It is not uncommon for drivers to encounter the fact that the car does not want to go in a straight line if it is not constantly monitored. If you let go of the steering wheel for a second, the car begins to be pulled to the left or right from the trajectory that was before.

If you are faced with a similar problem, then this article should help you. Here we will look at the main reasons that can lead to such behavior of the car, and also talk about how this can be corrected.

First, let's list the main reasons why a car may pull to the left or right when the driver lets go of the steering wheel.

- tire problems;

- incorrectly installed directional wheels;

- wear of steering tips or breakage of steering rods;

- wheel bearing wear;

- broken wheel alignment;

And so, let's start, as expected, with what you can check and fix with your own hands. Namely, from the tires. To diagnose this problem, you need to swap the wheels. Place the front ones back and the rear ones forward. If the situation has improved, you should put a spare tire on the side in which the car is heading. If the problem goes away, then all that remains is to change one wheel to working tires.

If you have directional wheels, make sure the arrows on them point in the correct direction. If the direction is correct, then it is necessary to check the wheel alignment. Alas, to do this you will have to go to a service station, since a similar procedure is not carried out in a regular garage. Often, it is violations of the correct camber and toe angles that cause the car to become obstinate on the road. In addition, the stability of the car decreases, tire wear increases and other unpleasant phenomena may appear. If everything is in order with this parameter, then the reasons should be looked deeper.

Worn steering tips or broken steering rods can also cause the car to pull to the right or left while driving. In principle, you can check these elements in your own garage, especially if it is equipped with an inspection pit. But if you don’t know how to determine steering system malfunctions for sure, it’s better to contact specialists, especially since you’re also unlikely to be able to replace them yourself. Therefore, contact a professional to diagnose your steering system.

Malfunctions in the hub, especially wear of the wheel bearing, can just as easily cause the car to spontaneously drift away from the correct trajectory. The actual wear of the wheel bearing can be clearly heard by characteristic knocking, crunching and grinding sounds in the area of the wheel on which the wheel bearing has worn out. As a result of such wear, the smooth rotation of the wheel is significantly impaired. Which cannot but affect the trajectory of the car. The wheel bearing should be changed not just in a repair shop, but in a repair shop whose quality of work you completely trust. This is not an easy task and the slightest mistakes can cause very rapid wear of the wheel bearing. Therefore, it should be changed by a truly conscientious and experienced specialist.

Rear wheel play Kalina 1

To check the condition of the wheel bearings, you need to hang the wheel and rotate it by hand.

The wheel should rotate evenly, without jamming or knocking. We take the wheel in a vertical plane and alternately pull the upper part toward you, and the lower part away from you, and vice versa. Making sure there is no backlash

Typically, when driving, a “squealing” noise is heard from a faulty wheel bearing.

Disassembly

We place the shoes under the front wheels of the car.

Loosen the rear wheel mounting bolts.

Raise the rear of the car and place a safety device.

Unscrew and remove the rear wheel.

Fully lower the parking brake lever.

Release the tension on the parking brake cables.

Using a 7 mm socket wrench, unscrew the two guide pins.

We clean the cylindrical seating surface of the brake drum on the hub from dirt and corrosion.

We treat the drum seat on the hub with penetrating liquid (VD-40, kerosene or brake fluid).

To ensure removal of the drum, tap it with a rubber mallet or through a wooden spacer with a hammer.

Using a puller or screwing M8 bolts into the two threaded holes of the drum (the length of the threaded part is 60 - 70 mm) and evenly turning them, we press the drum from the hub.

You can also remove it using a wooden spacer or a hammer with a soft working part. Tapping the drum from the back, evenly in a circle

To prevent the pistons from falling out of the brake wheel cylinder, do not press the brake pedal with the drum removed.

Use a screwdriver to pry it off and remove the protective cap from the wheel hub.

The O-ring remains on the cap

Use a narrow chisel or screwdriver to straighten the jammed collar of the nut.

Use a 30 mm socket to unscrew the hub nut.

Remove the nut and thrust washer

The bearing is mounted on the axle with a transitional fit, so the hub can be removed by hand.

If the hub does not come out by hand, then press the hub with a puller.

Remove the hub from the axle.

In this case, a cage with rollers, a protective ring and an inner ring of the bearing remain on the axis.

We take out several rollers from the bearing cage and remove the cage and the protective ring.

To remove the inner ring of the bearing, two flats are made on the axle for installing a puller.

The flats are located parallel to the brake pad spacer.

We hook the legs of the two-jaw puller to the inner ring of the bearing.

We press the inner ring of the bearing.

If there is no suitable puller, you can knock down the inner ring with a suitable chisel

Holding the hub in a vice, remove the retaining ring with pliers.

Use a cup puller to press out the bearing.

The cup puller is shown in Figure 13

If there is no puller, we knock out the bearing using a suitable head or a piece of pipe, striking the inner ring of the bearing.

