06 September 2017 Lada.Online 86 761 13

The main distinguishing feature of an automated transmission (AMT or “robot”) from a mechanical one is the electric actuators produced by ZF, which change gears at the command of the electronic “brains”. The manufacturer claims that the actuator unit is maintenance-free and cannot be repaired, but craftsmen have found a way to repair it with their own hands.

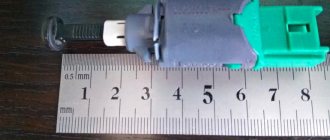

If the car’s warranty has already expired, then replacing the clutch release mechanism actuator yourself will cost tens of thousands of rubles (article numbers: 21820160901200 and 21820170501200). In an attempt to save money, you can try to repair it.

Replacement and repair of the AMT clutch actuator on LADA

The main distinguishing feature of an automated transmission (AMT or “robot”) from a mechanical one is the electric actuators produced by ZF, which change gears at the command of the electronic “brains”. The manufacturer claims that the actuator unit is maintenance-free and cannot be repaired, but craftsmen have found a way to repair it with their own hands.

If the car’s warranty has already expired, then replacing the clutch release mechanism actuator yourself will cost tens of thousands of rubles (article numbers: 21820160901200 and 21820170501200). In an attempt to save money, you can try to repair it.

Automated transmission design

You can eliminate the creaking of the clutch actuator on Vesta with your own hands after understanding the design features of the mechanism.

The robot is based on a conventional VAZ 21807 manual gearbox. A ready-made technical solution allows you to reduce the cost of car production and minimize the difference in cost with the manual version of the car. The main difference from a manual transmission is the replacement of the clutch pedal and gear shift knob with corresponding electromechanical type switches. To manage them, the following have been additionally implemented:

- Control block.

- Shaft speed sensor.

- Fork position sensor.

- Interior gear selector position lock.

AMT has one significant disadvantage of the operational plan: the electromechanical drive processes commands with a delay. A hydraulic alternative, unfortunately, is not available due to its high cost.

Replacing the AMT clutch actuator

How to remove the actuator

:

- Disconnect the negative terminal of the battery.

- The engine air filter has been removed.

- Remove the screw securing the wiring harness.

- Remove the three screws securing the AMT actuator unit.

All that remains is to disconnect the connector and pull out the actuator through the top.

Installation

in reverse order.

Why does the Vesta clutch actuator creak and how to eliminate it on your own?

Annoying sounds from the mechanism for controlling the position of the friction discs, as well as vibration of engines 21129 and 21179 at idle, usually appear after the break-in is complete. Most often, the specific acoustic design of transition modes occurs between 20,000 and 30,000 km.

Cause

At first, the defect appears inconsistently. Usually the clutch squeaks slightly in dry, warm weather, as well as in cold weather. This behavior is evidence that there is not enough lubrication on the rubbing surfaces. It is at this stage that you already need to think about how to lubricate the clutch actuator on Vesta or what lubricant to buy. Ignoring the initial symptoms is unacceptable - the effect will only intensify, manifesting itself in any weather conditions.

Dealers are reluctant to replace the actuator due to creaking. In most cases, representatives of the technical center activate a program to request the plant about the causes of the malfunction. The process is long and not always effective. Only a small percentage of dealerships will unconditionally replace the servo with a new one.

It is expensive to change the mechanism at your own expense - the price for a clutch actuator is at least 13,500 rubles. However, it is unlikely to be possible to find a new one yet - due to their scarcity, they are supplied only to officials.

How to fix

The manufacturer of electric actuators for Lada Vesta, represented by ZF, confidently declares that the drive is maintenance-free. If the clutch squeaks, he recommends replacing the assembly. Craftsmen believe otherwise - the servo drive can be disassembled and lubricated. At specialized service stations, a corresponding service has even appeared, the price of which is from 2,000 to 3,000 rubles.

Tool

When performing the operation, you will not need any exclusive devices. An ordinary “garage first aid kit” will be sufficient at all stages of dismantling and assembling the unit:

- Ratchet crank.

- Screwdriver for bits or screwdriver.

- Heads for “10” and “13”.

- Open-end wrenches for “13” and “27”.

- Attachments for a screwdriver or screwdriver Torx 20, 30.

