What is the part used for?

Let's look at what this part is, what are the features of its design, how its malfunctions can be diagnosed and how repair work should be carried out. This part secures the vehicle wheel to the following elements:

- to the hub;

- to the steering knuckle combined into a common structure with the hub.

Since the hub is an important component of the chassis of any vehicle, providing a connection between the axle and the vehicle wheels, and wheel bearings serve as the connecting element between the hub and the axle, the rotational resistance of the vehicle wheels when using them becomes minimal.

Disk temperature

During operation, the wheel bearing heats up, and if there are any defects in it, friction increases, which leads to an even greater increase in temperature. This is a rather indirect sign, but you can also rely on it. A large amount of thermal energy will be transferred to the surrounding metal parts, including the brake disc.

To check in this way, after acceleration, it is necessary to stop the car without using the brake - by simply coasting. Go out and touch the brake disc with your bare hand. A warm disc may indicate a failed wheel bearing.

Causes of wheel bearing failure

Original wheel bearings (which are installed on the car from the factory) can travel more than 250 thousand km. with proper use. The bearings can withstand such mileage thanks to the durable and reliable materials from which they are made. The following will lead to earlier wheel bearing failure:

- Frequently falling into potholes at high speed. When falling into holes, the entire suspension of the car experiences enormous loads, the wheel bearing is no exception;

- Overheating of the wheel bearing , for example, due to a jammed caliper or excessive tightening. If you ignore a breakdown such as a jammed brake caliper, the hub will become very hot and lubricant will leak out of it. Further operation of the wheel bearing will become impossible;

- Loss of lubricant . A very common cause of breakdown. The manufacturer usually does not put enough lubricant in cheap wheel bearings; such a bearing will last no more than 30 thousand km. If you take a high-quality wheel bearing, then over time the lubricant from it simply burns out or loses its properties;

- Wheel bearing is not properly tightened When installing a wheel bearing, you must know at what torque to tighten it. It is very important ! Do not neglect this point under any circumstances. The bearing can either be over-tightened during installation or under-tightened. If the bearing is installed incorrectly, it can last no more than 1 thousand km.

- Improper pressing of the wheel bearing. When installing a new bearing, be sure to check for any distortions. If the bearing is pressed in crookedly, the loads will be distributed unevenly. It is easy to understand that such a bearing will not last long;

- Overloading the vehicle . If you like to load your car with a massive load, know that the first thing that takes the full impact is the wheel bearing. Rest assured, such operation of the car will definitely lead to the replacement of the wheel bearing;

- Installation of wheel rims with an offset not specified by the manufacturer or installation of spacers . Discs with a large offset will also lead to premature failure of the wheel bearings. When installing such discs, the load on the wheel bearing increases significantly.

Replacing the wheel bearing.

It becomes clear that you need to avoid large potholes on the road, buy only high-quality spare parts, trust your car only to trusted professionals and operate the car correctly. If you follow these rules, the wheel bearing will serve you for a long time.

Signs of possible wheel bearing wear

Often the first sign is a hum from the wheel, but this is only the first signal. The field situation develops very quickly and the noise may be followed by a crash. Then the unit cannot maintain speed and falls apart while driving, which leads to a complete wedge and the car becomes uncontrollable. All this leads to failure of the suspension arm and deformation of the axle shaft. As a result, you will have to pay good money for repairs.

Therefore, it is important to be able to correctly identify a malfunction at the first signs and, if necessary, immediately eliminate it. The following signs will be the reason to check the wheel bearing:

- You can hear the wheel axle humming or crunching. More often it occurs when a certain speed is reached, approximately 60 - 70 km/h. When turning, especially at high speeds, the noise intensifies.

- A clear sign is the appearance of vibration along with a hum. It is transmitted both through the steering wheel and to the entire car and is caused by bearing runout.

- During long journeys, the wheel rim overheats. Sometimes the brake caliper overheats.

- Wheel jamming. When driving on a straight road, the car seems to steer to the side. This is caused by a defective wheel bearing inhibiting the rotation of the wheel. The symptoms are similar to an incorrectly adjusted wheel alignment.

To independently diagnose such problems on the go, you need to be able to listen to your car. And this comes with driving experience.

To accurately determine in which hub the bearing is humming, you should understand the causes of breakdowns and the principles of operation of the hub.

How to identify faulty wheel bearings

There are several ways to determine if your front or rear wheel bearings are faulty. Moreover, all of them do not require special skills or specialized tools.

