Many call the heart of the car its power plant. However, it would be most correct to consider the fuel pump as such. Its functions, which are quite easy to verify, are very similar to those performed by the heart in the human body.

In this material we will talk about how to determine that it is the fuel pump on the VAZ-2115 that is not working, and we will tell you about ways to eliminate the detected problems. In reality, the failure of this unit has very characteristic signs that make it easy to distinguish it from other malfunctions that occur with the machine during its operation.

Most often, the car engine suddenly stalls while driving. Moreover, if you start the power plant again, very specific sounds are heard from under the hood, but the starter spins as if nothing had happened. Repeated attempts to move also end in failure.

Also, sometimes the car stops starting the first time. This problem usually occurs if it has been in neutral for some time.

The most typical symptoms of fuel pump failure are:

- the power unit of the car does not want to start;

- too low pressure level in the fuel system;

- engine tripping;

- loud “growling” of the engine at low speeds.

However, the first can happen for other reasons:

- problems with candles;

- ECU error;

- Some sensor is faulty.

An 8-valve engine tripping is a fairly typical sign of a fuel pump failure. In this case, the car drives jerkily, because the fuel flows improperly, which leads to poor performance of the cylinders.

The loud “roar” of the engine in the vast majority of cases indicates a failure of the fuel pump. Much less often, this indicates that the filters are clogged.

Why else might the pump motor not start? Here are the most common reasons:

- fuse blown;

- relay failure;

- mass break;

- failure of the electric motor installed in the pump;

- contamination of power terminals.

The fuel pump does not work, the relay turns on.

Checking relay power.

In the case when the fuel pump relay turns on when the ignition is turned on, but the pump itself does not work, you need to check the power at terminal 87 of the fuel pump relay. To do this, touch terminal 87 of the relay socket with the output of the control lamp connected to the vehicle ground, and the lamp should light up. If the lamp does not light, it means the fuse has blown or there is a break in the wire.

If there is power at terminal 87, you should remove the relay from the socket, and instead place a jumper between pins 87 and 30. In this case, if the pump and connecting wires are working properly, the pump should start working and if this happens, the relay should be changed. If the pump does not start working, then, without removing the jumper, you need to touch the power wire on the fuel pump with a test lamp connected to the vehicle ground.

Checking the fuel pump power circuit.

If a submersible pump is installed on the car as part of the fuel module, you need to remove the connecting connector and touch one of the thick wires. When you touch one of them, the indicator lamp should light up. If the lamp does not light up on any of the wires, then it is necessary to eliminate the break in the wire from the fuel pump relay to the module connector or the pump itself, if the pump is of a remote type. One of the reasons for the break may be the anti-theft blocking of an installed non-standard alarm system.

In the case when the test lamp lights up on one of the thick wires of the connector or one of the terminals of the remote pump, you need to connect these terminals with a test lamp to each other. In this case, the control lamp should light up. If the lamp does not light, it is necessary to eliminate a break or poor contact in the wire connecting the pump to the vehicle ground.

If, when checking the wires and relay for turning on the fuel pump, no malfunction is detected, the electric motor of the fuel pump or its connection to the module connector is faulty. It is not difficult to find the cause by removing the fuel pump module from the tank. If there is poor contact with the connector, melting of the plugs will be visible. If melting is not noticed, then to check the pump itself, you can connect it to the battery. It should be taken into account that operating a submersible pump without liquid will damage the pump. A faulty pump should be replaced.

Buying a fourteenth fret is a young thing that does not require a large budget, both for the car itself and for spare parts. If you compare the VAZ 2114 with any foreign car of the same class, you will get a decent price difference in favor of the Lada. And even if a foreign car costs more, and servicing it is not more expensive than a Lada, then spare parts from the Russian automobile industry will be much easier to find in any of the most remote areas of our country.

Whatever you say, any car wears out and requires attention and care. So let's talk about a common problem with the fourteenth - the fuel pump does not pump.

Gasoline pump VAZ 2114

You're driving, and suddenly you stall. You start it, the engine growls, the starter turns, it starts moving and again there is a stupor. Or the ignition does not respond at all, you have to push it to start. This also includes the case when the engine responds every once in a while if you slow down for a couple of minutes and go to nitral. The battery is ok. We're sinning at the fuel pump.

