The VAZ-2107 car is the latest model produced by AvtoVAZ using the so-called classic layout, when the car was driven by the rear wheels.

And since the majority of our car enthusiasts prefer rear-wheel drive cars, the 2107 is still a popular car among the people.

The chassis of any car includes two main suspension components: front and rear wheels.

If we take into account the front suspension of the VAZ-2107, then it is more reliable than that of the VAZ-2108.

This is explained by the fact that the “Seven” has fewer front suspension components than the “Eight” due to the drive to the rear wheels.

But at the same time, due to the same drive, the rear suspension is more complex, which means there is a greater likelihood of a malfunction.

What does the VAZ suspension consist of?

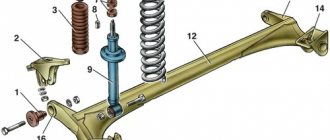

1 — transverse arm mounting bracket, 2 — stabilizer bar cushion, 3 — bar cushion bracket, 4 — stabilizer bar, 5 — transverse arm, 6 — stabilizer strut, 7 — ball joint, 8 — steering knuckle, 9 — telescopic strut, 10 — transverse arm extension, 11 — front mounting bracket for the transverse arm extension, 12 — cross member.

What should you pay attention to?

If you hear a knock in the front suspension while driving, the main reasons may be:

- — Malfunctions in the rack;

- — The bolts have become loose, the stretch marks or cushions with which the cross member is equipped may have worn out;

- — The attachment to the body is loose;

- — The rubber parts have collapsed, and the knocking has a distinct “metallic” sound;

- — A “limp” or even a broken spring knocks;

- — Wear of hinges;

- — Knocking due to wheel imbalance;

- — Settlement or breakage of the suspension spring;

The car pulls to the side when driving straight. The reasons for this malfunction may include:

- — Each spring has its own compression ratio. In this case, the spring that has lost its elasticity must be replaced;

- — Tires have different pressures. We check and correct;

- — The rubber element near one of the strut supports was destroyed. At the same time, a characteristic knocking sound is also heard while driving. The problem is solved by replacing this element;

- — The wheel alignment angles are incorrect. Increased tire wear may be associated with this malfunction.

Tire wear. This may be due to improper driving (rash acceleration, braking, exceeding the permissible load of the vehicle), or other reasons:

- — violations of wheel alignment angles;

- — high wear of the hinges;

- — wheel imbalance;

When driving with increasing speed, metallic noise increases:

- — Check the wheel bearings;

- — When starting to move, a characteristic “crunch” appears;

- — Inspect the CV joints, such a sound can only be made by balls that roll along the grooves, because have too much output.

Knowing the meaning and design of the suspension, you can check its condition every time you inspect the machine on a pit (overpass) and perform maintenance. Pay special attention to the condition of the protective covers on the ball joints. Check to see if any deformations, cracks or dents have appeared on the suspension due to shaking and bumps. You should also check the tightness of all nuts.

Be sure to check the condition of all rubber and rubber-to-metal parts, as well as the ball joint of each wheel. We must remember: a malfunction noticed and corrected in time is much less evil than repairs when everything is already falling apart.

How to change silent blocks on a VAZ 2107 yourself

Before changing the silent blocks on a VAZ 2107, stock up on the necessary tools. Please note that this work is difficult to do without special devices.

You will need:

- Special puller for dismantling silent blocks;

- puller for ball joints.

The equipment listed above can be purchased or borrowed from friends. As for the rest of the instrument, there will be no problems here. Prepare a pry bar, a hammer, a well-sharpened chisel, and calls for “thirteen” and “twenty-two.” In the first case, you will need a spanner and a socket wrench, and in the second - an open-end and a socket wrench.

Many car enthusiasts do not know which silent blocks are best for the VAZ 2107. Do not save in any way - buy original spare parts for your car. As for the material, you should choose products made of polyurethane. It has better resistance to various chemicals and a longer service life.

Main nodes

Let's talk about its device. The most important element of the front suspension is its strut (hydraulic telescopic) - indispensable in the matter of shock absorption, that is, ensuring a comfortable ride, without much shaking (as far as possible) over bumps and potholes on our roads. It is thanks to the rack, or rather its steering knuckle with an upper bolt equipped with an eccentric washer and a belt, that makes it possible to change the camber of the wheel.

Telescopic strut of the front suspension of VAZ 2110

The following are installed on the rack:

- Special spring;

- Buffer limiting the compression stroke, made of polyurethane;

- Upper support. Its structure is as follows: it is attached to a stand, to which the mudguard is attached with self-locking nuts. Therefore, if you make repairs yourself, do not miss this moment - you cannot use ordinary nuts;

- A bearing that makes it possible to rotate the stand together with the wheels;

- A shock absorber in which a spring and a plunger are installed for better performance.

The ball joint combines the lower parts: the steering knuckle and the lever. The longitudinal braces, lower arms, and supports that the crossbar has are connected to each other by rubber-metal hinges. With the help of special washers, it becomes possible to adjust the longitudinal inclination of the turning axis. An angular contact, non-adjustable bearing secures the wheel hubs.

Ball joint VAZ 2110

The cross member is the rod to which the lower arms are connected. It is attached to the body in the middle, helped by rubber cushions.

