A manual gearbox (MT) is designed to convert and transmit torque from the engine to the vehicle's transmission with a stepwise change in gear ratio.

Models of the Volzhsky Automobile Plant were equipped with four and five-speed gearboxes. The VAZ 2107 began to be equipped with a five-speed gearbox in 1982. This box is one of the successful design solutions of “classical” mechanics.

Like all mechanisms that have rotating and rubbing parts, the gearbox is also subject to intense wear. The structure of the unit is complex, so maintenance and repairs are best done in specialized workshops with the assistance of trained personnel.

Although every car enthusiast who knows how to hold a tool in his hands, having studied the device and the procedure for performing work, can carry out maintenance and repairs in his garage.

Five-speed manual transmission

The seventh model Zhiguli has a five-speed gearbox with five forward speeds and one reverse.

It is made of duralumin and has similar covers on the front and back. The clutch cover is attached to the front of the box using studs. A steel cover is installed on the bottom of the device. There are sealing gaskets between the box body and each lid.

The front cover is connected to the clutch housing using a press fit. There is a hole in it for the input shaft to exit and install the cuff.

Inside the box, shafts with gears, synchronizers and gear shifting devices are installed in a certain order. There is an oil filler hole on the right, and a drain hole with a magnetic plug on the bottom.

At the bottom left of the cover comes the speedometer cable, which is driven by the secondary shaft using a gear.

The gear shift lever is on top. Consists of a gear selection device, rods and a locking mechanism. A handle is attached to the lever on top. This entire structure is attached to the lid using three studs.

Type of gearbox:

- Clutch cover.

- Breather.

- Box body.

- Rear cover.

- Gear shift lever.

- Lever housing.

- Coupling flange.

- Screw.

- Speedometer drive.

- Tray cover.

- Hole for filling.

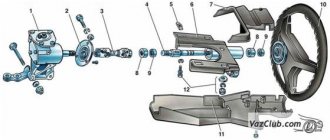

Exploded parts:

- Fork for engaging 3rd and 4th gears.

- Fork for engaging 1st and 2nd gears.

- Fork fastener.

- Engraving washer.

- Fork rod for engaging 1st and 2nd gears.

- Rusk.

- Fork rod for engaging 3rd and 4th gears.

- Gear shift lever.

- Fork rod for engaging 5th gear and reverse.

- Rusk.

- Rusk.

- 5th gear and reverse detent spring.

- Retainer cover with gasket.

- Retainer springs.

- Ball retainers.

- Fork for engaging 5th gear and reverse.

- Sleeve.

Moving parts of the gearbox:

- Intermediate shaft.

- Front intermediate shaft bearing.

- Rear main shaft bearing.

- Input shaft with 4th gear gear.

- Synchronizer clutch for 3rd and 4th gears.

- Synchronizer clutch hub.

- Synchronizer clutch for 1st and 2nd gears.

- Synchronizer clutch hub.

- Front secondary shaft bearing.

- Secondary shaft.

- Intermediate bearing of the secondary shaft.

- Rear secondary shaft bearing.

- 5th gear synchronizer clutch.

- Synchronizer clutch hub.

- Reverse gear.

- Gear with 5th gear synchronizer.

- Speedometer drive gear.

- Gear block for 5th gear and reverse gear.

- Gear block bearing.

- Reverse intermediate gear.

- Reverse idler gear axis.

- Rear intermediate shaft bearing.

- Gear with 1st gear synchronizer.

- Gear with 2nd gear synchronizer.

- Gear with 3rd gear synchronizer.

Types and differences of the VAZ Classic 4-speed gearbox from Vasily Batkovich's Alien

from 1993 - a gearbox was installed with gear ratios I - 3.830; II - 1.971; III - 1.321; IV - 1,000; V - 0.806.

The whole sadness of the situation is in the fact that it is difficult to get a new Pole, that they have saved what to eat and do not walk for a long time, they are starting to leak like bitches. And what’s most unfortunate is that you can’t find spare parts from them in a day’s time. And the Poles, however, are designed for engines with a displacement of 1.7 to 2.0 (there were such ones on Polonaises). Therefore, they practically do not fit the classics; they are installed (by cutting out a piece of the transmission tunnel), then they do not last long and the driving properties are improved purely personally.

Now I’ll move on to my own standard: the gearbox was purchased in September 2011, and in this case it was installed on the car. Gearbox model VAZ-21074-1700010-23. Five-speed ( gear ratios

see above) 5th gear What does the index 23 mean at the bottom (in the photo it is marked with a blue marker on the body): It is deciphered as follows: 20 - box for the main pair 4.1 03 - modification of the insides of the box.