First of all, pay attention to the following signs of possible front or rear bearing failure:

- a hum when driving, which depends on the speed of the car, and not on the gear engaged;

- light metallic knock when driving over bumps;

- increased play in the steering wheel, its shaking when driving at high speed on a road with defects in the road surface (one of the symptoms of a faulty front wheel bearing).

The main and most obvious sign of a wheel bearing failure is a hum. Its source is determined by a fairly simple method. On a flat, straight, and preferably empty stretch of road, accelerate to a speed at which the hum occurs. After this, slightly “throw” the steering wheel left and right. If the noise intensifies when you turn the steering wheel to the right, the bearing on the right is faulty; and vice versa.

After this, we hang out the side of the car on which the faulty bearing was identified. We rotate the front and rear wheels manually, rocking them in the horizontal and vertical plane. If a slight step-like rotation is felt on one wheel, the characteristic rustling of rolling balls or rollers is heard, or there is increased play - the wheel bearing is acting up on this particular axis.

Also, one of the signs of a wheel bearing malfunction is strong heating of the hub. If you suspect problems with the wheel bearing, after the ride, carefully touch all the wheels with your hand. The hub that is noticeably hotter than the others has problems with the bearing (or brake system).

Wheel bearing fault table

N Signs of malfunction Causes of malfunction Front Rear

| 1 | The appearance of extraneous noise (low-frequency hum) in the car interior. | lack of lubrication or incorrect choice, long service life, unqualified replacement, extreme driving, the state of our roads, impacts with potholes. | |

| 2 | When driving, vibration is felt in the steering wheel or brake pedal. | Vibration only in the brake pedal. | Possible wear on the tie rod end, wear on the wheel bearing or brake disc. |

| 3 | The appearance of grease leaks on the protective cap or oil seal. | Excessive lubricant, oil seal destruction. | |

| 4 | Excessive hub heating | Insufficient lubrication, incorrect tightening torque of the hub nut. Possible depressurization of seals. | |

| 5 | Grinding and knocking noise when the suspended wheels rotate. | The ball joint, brake discs, and car suspension parts may wear out. Diagnosis is necessary. | |

| 6 | When changing speed or entering a turn, the nature of the noise changes. | Worn wheel bearings. Other unpleasant noises may change: rattling of the exhaust pipe, gearbox transfer mechanism, tire noise. | |

| 7 | Axial play of suspended wheel | The CV joint or wheel bearings fail, the wheel bolts or wheel nut are insufficiently fastened. | |

| 8 | The ABS warning light is on. | The sensor is faulty, perhaps the magnetic ring is turned the other way, probably the number of teeth on the abs ring does not correspond to the original number for this car model. | |

| 9 | Loss of controllability, the car pulls to the side. | It is possible that the tires are unevenly inflated, the wheel alignment is incorrectly adjusted, or the hub is not pressed onto the axle shaft in a coaxial manner. Drives to the right - the problem is the right wheel, to the left - vice versa. The front wheels need to be checked. | |

Important to know: If you haven’t found the source of the unhealthy noise, contact experienced drivers or service station mechanics. Professional diagnostics will not be superfluous.

Why do bearings fail?

As a rule, the service life of these parts is quite long. But despite the fact that they can function for a long time in difficult conditions, in fact they wear out after a mileage of 100 thousand km.

For what reasons do wheel hub bearings fail:

- natural wear and tear;

- long-term off-road use of the vehicle;

- poor quality seal;

- poor lubrication of parts;

- errors made during installation (the author of the video is the VAZ 2101-2107 REPAIR AND MAINTENANCE channel).

Wheel bearing: what is checked at the service station

You can independently deliver the car to a service station, get advice on how to check the support bearing, and even watch how they fix your personal car on a lift and begin to diagnose the condition of the axle and running elements. What will a car mechanic pay attention to?

- He determines for himself the basic method of how to check a wheel bearing and applies it in the process.

- Alternately spins the wheels, first slowly, then faster. At the same time, he listens. If friction, clicking, or howling occurs, the auto mechanic looks at the location of the bearing and evaluates its external indicators.

- Wheel play is also assessed for play. To do this, the auto mechanic grabs the top of the wheel with one hand and the bottom with the other, and begins to loosen the wheel back and forth. If the tire gives way, the bearing is so worn that it requires immediate replacement. But at the same time, you should also evaluate the running parts of the machine, which may no longer operate in normal mode.

We determine the problem ourselves (at home)

In general, in addition to the crunching noise that you will constantly hear when moving. You can determine by the signs yourself literally around the house.

