The appearance of the car, among other things, depends on the wheels installed on it. Stylish alloy wheels can transform the simplest and most unprepossessing car, giving it originality. VAZ car owners have access to a wide variety of rims:

For each type you have to buy suitable bolts to securely fix the wheel. These fasteners are made from numerous materials:

- black metals;

- nickel alloys;

- metals with the addition of zinc or chromium;

- alloys with molybdenum, etc.

When choosing wheel bolts, be guided not only by their appearance and strength, but also by their dimensions: length, head type, thread size and pitch.

Types of fasteners

Here are the types of fasteners needed for alloy wheels:

- Bolts are metal rods with a screw thread at the end. Used to connect detachable elements.

- Nuts are round-shaped parts designed to fasten elements by screwing a metal die onto threaded rods.

Steel, aluminum or titanium alloys are used to produce products.

Titanium bolts are distinguished by high quality indicators. Black bolts for alloy wheels are made from steel with the addition of molybdenum or steel with a chrome or nickel coating.

Characteristics of bolts and nuts

Bolts and nuts differ in design features, so the choice is determined by the type of disk. The stamped disc is made from a durable type of steel. Moreover, it has a small thickness at the point of attachment to the central part of the rotating part. For an optimal connection, the bolt and nut must have a flat surface. The composition of cast wheels includes relatively light alloys. They have reduced reliability characteristics. The fastening system of the products is made in the form of a cone.

Thread

When purchasing bolts, you should pay attention to the threaded part. Not all elements have the same thread pitch. More often there are hardware with a thread pitch of 1.25 and 1.5 mm with a diameter of 12 or 14 mm. It is recommended to purchase new wheel bolts complete with rims or take into account the requirements of the car manufacturer's instructions.

Thread length

To select a bolt of the required length, the easiest way is to try it on site. This technique does not work if the bolt is coated with a coating that is difficult to scratch. Then another option will do; you will need to count the number of revolutions when unscrewing the old bolt. Next, the length of the threaded pin is divided by the resulting figure. The result will be the required length of the fastener.

By size, fasteners are divided into:

- short - used for fixing stamped disk products;

- long - used for tire mounting of alloy wheels.

Do wheel mounts need lubrication?

And one more question that torments many motorists, judging by the popularity of this request on the Internet. Is it necessary to lubricate the bolts and nuts securing the wheels on the car so that they do not stick? There is no clear answer to this question.

In most cases no lubrication is required. Moreover, it is strictly forbidden to do this. Many vehicle owner's manuals contain this warning, but not all.

Lubricating the threads of bolts or wheel nuts leads to a decrease in friction in the threaded connection, which in turn increases the tightening torque several times. Over-tightening can cause permanent deformation of fasteners and weakening of the structure. If the manufacturer recommends dry tightening, it means that he has provided the required tightening torque in this condition.

But there are exceptions to the general rule. Some manufacturers recommend the use of a specific type of lubricant. Accordingly, the prescribed tightening torque is calculated taking this circumstance into account. In any case, you should read the instructions and follow the manufacturer's recommendations.

If your car's instructions do not mention this, then whether or not to lubricate the threads and seating surfaces is up to you. I wouldn't risk it. Since there are no recommendations on what lubricant to use, then there is no point in experimenting. For such components subject to strong heating, a special one is needed. Regular lubricant can only do harm.

How to measure yourself

Measurements must be as accurate as possible, since the indicators differ in close values with a distance of a couple of millimeters, for example, 98 and 100 or 110 and 112, and they are not interchangeable. To eliminate errors, it is recommended to use a caliper or ruler.

Adjacent holes

Here's how to determine the distance between bolt holes. The dimensions of the circle on which the holes are located are taken. The diameter is determined using compatibility tables or by measuring using a ruler. The resulting distance between adjacent fasteners should be multiplied by a factor that depends on the number of holes. The circumference of a VAZ is 9.8 cm, and that of passenger cars is 139.7 millimeters.

Far holes

A simple measurement method is carried out on models with an even number of recesses - for 4, 6, 8 fasteners. Parallel Hole Distance – PCD.

And here’s how the far holes of disks with five bolts are measured: the calculation is made between non-adjacent recesses, the resulting figure should be multiplied by 1.051.

Hub window diameter

Indicative data for the central hub window are indicated in the table and in the complete bolt pattern formula. In the absence of information, readings are measured with a ruler or caliper. The diameter of the hub area on the VAZ 2110 = 58.6 mm.