See:

The same thing with the Niva: if the old gearbox had an additional index of 40, then the new one - 43. A distinctive feature of the 23rd modification - the speedometer drive gearbox for a pair of 2103 (4.1) - is marked with reddish paint.

Interchangeability of gearboxes: On rear-wheel drive VAZ (Zhiguli) cars of the first years of production, the same “2101” type gearbox was used. It was used for the VAZ-2101, “2102” models (until 1978 they were equipped with boxes without reverse light switches), in addition “21011”, “21013”, “2103”. In 1976, a “2106” type box with different gear ratios appeared. Since 1977, they began to install it on the VAZ-2121-Niva (this version does not have a speedometer drive, since in the Niva it is located on the transfer case). In the lower part of 1979, an additional variety appeared - “2105” with a personal series of gear ratios - intermediate between “2101” and “2106”. This is necessary to meet more stringent requirements for efficiency, toxicity, noise of new models - VAZ-2105, “2107”, “2104” and modifications.

The choice of gear ratios made it possible to use the “2105” box on all models with a traditional assembly, and since 1987 it has been equipped with it, which remains for our client to do in rear-wheel drive cars (Zhiguli). Only for the Niva, as before, they use a box with gear ratios

The boxes also differ in speedometer drives, any of which corresponds, as shown in table. 2.4, to a certain final drive ratio. Otherwise, the speedometer readings may deviate from the actual speed. To avoid this error, if necessary, immediately change the speedometer drive, guided by the table. 2. On the clutch housing, opposite the breather, a marking is applied with paint indicating which car model the box is intended for: the number “5” for VAZ-2105, “2104”, “7” for VAZ-2107.

Now some Zhiguli and Niva cars are equipped with a five-speed gearbox. It is developed on the basis of a four-speed one, is interchangeable with it locally, and differs from the outside in the configuration of the rear cover when a pair of fifth gears is located.

All-wheel drive VAZ-2121 vehicles use gearboxes with 2 variations of gear ratios: 4.3 and 4.1. Speedometer drives differ accordingly. When changing what is also called the repair of gearboxes on these machines, it is imperative that they have the same gear ratio on the front and rear axles.

Additional note regarding VAZ-2121 all-wheel drive vehicles. In order to increase the reliability and durability of the gearbox in the personal computer, the fixation of the satellite axis was changed, and nitrided spherical washers were installed under them. For this reason, the interchangeability of the bodies and axes of the satellites has been lost. Therefore, if you want to change the housing in a gearbox manufactured before 1986, you must install the entire set of modified parts: housing 2121-1802163-200, axle 2121-1802160-10 and slip washers 2121-1802161 under the satellites.

How to manage when changing the box? Remember that the box type “2105” is more universal for implementation. A five-speed gearbox is certainly a winning change, especially for those making long trips, but it is not yet very affordable. In general, the characteristics of the box were selected as a compromise between dynamic properties, efficiency and reliability. Therefore, the VAZ-2106 with the “2101” gearbox will become more dynamic, but this will affect the durability of the rear axle parts. On the contrary, VAZ-2101, “21013” with the “2106” gearbox accelerates more sluggishly.

In a similar way, a gearbox with a huge gear ratio provided improves dynamics, but “stimulates the appetite” of the machine, and at the same time the load on the side gears and axle shafts will increase. The reverse shift will manifest itself in a certain deterioration in dynamics, especially in direct transmission.

If, when changing a gearbox, you find that its markings have been erased, the gear ratio is determined without removing it from the machine. To do this, set the gear shift lever to neutral and lift one of the rear wheels using a jack (the second one should rest on the ground). Turn the raised wheel 20 revolutions and count in this case how many revolutions the driveshaft has made. By dividing the purchased number by 10, you can find out the final drive gear ratio.

At the time of purchase, the accessory costs 4,000 Khokhlobaks (hryvnia), which equates to about 8,000 thousand rubles.

Gear ratios at the gearbox

The seventh model of the Zhiguli received a good version of a five-speed gearbox. The designers of the Volzhsky Automobile Plant took a box from a VAZ 2105 as a prototype, replaced the gear ratio of the main gearbox pair from 4.3 to 4.1, then to 3.9 and obtained the following gear ratios.

| home | 1st gear | 2nd gear | 3rd gear | 4th gear | 5th gear | Reverse |

| 4,1/3,9 | 3,667 | 2,100 | 1,361 | 1,000 | 0,820 | 3,530 |

The gear ratio is the ratio of the number of teeth on the driven gear to the number of teeth on the drive gear.