We press in the new bearing using a cup puller, having first cleaned the inner surface of the hub and lubricated it.

If a puller is not available, the bearing can be pressed in a vice by applying force to the outer ring, through the ring from the old bearing.

Install the retaining ring.

Carefully, with light blows on the inner ring of the bearing, press the hub with the bearing onto the axle to a depth that allows you to tighten the nut.

By tightening the nut, we finally press the hub. Hub nut tightening torque 225–250 Nm (22.5–25 kgcm)

We jam the collar of the nut into the groove of the hub axle

We carry out the final assembly in reverse order.

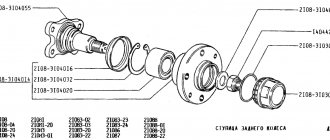

The part numbers for the rear hub of the Lada Kalina car are shown in the figure.

Normal battery leakage current

Current leakage refers to the presence of current flowing from the power bus to ground or to a common wire. It is known that the starting circuit of the ignition switch is powered by bus 15. Bus 30 powers the entire vehicle network from the positive terminal of the battery. Switching off the ignition does not interfere with the energy consumption of other devices. Checking the battery for current leakage is carried out by measuring with a multimeter and visually examining the condition of the wires.

Therefore, with a large leakage current, consumers from bus 30 are examined one by one:

- Car radio – on a working radio the leakage is 10 mA.

- Car alarm - the security device consumes up to 200 mA of current, depending on the brand. There is feedback, a transceiver, GSM, but modern systems minimize the permissible battery leakage current.

- The engine control unit is powered by bus 30, its leakage is a few milliamps.

- Climate control, ABS, body control and other control systems together allow a leakage current of 10 mA.

- A faulty generator will completely discharge the battery in 30 minutes; in a normal situation, the leakage is a few mA.

- Wet and dirty contacts create electrolysis currents and parasitic currents. With normal maintenance of wires and contacts, the leakage current is about 5 mA.

- Self-discharge of a battery is also a leakage current. Internal self-discharge is caused by the quality of the electrolyte, sulfation, destruction of the plates, and it can exceed all other losses.

The leakage current rate is calculated taking into account all consumers, depending on the type of car brand.

The most obvious problems with beam machines

The lion's share of budget cars are equipped with a beam in the rear. This is the simplest and cheapest rear suspension system that has proven its practicality. But this type of suspension does not offer incredible comfort and does not provide decent softness. Also, with these types of structures, various kinds of troubles often occur, which lead to knocking, rattling and other unpleasant consequences of breakdowns. All this suggests that you will often have to stop by a service station to carry out routine car repairs.

The most common breakdowns in this case are the following:

- parts of the stabilization system, which on such machines cannot be of really high quality and durable, bushings and dampers break, small knocks and play appear;

- beam silent blocks - these parts break quite often from driving on a bad road; poor-quality asphalt surfaces force the rubber bands to work under strain;

- shock absorber supports or dampers - usually these are simple rubber dampers that crack from excessive pressure and begin to knock with characteristic loud sounds;

- hub elements - this factor is worth talking about in more detail, so we will analyze the hub further in a separate section of this publication, this is the most common problem;

- fastening parts - the beam is quite heavy, so under heavy loads and on bad roads the fasteners may be damaged, this will lead to poor performance of all rear suspension systems.

Each car wheel rotates on a bearing. If you hear extraneous noise while driving from any direction on a flat road, the rear wheel bearing is probably failing. At first the noise is heard at high speeds - from 80 km/h, over time it becomes audible at lower speeds - from 50 km/h. When turning in one direction, the noise may decrease, while turning in the other direction, it may increase. During diagnostics, by hanging the wheels and rotating them manually, a hum is heard, and by shaking the wheel, you can feel play. All this indicates that it is necessary to replace the rear wheel bearing on the VAZ. Read on and you will learn how to change the rear wheel bearing on Kalina (VAZ 1118).

In order to make replacing the rear wheel bearing on Kalina as simple as possible, we jack up the side we will be working on (or lift the car on a lift). We remove the wheel from the Lada Kalina.

Remove the brake drum. Removing and replacing the brake drum is described in detail in the video “Replacing the rear brake pads and brake drum.”

Unscrew the central nut of the wheel bearing with socket No. 30 (counterclockwise). And remove the thrust washer of the hub nut.

Using a reverse hammer (but it is more convenient to do this with a special puller), we press the hub together with the bearing from the axle. If the puller screw is not long enough, it should be lengthened.

Attention! The inner half of the bearing race may remain on the journal. In this case, we knock it down separately with a hammer and chisel. If this does not work, you should make a cut across with a cutting machine, then the clip will easily get knocked off.

Next, remove the bearing retaining ring from the inside of the hub. Tap the ring first to make it easier to remove. Then use round pliers to remove the ring.

