Good day, dear readers! In the fourth issue of the BZ we will talk about small “jambs” that began to appear in my Lada Granta in the first hundreds of kilometers.

So, after installing the Methane gas system, my everyday work as a taxi driver began. As already mentioned in the 2nd issue of the BZ, the operation of the manual transmission and sound insulation of the new Lada Granta left much to be desired, and as the car was used, new “jambs” began to be added to these minor troubles. Let me make a reservation right away that all these “childhood diseases” are treated through simple manipulations, and some do not attach any importance to them at all. Therefore, my comments are not a “stone in the garden” of the Lada Grant, but a simple statement of facts, so to speak, my purely personal feelings from the operation of the car.

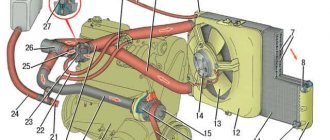

Front suspension "Lada Grants"

It has an independent suspension with wishbones and a stabilizer bar. Damping of vibrations is carried out by hydraulic shock absorbers. The main structural element is the stand. It includes a swivel bearing, shock absorber and spring. The latter uses coils of variable diameter. The spring itself is made of a metal rod with a circular cross-section. It can have variable and constant hardness.

The front suspension of the Lada Granta is designed so that the lower part of the strut rests on the steering knuckle. When the wheels turn, the spring and shock absorber rotate with it. The stand itself remains motionless. Thus, the engineers achieved an increase in the service life of the elastic element while maintaining the inlet hole in the shock absorber body.

The pillar support has also been improved. Suspension creaking on the Lada Granta appears much less frequently than on Kalinas and Priors. To reduce roll, the design includes a stabilizer bar. It is made of spring steel. The stabilizer is installed with its ends to the lower suspension arms. Its middle part is fixed to the body.

How to remove annoying noise?

They try to solve this problem in different ways:

- some glue foam rubber from the inside;

- others use self-tapping screws to disfigure the decor;

- Desperate car enthusiasts order and have leather upholstery made.

You can temporarily remove the creaking of plastic in a car, but it won’t work forever . Sooner or later, the panels have to be removed, then anti-corrosion treatment, then adding wiring, and then repairs, and the song begins all over again.

Many “tulips” were broken in the doors of domestic “Zhiguli” cars. And the linings with latches on foreign cars pinched the pockets of thousands of car enthusiasts.

If a couple of “bugs” break, replace the part. Sometimes car owners, for example, having removed the trunk trim, do not put it back in place; suddenly problems with the wiring begin again.

At first, manufacturers tried to solve this problem with the help of “self-adhesive”, but failed. The reason is disposability. As soon as you remove the part, dust instantly settles on the sticky surface and it loses its former stickiness.

The situation was slightly improved by the invention of Velcro (a system of hooks and loops).

It was a high-tech solution to the problem. Convenient and fast, and most importantly reliable. Well, not everything is so smooth here:

- Firstly, the weight of the parts held is limited.

- Secondly, over time, hooks and eyes become dirty and lose their tenacity.

And now, another breakthrough in this matter, from the famous company ZM (USA) . After the invention of the well-known scotch tape, they more than once surprised the world with all sorts of wonders.

They invented "fungi". These are plates with tiny mushroom-like “shoots”.

When squeezed, they adhere to each other with enormous strength. Moreover, such an action as removing and installing can be performed many times, and the load capacity is so strong that railway workers have become the main buyers.

Those who traveled in luxury cars probably noticed the new fasteners - this is the invention of the ZM company.

ZM fasteners have also been adopted by car manufacturers . Any panel of a modern foreign car is attached in exactly this way. ZM “Dual Lock” fasteners are now sold in almost all auto stores. You can place the fastener halves on the parts in different ways.

Rear suspension

Unlike the front, it has undergone virtually no changes. Here, just like on the first Soviet G8s, a semi-independent beam is used. It is attached to the body on hinges (fortunately, there are no “crabs” in the design). A helical spring with constant stiffness is used as an elastic element. To dampen vibrations and prevent swinging, two shock absorbers are used.