Primary shaft

The input shaft transmits torque from the engine crankshaft through the clutch disc to the gearbox. The disc is located on the splines of the front part of the shaft. A constant mesh gear is rigidly mounted on the shaft.

For free rotation, it is placed in two bearings. One bearing is located at the end of the crankshaft, the other is in the front cover of the gearbox.

Secondary shaft

In a complex gearbox mechanism, the secondary shaft is the final stage in converting torque and transmitting it to the cardan. The gears of the first three speeds move freely on this shaft. At a certain gear, they engage with the intermediate shaft gears and provide the required torque.

The shaft is placed in bearings, there are three of them. One is pressed into the end of the input shaft, the other into the box body, and the third into the rear cover.

Intermediate shaft

The intermediate shaft transmits rotation from the primary shaft to the secondary shaft.

He plays the role of a satellite. The gears and shaft are made from a single piece. It is installed on three bearings. The gears for fifth and reverse speed are located on it.

Forks

In the process of switching speeds, forks are involved, which move gears along the shaft to a certain place.

The gear shift lever moves the forks.

What kind of gearbox is used on Lada Granta, Kalina, Priora

Decoding of some gearbox models

:

Gearbox article

is formed from a model, part and index.

Gear ratio of the main pair

| 1700012 | 00 | 01200 | 3,7 | 21120-1701105-30 | |

| 10 | 80010 | 3,9 | 21120-1701105-20 | ||

| 21806 | 1700014 | 00 | Impact point method | 3,7 | 21120-1701105-30 |

| 21826 | |||||

| 21827 | 3,9 | 21120-1701105-20 |

Applicability

: This box is used on vehicles of the LADA Kalina, LADA Priora, LADA Granta families. Total volume of oil to be filled V=2.25 ±0.05l.

Impact point method

| Model | Detail | Index | Marking | Gear ratio of the main pair | Secondary shaft |

| 21810 | 1700012 | 00 | 3,7 | 2110-1701105 | |

| 77 | 4,3 | 21905-1701105-77 | |||

| 1700014 | 00 | Impact point method | 3,7 | 2110-1701105 |

Applicability

: This box is used on vehicles of the LADA Kalina, LADA Granta, LADA Granta LB family. Total volume of oil to be filled V=2.2 ±0.1l.

| Model | Detail | Index | Marking | Gear ratio of the main pair | Secondary shaft |

| 21900 | 1700012 | 00 | 2190 | 3,7 | 21120-1701105-30 |

| 01 | 2190-01 |

Applicability

: This box is used on vehicles of the LADA Granta family.

| Model | Detail | Index | Marking | Gear ratio of the main pair | Secondary shaft |

| 11180 | 1700011* | 00 | 18-00 | 3,7 | 21100-1701105 |

| 1700012 | 21100-1701105 | ||||

| 01 | 18-01 | ||||

| 20 | 18-10 | 21100-1701105 | |||

| 21 | 18-21 | 21100-1701105 | |||

| 11190 | 1700011* | 00 | 19-03 | ||

| 03 | 3,9 | ||||

| 1700012 | 00 | 19-00 | 3,7 | 21120-1701105 | |

| 01 | 19-01 | 3,9 | |||

| 03 | 19-03 | ||||

| 11190** | 12 | 19-12 | 3,7 | 21120-1701105-30 | |

| 13 | 19-13 | 3,9 | 21120-1701105-20 | ||

| 23 | 19-23 | 21120-1701105-20 |

** Clutch housing 21120-1601010

Note

: Total volume of oil filled V=3.1±0.1l.

Note

: The model 11190 gearbox has 3 starter mounting points.

Applicability

: This gearbox is used on cars of the LADA Kalina family

| Model | Detail | Index | Marking | Gear ratio of the main pair | Secondary shaft |

| 21083 | 1700012 | 13 | 13 | 3,7 | 21083-1701105-31 |

| 21100 | 00 | 2110 | 21100-1701105 | ||

| 20 | 12-20 | 21120-1701105-30 | |||

| 21120 | 00 | 12-00 | 21120-1701105-30 | ||

| 01 | 12-01 | 21120-1701105-30 | |||

| 10 | 12-10 | 21120-170105-30 | |||

| 11 | 12-11 | 21120-1701105-30 | |||

| 20 | 12-20 | 21120-1701105-30 | |||

| 21 | 12-21 | 21120-1701105 |

Applicability

: This box is used on vehicles of the LADA 2110, LADA Priora, LADA Priora Coupe family. The total volume of oil to be filled is V=3.1±0.1l.

