The end of the 90s required automobile manufacturers to introduce new power units in order to withstand competition from foreign firms. Then AvtoVAZ engineers decided to supplement their already sensational tenth family of internal combustion engines with new engine options. After this, the well-known VAZ 2110 engine appeared, which gained popularity among car enthusiasts.

The VAZ-21083 power unit, which the design engineers significantly modified, served as the base model for the production of this engine. The carburetor was still used as a power supply system in the engine design, so there was no point in talking about special innovations.

Specifications

| Engine capacity, cc | 1499 |

| Maximum power, hp | 70 — 78 |

| Maximum torque, N*m (kg*m) at rpm. | 104 (11) / 3400 115 (12) / 3000 116 (12) / 3000 |

| Fuel used | Gasoline AI-95 Gasoline AI-92 |

| Fuel consumption, l/100 km | 7.6 |

| engine's type | In-line, 4-cylinder |

| Add. engine information | distributed fuel injection |

| Maximum power, hp (kW) at rpm | 70 (51) / 5600 71 (52) / 5600 72 (53) / 5600 77 (57) / 5400 78 (57) / 5400 |

| Compression ratio | 9.9 |

| Cylinder diameter, mm | 71 |

| Piston stroke, mm | 82 |

| Valve drive | SOHC |

| Number of valves per cylinder | 2 |

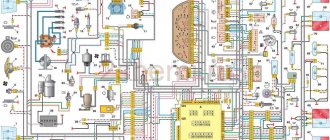

Error codes

Error codes from the engine's electronic control unit can often identify faults in electrical circuits and basic systems. Diagnostics are usually carried out to identify faulty sensors.

Decoding the error code: 0102 Low signal level of the mass air flow sensor 0103 High level of the mass air flow sensor 0112 Low level of the intake air temperature sensor 0113 High level of the intake air temperature sensor 0115 Incorrect signal of the coolant temperature sensor 0116 Incorrect signal of the coolant temperature sensor 0117 Low coolant temperature sensor signal level 0118 Coolant temperature sensor signal high 0122 Throttle position sensor signal low 0123 Throttle position sensor signal high 0130 Oxygen sensor 1 signal incorrect 0131 Oxygen sensor 1 signal low 0132 Crankshaft sensor signal high 1 0133 Oxygen sensor 1 response slow 0134 Oxygen sensor 1 signal missing 0135 Oxygen sensor 1 heater fault 0136 Oxygen sensor 2 short to ground 0137 Oxygen sensor 2 signal low 0138 Oxygen sensor 2 signal high 0140 Oxygen sensor 2 open 0141 Oxygen sensor heater fault 2 0171 Mixture too lean 0172 Mixture too rich 0201 Injector control circuit open 1 0202 Injector control circuit open 2 0203 Injector control circuit open 3 0204 Injector control circuit 4 open 0261 Injector circuit short to ground 1 0264 Injector circuit short to ground 2 026 7 Short circuit to ground of injector circuit 3 0270 Short to ground of injector 4 circuit 0262 Short to +12V of injector 1 circuit 0265 Short to +12V of injector 2 circuit 0268 Short to +12V of injector 3 circuit 0271 Short to +12V of injector 4 circuit 0300 Many misfires 03 01 Misfire in cylinder 1 0302 Misfire in cylinder 2 0303 Misfire in cylinder 3 0304 Misfire in cylinder 4 0325 Open circuit of knock sensor 0327 Low signal level of knock sensor 0328 High level of knock sensor signal 0335 Incorrect signal from crankshaft position sensor 0336 Error in position sensor signal crankshaft 0340 Phase sensor error 0342 Low phase sensor signal 0343 High phase sensor signal 0422 Low converter efficiency 0443 Malfunction of the canister purge valve circuit 0444 Short or open circuit of the canister purge valve 0445 Short to ground of the canister purge valve 0480 Malfunction of the fan circuit a cooling 1 0500 Incorrect sensor signal speed 0501 Incorrect speed sensor signal 0503 Interruption of speed sensor signal 0505 Idle speed controller error 0506 Low idle speed 0507 High idle speed 0560 Incorrect on-board network voltage 0562 Low on-board network voltage 0563 High on-board network voltage 0601 ROM error 0603 Error External RAM 0604 Error Internal RAM 0607 Knock channel malfunction 1102 Oxygen sensor heater resistance low 1115 Oxygen sensor heater circuit faulty 1123 Idle rich 1124 Idle lean 1127 Part Load rich 1128 Part Load lean 1135 Sensor heater circuit oxygen 1 break, short circuit 1136 A rich mixture in small load 1137 Poor mixture in small load mode 1140 The measured load differs from calculating +12V 1425 Control circuit of the canister purge valve short circuit to ground 1426 Control circuit of the canister purge valve open 1500 Open circuit of the fuel pump relay control circuit 1501 Short circuit to ground of the fuel pump relay control circuit 1502 Short circuit to +12V of the fuel pump relay control circuit 1509 Overload of the idle speed regulator control circuit a 1513 Idle air control circuit short circuit to ground 1514 Idle air control circuit short circuit to +12V, open 1541 Fuel pump relay control circuit open 1570 Incorrect APS signal 1600 No connection with APS 1602 Loss of on-board power supply voltage to the ECU 1603 EEPROM error 1606 Yes rough road mark incorrect signal 1616 Rough road sensor low signal 1612 ECU reset error 1617 Rough road sensor high signal 1620 RFOM error 1621 RAM error 1622 EPROM error 1640 EEPROM Test error 1689 Incorrect error codes 0337 Crankshaft position sensor, short to ground 0338 Crankshaft position sensor, open circuit 0441 Air flow through the valve is incorrect 0481 Cooling fan circuit malfunction 2 0615 Starter relay circuit open 0616 Starter relay circuit short circuit to ground 0617 Starter relay circuit short circuit to +12V 1141 Oxygen sensor 1 heater malfunction after the neutralizer 230 Fuel pump relay circuit malfunction 26 3 Driver failure Injector 1 266 Injector Driver 2 Malfunction 269 Injector Driver 3 Malfunction 272 Injector Driver 4 Malfunction 650 CheckEngine Lamp Circuit Malfunction