1) Place the car on a flat, preferably paved area.

2) You need to check the play along the vertical axis. To do this, we take the wheel at the top point and try to swing it with all our might. If you hear clicks and there is play, then this is definitely “hub”.

3) To be completely sure, you can lift the wheel on a jack and rotate it. If you hear a crunching sound, there is a malfunction.

4) There is another method (works only on front-wheel drive), but it is advisable to do it on a lift. You need to lift the car, start it, put it in gear and accelerate the wheels, then turn off the engine and listen. The side that makes noise, crunches and vibrates is faulty.

Now a short video version of the article

How to check a wheel bearing while driving

While the car is moving, if there is extraneous noise in the cabin, it becomes a hearing irritant for the driver. Finding the source of noise is sometimes difficult, because many components and parts of a machine can produce sound. Try to accelerate the car. Some tires can create a hum at high speeds, thereby misleading the driver.

You can find out which side the fault is on by maneuvering:

- Turn left, the load on the left axle will decrease, if the sound disappears or weakens, then the problem is on the left side.

- Turn to the right, the load on the left side will increase, a hum will appear, which means the assumption that the fault is on the left side is correct.

- Try varying your speed and alternating turns left and right.

- Listen to how the frequency and tone of the sound changes. It can decrease, increase, and sometimes disappear altogether.

Unbend the car on a flat road, release the gas, and move by inertia. Let the passenger listen to where the hum is coming from. Test your assumptions. Perform diagnostics on the car's wheels hanging up using a jack.

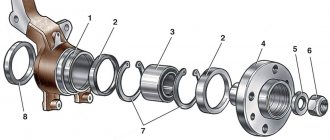

Replacement

It may seem that replacing a bearing in a wheel hub is not a difficult task. However, this is only at first glance. You will need at least two special pullers, mechanical experience, and an understanding of suspension design.

It should also be borne in mind that in some cases the bearing is not removable at all, then you will have to buy and replace it together with the hub.

For pressing, a special clip will be required. Under no circumstances should sharpened tools be used. When seating a bearing in a hub, the force should be transferred to the outer ring, and when installing it on an axle, to the inner ring.

Do not forget also about the correct axial clearance and the need for tightening to a certain torque. A misaligned or overtightened bearing will not last long.

All this speaks in favor of entrusting the work to experienced specialists, whose selection should be approached responsibly

Tips for maintenance and operation of bearings

- How to lubricate a wheel bearing.

- Keep dust away from grease and bearings. Lubrication of external surfaces prevents corrosion. For external lubrication, perform the following operations:

- First, you need to cleanly rinse the seat of the clip with kerosene, wipe it dry, then lubricate the seating surface with a thin layer of lubricant. Put on a clean rubber glove, apply lubricant to your palm and rub it into the bearing, then insert the part inside and additionally wipe the surface with a rag moistened with lubricant.

- You can use any anti-corrosion lubricant; specialized lubricants for bearing units are sold on the market. When applying, observe the amount of lubricant - there should be no leaks from the unit.

- Lubrication of the bearing inside is possible if it is open or has rubber seals. Add lubricant inside, but here you also need to follow an important rule - there should be no excess lubricant (turn the races repeatedly, excess lubricant will come out, it should be removed).

Recommended lubricant is presented in the table:

Lubricant brandsManufacturersThickenerBase oil

| RareMax AF-1 | Kyodo Yushi Co., Ltd. | Urea | Mineral oil |

| 6459 Grease N | Showa Shell Sekiyu, KK | Urea | Mineral oil |

| Pyronoc Universal N-6C | Nisseki Mitsubishi Oil Corporation | Urea | Mineral oil |

| HB-1 | Kyodo Yushi Co., Ltd. | Urea | Mineral oil |

| Ronex MP | Exxon/Mobil | Lithium | Mineral oil |

- How to extend service life.

Tighten the axle nut to the recommended torque. Excessive tension will cause excess friction, the lubricant will heat up, dry out, and the rubbing parts will become deformed. Insufficient fastening torque will cause more play than is permissible, which will lead to premature wear. Use original spare parts (nut, cotter pin, retaining ring, etc.) to repair bearings.

Which wheel bearing to choose based on manufacturer, and what to look for when purchasing.

The original number is indicated on the case; the manufacturer recommends installing it. If it is not possible to get the original, there are replacement brands. The main thing is that the dimensions and technical characteristics match. On the packaging, look at the inscriptions, barcode, stamped number on the case, and the package contents.