Source

Technical characteristics of manual transmission

In the operating instructions, the technical characteristics of the box are indicated together with the characteristics of the transmission. This is given in tabular form:

| Clutch | Single-disk, dry with hydraulic drive and central diaphragm spring |

| Transmission | Mechanical, five-speed, three-way, three-shaft, with synchronizers on all forward gears |

| Gear ratios | |

| First | 3.667 |

| Second | 2.100 |

| Third | 1.361 |

| Fourth | 1.000 |

| Fifth | 0.820 |

| Reverse | 3.530 |

| Cardan transmission | Twin-shaft with intermediate support and elastic coupling |

| main gear | Hypoid |

| Final drive ratio | 3.9 or 4.1 |

| Differential | Conical, two-satellite |

What is a gearbox?

The gearbox converts the torque in the box. Each gearbox is characterized by efficiency, gear ratio, specific power, angular speed of shafts, their number, etc.

The VAZ gearbox has one gear, two driven shafts and one drive shaft. Factory relations (3.9 – 4.1 – 4.3 – 4.4). Or, in other words, the cardan needs to make so many revolutions for the wheel to turn once.

The graph shows how the speed of the car (numbers on the horizontal axis) will depend on the crankshaft speed of the engine, (numbers on the vertical axis) which has different main pairs in the gearbox:

What kind of gearbox can be installed on a VAZ 2107

Initially, the “Seven” was produced with a “four-speed”, so you can install any VAZ gearbox from rear-wheel drive “Zhiguli” on it. You should know what functions the car will perform. If you use it as a workhorse, carry loads, pull a trailer, then a four-speed gearbox will do. It is more durable and resistant to variable loads. If high-speed driving on highways is necessary, then a five-speed gearbox is suitable.

It is possible to install boxes from foreign cars.

The best option is a box from an Italian Fiat model, since this is a prototype of our VAZ.

You can also install it from an early model BMW, but for installation you will have to redo the fastenings.

Replace the secondary shaft and differential gear

The gearbox on the VAZ 2109 with tuning is not limited only to the gears of the box; the differential also requires tuning:

- During the usual replacement of the main pair (secondary shaft gears as well as the main differential gear) in a five-speed gearbox of cars from the VAZ family, with an initial gear ratio of 3.7 or 3.94 teeth (as a standard) with a gear ratio of 4.13, which was once made for “chisels” with 1100hp engines and a five-speed gearbox, it opens up the possibility of improving the dynamics of your car without resorting to boosting the engine

- In the city, gasoline consumption is unlikely to change, but on the highway there may be a noticeable increase in consumption by 3% if you drive at maximum speed, you will agree that this is not significant

- But the acceleration dynamics will improve quite noticeably; it will be much easier for the engine to reach high speeds

- At the same time, fifth gear becomes more usable, and you will also find the pickup in any gear smoother

- The car will become much easier to start, to overcome even steep hills, you will have to change gears less often when driving moderately or when moving in traffic around the city

This is important for everyone to know

All dealers of VAZ spare parts received a circular, which practically sets out a report on the beginning of the recall of all VAZ cars that were equipped with the 2110 gearbox and were produced before May 2000. So:

- The reason for this is the design flaw of the gearbox, or rather its secondary shaft is hollow, there is a through channel inside it

- This could cause the flat snap ring on the output shaft to break it in half.

- This drawback is completely unsafe: since the fragments immediately fall between the gears and the gearbox becomes tightly jammed

- In addition, there were cases when fragments of the secondary shaft broke through the gearbox housing (“the hand of friendship,” so to speak)

- After conducting a series of additional tests, VAZ manufacturers changed the shape of the retaining ring; this, according to designers from the factory, resolved the problem

- Although the problem has not been fundamentally solved at its core, only a complete replacement of the hollow secondary shaft with a solid one can provide you with a 100% guarantee

- The secondary hollow shafts continued and continue to break, no matter how annoying it may sound.

- That is why it is recommended to switch to a 4.13 main pair with a solid secondary shaft

- And again, I’ll emphasize separately - specifically, that the shaft be solid, since the market is full of cheaper options for the main pairs of 4.13 with a hollow secondary shaft

- Understand, you shouldn’t save money here, because in the end, replacing the gearbox housing and internals (or a new gearbox) is much more expensive

Transmission malfunctions

The box on the seventh model Zhiguli is considered a reliable unit. If you maintain it regularly and treat it with care during operation, then repairs will not be needed for a long time. However, all components and parts are subject to wear. There are many reasons for this. In any case, if a malfunction is detected in the gearbox, it is necessary to carry out diagnostics and repairs.

