 4200 rpm Fuel - AI95 Fuel consumption - city - | track - | mixed 7 l/100 km Oil consumption - up to 100 g/1000 km Oil for viburnum 1.4: 5W-30 5W-40 10W-40 15W-40 How much oil is in the engine viburnum 1.4 11194: 3.5 l. When replacing, pour 3-3.2 liters.

Resource: 1. According to the plant – 200 thousand km 2. In practice – 200 thousand km

TUNING Potential - no data Without loss of resource - up to 100 hp.

Engine installed on: Lada Kalina

Technical properties of Kalina station wagon

| Engines | 1.6 l, 8 cells | 1.4 l, 16 cells |

| Length, mm | 4040 | 4040 |

| Width, mm | 1700 | 1700 |

| Height, mm | 1500 | 1500 |

| Base, mm | 2470 | 2470 |

| Front wheel track, mm | 1430 | 1430 |

| Rear wheel track, mm | 1410 | 1410 |

| Luggage compartment size, dm 3 | 350/650 | 350/650 |

| Weight when equipped, kg | 1080 | 1080 |

| Total vehicle weight, kg | 1555 | 1555 |

| Permissible total weight of a towed trailer with brakes, kg | 900 | 900 |

| Permissible total weight of the lettered trailer without brakes, kg | 450 | 450 |

| Wheel formula/drive wheels | 4x2/front | 4x2/front |

| Vehicle layout diagram | front-wheel drive, engine placement frontal, transverse | |

| Body type/number of doors | station wagon/5 | station wagon/5 |

| Motor type | gasoline, four-stroke | gasoline, four-stroke |

| Supply system | Electrically controlled distributed injection | |

| Number and placement of cylinders | 4, in-line | 4, in-line |

| Engine displacement, cm 3 | 1596 | 1390 |

| Maximum power, kW/r.min | 59,5 / 5250 | 65,5 / 5250 |

| Maximum torque, Nm at rpm | 120 / 2500-2900 | 127 / 4200-4800 |

| Fuel | unleaded gasoline AI-95 (min) | unleaded gasoline AI-95 (min) |

| Fuel consumption by driving cycle, l/100 km | 7,8 | 7,0 |

| Maximum speed, km/h | 160 | 165 |

| Box | With manual control | With manual control |

| Number of gears | 5 forward, 1 reverse | 5 forward, 1 reverse |

| Main gear ratio | 3,7 | 3,7 |

| Control management | with electromechanical amplifier, rack-and-pinion control mechanism | |

| Tires | 175/65 K 14 (82,N); 185/60 K14 (82,N) | 175/65 K 14 (82,N); 185/60 K14 (82,N) |

| Fuel tank capacity | 50 | 50 |

Installed engines on generation 2

With the advent of the 2nd generation Lada Kalina, new engines also began to be installed on this model. But AvtoVAZ’s technical progress has not only advantages, but also disadvantages. Let's look at some of the advantages and disadvantages of new power units:

- The advantage of the new engines is increased power and lower fuel consumption.

- The disadvantage of all these engines is the fact that if the timing belt breaks, the valves meet the pistons and you end up with expensive repairs.

Below I would like to consider each new power unit separately and compare them in more detail.

VAZ 21116

This design is probably known to everyone from the Lada Granta model. This is a follower of the previous engine model from Kalina with index 21114. But only in the new engine a number of changes were made, the main focus of which was to lighten the connecting rod and piston group. Due to this, power increased slightly from 81 to 87 horsepower.

One can also note a positive point - it has become much quieter and there is no more diesel or bubbling noise, like on the same 114th. Personally, the dynamics of the car with the new engine are a little better, it runs smoother and is more pleasant to the ear.

But I think everyone already knows the main disadvantage of making the piston group lighter. This is the danger of pistons colliding with valves when the timing belt breaks. In this case, not only the valves suffer, but in most cases the pistons have to be changed (there are a lot of examples).

VAZ 21126

This engine is familiar to us from the Priora model, but it has been installed on the Lada Kalina for a long time, and now on the 2nd generation too. Excellent dynamics and low fuel consumption - all this is now a thing of the past! And why? Yes, because paired with this engine, only an automatic transmission will now be installed.

In this regard, the average fuel consumption will increase significantly. For example, if on a manual transmission it is 7 liters, then on an automatic transmission this figure is at least 8 l/100 km. The dynamics will also suffer, it’s an automatic! Acceleration to 100 km/h is achieved in as much as 14 seconds, while with a manual transmission this could be done 2 seconds faster.

As a result, we get the advantage of an automatic transmission, but on the other hand, comfort has a negative impact on the driving and dynamic characteristics of this unit.

VAZ 21127

This is a completely new engine, as AvtoVAZ claims. Due to some improvements, the low-end torque has increased, and the operation of Kalina-2 with such a unit should be more interesting, especially in urban conditions. Power increased from the previous 98 to 106 hp.

But not only advantages, but also disadvantages are immediately visible. Firstly, the threshold of 100 horsepower has been crossed, which means that now the owners of such cars will pay increased transport tax, which will negatively affect the wallet of the owner of such a car. Secondly, the problem with bending valves and damaging the ShPG also has not gone away. Perhaps this is no longer worth taking so categorically, because most foreign cars have such an engine design. But knowing the quality of spare parts and components on the domestic market, there is no way to be sure of the same timing belt or timing rollers.

Tuning

There are several possible ways to increase engine power. Let's talk about these tuning options in more detail:

- Chip tuning of the VAZ 2115 engine will not allow you to obtain any noticeable effect. Even by replacing the engine control unit, the car owner will be able to get 3-5 horsepower, the increase of which will be almost imperceptible.

- Deep engineering tuning of VAZ 2115 engines, which involves replacing the camshaft and other power elements, will increase the engine power to 85 horsepower. Such an increase of 10 horses will already be noticeable, and the car will accelerate faster, especially from low revs.

- Replacing the throttle body and exhaust will increase power to 95 horsepower.

- If the engine power limit of 100 horses is important to you, then you need to install lightweight valves, mill the cylinder head and replace the intake manifold. A car with such a tuned engine will accelerate 1-2 seconds faster than with a basic 78-horsepower engine. A further increase in power by replacing internal power parts will not allow you to obtain the desired horsepower, and the service life of the motor is significantly reduced.

- An alternative way to increase the power of a VAZ 2115 engine is to install a compressor with a pressure of about 0.5 bar. If the compressor is properly configured, the engine power will be about 120 horsepower. At the same time, when resorting to such tuning, the car owner must be prepared to reduce the service life of the engine, which may require appropriate major repairs after only 75-100 thousand kilometers.