Why the VAZ-2115 fuel pump does not work and what to do

Many call the heart of the car its power plant.

However, it would be most correct to consider the fuel pump as such. Its functions, which are quite easy to verify, are very similar to those performed by the heart in the human body. In this material we will talk about how to determine that it is the fuel pump on the VAZ-2115 that is not working, and we will tell you about ways to eliminate the detected problems. In reality, the failure of this unit has very characteristic signs that make it easy to distinguish it from other malfunctions that occur with the machine during its operation. Most often, the car engine suddenly stalls while driving. Moreover, if you start the power plant again, very specific sounds are heard from under the hood, but the starter spins as if nothing had happened. Repeated attempts to move also end in failure.

Also, sometimes the car stops starting the first time. This problem usually occurs if it has been in neutral for some time.

The most typical symptoms of fuel pump failure are:

- the power unit of the car does not want to start;

- too low pressure level in the fuel system;

- engine tripping;

- loud “growling” of the engine at low speeds.

However, the first can happen for other reasons:

- problems with candles;

- ECU error;

- Some sensor is faulty.

An 8-valve engine tripping is a fairly typical sign of a fuel pump failure. In this case, the car drives jerkily, because the fuel flows improperly, which leads to poor performance of the cylinders.

The loud “roar” of the engine in the vast majority of cases indicates a failure of the fuel pump. Much less often, this indicates that the filters are clogged.

Why else might the pump motor not start? Here are the most common reasons:

- fuse blown;

- relay failure;

- mass break;

- failure of the electric motor installed in the pump;

- contamination of power terminals.

Symptoms of a problem

- The first sign indicating a breakdown of the fuel pump will be a banal refusal of the engine to start. Of course, such an indicator as an unstarted car is very general. In this case, it is worth checking the spark plugs, which may become oily and not produce a spark and the ECU.

- The second point is the pressure of the fuel system. If the fuel pump is OK, it creates a pressure of 3.2 bar. The fuel rail is characterized by the following indicators:

- for a volume of 1.5 l – from 285 to 325 kPa,

- for a volume of 1.6 l - from 375 to 390 kPa.

- A very common problem is when the signal does not reach the fuel pump after ignition. When you turn the key, you usually hear a slight vibration from the fuel pump, but here it doesn’t happen. Most likely the wiring has failed. We'll have to call her and figure out what's what.

- The engine is tripping. Like reason number one, this indicator is not a benchmark. It is believed that the signs of a malfunction of the VAZ 2114 fuel pump are represented by other obvious causes of malfunctions. However, if the fuel pump is not working properly, the engine begins to jerk (which is natural, fuel combustion in the cylinders occurs incorrectly), and operate intermittently out of the blue.

- The engine may jerk even before starting or at low speeds. This reason is closer to the truth: either the fuel pump or its mesh – a low-purity filter – is not working.

The fuel module, which includes the pump itself, is expensive - from 2,000 to 3,000 rubles. The inept owners of the fourteenth buy it entirely (together with the filter, fuel level sensor, float and intake chamber) and install it to replace the deceased. In fact, the price of a VAZ 2114 fuel pump is only 700-1000 rubles, you only need to take and install it, the rest of the module almost always remains intact.

Just don’t immediately run to the spare parts store and buy a new one! There are plenty of reasons for the breakdown, including those that may lie in the power system. Here are the main ones:

- Fuel pump fuse VAZ 2114

- Fuel pump relay VAZ 2114

- Poorly secured mass of the VAZ 2114 fuel pump

- Fuel pump motor VAZ 2114

- Contacts of the fuel pump system VAZ 2114

- The fuel pump itself

All these spare parts can break and stop the normal operation of the fuel module system. In fact, the fuel pump is the part of the fuel system that passes gasoline under pressure. The mechanism is complicated, we will understand it step by step.

Why the VAZ-2115 fuel pump does not work and what to do

Many call the heart of the car its power plant. However, it would be most correct to consider the fuel pump as such. Its functions, which are quite easy to verify, are very similar to those performed by the heart in the human body.