The elements come from the factory are oil type. The spring is fixed together with the shock absorber. This greatly simplifies maintenance work, but has a negative impact on handling. Often the rear axle skids when cornering. But despite the archaic design, the owners speak positively about this suspension and highlight a number of advantages:

- High reliability. The design does not have additional levers, which, in addition, can bend when falling into a large hole.

- Energy intensity. The Lada Granta absorbs all bumps perfectly, especially if oil shock absorbers are installed at the rear.

- Cheap maintenance. Due to its simple design, this pendant can be rebuilt even with your own hands. And the cost of new rubber-metal elements is unlikely to empty the pockets of even the most stingy car owner.

The main difference between the “Grant” suspension is the wheel alignment angles.

They have a positive camber of about 0.1°). On Priora, for example, this figure is -1 degree. Next, we will consider the main malfunctions of the chassis on the Lada Grant.

Creaking in the cabin or “live” Lada Granta

Has this ever happened to you when suddenly something somewhere could “prick”, “get sick”, but then go away just as quickly as it started? This happens to everyone and we don’t pay much attention to it, because different processes take place in a living organism, the essence of which we may not fully understand. So, what am I talking about? Lada Granta, it seems, is also a “living organism”. During the winter, strange things began to happen to her. For example, while driving, a strong creaking sound (cricket) could suddenly appear in the cabin, and in the most unexpected places. You’re driving along calmly, and then suddenly... and suddenly something starts to creak.

While you are racking your brains about what it could be, the creak could just as quickly disappear as it appeared. Of course, this can be easily explained. As the car warms up/cools down in winter, the interior elements begin to expand or contract (the law of physics), but at different speeds, because they are made of different materials. The gaps between the parts also begin to “walk,” which causes a squeak when one part begins to “rub” against another. After time, the mating parts should form their own “working gap” through friction and the “temperature” squeaks will go away (I would really like to believe this), but time will tell.

Shock absorber

This element is a damping device. The shock absorber serves to reduce the range of vibrations of the car body. In other words, the element prevents spontaneous rocking. The work of the shock absorber is based on hydraulic resistance. Inside it there is a liquid of a certain viscosity. It moves through a special valve. Thus, the device absorbs sharp impacts while preserving vulnerable suspension parts. Therefore, the shock absorber is one of the most important components in the chassis. On our roads, this element lasts about 60-80 thousand kilometers. But this period may be shorter, even with careful driving. It is enough just to damage the protective boot, and all the dirt will accumulate in the rod seal.

The rear shock absorbers suffer the most wear because they have much longer stroke. When driving quickly through potholes, the hydraulic fluid may simply boil. This is one of the reasons why a shock absorber fails. But most often it leaks - the valve loses its tightness due to a strong breakdown or impact. As a result, the outer side of the cylinder becomes coated with an oily liquid. How to determine that this element has failed? It’s very simple - you will hear a characteristic knock in the suspension of the Lada Granta. Moreover, it is clearly visible in the cabin. From the outside, you can hardly hear a broken shock absorber. This knock is so strong that even good music cannot interrupt it. You will hear a broken shock absorber immediately.

Also note that the damping element changes in pairs. That is, in the event of a breakdown of the rear left shock absorber, the rear right shock absorber also changes. As for the front struts, they are more durable. Often they are replaced already assembled with a spring, since they fail no earlier than after 150-200 thousand kilometers.

Expert answer

I had a similar knocking sound that sounded like "DUK-DUK-DUK". The sound is the same as in the video, only weaker.

It is less likely to assume that a pebble hit the drum, but this is a very rare case.

If you have exactly this sound, then it is almost 100% that the brake pad is clinging to the drum. It remains to find out why this happens.

Worn or incorrectly installed pads

When you removed the drum, did you look at the wear state of the brake pads? Most likely, you either have grooves on the block or on the drum, or their geometry has been disrupted. It is necessary to remove the rear drum again and carry out more thorough maintenance.