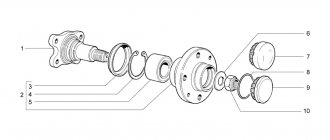

Wheel bearing kit - what it includes.

The repair kit includes consumable parts: wheel nuts 1 or 2 pcs., wheel bolts - set, lock ring 2 pcs. cotter pin Possible oil seals, outer races and even lubricant.

What to use a press or puller.

For high-quality work, use a press, remove the assembly, take it to a service station, and for a small fee they will replace the assembly parts in 1-1.5 hours. The puller is used when replacing independently, purchased or rented. An assistant's hand will be useful for holding the key.

Important point: Do not put pressure on the inner race of the bearing, as this can lead to damage to the elements of the bearing assembly.

ABS bearings.

The presence of an impulse ring can be easily checked by placing a metal object on one side of the seals. The magnetized side is placed inside the hole of the fist to the connector of the reading sensor.

Recommendations

If necessary, replace the Kalina front wheel bearing; all connections should be cleaned during reassembly. Removing dirt allows you to increase the service life and improve the quality of fit of parts and elements;

We also recommend reading the article on how and with what to lubricate a wheel bearing. In this article you will learn why you need to lubricate your wheel bearings, as well as how to lubricate your wheel bearing.

During the process of reassembling the connections, it is also important to fill them with lubricant. Graphite lubricant (graphite) is well suited for these purposes. Additional lubrication also increases the service life of parts, and also greatly simplifies subsequent disassembly.

Video on the topic

Sources

- https://podtrade.ru/info/articles/stupichnye_podshipniki/

- https://family-auto.ru/stupichnyj-podshipnik/

- https://topdetal.ru/stati/kak_vyyavit_neispravnost_stupichnogo_podshipnika/

- https://zamena-podshipnikov.ru/kak-proverit-peredniy-i-zadniy-stupichniy-podshipnik.html

- https://tire1.ru/prov-stup-podship/

- https://zamena-podshipnikov.ru/zamena-podshipnika-zadney-stupicy.html

- https://AvtoNov.com/%D0%BF%D1%80%D0%B8%D0%B7%D0%BD%D0%B0%D0%BA%D0%B8-%D0%BD%D0%B5% D0%B8%D1%81%D0%BF%D1%80%D0%B0%D0%B2%D0%BD%D0%BE%D1%81%D1%82%D0%B8-%D1%81%D1 %82%D1%83%D0%BF%D0%B8%D1%87%D0%BD%D0%BE%D0%B3%D0%BE-%D0%BF/

What happens if you don't change the bearing when it hums?

If an unpleasant, suspicious hum appears when reaching a certain speed and/or entering turns, it is necessary to check the hub as soon as possible. Operating a car with a broken wheel bearing is not only harmful to the car, but also dangerous!

What happens if the wheel bearing jams? Clearly

So, if you do not change a failed wheel bearing in time, this can lead to (or simultaneously several) emergency situations:

- Additional load (vibration) on the chassis of the vehicle and its steering. This leads to a decrease in the service life of their individual parts and assemblies.

- The engine thrust and its efficiency decrease, which can also lead to an increase in fuel consumption.

- Overheating of the brake assembly may cause the brake fluid to boil. This will lead to partial and even complete failure of the braking system!

- When turning, the wheel may simply “lie down”, which will lead to loss of control over the car. At speed this can be fatal!

- If the wear is critical, the bearing may jam, causing the wheel to stop. And if such a situation occurs while driving, it can cause a significant accident!

If for some reason at the moment you do not have the opportunity to urgently change the hub bearing, then when the hub begins to hum, you can drive at low speeds, up to approximately 40...50 km/h, and drive no more than 1000 km. It is highly not recommended to accelerate faster and ride longer!

How to change the front bearing: what tools are needed

- A new bearing, purchased independently, as soon as you started thinking about how to change the wheel bearing;

- Special retaining rings and hub nut;

- The vice is standard and stationary;

- Special devices for pressing the bearing out of its seat in the hub;

- A set of keys and sockets with cranks, which are usually used by auto mechanics;

- Round-nose pliers, pliers typically used to remove a retaining ring;

- New lubricants. Usually they buy litol;

- A piece of a pry bar, if it becomes necessary to use the lever method when pressing out the part;

- Jack or lift for the car;

- mechanical or hydraulic pullers for wheel bearing removal.

All repair work is carried out on a spacious, flat area where tools and components can be placed. For beginners, it is better to have accompanying technical documentation on the machine, use instructions for performing repair work, and advice from qualified specialists.