In this material we will talk about how to determine that it is the fuel pump on the VAZ-2115 that is not working, and we will tell you about ways to eliminate the detected problems. In reality, the failure of this unit has very characteristic signs that make it easy to distinguish it from other malfunctions that occur with the machine during its operation.

Most often, the car engine suddenly stalls while driving. Moreover, if you start the power plant again, very specific sounds are heard from under the hood, but the starter spins as if nothing had happened. Repeated attempts to move also end in failure.

Also, sometimes the car stops starting the first time. This problem usually occurs if it has been in neutral for some time.

The most typical symptoms of fuel pump failure are:

- the power unit of the car does not want to start;

- too low pressure level in the fuel system;

- engine tripping;

- loud “growling” of the engine at low speeds.

However, the first can happen for other reasons:

- problems with candles;

- ECU error;

- Some sensor is faulty.

An 8-valve engine tripping is a fairly typical sign of a fuel pump failure. In this case, the car drives jerkily, because the fuel flows improperly, which leads to poor performance of the cylinders.

The loud “roar” of the engine in the vast majority of cases indicates a failure of the fuel pump. Much less often, this indicates that the filters are clogged.

Why else might the pump motor not start? Here are the most common reasons:

- fuse blown;

- relay failure;

- mass break;

- failure of the electric motor installed in the pump;

- contamination of power terminals.

Pressure system

The gasoline pump creates pressure in the fuel rail for normal gasoline supply functionality. Let's measure the pressure and we'll understand a lot right away.

Normal parameters of atmospheres in the system are as follows:

- Idle – 2.5

- Ignition – from 3

- Without pressure regulator tube – 3.3

- With pinched drain – 7

- We press on the gas - from 3 to 2.5.

We will measure in these five states with a pressure gauge with a small range of atmospheres (up to 7, to reduce the error to a minimum). Under the hood we found a pressure fitting (just unscrew the cap in advance), attached a pressure gauge (hose) to the fitting and off we went. The ignition is turned on, the pressure gauge is zero: the fuel pressure regulator is broken. We press on the gas, the pressure gauge goes to zero: the fuel pump itself is broken (now you can do some shopping at a spare parts store). There may still be a situation. When the pressure gauge needle lazily rises, look at the condition of the fuel filter.

By the way, if you don’t have a pressure gauge, it’s sad and sad, because it’s an expensive pleasure. Similar diagnostics in the service will cost half as much.

Models of fuel pumps for VAZ 2114/2115 cars

VAZ 2114/2115 cars are equipped with 1.5 cm 3 and 1.6 cm 3 gasoline engines with a distributed injection system. A submersible electric fuel pump is used to supply fuel. It is part of the fuel module installed at the top of the gas tank (under the rear seat). In addition to the pump, the module includes a fuel accumulator (cup), a coarse filter and a fuel level sensor with a float.

The VAZ 2114/2115 fuel pump is a conventional DC electric motor in a sealed housing with a one-way valve at the outlet. An impeller of a special shape is located on the electric motor shaft. Its rotation ensures the fuel supply.

The fuel pump is powered from the vehicle's on-board network. The electrical circuit of the pump, protected by a fuse, is closed using a separate relay.

Electric fuel pumps for VAZ cars are produced by both domestic (Utes, SAAZ, Pekar) and foreign companies. The latest modifications of the VAZ 2114/2115 are equipped with BOSH pumps, which are distinguished by their high reliability, long service life and relatively low price.

Catalog numbers of standard fuel pumps for VAZ 2114/2115:

- 2112–1139009–12 - for engines with a volume of 1.5 cm 3;

- 2112–1139009–01 - for engines with a volume of 1.6 cm 3;

- 580453453 (BOSH) - for engines with a volume of 1.5 and 1.6 cm 3.

These models differ in operating pressure. The former are capable of creating a pressure of 2.8–3.2 kPa in the fuel system, the latter - 3.7–3.9 kPa. BOSH fuel pumps are rated at 3.5 kPa.

Wiring contacts

The wiring system goes to the fuel pump in the number of three wires: positive, negative and gasoline level indicator. The cause of a fuel pump failure may be a simple power failure in the wiring. If everything is normal with the pressure, then we check the contacts.