This, in a nutshell, is the front suspension design. Now let’s look at possible malfunctions, which in some cases can be fixed with your own hands, in others it is better to contact specialists.

Cross member VAZ 2110

Ball joints

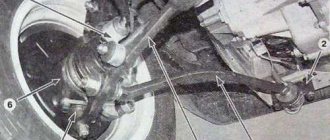

To replace ball joints, you must first remove the wheel and clean the suspension parts from dirt. Then the jack is placed on the lower arm and they begin to lift the car. This is done in order to load the suspension.

Use a wrench to unscrew the ball joint pin nut, starting with the top one. Then the support pin is pressed out of the steering knuckle.

After the finger comes out of the fist, you need to unscrew the fastening of the ball joint and remove it along with the protective cover from the upper arm.

A new one is installed in place of the old ball joint and assembly is performed in the reverse order.

The lower ball joint is changed in the same way as the upper one. After replacing all the ball joints, you need to contact a service station to check and, if necessary, adjust the camber and toe angles of the front wheels.

Possible breakdowns

Knock

If you hear a knock in the front suspension while driving, the main reasons may be:

- Faults in the rack;

- The bolts have become loose, the stretch marks or cushions with which the cross member is equipped may have worn out;

- The attachment to the body has become loose;

- The rubber parts have collapsed, and the knocking has a distinct “metallic” sound;

- A “limp” or even a broken spring knocks;

- Wear of hinges;

- Knocking due to wheel imbalance.

In principle, in any of the listed cases, repairing the VAZ 2110 front suspension, done by yourself, can help, during which you need to replace a worn part or (in the latter case, the reasons why a knock is heard) - balance the wheel.

Vehicle pull to the side

The car pulls to the side when driving straight. The reasons for this malfunction may include:

- Each spring has its own compression ratio. In this case, the spring that has lost its elasticity must be replaced;

- Tires have different pressures. We check and correct;

- The rubber element near one of the strut supports was destroyed. At the same time, a characteristic knocking sound is also heard while driving. The problem is solved by replacing this element;

- The wheel alignment angles are incorrect. Increased tire wear may be associated with this malfunction. If you can’t handle it yourself, it’s better to entrust this task to specialists.

Rear axle

The design of the rear axle chassis of the VAZ 2109 is much simpler, this is explained by the fact that, unlike a classic rear-wheel drive car, it does not have transmission-related parts. And the load taken by the chassis is much less than that of a truck.

Rear axle chassis parts

Due to the milder operating mode (compared to the rear-wheel drive of previous models), the designers had the opportunity to simplify the design and design of this unit of the VAZ 2109. Thus, in the rear suspension of the chassis there are no stretch marks and parts for transmitting rotational force to the wheels, stabilizers (since their role is played by the beam), this slightly worsened the dynamic parameters of the car, but significantly increased reliability. The diagram of this chassis unit includes:

- Trailing arms;

- Central beam;

- Brackets for fastening the vehicle axle to the side member;

- Hydraulic shock absorbers;

- Springs (pair);

- Flanges for mounting wheels.

Rear axle design

The main element of the rear axle of the chassis of the VAZ 2109 is a beam, which in turn consists of three parts - two trailing arms and a connector. These three units are connected by welding with reinforcing linings. Brackets for installing car shock absorbers and flanges for installing wheel axles are welded onto the arms.

In the front part, hinges are installed with a lever; bolts pass through them to secure the chassis to the hinges mounted on the body side members. The shock absorbers of the rear axle of the VAZ 2109 are hydraulic with added coil springs. In their upper part, through rubber-metal bushings, they are fixed in the parts of the car body.

Suspension check

Knowing the meaning and design of the suspension, you will be able to check its condition every time you inspect the machine on a pit (overpass) and perform maintenance. Pay special attention to the condition of the protective covers on the ball joints. Check to see if any deformations, cracks or dents have appeared on the suspension due to shaking and bumps.

Be sure to check the condition of all rubber and rubber-to-metal parts, as well as the ball joint of each wheel. Remember: a malfunction noticed and corrected in time is much less evil than repairs when everything is already falling apart.

Polyurethane or regular?

On sale you can find two types of elements - polyurethane and rubber-based. The question is: which ones are better to use on the VAZ 2107? Rubber ones have many disadvantages:

- Even the new ones squeak.

- They have a relatively small resource.

- Under the influence of an aggressive environment they quickly become unusable.

But they also have a big advantage - a fairly low price. Depending on the “appetites” of the seller, you can purchase a set for 500-700 rubles. But polyurethane ones have higher characteristics. They are practically not exposed to aggressive environments, have a long service life (at least twice as long), but there is one drawback - the price. It is within one and a half thousand. Look at how you are used to using your car.

Which ones should you install on your VAZ 2107? The question is not easy, you need to weigh everything to answer it. And most importantly, assess your financial capabilities.

You also need to pay attention to your driving style. If aggressive, then polyurethane will be more suitable for the job.

But if you drive quietly and the suspension is not subjected to significant loads, then you can install regular rubber ones. But we need to make a reservation again - it all depends on your capabilities and preferences. Polyurethane ones are many times better than rubber ones on the VAZ 2107 and similar models. And they are free from the main drawback of rubber joints - they do not creak.