Often this sound occurs due to the fact that the brake pads touch the drums with their end.

Properly installed rear brake pads

Brake cylinder failure

Check the operation of the brake cylinder

Also in my practice, there have been cases when the reason for the appearance of extraneous sounds during braking was a faulty brake cylinder or brake distributor. In this case, you need to lift the car on a lift, or hang both wheels, and see with your partner how the rear wheels grip.

The brake cylinder may jam and give a sharp blow from the shoe to the drum. And then, as a result of the same wedge, the block slowly returns to its place, and extraneous sounds are heard.

Silent blocks

By 100 thousand, the silent blocks of the cross member and lower arms fail. Signs of a malfunction are a dull knock from the front suspension of the Lada Granta. Motorists recommend replacing these elements with polyurethane ones.

They are characterized by higher strength and good service life. At the factory, rubber silent blocks are installed that do not withstand the impacts of our roads. To replace, we need to press out the old element. First, the bead is cut off from it, and then knocked out using a mandrel or chisel. Pressing is done using a vice. It is important to maintain alignment and not mix up the installation side. For easier pressing, it is recommended to use lubricant.

The silent blocks of the anti-roll bar also fail. These bushings are also replaced with polyurethane ones.

Lada Granta paint chips

The first trip to Chelyabinsk (150 km from Zlatoust) was a serious blow to the paintwork. Imagine my surprise and disappointment when, after the first trip, I discovered numerous chips in the paintwork (I counted about 20 chips). Moreover, they were not only on the hood, but also on the doors. To be honest, I was not ready for this.

Now, in order to stick on the “armor,” you first need to touch up the chips with a pencil and bring the paintwork into proper condition. However, it’s winter outside, and at sub-zero temperatures in the garage, this will be difficult to do, to put it mildly, so we’re waiting for the warmth... I plan to record the entire repair process and post it in one of the issues of the BZ. Below in the photo you can see examples of chips and their sizes.

Photo 1: Chips in paintwork on Lada Granta

Maybe the reason for such chips is not the quality of the paintwork as such, but the peculiarities of our area? I will try to clearly demonstrate what I mean.

Carefully! "Stone bullets" on the road

In the Urals, the terrain is predominantly mountainous, but I’m generally silent about Zlatoust :)). In our city and beyond, horizontal surfaces are in great short supply! Therefore, to prevent cars from “piling up” under every hill in winter, the roads are generously sprinkled with “dropouts” (and not only the roads). Crushed stone screening is a by-product from the processing of hard rocks or, simply put, production waste. Since there are many mining enterprises in our territory, the by-product of which is “screenings” - we have it as “dirt”. The photo below shows what it is.

Photo 2: Screening as an anti-icing powder

Now it’s not difficult to imagine how these “stone bullets” fly out from under the wheels of oncoming cars and “attack” your car. I wonder how fast they fly into the arms of your paintwork? Let's do the math. For example, you are moving along the highway at a speed of 100 km/h, and an oncoming truck is rushing at a speed of 90 km/h. A small pebble flying out from under the wheel of a “truck” also has its own speed (+60 km/h). By adding the speeds, we get no less than 250 km/h. This is approximately the speed at which this “rock bullet” penetrates your paintwork. And the more “dropouts” on the road, the higher the likelihood of getting caught in “crossfire.” What kind of paintwork will withstand this? Yes..., only polyurethane armored film will help us (don’t even consider vinyl film, it’s just decor).

Cause of malfunction

The main cause of element malfunction is a violation of the boot seal. Once it starts to crack, dirt and dust will get inside. They act on the ball like an abrasive. As a result, play appears and the support begins to break on its own. Is it possible to repair it? The Lada Granta suspension is designed in such a way that the ball joints cannot be restored and must be replaced entirely with new ones.