We take a simple 12 V light bulb and attach its wires to the positive and negative contacts on the external connector of the fuel pump, respectively. We turn the ignition: the light blinks, there is contact. Then you need to dig deeper - look at internal contacts.

An external problem with the wiring if the light does not light up: alternately connect the positive and negative contacts removed from the fuel pump connector to the ground of the fuel pump, and then to the snout. Negative contact on ground, turn on the ignition, the light blinks - the contact is not working, the light does not blink - the positive contact is not working. When the contact is on the snout and the light comes on, the wire is damaged in the area from the fuel pump to the snout.

How to check the performance of the fuel pump

Often, for those problems for which the car owner blames the fuel pump, other elements of the fuel system are to blame. To establish whether a fuel pump has failed, you will need to know the reasons why it might break.

Causes of fuel pump malfunctions

Most often, the device may fail while the vehicle is moving. The gas pump may simply refuse to pump fuel from the tank to the engine, or a leak may form, causing the device to malfunction. If the power supply is interrupted, the pump stops working completely.

The main causes of fuel pump malfunctions include the following:

- lack of tightness in the pump itself (leakage);

damage to membrane surfaces;

the resource of the pump motor has been used up;

contacts have oxidized;

wiring or relay problems;

dirt and debris in the fuel tank, which, along with gasoline, enter the pump.

As you can see, there can be many reasons for a fuel pump to fail.

Dirt deposits on the filter mesh are a common cause of fuel pump malfunctions.

Symptoms of a problem

There are only four main signs by which you can diagnose malfunctions in the fuel pump without special tools:

- The car simply won't start. Of course, the engine may not function for a number of other reasons, however, first of all, you will need to check the functionality of the fuel pump itself.

After the car starts, the characteristic buzzing of the fuel pump is inaudible. The whirring noise should be clearly audible in the rear of the cabin, as the fuel pump is located under the rear seats.

Recently, interruptions in the operation of the power unit have begun to be observed: the engine does not start the first time, while driving you can hear the engine straining.

The car starts to jerk when driving at low speed.

Motor

Fuel pump motor VAZ 2114

We checked the pressure and wiring, everything works like clockwork, but the engine stalls. The fuel pump may not pump due to a breakdown of the motor - the main element that drives fuel. We check its functionality with the same light bulb: attach its wires to any terminal of the motor, turn the ignition. The lamp blinked - it was time to throw out the motor. And again, run to the store for a brand new motor.

The terminals may oxidize and not make contact, as a result of which the fuel pump will not pump. The motor in this case may be normal. And the terminals just need cleaning (possibly re-soldering). There is an opinion that the terminals are oxidized due to low-quality fuel (the octane number does not match the declared one).

Causes of malfunction

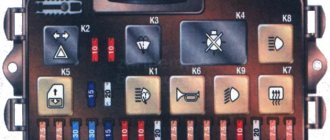

- Fuses under the dashboard on the ECU. The top one is 15A (fuel pump) and the bottom one is 7.5 A (goes to the ECU, to the ignition module.

- Faulty fuel pump relay. It is located under the dashboard, the topmost relay (below the top fuse).

- Poor fuel pump ground. The ground for the fuel pump is attached under the dashboard, where the handbrake is. The mass needs to be cleaned and re-secured. If the mass falls off, the fuel level indicator also does not work.

- Lack of positive contact. We remove the rear seat and check the presence of contacts in the wiring block. If there is no positive, then it is either a relay or a fuse.

- Fuel pump motor not working.

Fuel pump weight

The contact system is normal, but the gasoline level sensor is acting up. Let's see what happens to the mass of the fuel pump. It may be poorly secured. In this case, the fuel pump will not be able to pump anything.

The mass of the fuel pump itself is attached to it in the area of the handbrake, under the dashboard. When you pull the handbrake, you can touch the ground contacts of the fuel pump, and the connection may be lost.

It is not difficult to tighten the mass of the fuel pump, it is difficult to reach it. Namely: get the grounding contact of the ground conducting the lost connection. We remove the plastic under the handbrake and the floor covering of the car, respectively; We clean the contact and firmly attach the mass to the fuel pump.

