The car should always respond clearly to rotations of the steering wheel. If this does not happen, then there can be no talk of any security. This applies to all cars, including the VAZ 2107. The main steering unit is the gearbox, which has its own faults, which can be identified and eliminated without visiting a service center.

- Steering column

VAZ 2107 steering column deviceSteering wheel

- Steering shaft

- Gearbox

- Lubricant leak

- How to remove a column

Video: how to replace the steering gear on a “classic”

- Video: repairing the steering column of classic Zhiguli cars

- Video: how to change the oil in the steering column

- Video: how to reduce play in the classic steering gear

Repair and maintenance

Over the years of operation it has been proven that the steering on VAZ 2107 vehicles has impressive reliability. However, this does not take away the fact that the machine requires periodic inspection and repair.

- When performing maintenance, it is important to check for increased play as well as increased wear on the ball joints. To do this, you need to turn the steering wheel from one side to the other. If the wheels do not respond when the steering wheel is turned 5 degrees from its original position, this indicates severe wear. Here you will need to repair the steering column on a VAZ 2107.

- To avoid the need for urgent and rather expensive repairs of the steering gear on a VAZ 2107, it is necessary to change the oil in the worm gear housing. This is done at intervals of 60 thousand kilometers. Leaks may occur through the seals, so they are carefully checked 2-3 times a year. This is one of the weak points of the system.

- The swing arm should be inspected by slowly rotating the steering wheel from side to side. If the parts move in a vertical plane, then surgical intervention is required.

If any malfunctions are detected, the breakdowns should be repaired immediately.

To do this, the drive and steering mechanism are dismantled completely or partially. Everything depends directly on the nature of the breakdown.

Check which parts have defects and what has failed. Inspection is required for each component of the mechanism. If parts are worn out, there is no point in trying to repair them. There is only one way out - a complete replacement of worn-out components of the steering system on a car from a Volga company.

If problems arise with the steering, it is advisable to contact a professional service station.

Photo of the VAZ 2107 steering gearbox

You can replace the gearbox yourself, but the process is complicated and requires at least minimal experience and skills.

The VAZ "Seven" is a true classic of the domestic automotive industry. Unlike modern LADAs, they are more reliable and durable, which is proven by the huge presence of these cars on our roads.

Of course, the VAZ 2107 has long been outdated, it does not have a hydraulic booster, and you have to apply sufficient force to turn and maneuver. But for connoisseurs this is not a problem.

What affects the cost?

The cost of a steering column is influenced by the following factors:

- Manufacturer.

- Country of origin (Eurasian compliance standards).

- Type of component.

- Type of equipment.

- State.

- Brand.

- Type of spare part.

- Type of modification (without hydraulic booster).

- Model.

- Serial compatibility.

In addition to such key parameters, the cost is also affected by the type of packaging and internal placement of the product. Original steering columns, which have a clear centering position with a noticeable effort to overcome it, regardless of the direction of rotation, are always equipped with an output shaft mounting bipod. The latter prevents its rotation and axial displacements in the bearing and oil seal. Also, the original AvtoVAZ packaging is different:

- Complete with technical data sheet and warranty card (separate sealed bag).

- Security seal with laser engraving on the top and bottom.

- Since February 2016, compliance with Eurasian standards is indicated on the side of the box, instead of specifications.

Also included in the price is the oil used to fill the steering column. During transportation, the adjusting bolt and gasket are in a free state, which requires compliance with the orientation of the product in space.

Mechanism design

To repair the steering column on a VAZ 2107, you first need to understand its structure, as well as the principle of operation.

The seven is in many ways similar to the “penny”. Therefore, the device and design received minor changes. The structure includes:

- A mechanism that transmits the driver’s force to the executive components;

- A steering drive that turns at an angle specified by the driver.

In turn, the steering mechanism consists of:

- Composite shaft with cardan transmission;

- Steering wheel (steering column together with a steering wheel with a diameter of 520 mm);

- Worm gearbox of the VAZ 2107 steering mechanism.

The control system has the following components:

- Bipod;

- Pendulum arm;

- Swivel arms;

- Steering rods for VAZ 2107 (one middle, two side).

The outer rods include two parts, which allows you to change their size by adjusting the toe angle.

Tie rod/end set for VAZ 2107

The operating principle of the steering mechanism looks like this:

- The driver begins to rotate the steering wheel, the wheel size of which ensures that this task can be performed quite simply;

- By means of a composite shaft, a worm gear is activated, which reduces the speed;

- The steering mechanism is lubricated with special oil (TAD 17) poured into the gearbox;

- The worm gears rotate, which causes the double ridge roller to move;

- This, in turn, causes the secondary shaft to rotate;

- The tray mounted on the secondary shaft makes a turn and pulls the rod system behind it;

- These components influence the levers that synchronously rotate the wheels to the required angle specified by the driver.