Most malfunctions occur of the following types.

One of the gears does not engage

Without opening the box, we can assume that:

- the hinges and springs are worn out and need to be replaced, or better yet, a complete repair;

- on synchronizers, the rings have become unusable and need to be replaced;

- synchronizer spring burst, replace;

- The teeth on the transmission gears are worn, replace the gear.

Knocks out gear when driving

It happens that when you turn on a gear, it does not turn off randomly. Possible reasons:

- the lever hinge is jammed, inspect and clean;

- the clutch is faulty, it may not engage completely, adjust it, if the disc is worn, replace it;

- The shift lever is broken, replace it with a new one;

- Forks, shift gears are bent, replace with new ones.

Crunching and grinding in the box while driving

This problem appears for the following reasons:

- the bearings are worn out, they should be replaced, and at the same time check the seals;

- the teeth of the gears are worn out, in this case it is better to make a major repair;

- There is not enough or no lubricating fluid in the gearbox, find the leak and fix it, add oil.

Grease leaking from box

The gearbox is designed so that lubricant cannot leak out spontaneously. But if an oil stain has formed under the car, an inspection should be made and the leak eliminated.

The reason may be:

- wear of oil seals and sealing gaskets due to natural aging of rubber must be replaced with new ones;

- the fastenings of the covers on the box have become loose, tighten all the nuts and bolts completely;

- mechanical damage to the body or lids of the box; if the steel lid is damaged, it can be welded. If the crankcase is damaged, it is better to replace it, since it is cast from an aluminum alloy.

A short summary

General structure of manual gearboxes on VAZ

VAZ manual gearboxes are very reliable, unpretentious gearboxes, their gearshift scheme is the most standard, no exotic ones. And this is a huge plus, since their maintenance and repair are just as simple and straightforward. They have to be repaired relatively rarely, since they perfectly hold the torque from the ring shaft of VAZ engines, even forced ones. For comparison, many manual gearboxes have difficulty maintaining the torque of stock engines, comparable in power to VAZ ones, and very quickly fail at the slightest increase in engine power. What makes VAZ manual transmissions so durable? Let's look at the diagram of their design and understand why they are good and what their shortcomings are.

Gearbox seals and their replacement

Oil seals in any mechanism where they exist act as gaskets. In this case, they are designed to seal the holes from which the primary and secondary shafts come out. Previously, oil seals were cast from rubber.

Currently made from modern composite materials, more resistant to temperature changes and aggressive environments.

Input shaft oil seal

The oil seal, which is installed on the input shaft, has the following dimensions:

- • outer diameter – 47 mm;

- • internal diameter – 28 mm;

- • width – 8 mm;

- • weight – 20 grams.

It is installed in the shaft output hole in the clutch housing and serves to prevent lubricant from flowing through the shaft.

There is no difficulty in replacing the oil seal, but the gearbox will have to be removed.

The order of work to change the oil seal is as follows:

- Remove the clutch cover from the gearbox.

- Remove the release bearing and clutch fork.

- Remove the used oil seal by picking it up with a screwdriver or knife.

- Clean the place where the oil seal was located and wipe it dry.

- Install the new oil seal in its original place.

- Replace all the parts that were removed from the box in reverse order.

Secondary shaft oil seal

The oil seal, which is installed on the secondary shaft, is larger and has dimensions:

- outer diameter – 56 mm;

- internal diameter – 32 mm;

- width – 10 mm;

- weight – 10 grams.

It is installed at the output of the secondary shaft at the rear of the box.

The order of work to change the oil seal is as follows.

- Unscrew the nut securing the flange, having previously secured it.

- Remove the centering metal ring from the shaft.

- Remove the flange and washer using a puller.

- Pull out the old oil seal using a tool.

- Clean and wash the seal area.

- Install a new oil seal.

Gear shift drive diagram:

| 1 – gear selection rod lever; | 10 – hinge bushing; |

| 2 – gear selection lever; | 11 – hinge tip; |

| 3 – gearbox housing; | 12 – clamp; |

| 4 – clutch housing; | 13 – protective cover of traction; |

| 5 – gear selection rod; | 14 – gearbox control drive rod; |

| 6 – rod bushing; | 15 – gear shift lever; |

| 7 – rod seal; | 16 – ball joint cage; |

| 8 – protective cover; | 17 – ball joint of the gear shift lever; |

| 9 – hinge body; | 18 – jet thrust. |

The gearbox control drive consists of a gear shift lever (15), a ball joint (17), a rod (14), a gear selection rod (5) and gear selection and shift mechanisms (crumpled “P”).