In the same place as the fixed mass of the fuel pump, under the dashboard, its relay is located.

Ideally, when ignited, the relay creates the required pressure in the system in a couple of moments and turns off. If this does not happen, the pressure is normal, but the process does not proceed, we completely lift the front facing panel that covers the contacts of the music and air conditioner and look from the passenger side: there are three switches, the lowest one is from the fuel pump. When you turn the key, the relay makes a characteristic click and works. If there is no click, the relay or its contacts are closed.

As they say, there is no need to waste time on trifles, if the motor terminals can be reanimated, then it is better to replace the relay and its contacts. The pleasure is inexpensive, the location for replacing spare parts is very convenient.

The fuel pump does not pump: causes and diagnostics

Let's start with the fact that if the gas tank is full, the battery is charged, the spark plugs are dry and there is a spark, the starter turns the engine normally, but the engine does not seize, then you should pay attention to the gas pump. A common problem is that there is no power to the fuel pump after the ignition is turned on. In a similar way, the malfunction manifests itself in motion, when the power to the fuel pump is lost and the engine suddenly stalls.

An equally important point is how much the fuel pump pumps. In other words, the pump may hum and buzz (power is being supplied), but not create the required pressure in the fuel line. The pressure in the fuel system with a working fuel pump must be more than 3 bar (which depends on the specific car model). The indicated pressure is accumulated in the fuel rail and has an indicator of 300 kPa and above.

To check, you need to measure the pressure in the fuel rail with a pressure gauge, taking into account the indicators that are the norm for a specific car model. Using the example of injection VAZs, the pressure when the ignition is turned on is 3 atmospheres, at idle the figure is 2.5 atmospheres, when you press the gas 2.5-3 atmospheres. This method will help you accurately determine:

- malfunction of the fuel pressure regulator in the rail;

- breakdown of the fuel pump or a noticeable decrease in its performance due to wear;

- severe contamination of filters (fuel filter and/or fuel pump mesh);

In the second case, when you press the gas, the pressure does not increase; in the latter case, the pressure gauge needle rises, but very slowly or jerkily.

We also recommend reading the article on how to check the fuel pressure in the fuel rail yourself. From this article you will learn how to correctly measure gasoline pressure with a pressure gauge in the process of diagnosing a gasoline pump with your own hands.

A decrease in pressure below the norm will lead to the fact that the engine may not start or start with difficulty, stall, jerk, operate unstably and with failures. If this happens due to the fault of the pump and not the fuel filter, then there is a high probability that the coarse filter screen of the fuel pump is clogged. In this case, there is no need to change the fuel pump itself, since it will be enough to replace or even clean the mesh.

We also recommend reading the article on how to clean the fuel pump stack yourself. From this article you will learn how and what means you can clean the fuel pump filter with your own hands.

If you suspect that there is no voltage to the fuel pump, there is a quick way to check. It is enough to turn the ignition key and listen, as when you turn the key you should hear a slight hum from the fuel pump. If such a buzzing noise is not heard, it means there is no power to the fuel pump, there are problems with the wiring, etc.

We add that this method of determining the operation of the pump by sound is not suitable for all cars. On some models (especially premium ones), sound insulation is at a high level and the fuel pump turns on immediately after opening the driver's door, and not when turning the key in the lock. In this case, it may seem that the fuel pump does not work when the ignition is turned on, and the sound of the pump may simply not be heard.

Also in the general list of possible reasons why the fuel pump does not pump, the following are noted:

- failure of the fuel pump fuse;

- fuel pump relay failure;

- problems with the ground of the fuel pump;

- malfunction of the electric motor of the fuel pump;

- oxidation or damage to fuel pump contacts and terminals;

- the fuel pump itself is faulty;

Wiring to the fuel pump

On most cars, the wiring to the fuel pump consists of three wires: “plus”, “minus”, and also a wire for indicating the amount of fuel in the gas tank. If the fuel pump does not pump, then the cause may be a lack of power.

To check the power to the fuel pump, just take a 12-volt light bulb and supply it with power from the external connector of the fuel pump. After turning the ignition, the control lamp should light up. If this does not happen, then the problem is in the external circuits. If the lamp comes on, it will indicate the need to check the internal contacts of the fuel pump.