We install the hub on the press and press out the bearing, pressing the moving part of the press on the inner race. The bearing can also be knocked out with a hammer using the old bearing race as a guide, but this may not be an easy task.

We install a new bearing by pressing it in with a press. We press the moving part of the press onto the outer race. You can press the bearing in with a hammer, but you cannot hit the bearing itself, as this will damage it.

Reinstall the retaining ring.

Thanks for subscribing!

Now we install the hub back on the axle. You may have to hammer it through the tube along the inner ring. Before putting the hub back on the axle, clean it with a brush with metal bristles. All pressing must take place without jamming, jamming or scuffing.

Then install the thrust washer and tighten the hub nut.

We assemble the remaining elements in reverse order:

- put the brake drum in place - install it so that the holes for the guide bolts coincide;

- twist the guides and clamp them with a key;

- put the wheel on and tighten the nuts.

Replacing a wheel bearing is not an easy task, and you should be well prepared for it. Your safety on the road depends on the results of your actions. You can learn how to extend the life of a wheel bearing from the article “Prevention of the rear suspension wheel bearing.”

Hub - what could be loose and knocking here?

The hub assembly most often causes unpleasant sounds in the rear of the car's suspension. It's easy to check. Place the car on a level surface, grab the wheel with both hands, and forcefully rock the car in different directions. If you feel a slight knocking sound in your hands, the problems are most often associated with the hub and its parts. Also lift the rear of the car on a jack to hang the rear wheel off. Rock the wheel and check for play. This way you can check the condition of the bearing in a garage.

There are different breakdowns in this situation:

- wear of the bearing seat in the hub is the most important point that you need to pay attention to when diagnosing a car, so as not to sacrifice the quality of the ride;

- the bearings themselves are worn out, you can tighten them using an adjusting nut, but this must be done carefully so as not to overdo the tightening and not overtighten the bearing;

- the wheel is not fastened - very often frightened owners come to the service station with complaints about the rear suspension falling apart, but after checking it turns out that one of the wheels is unscrewed;

- problems with the rear brake drum - this braking system has already become obsolete, but is still found on budget cars; the complex is unreliable and often brings problems to owners;

- on a disc brake there is a problem with the caliper - this can also produce unpleasant knocking noises and bring extremely difficult moments with the operation of the car, including failure of the braking system.

You need to carefully check every detail in the rear of the car that may cause unpleasant manifestations. If the inspection is poor or inattentive, within a few months you may experience a significant deterioration in the quality of driving your car. Be careful when diagnosing such problems. Knocks in the rear suspension often start serious problems that will lead to not very comfortable driving and a number of expensive breakdowns. Repairing a car after complex problems will be very expensive.

Play in rear wheel bearings

Just two weeks ago I contacted my service about this topic. In short, everything was resolved quickly, the mechanic simply tightened the nut on the hub half a turn with a large mega wrench and the play disappeared. I didn't even have to remove the wheel. In general, all this should be carried out at the first maintenance.

- Login or register to post comments

Offline

At TO-1 in Rostov-Lada, he complained about play (along the axis) of the wheels on the right side. They said that this is normal(?), because... there is no swing of the wheel in the transverse plane with both hands. This raised doubts in me that still plague me to this day. It should be?

- Login or register to post comments

Offline

I had play on the right rear hub. The issue was resolved by tightening the hub with a 32mm wrench (I think). The backlash has passed. I found out the reason when I underwent the GTO.

- Login or register to post comments

Offline

The maximum axial play of the rear wheel hub is a strictly standardized value. It is checked, according to the mind, not by shaking the wheel by hand, but by measuring the beating of the hub. The rocking of the wheel method is, of course, accessible and simple to understand, but not always correct. The criterion for assessing the condition of the hub is the actual runout and the presence of extraneous noise ( hum) during bearing operation. From experience. 50% of bearings tightened by mechanics are overtightened. Which leads to premature bearing failure. Backlash and clearance must be within tolerance; they cannot be completely selected.

In general, the factory prohibits tightening wheel bearing nuts. If there is noise or play (exceeding permissible), the bearing or hub is replaced. Moreover, it is always clear whether the nut has been pulled (by the punch), and a situation may arise when the service station refuses to replace it under warranty, and with good reason.

- Login or register to post comments

Offline

Thank you for the clarification. The play is small. It’s only noticeable if you pump the wheel hard. So there’s no need to worry.

- Login or register to post comments

Offline

What amount of play is considered acceptable?

- Login or register to post comments

Offline

What amount of play is considered acceptable?