It is convenient to carry out manipulations to eliminate the creaking of the Lada Vesta clutch actuator on a lift, overpass or pit. If there are no such means nearby, you can use a good rolling jack and safety stands.

Dismantling method

All work on applying the lubricant is carried out exclusively on the dismantled servo drive. Although access is limited, the assembly is easy to remove. Getting to the inside of the structure is also easy.

Important! Further measures are carried out with the negative terminal of the battery disconnected. The system does not identify dismantling, therefore, there will be no need to perform adaptation (setting up the drive using a computer).

The initial task is to free up space around the device. Two elements must be dismantled: the air filter housing and the engine crankcase protection. The actuator itself is mounted on a black bracket. It is more convenient to remove the drive assembled with the fastening element using the following method:

- Disconnect the power connectors (one is located on top, the other on the bottom). This is easier to do with the wiring fasteners unscrewed.

- Unscrew two nuts from the hood side and two from under the bottom.

- Remove the assembly.

Disassembling the AMT clutch actuator

Unscrew the top cover. We “discharge” the actuator (turn the gear as in the video) and remove the cover (do not open without the clutch load).

Remove the white compensator (Caution! The spring is very powerful!). The thrust rod is simply removed with force.

When assembling, carefully “cock” the mechanism (photo 1 - unloaded, photo 2 - cocked).

There is no need to make any adjustments to the clutch actuator after installation on the vehicle.

Problems on Vesta with the robot box

Sooner or later, all owners of this car with a robotic gearbox are faced with squeaking during shifts. This also happens when you press the gas or brake pedals. The clutch release actuator begins to creak.

It is located under the resonator, which must be removed to get to the actuator. This device cannot be repaired using repair kits, but is replaced with a new one. To get rid of the squeak, you need to disassemble this unit, or rather, remove the top cover. Then lubricate the parts.

We recommend synthetic lithium lubricant, which is used for mechanisms with metal and plastic parts. It is ideal for such purposes.

AMT clutch actuator repair

Clean the inner surface with solvent. Let's examine the insides. In this example, wear on the ball stops and a crack on the plastic part of the actuator were detected. The problem is that there are no repair kits. That is, AMT clutch actuator parts are not sold separately. If you cannot restore the old ones, all that remains is to lubricate the mechanism.

LIQUI MOLY Thermoflex Spezialfett was used as actuator lubricant. It is very similar to the one that was in the actuator from the factory. Read more about actuator lubrication here.

We perform reassembly and installation of the AMT actuator on the car (see above).

Let us remind you that if other malfunctions occur in the operation of the AMT (howling, crackling, the car jerks, jerking, rattling, etc.), you can determine the cause using these instructions.

Categories of products that may be of interest to you based on the article “Replacement and repair of the AMT clutch actuator on LADA”:

Lubrication without removal

One of the Lada Vesta owners suggested lubricating the actuator without removing it. To do this, he removed the air resonator and made two holes in the area of the gear and compensator (using a self-tapping screw with a drill). To prevent chips from getting inside, the drill was lubricated with lithol. The lubricant was forced inside through the holes using a syringe. You can close the holes with cut screws or rubber plugs.

Another reason for a squeaking clutch may be a rusty release lever stop. Lubricate it with Bechem High-lub L2 MO (photo by premoy).

Let us remind you that we previously told you how to check the technical condition of the AMT box in case of problems.

Share on social networks:

Found an error? Select it and press Ctrl+Enter..

Source

Clutch, gearbox, transmission Lada Vesta

Products from the Dustershop77 range on the topic of the article:

| Name | Manufacturer | Price | Availability | Add to cart |

| DC952-7703062062 | Gasket for gearbox drain plug, transfer case Renault Duster / Terrano / Captur original 7703062062 | Original | 200 / 100 rub. Discount: 80 rub. | >10 |

| DC1560-8200884113 | Drive oil seal original Renault 8200884113 left | Original | 1000 / 800 rub. Discount: 700 rub. | 2 |

| DC1667 | Clutch kit Vesta (1.6l 21129 + manual transmission VAZ / AMT) LUK | Analogue | 5500 / 4600 rub. Discount: 4400 rub. | 1 |

| DC524-302054100R | Clutch kit for 1.6 (H4M) 4×2 gearbox JR5 (5-speed) original art. 302054100R | Original | 8000 / 7400 rub. Discount: 7000 rub. | 1 |