To prevent spontaneous switching off of the P due to the axial movement of the power unit on its supports when the vehicle is moving, a reaction rod (18) is introduced into the gearbox control drive, one end of which is connected to the power unit, and a clip (16) of the ball joint of the lever (15) is attached to the other end ) switching P.

A lever (1) is attached to the inner end of the rod (5), which acts on the three-year lever (2) of the P selection mechanism. This mechanism is made as a separate unit and is attached to the plane of the clutch housing.

Replacing gears and synchronizers

The work of replacing gears and synchronizers is one of the most difficult when repairing a gearbox. There is a standard repair kit containing all the necessary parts to help cope with the task. It is advisable to prepare a special tool.

Gears and synchronizers on the primary and secondary shafts are changed in almost the same way.

The process goes like this:

- remove the shaft from the box;

- clamp the shaft in a vice, wrapping it in something soft;

- Remove the retaining ring from the shaft using a special tool or a screwdriver:

- press the bearings off the shaft;

- remove the shaft from the vice, place it vertically, resting the first gear on two supports;

- carefully press the gear off the shaft;

- Carry out similar operations with the remaining gears and synchronizers.

Removing and replacing the fifth gear gear occurs differently.

The video clearly shows and explains how to do this:

Disadvantages, breakdowns and problems of the Lada 2112 box

Owners consider the gearbox to be unreliable and criticize it for unclear switching and a strong whine.

People often complain about crackling and noise during shifts due to synchronizer wear.

Also, oil leaks from oil seals, pan gaskets and even breather often occur.

Wear of plastic bushings leads to failure of engagement or knockout of the gear

After 100 thousand km, some gears and bearings may exhaust their service life

Video about repairing a 5-speed manual transmission from a VAZ 2112

All texts were written by me, are authored by Google, included in the original Yandex texts and notarized. For any borrowing, we immediately write an official letter on company letterhead in support of search networks, your hosting and domain registrar.

Next we go to court. Don’t try your luck, we have more than thirty successful Internet projects and have already won a dozen lawsuits.

Source

Transmission oil for gearboxes

To select gear oil for the Lada gearbox, you need to take into account the region where the car will be operated.

Two types of oils are offered. The first - with a temperature range from +35 to -26, this is SAE 80W85 and the second - with a temperature range from +45 to -40, this is SAE 75W90.

The best oil is synthetic, but semi-synthetic and mineral oils will not harm the Seven’s transmission. The amount of oil in the VAZ 2107 gearbox is about 1.6 liters. The oil change time is carried out according to the instructions in the technical instructions supplied with the car.

Manual transmission oil level

The oil level in the box is checked as follows:

- drive the car onto an overpass or pit;

- clean the filler plug;

- unscrew the plug;

- measure through the hole with a probe or other object resembling a probe. The oil should be level with the end of the filler hole; top up if necessary.

Oil change

It is better to change the oil on an overpass or pit with a warm engine, so the oil will drain faster. Prepare the tool in advance, a container for working out at least two liters, oil for changing.

The order is as follows:

- clean the fill and drain plugs from dirt;

- Place the prepared container for used oil under the drain hole;

- open the drain hole and wait until the oil completely drains into the container;

- clean the plug of old oil and close the drain hole;

- pour 1.5 liters of new oil into the box through the filler hole (it’s better to fill it with a supercharger);

- let it sit for ten minutes, then check the level and top up if necessary.

Transmission tuning. How to choose gear ratios for a gearbox?

Most of the technologies used in transmission tuning are proven in motorsports.

The transmission of any, especially a sports car, is the most important mechanism for realizing the dynamic characteristics of the engine. Even with a relatively weak engine, the car can be fast due to correctly selected gear ratios. In motorsport, synchronized (as on 'road' cars) and non-synchronized (cam) gearboxes are used. Based on the shifting principle, they are divided into conventional (H-pattern) and sequential (with sequential gear selection, like on motorcycles).

In cars of a fairly serious level of preparation, cam gearboxes are used. They have a number of advantages - they can withstand higher loads (due to the shape of the tooth and the gear-cam clutch engagement), allow experienced pilots to spend less time changing gears due to incomplete squeezing of the clutch or without squeezing the clutch at all, they do not destroy synchronizers (which are simply No).

For normal road traffic, cam gearboxes are practically unsuitable, since they are quite noisy (due to the operation of spur gear pairs), “hard” when engaging a gear, and have a relatively short resource. In addition, they are disproportionately more expensive than synchronized ones and require regular qualified maintenance.