- Login or register to post comments

Offline

Serviceman, the next question is for you. As I wrote, this reason was found out at the GTO. Without this decision, I was simply not given a technical inspection ticket. Then the car was only a couple of days old. I went to the VAZ service center and they tightened the hub for me without any complaints. And as I understand this, there is a disagreement between you and our service. So, where you can read information about what services should or should not do, so that you can then have an arsenal of information with you for future communication with IPG. Thank you

- Login or register to post comments

Offline

I found an article on repairing AZLK-2141. It says: “In the hub bearings of the front and rear wheels, the design provides for an axial clearance of 0.06–0.085 mm, which can be felt when the wheel rocks perpendicular to the plane of rotation on the car as play.” I have 0.04 mm play in the right wheel hub and 0.03 mm in the left wheel hub.

- Login or register to post comments

Offline

I think that the technology for repairing VAZ cars is the same for all certified services. further, as in the famous aphorism, everyone lives by the same principles, but violates them in different ways.

to consumer info. provided in the set of documents for the car. The rest of the information should be with the IPG (or another official responsible for maintenance). He will decide for himself whether to share it with you or not; in principle, he is not obligated. He is obliged to put the car in good condition (or make sure that it is in good condition) and record this in writing. There is no formal obligation to talk about beats and stresses in detail.

I repeat once again, it is impossible to pull the wheel bearings formally, and mentally, this is my firm conviction, based both on personal work experience and on factory regulations. Just like you can’t pull steering racks, etc. But everyone is dragging their feet. My opinion is that such operations reduce the service life and increase the likelihood of bearing failure, incl. may be grounds for denial of warranty. I have not allowed mechanics to pull wheel bearings on any of my re-drive VAZs, or on the cars of friends I helped with repairs. Moreover, the “fight” with mechanics and craftsmen who are addicted to this kind of thing on our service was carried out long and persistently before we managed to wean them off this nonsense. But in most services they drag it out and don’t think about it. Unfortunately.

The specifics are as follows: the reason for replacing the wheel bearing is: 1. noise, the hum of the bearing is noticeable when moving or strong extraneous noise, rolling when the wheel rotates. 2. Axial play of the hub. Maximum for machines in operation 0.05mm. For new cars (not used) 0.03mm It is clear that with a hub runout of 0.04mm, for example, wheel play will be noticeable. Which scares many people. 3. traces of overheating and mechanical damage to the bearing.

PS there is no mass defect in bearings. 3-4 years ago they replaced them with boxes, and at the same time they pulled them on every serviced car. now - only a few, and based on a car with decent mileage. I also don’t know of any emergency situations that have arisen due to bearings on cars that are normally maintained, but a deaf person is not driving.

Let's sum it up

Modern cars very often show problems with the technical part. Many cars even force the owner to visit the station more often than he would like. To avoid problems with the rear suspension, it is necessary to test it in a timely manner and use the maximum range of possibilities for recovery in case of minor problems. It must be recognized that each car has its own set of childhood problems. But in the area of the rear chassis, almost all cars with the same type of equipment have the same problems. So you can diagnose equipment at any good station.

Before you go to the service station, check to see if there are other possible causes of problems with your car's suspension. Sometimes you can find a variety of secondary causes of knocking, which obviously do not require money and time to eliminate. Monitor the condition of your car and carry out quality preventive inspections on time. If a problem is detected, you must fix it, and not expect that the problem will go away on its own. The sooner you repair your suspension, the less damage this trouble will cause. Have you ever encountered unpleasant knocking noises from the rear suspension of your car?

When the steering tips wear out, extraneous sounds appear when driving. You can hear them especially clearly when driving over bumps. To check the tips, you need to use a pry bar. It is worth hanging the steering arm. There should not be any mechanical play, but if there is, it means that the service life of the steering tip has expired.

Wheel beating can appear either while driving or grow from a slight noise into a ringing or a distinct hum over time. If the steering wheel begins to wobble while on the road, you should definitely stop and inspect the car. The reasons for vibrations can be different, we will consider each of them below.

Hernia on a tire

Hernia on a tire

If a hernia appears on the front wheel, you can temporarily solve the problem. If you don't have a spare wheel, it's better to put the front one back and the rear one forward instead.

Brake disc is deformed

Repair of a deformed brake disc

The brake disc can become deformed due to temperature changes, for example when driving through a puddle, or in the case of intense braking. The disk can not only change its geometric shape, but also its properties. If cracks form on it, even more vibrations will appear.

To check whether the problem is in the disc or not, you need to unscrew the 4 bolts and remove the wheel. Then turn the brake disc, if radial runout is noticeable, then this is probably the reason.

Bearing loose or worn

If the reason is obvious and the problem is a worn bearing, you need to use a puller and replace the bearing with a new one.

Curved rim

To determine which wheel has failed, you need to drive slowly and see which way the steering wheel is pointing. If the car drifts to the right side, it means the problem is in the right wheel; if it drifts to the left, it means the left disk is deformed. Perhaps the problem with the disk will be solved at a tire shop.