The bolt pattern is carried out taking into account the relative size of the vertical axis of symmetry of the disk to the area adjacent to the hub.

Consequences from another bolt pattern

Using inappropriate bolts is a safety hazard. When a bolt pattern occurs, an axial displacement of the entire wheel relative to the hub occurs. At high speeds, the wheel spins unevenly, the car will shake, which is accompanied by a beating in the steering wheel.

When installing wheels, car enthusiasts often encounter such a problem as a discrepancy in the diameter of the fasteners. In this case, eccentric bolts with a movable conical part are suitable, which will eliminate discrepancies in size.

How to choose wheel fasteners

The entire line of bolts and nuts is spherical or conical in shape. The characteristics of the connection are determined by the softness of the metal of the cast disk, which leads to an increase in the contact area of the disk and the fastener.

The thickness of alloy wheels is greater than the thickness of steel products, for this reason it is better to use extended bolts. Due to the softness of metal products, it is necessary to periodically inspect the tightening of the fastening system.

Tightening the wheel fasteners

Another important parameter is the tightening torque of bolts and nuts. Do not tighten the bolts and nuts haphazardly. The instructions for any car indicate a specific value - the force with which you need to tighten the car wheel fasteners specifically for this model. Also, many manufacturers of alloy wheels indicate the maximum tightening torque applicable to their product. That is, you should not pull the cast disk with all your might with a pipe, as it can break.

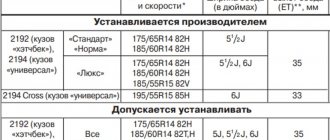

The instructions for the car also contain recommendations on the process of tightening bolts and nuts. The tightening sequence of bolts or nuts and the recommended torque are indicated. The fragments below are taken from the instructions for cars of various brands.

Unfortunately, not every car owner has a torque wrench. Moreover, not all tire shop workers have and use this tool.

When I talked to tire service workers and asked if they had a torque wrench, I met the following answers: “Why? Put the pipe on longer, tighten it tighter - you won’t lose the wheel, don’t worry!” I personally understand the level of their knowledge; I will not go to such specialists to replace tires.

What to do if you have to change a tire on the road? Based on this circumstance, car manufacturers manufacture the wheel wrench in such a way that, using it, a physically healthy adult can tighten the wheel bolts or nuts with approximately the required force recommended by the manufacturer. No need to use attachments or extensions - you will overtighten the fasteners.

Tightening fasteners on alloy wheels

Before installing the bolts into the mounting recesses, it is recommended to treat the hardware with graphite lubricant. As a result, when it comes into contact with the disk, the head of the bolt or nut will rotate and make full contact. This will prevent blocking during starting power due to friction between the disc and the mounting system. Bolts are produced that compensate for minimal deviations in fastener dimensions. A loose connection will lead to cyclical failures in the fastening system; the bolts and nuts will begin to unscrew themselves.

Why change fasteners when changing rims?

Upon arrival home, as soon as I had free time, I was puzzled by this question and went to the Internet to look for answers, as well as ask questions to the tire shop experts.

Having studied a large number of different resources, forums, GOSTs and interviewed some experts, I learned a lot for myself and decided that it was worth sharing the information received and my conclusions with those who are interested in this topic and with those who have not even heard about it.

Indeed, the attachment of cast and stamped discs to the hub is different. And this difference is due to two main factors. The first thing that influences the choice of fasteners is the difference in mounting locations - places where bolts or nuts are attached. The second is the difference in the materials from which cast and stamped wheels are made.

Locking bolts for alloy wheels

Secret bolts for alloy wheels are another subtype. If you install locks, car tires will be protected from theft. You won't be able to remove the wheel with a regular wrench. To unwind the secrets, you will need a key that comes with them in one set.

When selecting fasteners for wheels, you should remember that cast products are relatively thick. Accordingly, longer bolts are selected for them than for stamped discs.

Bolts for forged wheels VSMPO

You can install new VSMPO forged wheels of the ANTARES model on a VAZ using the bolts that hold the standard VAZ alloy wheels. These fasteners are similar in length, but differ in the shape of the skirt. There are original bolts for forged wheels, but even with standard fasteners from factory casting they will hold securely. Many VAZ owners confirm this on specialized forums, but some still purchase forged wheels along with a set of new bolts.

Author: VND, November 20, 2008 in Khodovaya