Synchronized gearboxes differ from standard ones only in gear ratios. In some cases (VAZ-2108 and -2110) it is possible to add a 6th gear. The correct selection of gear ratios of the main gearbox pair, the input shaft and the driven gears of the secondary shaft is the key to coordinated operation of the transmission. Gear ratios are selected depending on the power and torque characteristics of the engine, wheel size and, most importantly, on the wishes of the car owner.

Transmission repair: when to do it

Repair of the VAZ 2107 gearbox may be required in the following cases:

- Excessive noise is produced when the box operates. This noise is caused by increased wear of bearings, gears and synchronizers.

- It becomes difficult to change the transmission. The reasons for this consequence are hidden in the wear of the lever, the lack of lubricant inside the box, and the deformation of the gearbox lever. Also, the cause of this phenomenon may be jamming of the blocking cracks or damage to the coupling splines.

- Spontaneous transmission shutdown. The reasons for this consequence are wear of the ball holes on the rods, jamming of the clamps, blocking rings and the synchronizer itself.

- Oil leakage occurs. Repair of the VAZ 2107 gearbox must be carried out when oil leaks are detected on it. The causes of leakage can be either serious damage or simple wear of oil seals and seals.

In any case, disassembling the gearbox will be required if one of the above symptoms occurs, which will allow us to identify the exact cause of the malfunction and eliminate it. If even the slightest malfunction of the gearbox is detected, it is necessary to begin repairing it, which will prevent unforeseen consequences in the form of complete failure of the gearbox.

Features of repairing a gearbox on a VAZ 2107

The design of the gearbox is no more complicated than the design of the engine itself, but in order to carry out repairs correctly, a certain sequence must be followed. We will find out in more detail in what sequence the disassembly and assembly of the gearbox is carried out.

- Initially, the gearbox should be removed from the vehicle. We will not consider how to remove the gearbox, since there is appropriate material for this. One has only to note that first you need to drain the oil from the gearbox. We will begin repair work immediately.

- The box is dirty and oily, so it is recommended that you take your time with the repair and clean the outer surface of the product.

- Using a screwdriver, you need to pry off the cover of the fork, which is used to disengage the clutch. The fork is moved to the side. To remove the plug, you need to rotate it 90 degrees and remove it from the hole.

- The gearbox disassembly scheme is common for both 4 and 5 mortars. You need to unscrew the clutch housing mounting nuts, then unscrew and remove the spring washers. These washers are located directly behind the nuts.

- When the fasteners are removed, you can continue to disassemble the gearbox. To do this, you need to pull the crankcase, disconnecting it from the main device.

- There is a sealing element behind the crankcase that also needs to be removed. If the gasket is worn, it should be replaced. There is a spring washer on the shaft, which also needs to be removed.

- Using a “10” wrench, you need to unscrew the 10 nuts securing the crankcase cover. After unscrewing all the nuts, remove the spring washers located behind these nuts. The cover also needs to be removed.

- Behind the cover there is a seal, which should also be removed by prying it off with a screwdriver.

- The photo below shows the nuts that need to be unscrewed. These nuts secure the rear engine mount to the gearbox housing. Behind the nuts there are washers that must be removed, as well as a cushion complete with a cross member.

- Do-it-yourself disassembly of the gearbox continues with unscrewing the speedometer drive nut. After unscrewing this nut, it is necessary to dismantle this drive.

- The VAZ 2107 transmission is a mechanism with a set of gears and forks through which the vehicle moves. Having turned the gearbox over to the other side, you need to remove the reverse light switch.

- The bolt securing the fork, which is responsible for switching third and fourth gears, is unscrewed.

- You need to turn on the first transmission using the gearshift lever on the VAZ 2107.

- At the same time as first gear is engaged, fourth gear must also be engaged. Using a screwdriver, move the synchronizer clutch to the side to connect it to the gear.

- You may ask, why is it necessary to engage 2nd gears at the same time? This is done in order to block the rollers from turning.

- The retaining ring is dismantled by prying it with a special puller on the secondary shaft.

- Using chisels and a hammer, bend the locking plate securing the flange nut.

- The nut must be loosened by 2-3 turns, which will allow the coupling centering ring to be removed. After moving the ring, you need to screw the nut.

- Using a special kind of puller, you need to dismantle the coupling ring.

- After removing the ring, it is necessary to dismantle the centering ring seal.

- Now you can use a wrench to unscrew the nut.

- There is a retaining ring behind the nut that also needs to be removed.

- Using another puller, it is necessary to dismantle the flange.