The rear wheel hub axle is not secured

Wheel bolts are not tightened

Such situations are especially often possible after changing wheels. If you don't tighten the bolts enough, they will come off during the ride and a lot of play will form. The main thing in this case is not to hesitate to stop. Such negligence can lead to the loss of a wheel or an accident.

Severe wear on the steering rack

Steering wheel wear

When the steering tips wear out, extraneous sounds appear when driving. You can hear them especially clearly when driving over bumps. To check the tips, you need to use a pry bar. It is worth hanging the steering arm. There should not be any mechanical play, but if there is, it means that the service life of the steering tip has expired.

Replacing a tire with a new one

Continuing to drive on a tire with a herniation is putting yourself and your passengers in danger. No matter what they do at the tire shop, the tire will still not be like new. Therefore, it is worth replacing the tire so that the car behaves confidently on the road.

Replacing the brake disc with a new one

If the disk has led, there is no point in aligning or sharpening it. To prevent the new brake disc from misbehaving like the old one, you need to use engine braking on wet roads. Perhaps we need to install a better braking system that will withstand intense braking. Despite this, no brake system will withstand strong temperature changes, and the disc will start to move.

Replacing or rolling a wheel rim

Rolling a disc is the process of aligning it against indentations. When the disk is slightly damaged, the geometry can be restored by rolling. But more often, cracks appear in titanium discs, which are then welded.

If the situation with the disc is extremely sad, the tire shop will tell you about it, and you will have to buy a new one.

Replacing the hub bearing

Wheel hub axle tightening

Wheel bolt tightening

To prevent the wheel from spinning further on the road, you need to tighten it with a torque from 186.3 to 225.6 Hm. The bolts must be tightened diagonally.

Steering rack replacement or repair

The steering rack is being repaired. To make the steering play less, you need to tighten the rack. A special key is used for this.

Replacing the steering rack

If you cannot tighten the rail yourself, it is better to have it repaired. You can repair it much cheaper than buying a new one.

Replacing the steering tip with a new one

There is no need to invent anything with the steering tips. They are inexpensive and easy to change. True, after replacement you need to do a wheel alignment.

Installing the wheel bearing in its place

First of all, thoroughly lubricate the inside of the hub, as shown in the photo below:

And also, without removing it from the vice, it is necessary to install the new bearing in place. To do this, we set it exactly in the center, and use a suitable spacer to hammer it in. If you act carefully, you can do this even with the help of an ordinary block (wooden), tapping evenly from different sides so that there are no distortions:

Then you can also take a 30mm head or an old bearing and drive in a new one until a seat for the retaining ring appears:

We install the ring in its original place and then you can put this entire assembly on the axle shaft. Installation, fortunately, is carried out quite quickly and without unnecessary problems, since everything gets clogged even with the efforts of two hands. Of course, the axle shaft should also be better lubricated beforehand!

As for the price, a new bearing costs about 500 rubles in the store.

This is probably all that can be said about this repair of the Lada Kalina. I hope that my efforts will not be in vain and will help you if a similar problem arises! Oh, by the way, there will be video tutorials on the blog soon, so stay tuned for the next articles!

Why does the steering wheel pull to the side when coasting or accelerating:

- Uneven tire pressure is the first thing to check, because it is the difference in pressure in the front wheels that most often leads to steering wheel pull when driving, is the easiest to diagnose and no less easy to correct, and is also the most common cause of this symptom. Just check the pressure in the tires of your car and, if they are different, pump them up and make them the same on both tires of one (front, obviously) axle of the car. The pressure on the side where the car is leading should be less than on the other side - only in this case this is the reason. After pumping, drive again in different conditions, on different roads and at different speeds to make sure that the symptom disappears. If you don’t know what pressure should be in the wheels of your car, you can find out in one of our tables by selecting your car brand.

Wheel bearings

We continue to study why the rear right wheel knocks when driving. Whether it’s the 9th Lancer or a VAZ, it doesn’t matter – the bearings make the same noise when they wear out. But the sound is very insidious. At first it will be barely noticeable. If it is not detected in time, the broken holder may simply jam the wheel at speed. Also, knocking noise occurs if the bearing is not tightened properly. To diagnose this, just lift the rear wheel on a jack and shake it from side to side.

Note! The bearing should not be over-tightened. You need to leave a small gap in case of thermal expansion. Minor play is allowed. But if the wheel wobbles, this already indicates a problem.

Replacement algorithm

Before starting work, you need to place wedges under the front wheels of Kalina.

- We remove the protective cap of the hub nut so that it does not interfere with us in the future.

First we remove the wheel nuts.

Unscrew the hub nut with a 30mm head.

If the hub does not come off by hand, we use a three-legged puller.

The bearing is secured in the hub with a retaining ring.

To press in a new bearing we use a race from the old bearing.