| DC1630-7703075180 | Filler plug for gearbox / transfer case original 7703075180 | Original | 200 / 150 rub. Discount: 100 rub. | 4 |

| DC422-510009710 | Release bearing H4M 4×2 JR5/JH3 5-speed. LUK 510009710 306200650R 7701478631 8200046103 8200764613 8200990502 306205482R 306205482R 306206219R 306201586R | Analogue | 4500 / 3900 rub. Discount: 3500 rub. | 2 |

| DC383-ASAM-30799 | Gear shift lever bushing ASAM-SA 30799 original art. 7700732903 | Analogue | 400 / 150 rub. Discount: 100 rub. | 2 |

| DC440-8200410813 | Drive shaft retaining ring original art. 8200410813 | Original | 500 / 300 rub. Discount: 250 rub. | 3 |

| DC1631-8200201381 | Transmission/transfer case filler plug gaskets original 8200201381 | Original | 500 / 350 rub. Discount: 300 rub. | 3 |

| DC950-321031MG0B | Rear gearbox filler plug Renault Duster / Captur / Nissan Terrano 4x4 321031MG0B | Original | 1500 / 1200 rub. Discount: 1100 rub. | 4 |

| DC956-7700102458 | Automatic transmission filter DP2 original 7700102458 | Original | 900 / 600 rub. Discount: 500 rub. | 1 |

| DC1964-21102301034 | Right drive oil seal Vesta, Largus, X-Ray article 21102301034 (black 35x57x9) | Original | 200 / 150 rub. Discount: 110 rub. | 4 |

| DC1316-8201630012 | Guide (tool) for centering the clutch and release (H4M-JR5/JH3) original 8201630012 | Original | 2000 / 1800 rub. Discount: 1600 rub. | 1 |

| DC1818-7701209239 | Boot of outer CV joint Duster, Terrano, Captur 1.6 / 1.5 4×4 manual transmission 7701209239 original | Original | 3200 / 2500 rub. Discount: 1900 rub. | 1 |

| DC2046-8200544206 | Gearbox input shaft oil seal TL4/TL8/JR5 8200544206 | Original | 1200 / 800 rub. Discount: 600 rub. | 2 |

| DC2245-7703065290 | O-ring, oil pump oil seal, automatic transmission original 7703065290 | Original | 800 / 700 rub. Discount: 500 rub. | 2 |

| DC1956-21820160121100 | Clutch fork boot Grant, Vesta, X-Ray 21820160121100 | Original | 150 / 100 rub. Discount: 70 rub. | 1 |

| DC2159-6001548446 | Clutch master cylinder Duster and others original 6001548446 | Original | 4600 / 4200 rub. Discount: 3900 rub. | 1 |

| DC2163 | Clutch basket Vesta, X-Ray 1.8 21179 JR5 original 21179-1601085-10 | Original | 7300 / 6500 rub. Discount: 6100 rub. | 1 |

| DC2164 | Clutch disc Vesta, X-Ray 1.8 21179 JR5 original 21179-1601130-11 | Original | 6400 / 5300 rub. Discount: 4900 rub. | 1 |

| DC1963-21102301035 | Left drive oil seal Vesta, Largus, X-Ray article 21102301035 (red 35x57x9) | Original | 200 / 120 rub. Discount: 90 rub. | 0 |

A few words about regular MMT

Toyota Corolla 150, 2007, 2008 cars are equipped with MMT 89530-12290. This device has a number of imperfections and shortcomings, which, by the way, was recognized by the automobile concern.

In order to find out which actuator is installed on the car, it is necessary to remove the lower glove compartment cover, and from the driver's seat on the car body you can find the number of the MMT installed on the vehicle.

Results

The Toyota Corolla robotic gearbox has two actuators: MMT and AMT. The first is responsible for the clutch, the other for shifting gears. When the MMT fails, the AMT also begins to operate unstably. Almost all mechanisms of the Corolla robot operate according to this “domino principle”: if one is broken, then the other will not be able to function as it should. To repair it, you need to completely disassemble the box repair kit. There are many descriptions and photos on the Internet that tell not only about manual transmission breakdowns, but also about methods for deep modernization of the MMT clutch actuator.