These elements are replaced as a set. The price of two balls is about 700 rubles. The service station will charge about 600 for installation. Although you can replace them yourself. All you need: a jack, a pit, a set of sockets and a special sprocket wrench. But please note that the bolts in this place may become sour. When replacing, there is a high risk of licking off the edges of the sprocket. Unscrew all bolts very carefully - do not press too hard. The service life of original ball joints is about 40 thousand kilometers.

Passenger door handles Lada Granta

Another problem I had was with the passenger door handles, which very quickly lost their “pristine appearance.” The silver paint on them began to peel off literally from the first days of use. The photo below shows what I mean.

Photo 3: Paint peeled off by wedding rings on the Lada Granta door handle

Why does this happen? The paint is peeled off like a scraper by the wedding rings on the passengers' right hands, and in a day there can be many such passengers in a taxi. Repainting the handle trims is not an option. The only way to preserve the “pristine appearance” of door handles for some time is to cover them with film. I haven’t decided yet what kind of film it will be in my case. In one of the next issues of the in-flight magazine I will definitely share the solution to this problem.

Perhaps these are all the minor troubles that caught my attention, and which I plan to address in the near future. See you again in new issues of the BZ!

Wheel bearing

This element serves for uniform rotation of the car wheels. There are 4 such bearings on the Grant. On average, their resource is 100 thousand kilometers. What are the signs of a problem? The main symptom is a characteristic hum when moving. It may get worse as the car turns. The hum can occur on either side of the car, depending on which bearing has fallen apart. The entire assembly is replaced with a new one, and it doesn’t matter whether the Lada Granta’s rear suspension or the front one. It is pressed out using a puller with special paws. Pressing takes place in a vice. It is important to maintain alignment when pressing. If a bearing is installed crookedly, it will be subjected to high loads and may fall apart after just a thousand kilometers.

The main enemy of a bearing is moisture. Therefore, during installation it is so important to ensure the element is sealed. Some manufacturers cover it with a special cap (it is put on the fastening nut), which will prevent salt, water and other reagents from getting inside. But as soon as dust penetrates the bearing, the latter begins to operate outside of its temperature range. As a result, the lubricant is washed away, and the dirt acts as an abrasive. Untimely replacement of this element can provoke a sudden wheel wedge, which is fraught with consequences.

Lada Granta side windows rattling

At the time of purchasing Granta, the temperatures outside were above zero, but winter soon began, and with it came the rattling of the side windows in the doors. The rear windows began to cause particular problems. If I have electric windows on the front doors and I can “pull” the glass up at any time, then the rear doors have ordinary “oars”, which for some reason constantly fall down along with the glass while driving. This makes the glass begin to rattle even more.

The feeling is very unpleasant, especially when you are carrying a passenger, and everything inside is rattling and rattling. The passenger probably thinks: “What kind of trough is this?... But it looks like new.” It is clear that this rattling can be easily eliminated by installing the hose into the seal (the Internet is full of videos on this topic). However, it’s winter outside and it’s cold in the garage, so I left the rattling noise alone until better times, but for now I decided to just periodically tighten the rear windows.

To begin with, about what and why it creaks

The dashboard, “tidy”, as they call it, is the instrument panel, which is located in the cabin under the windshield, directly in front of the driver and passenger seat. The purpose of the instrument panel is, as a rule, purely aesthetic; it hides a large number of wires and components located in the cabin, making it more attractive. Also on the instrument panel there are often various gadgets, a passenger airbag and the electronic instrument panel itself (speedometer, tachometer and other indicators and control lights).

In most cases, dashboards are made of elastic, but not hard materials; initially, this decision had one goal - ensuring safety in the event of an accident. However, with the advent of the Airbag, or more simply put, “airbags,” the instrument panel has become nothing more than just a beautiful shelf, the design of which is carried out by entire creative studios in order to attract the attention of a fastidious buyer. Basically, the “tidy” is made from soft foam compounds based on polyurethane foam or polyolefin, which do not withstand temperature changes and increased vibrations. The latter is very relevant for our roads, which are more like a test track or a washboard, and certainly not a public road.