We press the hub onto the axle with light blows of a hammer on the inner ring of the bearing, then attach the nut and use it to push the hub until it stops. After the final tightening of the nut, we jam the collar into the groove.

When to change

The rear wheel bearing is characterized by gradual wear. It can fail immediately only in the event of an accident. Often wear occurs so slowly that many motorists do not notice a deterioration in the car's performance.

In the early stages, a malfunction can only be recognized with the help of service equipment. When jacking up the rear wheel, we begin to rotate it. If a crunching sound is heard and play is felt, then the bearing should be changed.

Let's look at the main signs that the rear wheel bearing has failed:

- While driving, a hum is heard from the rear wheel. This indicates significant depletion of the part.

- Gradually the hum increases and begins to be accompanied by a crunching sound.

- There are problems with controllability. The car is driven to the sides.

- When you tap the tires with your foot, you feel play and the car begins to wobble.

Checking generator operation

Sometimes measurements do not change because the generator is not functioning well. After turning the ignition key, the generator does not transmit an impulse and the battery does not charge.

The generator is checked in the following sequence:

- The ignition is turned off and the key is removed.

- Electric current consumers are switched off.

- Wires with clamps from the multimeter are connected to the battery. In this case, the correspondence between plus and minus is monitored.

- To establish the voltage, use the voltmeter mode. The indicator should be 12.9 V.

- Starting the engine, connecting the heater, turning on the headlights.

- Check the voltage (increase to 14V).

When a lower voltage is determined, the functionality of the generator is checked. Craftsmen are involved in this event and the services of automobile workshops are used. They set the acceptable indicator quickly. Using modern stands, the condition of the generator and the presence of breakdowns are established.

Payment via Portmone

After selecting payment through Portmone, the payment system will launch, where you need to select the payment method: bank card or Portmone account.

The price in the Portmone payment system is converted into dollars at the exchange rate of the Central Bank of the country where you are located.

If you have a bank card in a currency other than the dollar, then the money will be debited from the card at the rate of the Central Bank of your country at the time of the purchase.

After specifying payment details and confirming payment, payment for the goods will occur.

Official website of the Portmone payment system https://www.portmone.com

How does a wheel wedge or jam manifest itself?

If the right or left front wheel, as well as any other wheel of the Kalina, does not jam too much, then while the car is moving it should spin in the same way as the others, but the wheel rim gets very hot and fuel consumption increases. If there is a strong jam, the car begins to pull towards the problem wheel: the left one pulls to the left, and adjusting the wheel toe does not change the situation. If it is completely jammed, it does not rotate, at least when moving slowly, and driving is always accompanied by the smell of burning rubber.

It happens that the wheel disk does not brake constantly, but periodically seems to catch it. The driver does not immediately notice the problem. But as soon as you find it, you need to immediately repair the car, because such tacks can easily turn into a complete blockage.

knocks out 2nd gear

I was driving and stuck the 2nd one. knocked out. when you keep it to the norm, repairing the gearbox or they told me about synchros, any thoughts on what to do? Tell me...

My opinion leans closer to the synchronizer, but by 40%, although I also had problems with the 2108, I actually changed the release valve and everything became normal.

I completely changed the clutch less than a month ago.

I have the same crap, I should say I need to fix the synchronizers and something else

So the synchronous gear needs to be changed and the 1st-2nd gear clutch needs to be changed.

gears, or are there none in the PP?

buddy, I have no idea myself, so I’m writing here for advice from experienced guys.

Thanks for the advice, but I’ll go with the simplest and cheapest)

The simplest and cheapest option can be taken from the arsenal of Tavrie breeders. It's called ROGULKA. This device is a stick 30-40 cm long with (as indicated in the name) a flyer at the end. Operating instructions (brief): 1) Engage the gear you have chosen (note - how to engage a gear is described in the instructions for your vehicle). 2) While holding the clutch pedal depressed, place the device (FLYER) so that its forked end rests on the gear shift lever, and the opposite end rests on the dashboard, or on the technological projections of the floor tunnel between the front seats of the vehicle. Note: the location of the stop of the opposite end of the device (FLYER) depends on the gear you choose. 3) Smoothly release the clutch pedal while lightly pressing the gas pedal. This product is patented and protected by the Copyright Law and before its use, copying and mass production it is necessary to contribute funds to the Fund for Support and Development of the Transmission Department of KB MeMz. Whoever can.

thanks for the advice, IMHO collective farm, with my driving habits it will crash after a few traffic lights, I would prefer normal repairs. WITH RESPECT, for the information provided.

100% second gear synchronizer with fork. Repairs at the service center will cost 5-6 rubles)) The second gear assembly is ready for replacement. At the same time, you can check the other gears))

If it's a synchronizer, why change the transmission assembly?