Peculiarities

The company's engineers produced the VAZ 2110 8-valve engine from 1995 to 2000. This power unit was produced in the city of Tolyatti, and it was based on its predecessor 21083. After the production of the engine was suspended, it was replaced by the VAZ-21102 fuel-injected internal combustion engine.

This is a classic in-line naturally aspirated engine running on gasoline for manufacturers. Its design includes four cylinders, giving a total working volume of 1.5 liters. The engine's peak power is 72 horsepower and its maximum torque reaches 104 Nm.

The engine block of the VAZ 2110 is traditionally made of cast iron with increased strength. The cylinders are machined directly into the block and it is not lined. The cylinder head is cast from aluminum. The crankshaft is made of cast iron, and it is fixed using five supports.

The material used to make the pistons was also classic - aluminum, only now they have steel inserts. The pistons are designed with two compression rings and one oil scraper ring. The connecting rods are made of steel and forged. The upper head contains a bushing made of a bronze-steel alloy.

The gas distribution mechanism is driven by a belt. If it is not replaced in time, it may break. But the VAZ 2110 1.5 engine is advantageous in that if the belt breaks, the pistons do not come into contact with the valves. The engineers managed to achieve this thanks to the fact that they made special grooves in the piston bottom.

The structure of the cylinder head provides for the presence of one camshaft and 8 valves. There are no hydraulic compensators in the design, so the thermal clearance of the valves will have to be adjusted independently. A combined lubrication system is used, and the gear-type oil pump is used.

A carburetor is used as a power system, only it has a semi-automatic start function. The carburetor was installed from a partner company - Solex, only this time it was different from the others, since it had two chambers.

Most owners of cars with such engines say that the power system is completely unpretentious to the quality of the fuel used. But despite such statements, it is necessary to choose gasoline solely based on the manufacturer’s recommendations.

The design uses a contactless ignition system. The high-voltage coil is installed dry and has a magnetic circuit, but there are other versions of the motor that provide for the installation of an oil-filled coil with an open magnetic circuit.

The VAZ 2110 engine cooling system is liquid, and is characterized by forced circulation of liquid. It is designed as a closed type, which allows it to provide an optimal operating temperature range not only in severe frost, but also in fairly hot weather.

Finding the VAZ 2110 engine number is not very difficult, since to do this you only have to dismantle the air filter housing. After this, you should pay attention to the place where the block connects to the flywheel, and above it you will find an identification number.

Modifications

The standard VAZ 2110 contains new developments and some features.

The first car was completely carburetor and 8 valve. This system had a volume of 1.5 liters and made it possible to develop about 70 horsepower.

This potential was enough to get real pleasure from movement. As for the maximum speed, it varies within 160 kilometers per hour.

After the carburetor engine, the designers decided to make an injector (already 16 valve). Essentially, these are the same 1.5 liters of volume, but with slightly increased engine power to 79 horsepower. This move made it possible to improve dynamism and increase maximum speed.

A small feature is that the system has a 16 valve VAZ engine. This is very unusual for cars of this class.