- The gearshift lever must be set to the neutral position, and then the sealing collar must be pulled up.

- Behind the cuff there are nuts that need to be unscrewed. After unscrewing them, the lever or rocker is dismantled.

- Behind the scenes there is a seal that must be removed.

- The gearbox on the VAZ 2107 is further disassembled by unscrewing the two nuts securing the exhaust pipe.

- There is a bolt behind the bracket that should also be removed.

- To remove the back cover of the box, you need to unscrew the 5 outer nuts.

- Another nut secures the cover from the inside, so after unscrewing the 5 outer nuts, you should proceed to the last one - the inner one.

- It is necessary to disconnect the back cover and the box housing, which requires moving the back cover. The fastening nut is unscrewed, and then the washer is removed.

- After unscrewing all the nuts, it is necessary to remove the rear cover from the crankcase, rocking it. The crankcase cover will come off on its own.

- After removing the cover, it is necessary to remove the inner ring from the secondary shaft. Behind the ring is the speedometer drive gear, which must also be removed.

- The cover of the clamps is found, after which the two bolts securing it are unscrewed. After removing the bolts, you must remove the cover.

- There is a gasket under the cover that needs to be removed.

- The spring clips are removed.

- The gearbox must be turned over, thereby removing the retaining balls.

- You need to find the drive gear retainer ball and remove it. The oil deflector washer also needs to be removed.

- You should continue further if two gears are engaged at the same time. With two gears engaged, it is necessary to unscrew the bolt securing the 5th gear gears. As you guessed, this procedure is performed for the VAZ 2107 5 mortar gearbox.

- The fastening of the 5th gear shift fork, as well as the reverse gear, is unscrewed. After unscrewing, you must remove the plug.

- By holding the rod of the 5th gear, as well as the reverse transmission, you need to remove the rod from the crankcase and the shift fork.

- The gear block of the 5th gear and reverse gear is dismantled manually.

- The gear bushing is removed in the same way from the secondary shaft.

- Once the bushing is removed, you will need to remove the gear, ring gear, locking ring and synchronizer clutch for the five-speed transmission.

- The 5th gear synchronizer clutch hub is removed.

- The reverse control gear is also removed.

- From the inside, the intermediate shaft bearing is pressed out. To do this, you will need to take a hammer and a punch, and apply light blows.

- Next, the bushing is removed from the secondary shaft. It is also necessary to remove the outer ring from the rear bearing.

- Using a puller, you need to unclench the locking ring and remove it.

- Two gears are engaged at the same time - first and fourth. The bearing securing bolt is unscrewed.

- Place a screwdriver between the outer side of the ring and the shaft gear, thus removing the bearing ring together with the balls.

- The rear inner ring is pressed out.

- The intermediate shaft is removed.

- The locking block of the transmission rod 3 and 4 is removed.

- Crackers vary in size, so remember their location.

- The shift rod 3 and 4 of the transmission is removed.

- The 3rd and 4th gear shift fork is removed.

- The bolt securing the fork 1 and 2 of the transmission is unscrewed.

- The transmission rod 1 and 2 is removed.

- The locking block 1 and 2 of the transmission is removed.

- The fork for selecting these gears is removed.

- The complete input shaft is removed.

- The needle bearing is removed.

- It is necessary to unfold the locking plate until it disengages from the groove.

- The reverse gear axis is removed.

- The intermediate ring is removed.

- The key is removed from the groove of the secondary shaft.

- The intermediate bearing is removed.

- The secondary shaft is recessed into the inside of the crankcase, thereby removing it.

- Using a hammer, it is necessary to press out the secondary shaft bearing.

- The sealing gland is removed.

- The bearing from the 5th gear can be removed with a screwdriver, using it as a lever.

Splines and forks

There is a reverse gear between the wall of the VAZ-2107 gearbox housing and the fifth gear. Since it produces a reverse movement, the part is not connected directly, but through an intermediate gear. It is installed on the axis of the rear wall of the transmission housing. The gear fork fits into the groove of the gear. When it moves, the intermediate element engages with the reverse gear. The secondary shaft has synchronization clutch hubs. They are motionless. A speed synchronization clutch is put on the gear ring of the hub.

As for the shift fork, it fits into the annular groove of the synchronization clutch. The latter moves along with the movement of the rod. The clutch begins to act on the synchronizer blocking ring and, as a result, moves it. Thanks to the friction force, the rotation speed of the hub and gear is equalized. The teeth mesh with the gear timing ring. Torque begins to flow to the secondary shaft through the hub and clutch from the gear.