Source

Rear wheel play Kalina 1

Sany4ka View Lema's profile View malega's profile View Thyssen's profile View malega's profile View Lema's profile View Thyssen's profile View Lema's profile View Lema's profile View Thyssen's profile View Lema's profile View Thyssen's profile View profile In the photo from left to right: AT, LSA, Samara, FAG (fake) ,Hola,SCT,VBF lema View profile In the photo from left to right: AT,LSA,Samara,FAG (fake),Hola,SCT,VBF

How to distinguish a fake from a good one?

In the photo from left to right: AT, LSA, Samara, FAG (fake), Hola, SCT, VBF Thyssen View Lema's profile View profile Thyssen View profile

There is a fake and not very distinguishable from the outside. When I have time, I’ll take a photo (it’s high time to make a “Fakes” theme). VBF at retail is 150 and above, but still you should not rely on price.

Added: I set myself only VBF, partner with hands and feet for SCT.

Why does the 2nd speed of the Priora slip out?

Because You are not logged in. To come in.

Because you are not a trusted user (phone number is not verified). Enter and confirm your phone number. Read more about trusts.

Because The topic is archived.

Help, friends.. I don’t know what to watch anymore.. The question is more for the experts

This is not the first time I’ve been going through the box on my swallow, but this is the first time I’ve encountered something like this. (VAZ 2112)

Replaced with a new one: Second gear Block ring of the second clutch 1-2 gears assembly (i.e. + hub with retaining springs) 1-2 gear shift fork rod of the 1-2 gear fork (too annoying) plus, of course, the third gear and GP gear on the differential)

result: everything is as it was before the bulkhead. The second one sticks in and comes out immediately after releasing the clutch.. if you release it sooooo slowly, it won’t fly out, but if you half-add the gas, it goes straight to neutral..

People please tell me what to do. Today the second gear started to fly out... it engages, but as soon as you release the clutch, it immediately crashes out (((Mileage 30350... Before that I went to the dealer, about 1000 years ago I did the maintenance myself. Now I’m thinking what to do... and the warranty seems to be up to 30500 (provided they don’t notice the homemade maintenance =)))

what to do? please advise!

Operations for removing (replacing) the rear wheel wheel bearing Lada Kalina

1. Remove the protective cap.

2. . and loosen nut 5 (see Fig. 1) securing the hub.

3. Engage 1st gear and install chocks under the front wheels. 4. Loosen the wheel mounting bolts and hub nuts. The hub nut is tightened with a large torque, so it is recommended to use, for example, a piece of pipe as a lever.

5. Raise the rear of the vehicle and place it on secure supports. 6. Remove the wheel from the side of the bearing to be replaced and the brake drum. 7. Completely unscrew the hub nut and remove the thrust washer.

8. Install the puller and press the hub off the axle.

9. Clamp the hub in a vice and remove the retaining ring 8 from it (see Fig. 1).

Current consumption rate in a car battery

Some car appliances are constantly running on electric current. Let's list them:

- watch;

- memory of the electronic control unit;

- standard anti-theft system;

- signaling.

These devices continuously consume electricity. The ECU memory, after it is rebooted, begins to function and remembers the current installation functions. The alarm starts working as soon as you leave the car in the parking lot. The listed car appliances depend on electric current, so they continuously consume a small amount of electricity.

Since electric current is used by many automobile appliances, a standard for current leakage has been established. This indicator is constant; it can be determined by adding up the amount of electricity used by each device. For example, when a car clock, alarm system, and multimedia continuously consume current, the total amount of current consumed will be 24 mA (1 mA + 20 mA + 3 mA). However, if we add up the volume of electrical current consumed by all devices that operate continuously, we get a value from 50 to 80 mA.

For reference, a turned-on headlight consumes 500 mA, so a small electrical leak in the car equal to 50 mA will not cause the battery to run out.

Is it possible to check the current leakage in a car and find out the norm? To do this, it will have to be diagnosed by measuring current consumption. If it turns out that the amount of current consumed exceeds the standard indicators, you will have to find and eliminate the electrical malfunction.

How to change the rear wheel bearing on Kalina

Before you begin the replacement procedure, you need to give the car a working position - hang the rear wheels, while securely fixing the front ones. It is enough to post only the side on which repair work is planned. Next, we sequentially follow the algorithm outlined below:

- We unscrew the wheel bolts and remove the wheel from the “damaged” side;

- Remove the nut in the center of the hub and the cap;

- Lightly tap the guide bolts with a hammer and then remove them;

- We dismantle the brake drum: before the procedure, it is recommended to treat the fasteners of the part with VD-40 (for these purposes, car shops have special drum pullers);

- After dismantling the drum, access to the central nut opens. We remove it;

- Push back the hub axle to gain access to the bearing races. Before proceeding with dismantling, you need to carefully inspect the unit. If there are signs of bearing rotation on the axle, then the hub is not suitable for routine repairs - replacement is required;

Upon completion of the work, you need to hang the car and rotate the wheel. If there is no noise or crunching, the hub is “healthy”.