Until the 90s, the vehicle had a rather sparse interior and exterior. The designers made the car as a means of transportation, not a luxury. Only after the 90s were customers able to get a spacious trunk, comfortable seats, an adjustable steering wheel, air conditioning, and so on. Over the entire production period of the VAZ 2110, a huge number of modifications of its engine were developed: both an 8-valve carburetor and a 16-valve injector.

Advantages

The internal combustion engine turned out to be quite successful, despite the fact that it was not produced for very long. This resulted in the fact that it is quite common among domestic cars and their owners note a fairly large number of significant advantages:

- An interesting fact is that the VAZ 2110 engine can be started without any problems in almost any weather. The power system was designed to ensure uninterrupted operation in extreme cold and heat.

- The valves of the VAZ 2110 engine do not bend in the event of a break in the timing belt. This was achieved thanks to the special design of the piston, so there is no need to worry about having to overhaul the engine prematurely.

- Excellent pickup. Many owners of cars with such a power unit note that its use in urban conditions does not cause problems at all, since the power is enough to keep up with the flow.

- Good resource. Like all related engines, this engine can travel about 200 thousand kilometers without serious problems and the need for major repairs. But this can only be achieved if it is serviced in a timely manner.

- Unpretentiousness to fuel quality. In our country this is a very important factor, since most gas stations cannot guarantee high quality gasoline, but for this internal combustion engine this is undoubtedly not a problem.

Engine repair includes:

- complete disassembly of the engine;

- engine fault detection and diagnostics;

- selection of necessary parts;

- boring the cylinder block;

- flat-top cylinder honing;

- repair of connecting rod and piston group. Weight distribution.

- geometric renewal and restoration of the crankshaft (if necessary, its replacement);

- high-quality polishing of automotive crankshaft journals;

- installation and adjustment of the engine.

Problems

But despite a fairly large number of positive qualities, the engine is also characterized by classic malfunctions that most owners will have to face. Typically they are as follows:

- Fuel supply system. One of the most capricious parts of the engine is the carburetor. Owners of such engines no doubt know about the forced idle economizer and the main dithering system. It is also worth learning how to disassemble the carburetor in order to constantly clean the jets..

- Owners very often encounter constant fogging and leaks. Most often, the reason for this is that lubricating fluid begins to drip from the seals or around the valve cover.

- The temperature of the VAZ 2110 engine may be increased during operation. In this case, you should first pay attention to the thermostat, which may jam. If it is working properly, then you should check all the cooling system pipes for cracks.

- This engine also did not do without a lot of noise during operation. The cause of this problem may be a broken thermal gap in the valves. If this does not help, then you should start collecting money, since the pistons or main bearings of the crankshaft may start knocking.

- Often the VAZ 2110 engine troits. You shouldn’t start worrying right away, but just check the VAZ 2110 engine sensors, which often fail. All this can be eliminated literally in a garage and without additional knowledge.

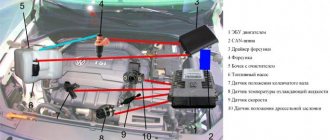

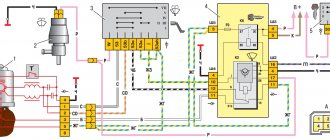

ECU diagnostics

In modern times, many methods have become available for conducting self-diagnosis or diagnosing a power plant malfunction with your own hands. Without any problems, you can purchase various diagnostic equipment, and you don’t have to go to a car service center. So, you can connect to the ECU using a standard OBD II cable and a tablet, or purchase an ELM 327.

Also, some errors can be diagnosed using the instrument cluster. First you need to enable test mode:

- The ignition is turned off. Battery included.

- Press the “Reset” control button and, holding it pressed, turn on the ignition. All positions of the familiar areas (segments) should light up on the LCD—LCD control.

- Press any of the control buttons. The LCD should display the program version (Ver 1.0).

- Press any of the control buttons. The following error codes (if any) should be displayed on the positions of the first and second lines of the LCD.

- Press the “Reset” control button and hold it for no more than 3 seconds. (maybe a typo, I need more than 3c). Error codes should clear to zero.

- Press any of the control buttons. All positions of symbols (segments) should light up on the LCD - LCD control.

Error codes: 2-overvoltage of on-board network;

3-fuel level sensor error (if a break in the sensor circuit is detected within 20s);

4-error of the coolant temperature sensor (if an open circuit of the sensor is detected within 20s);

5-outside temperature sensor error (if there are no sensor readings within 20s, indication on the LCD is “-C”);

6-engine overheating (the criterion for triggering the acoustic alarm is met);

7-emergency oil pressure (the criterion for triggering the acoustic alarm is met);

8-defect of the brake system (the criterion for triggering the acoustic alarm is met);

The 9-battery is discharged (the criterion for triggering the acoustic alarm has been met);

E-determination of an error in a data packet stored in EEPROM.