To check the external wiring, you should alternately connect the positive and negative contacts, which are removed from the fuel pump power connector, to the ground of the pump. The contacts must also be connected to the fuel pump relay. If you place the negative contact on ground, after which the ignition is turned on and the light comes on, then this means that this contact is faulty. If the light bulb does not light up, then problems with the “plus” are obvious. If you place a contact on the relay and the light comes on, there is probably damage to the wire on the section that connects the relay and the fuel pump itself.

Fuel pump electric motor

If checking the pressure in the fuel rail and the external wiring to the fuel pump gives positive results, then you should check the fuel pump motor. This electric motor is responsible for circulating gasoline inside the fuel pump.

When checking, you need to take into account that the terminals on the fuel pump themselves tend to oxidize, as a result of which power is not supplied and the pump does not pump. In this case, the motor is working, but the terminals need to be cleaned or re-soldered.

To check the fuel pump motor, you will need to attach the test lamp wires to a cleaned and serviceable terminal of the electric motor, after which you should turn on the ignition. If the light comes on, this will indicate that the fuel pump motor is not working.

Fuel pump ground contact

Problems with the fuel pump mass may be indicated by a fuel level sensor that is not working correctly. The mass may be poorly secured; in this case, the fuel pump does not pump fuel. The ground wire is usually located under the dashboard and runs through the cabin. It is necessary to find the specified wire, check and clean all contacts, then securely fasten the ground to the fuel pump.

Fuel pump relay

The fuel pump relay is often mounted next to the fuel pump ground, that is, under the dashboard.

A normally operating relay after turning on the ignition for a couple of seconds allows the pump to create pressure in the system and immediately turns off. When the ignition key is turned, the driver hears a characteristic click (the relay is turned on), then a similar click will indicate that the fuel pump relay is turned off. If such clicks are not heard, this indicates a malfunction of the relay or its contacts. The optimal solution would be to replace the fuel pump relay with a new or known-good device. Let us add that the cost of spare parts is quite affordable.

Fuel pump fuse

During diagnostics, be sure to check the fuel pump fuse. The specified 15 A fuse is usually located in the fuse box in the engine compartment and is marked FUEL PUMP, which means fuel pump.

The fuel pump fuse needs to be pulled out and its contact inspected. The integrity of the contact will indicate that the device is normal. A damaged contact will indicate that the fuel pump fuse has blown. In this case, you need to install a new fuse, which has a very low cost (as in the situation with the fuel pump relay).

Fuse

Fuse 15 A

One of the final stages of checking a malfunctioning fuel pump is its fuse. Like the relay, the fuse can be seen from the inside. Or you can climb in from the outside, through the hood. Under the hood, closer to the windshield, there will be a dark box, right on the electronic control unit. You need to open it and find the topmost fuse with a current of 15 A and the English inscription fuel pump. We take it out and look at the insides: the contact is not damaged - the fuse is alive. The contact is damaged (blown) - you need to install a new fuse. As with the price of the relay issue, buying and replacing a fuse will not be a big waste of money and time.

Not every master's hands grow from the right place. For this reason. The reason that the fuel pump does not pump can be simple stupid shortcomings of simple tuning.

For example, the alarm was installed in such a way that all the contacts were mixed up, and power simply does not go to the fuel pump. Not because the alarm should not be on the car, or the wiring system is acting up, it’s just that the person who installed it didn’t have enough brains and practice. Check all connections carefully if you decide to add some style to your little one.

Or anti-theft. The button is placed in such a way that it interrupts the integrity of the fuel pump ground contact system, and almost always fails. By the way, if you have such a lotion, I don’t think it will be very effective in the absence of a signal. And if there is a signaling system, then anti-theft is not needed at all.

In any case, remember: in any situation where a VAZ breaks down, the point is not that it is a VAZ, and it was made poorly. It’s just that the Russian auto industry is a little more delicate than the foreign one, it requires a little more attention and your ingenuity.