Finding the root problem

One of the key factors causing the problem is any electronic device or support for the operation of additional equipment. These devices are being used more and more often in cars. During the search, devices installed independently of each other must be taken into account. The factory circuitry in the machine is well protected and a short circuit will only occur if there are significant defects. For example, if the protective cover is accidentally damaged. Sometimes the car owner misplaces the wires, placing them in the wrong position, which seemed most suitable to him. This usually causes a short circuit.

Failure results in loss of current in the battery. Wiring installed by the vehicle owner may be dangerously close to the engine. During operation, the motor becomes hot and the wire insulation may melt. The cord rubs against the edges of metal elements, especially in places where the door closes. As a result, the insulation is broken and a short circuit occurs in the electrical network.

After measuring the current consumption, it is necessary to begin a visual inspection of all equipment if the rate of loss of electricity in the machine does not correspond to the readings of the multimeter. It is necessary to take into account individual parts and assemblies that are subject to any mechanical stress. If it is difficult to identify breakdowns, you should move on to in-depth diagnostics.

Payment via Portmone

After selecting payment through Portmone, the payment system will launch, where you need to select the payment method: bank card or Portmone account.

The price in the Portmone payment system is converted into dollars at the exchange rate of the Central Bank of the country where you are located.

If you have a bank card in a currency other than the dollar, then the money will be debited from the card at the rate of the Central Bank of your country at the time of the purchase.

After specifying payment details and confirming payment, payment for the goods will occur.

Official website of the Portmone payment system https://www.portmone.com

Lada Kalina Sport barabashka › Logbook › Solving the problem of uneven braking of the rear wheel

The problem started a long time ago, but only received a solution yesterday. I couldn’t find the beginning of the first entry in the viburnum community, so I found this backstory. For those who are too lazy to read, I’ll describe it briefly: With relatively sharp braking there was: - the car pulled to the left. — blocking the rear left wheel. ABS did not unlock it. If other wheels jammed during braking, the ABS would work and the car would not pull to the left.

There were no ABS errors. And I couldn’t understand why the ABS wouldn’t release the rear left wheel. At first I tried to solve the problem myself. I took the drums apart and compared them. I didn't see any obvious defect.

I contacted a service center near work (the tenant there had recently changed), and I didn’t really like the new guys. I described the problem to them. While they were removing the drums, one was dropped and a piece broke off. They said the left rear brake cylinder was leaking. Alternatively, the handbrake cable gets stuck in the housing, causing uneven braking. Then it was replaced: - cylinder. — handbrake cables. — All the springs are in the left drum.

Packed up, I left. The first braking was not accompanied by uneven braking, but then it began to appear.

And now it has become critical and dangerous to drive. I wanted to call on the same guys so that they could fully understand the problem, but apparently they don’t have any work and the box is closed. Apparently this was for the better.

I decided to definitely check that ABS had nothing to do with it. I pulled out 1 fuse out of 3. The ABS and parking brake lights came on. The effect is the same - the left one is blocked. skids the car.

Yesterday I called Andrey (the master who sharpened my internal combustion engine and assembled it for Gromozek Pistons. By the way, he has already converted two viburnums like this.), He turned out to be free at 15 o’clock and I drove up to him.

Having described the problem to him, he suggested that the reason was not in the left wheel, but, for example, in the right, that it braked poorly. They lifted the car onto a lift, I was sitting in the car. Andrey says that I would pull the handbrake, and then he would rotate the wheels, then I would hold the brake, he would rotate again. It turned out that with one braking force, the left wheel holds worse than the right (the rear, of course).

And then I began to think about the difference in the approach to solving the problem of different service providers. Andrey’s approach seemed to me more competent and constructive compared to the first guys. (I go to the service very rarely, so the comparison only worked now))))

But it remains strange to me why, if the braking efficiency of the left wheel is worse, then it even gets blocked while moving.

Andrey checked the diameter of the brake drums (which those “masters” did not do): right: 201mm left: 201.2mm

In general, we decided to replace: drums - cast iron FENOX 1640 rubles, like a pad (one peeled off, the pads came off for 2 years.) VAZINTESERVICE-400 something rubles, both cylinders. I don't remember the company. without a box. in a box of 10 pcs. 240 like rubles.

For what reasons do interruptions occur?

There can be many reasons why gears do not shift when the engine is running. However, all of them, in one way or another, are connected with the two most important units of the car - the engine or gearbox. In case of serious damage, you should contact a good car service.

If the problem is in the gearbox, it will need to be removed for further disassembly and troubleshooting. If the problem is with engine components, they may need to be replaced. However, there are cases when, to eliminate a malfunction, it is enough to carry out preventive maintenance: removal, lubrication and careful adjustment of the components.