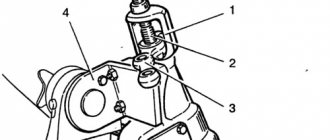

Parts of the steering gear housing: 1 - housing; 2 - bipod; 3 — lower crankcase cover; 4 — adjusting shims; 5 — outer ring of the worm shaft bearing; 6 — separator with balls; 7 — bipod shaft; 8 - adjusting screw; 9 — adjusting plate; 10 — lock washer; 11 - worm shaft; 12 — upper crankcase cover; 13 - sealing gasket; 14 — bipod shaft sleeve; 15 — worm shaft seal; 16 — bipod shaft seal.

Steering column parts: 1 — steering gear housing; 2 - shaft seal; 3 - intermediate shaft; 4 - upper shaft; 5 — fixing plate of the front part of the bracket; 6 — bracket for fastening the steering shaft; 7 - upper part of the facing casing; 8 — bearing sleeve; 9 — bearing; 10 — steering wheel; 11 — lower part of the facing casing; 12 — bracket fastening parts

Types and prices

The original steering column for passenger cars of the VAZ 2101-07 family has catalog number 21050-3400010-00 . Its cost varies from 2,172 to 4,449 rubles . In order for the classification of goods to be as complete as possible on the part of the buyer, the price can be divided by series and compatibility. The latter looks like this:

- VAZ 2102, 1973-1985 – 2,797-4,449 rubles.

- VAZ 2103, 1972-1984 – 2,797-4,449 rubles.

- VAZ 2106, 1975-2006 – 2,430-4,300 rubles.

- VAZ 2101, 1970-1988 – 2,172-4,301 rubles.

- VAZ 2106, 1975-2005 – 2,430-4,250 rubles.

- VAZ 2104, 1984 – 3,934 rubles.

- VAZ 2105, 1981 – 4,012 rubles.

- VAZ 2107, 1982-2012 – 2,640-4,449 rubles.

- VAZ Niva (2121), 1976 – 2,970-4,440 rubles.

- VAZ 2121, 1994-2006 – 2,970-4,440 rubles.

- VAZ 21213, 2001-2006 – 2,700-4,449 rubles.

If we take into account the gradation by series, the pricing policy is as follows:

- 2101, 1970-1988 – 1,450-4,449 rubles.

- 2106, 1975-2005 – 2,797-4,449 rubles.

- 2107, 1982-2012 – 2,400-4,449 rubles.

Prices are given for original AvtoVAZ products and their copies in similar packaging, configuration, as well as manufacturer’s warranty. Each of the items contains oil in the crankcase of the lubrication system.

Installation and repair of the steering column on a VAZ 2107

One of the elements of the VAZ 2107 car, which received a number of improvements in this model compared to the previous ones, is the steering column.

How is its device different? In the VAZ 2107, the steering column shaft consists of two parts connected by a cross. Thanks to this design, driver safety is significantly increased, since in the event of a collision the shaft simply bends at the hinge joint and does not cause serious harm to the person. Also, the shaft in the VAZ 2107 has bearings, so turning the steering wheel requires much less effort. The steering column of the VAZ 2107 consists of a shaft with an articulated joint and a gearbox with a worm gear. Column repair is a very rare occurrence. If you ensure timely maintenance of this unit, it may never be needed. Steering column maintenance work includes lubricating the steering shaft joint, tightening the steering wheel nut, changing the oil and adjusting the gearbox. Let's look at possible problems associated with the steering column and methods for eliminating them.

Removing the gearbox

The design of the gearbox does not allow it to be repaired without removing it from the vehicle. In order to remove it, you must:

- Disconnect the tie rod ends from the gearbox. First, they are uncoiled, then the nuts are unscrewed with a 22 wrench and the tips are pressed out using a special puller.

- Unscrew the clamp securing the steering shaft to the gearbox.

- Remove the three bolts that secure the gearbox to the car body.

The gearbox design should not cause any particular difficulties when repairing it. You just have to take into account that the worn elements, called the worm pair, are both replaced at the same time. After this, adjustments must be made.

everything useful is here

Replacing the steering shaft

Remove the negative terminal from the battery. Remove the steering wheel, steering shaft mounting bracket covers, steering column switches, disconnect the ignition switch connector

Using a 13mm wrench, unscrew the nuts from the coupling bolts of the intermediate shaft universal joint forks and remove the bolts.

Using a 10mm wrench, unscrew the two shear screws securing the steering shaft bracket.

If the bolts have their heads cut off, use a chisel to loosen the remaining round heads and finally unscrew them with pliers. Locking washers are installed under the screws. Using a 13mm wrench, unscrew the two nuts securing the steering wheel bracket... ...and remove the bracket. We remove the upper shaft from the splined connection with the intermediate shaft. Remove the intermediate shaft from the splines of the gearbox worm shaft. Flare the curved edges of the bracket pipe on the steering wheel side, insert the key into the ignition switch and turn off the lock. With light blows we knock the shaft together with the bearing out of the pipe.

The second bearing can be knocked out using a suitable piece of pipe. The needle bearings are installed in shock-absorbing plastic cages. If the shaft or its bearings are worn or damaged, replace them.