Repair of fuel pump VAZ 2114/2115

When repairing the fuel pump, we will proceed from the fact that we have already removed the fuel pump from the tank. How to properly dismantle the device will be written below, but we will dwell in more detail on the description of the progress of the repair work:

You will need to remove the protective cup from the module - to do this, you will have to pry the cup latches with a screwdriver, and the fuel pump will come out freely.

We unscrew the two screws from the fuel pump housing that secure the fuel level sensor, then disconnect the cable of wires coming from the sensor and put it aside.

Next, you will need to disconnect the filter mesh from the pump using a flat-head screwdriver.

To complete the disassembly, you need to remove the housing itself from the device - there is a cotter pin on the surface that needs to be pulled out.

You will need to carefully examine all parts of the device for cracks, tears and deformations. As a rule, most often some specific parts of the fuel pump fail, which are much easier and cheaper to replace than to buy a new device. Replacing membranes, rubber bushings or filters is not particularly difficult: use a screwdriver to pry off the old product and pull the new one in its place. The fuel pump mesh, float or fuel level sensor can also be easily mounted with a regular screwdriver.

The unit is reassembled in the reverse order.

Video: how to repair a fuel pump on a VAZ 2115 with your own hands

Selecting and replacing the fuel pump

Russian car owners prefer BOSH fuel pumps. You should only buy a new pump in specialized stores. The original product must be packaged in thick plastic film filled with special preservative oil. At the same time, a branded BOSH pump cannot cost less than 2 thousand rubles.

To replace the electric fuel pump on a VAZ 2114/2115 you will need:

- screwdriver with Phillips bit;

- thin slotted screwdriver;

- key or head 7;

- key to 10;

- key to 17.

The sequence of actions is as follows:

- Using a 10mm wrench, remove the negative terminal from the battery.

- Open the gas tank cap to reduce the pressure in it.

- Remove the rear seat cushion and peel back the carpet and sound insulation.

- Using a screwdriver, unscrew the two screws securing the fuel module hatch and remove it.

- Disconnect the power connector.

- Using a 17mm wrench, unscrew the nuts on the fuel pipes. We disconnect the tubes from the fittings and move them apart.

- Using a 7 socket, unscrew the eight nuts securing the fuel module cover.

- Remove the pressure ring and remove the fuel module.

- Use a thin slotted screwdriver to disconnect the coarse fuel filter.

- Using the same screwdriver, remove the retaining rings on the glass guides.

- Disconnect the fuel pipes from the cap fittings.

- Disconnect the electrical connector.

- Remove the glass from the guides.

- Using a slotted screwdriver, move the latches securing the electric fuel pump to the sides and remove it.

- Install a new pump.

- Repeat all operations in reverse order.

If, when disassembling the fuel module, it is discovered that the coarse filter is clogged, it should be replaced. The fuel level sensor with float must also be replaced.

Thus, diagnosing and replacing the fuel pump of a VAZ 2114/2115 car is quite simple. And in order for the pump to serve for a long time, always refuel only with high-quality gasoline.

Didn't find the information you are looking for? on our forum.

Weight

The fuel pump mass is located under the steering wheel, not far from the handbrake handle. It is its use that most often leads to wire breakage. In this case you will need:

- remove the cover;

- clean the ground contacts;

- attach it to its original place.

There is also a relay that controls the operation of the fuel pump. It is necessary so that when the ignition is turned on, operating pressure is immediately formed in the fuel supply system. It is important not to get confused, because there are three relays, and only one of them is related to the pump.

This element cannot be repaired and is simply replaced with a working one.

Pressure

First of all, you will need to measure the pressure in the fuel supply system.

If the pump works as it should, it is about seven atmospheres. To check, the pressure gauge is connected to the ramp through the fitting there. Remove the cap from it and screw on the measuring device. If everything is in order, then the readings will be as follows:

- 2.5 kPa (idle);

- 3 (ignition on);

- 7 (if you pinch the fuel outflow hose);

- 2.5-3 (increase in speed).

In the same situation, if after the ignition is triggered the pressure gauge does not show anything, then most likely the pressure regulator has failed.

When no changes occur even after gaining speed, then the issue here is clearly in the fuel pump. A slow change in readings indicates a clogged filter mesh.