Maintenance

In order to ensure optimal engine mileage, you just need to take good care of it. Fortunately, the design is as simple as possible, so there are no problems. First you need to pay attention to adjusting the thermal clearances of the valves. This must be done after traveling 20 thousand kilometers using washers.

Do not forget also about the lubricating fluid, which must be replaced after 15 thousand kilometers, since after that it loses its properties. Many people still don’t know how much oil is in the VAZ 2110 engine, and the answer here is quite simple - 3.5 liters, but during replacement you need to use 3.2 liters. Also, if you do not know what kind of oil to pour into the VAZ 2110 engine, then it is recommended to use types 10W-40 and 5W-40.

Transmission and suspension VAZ 2110 8 valves injector

Lada 21102 has a built-in five-speed manual transmission (MT).

This box is used on all versions of the 2110 line. It has good noise insulation, the lever stroke is comfortable, and the smoothness of switching is much better than that of Zhiguli and Samara. The body (casing) of the box is made of aluminum alloy. Inside the casing there is a primary (drive) and secondary (driven) shaft. The shafts are combined with the differential and final drive. The five forward gears are equipped with synchronizers, which improve smooth shifting. Gear ratios: 1st gear - 3.636, 2nd - 1.95, 3rd - 1.357, 4th - 0.941, 5th - 0.784. For reverse gear - 3.5. The final drive ratio is 3.7. The operating instructions state that you need to change the transmission oil every 75 thousand km.

Mitigating the impact of the chassis on the body, as well as ensuring stability and smoothness, is carried out by the front and rear suspension of the Lada 2110. An independent design is used on the front axle.

Each wheel has an independent coil spring, inside of which a MacPherson strut is placed. Each strut has its own hydraulic shock absorber. The lower control arms are attached directly to the steering knuckles, and the anti-roll bar is attached to them. Levers help reduce wheel roll (rotate it around the longitudinal axis). When the car makes a turn, the wheel, which is turned “inside the body,” can move away from the axis of rotation. The stabilizer prevents this from happening by twisting. Thus, the front suspension of the Lada 2110 allows you to maintain the stability of the car when cornering. The rear suspension

is a rigid structure, the main element of which is the transverse beam. Since the rear wheels do not rotate, there is no need to provide maneuverability, but rear stability must be at a high level. Therefore, this design was used. The beam consists of trailing arms attached to each wheel and a connector that welds the arms together. The wheels on the rear axle are also equipped with hydraulic shock absorbers to soften impacts. The Lada 2110 is equipped with 175/70 radial tires. Ventilated disc brakes are used on the front wheels, and drum brakes on the rear wheels.

Advantages and disadvantages

Speaking about the former dream of car enthusiasts, it is difficult not to touch upon the issues of its advantages and disadvantages. For convenience, we list them in the table:

| Advantages | Flaws |

| Economical fuel consumption during moderate driving | Low level of security. No airbags, ABS |

| Cheap spare parts, there are analogues from foreign cars | Outdated design |

| High ground clearance – 170 mm, allowing movement on light off-road conditions | Cramped interior, non-folding rear row of seats |

| Repairable engines | Rapid metal corrosion |

| Low cost on the secondary market | Sticky electric windows |

Unfortunately, the VAZ 2110 has much more disadvantages than advantages. Among them, it is also worth noting the failure of the door lock drive - this is one of the most common problems. Burnout of electrical wiring also often occurs in 10-20 year old specimens. Car shock absorbers are like a lottery - they can travel 120-150 thousand kilometers, or they can fail after 30. Practice shows that it is advisable to replace them with foreign analogues.

During active use of the vehicle, jamming or leakage of the rear brake cylinder may occur. This problem manifests itself as vibration when braking.

Among the main advantages of this model, its low cost should be highlighted. Now the most expensive copy of 2012, with one owner and 90,000 km on the secondary market costs 205,000 rubles.

Options

The configurations of dozens today can be regarded as poor. Of course, at one time, even a minimal set of options was enough for comfortable movement, but now, with the development of technology, there are many more “wants”.

The VAZ 2110 was equipped with electric windows, heated front seats, power steering and air conditioning. The Bogdans were equipped with electric power steering. Airbags and ABS were not provided.

In the “Norma” configuration, the VAZ 2110 interior was trimmed with velor fabric and supplemented with rear headrests. The more expensive “Lux” package differed from the others in the presence of an on-board computer and heated side mirrors.