We disassemble the engine for its overhaul. Before disassembling, clean the engine of dirt. We dismantle the cylinder head (see “Removing and disassembling the cylinder head”). To further disassemble the engine, we mount it on a disassembly stand or place it on a workbench. We remove the flywheel (see “Replacing the rear crankshaft oil seal”), the oil pan (see “Removing the oil pan”), the oil receiver (see “Removing the oil receiver”), the oil pump (see “Removing and disassembling the oil pump”) and oil filter (see “Changing the engine oil and oil filter”).

Using a 10mm socket, unscrew the two bolts securing the coolant pump supply pipe to the cylinder block...

...and remove the pipe (the connection is sealed with a gasket). Remove the coolant pump (see “Removing the coolant pump”).

Using the E-8 head, unscrew the six screws securing the crankshaft rear oil seal holder. Using a slotted screwdriver, pry the holder by the bosses made on its body...

...remove the rear oil seal holder. The connection between the holder and the cylinder block is sealed with a gasket. We unscrew the connecting rod cap screws one by one and remove the connecting rods with pistons from the cylinders (see “Removing the connecting rod and piston group on a car”).

We remove the connecting rod bearing shells from the caps and lower heads of the connecting rods. If the parts of the connecting rod and piston group are not damaged and have little wear, they can be used again. Therefore, during disassembly, we mark the parts so that during subsequent assembly they will be installed in their places. To remove the piston rings, lightly clamp the connecting rod rod in a vice with soft metal jaw linings.

Without applying much effort, we open the lock of the upper compression ring...

...and remove it from the annular groove of the piston. Similarly, remove the lower compression ring. Unclipping the oil scraper ring...

...remove the ring and its expander. To disassemble the piston and connecting rod...

... use a thin slotted screwdriver to pry up the piston pin retaining ring and remove it from the annular groove of the piston boss. In the same way, remove the piston pin retaining ring from the other side of the piston.

Use a mandrel to push out the piston pin...

...remove the piston from the upper head of the connecting rod...

...and remove your finger. We carry out similar operations with other pistons and connecting rods.

Using a 17mm socket, unscrew the two bolts securing the crankshaft main bearing cover.

Remove the main bearing cap.

Remove the lower crankshaft main bearing shell from the cover. In the same way, remove four more caps of the crankshaft main bearings.

We remove the crankshaft from the cylinder block beds.

We remove the two thrust half-rings of the crankshaft from the grooves in the support of the third main bearing.

We remove the upper crankshaft main bearing shells from the cylinder block supports. After disassembling the engine, we thoroughly wash and clean the parts of the cylinder-piston group from carbon deposits to check their technical condition. We inspect the cylinder block. Cracks anywhere in the cylinder block are unacceptable. There should be no deep marks, scuffs or burns on the cylinder mirror; only small rubbing marks that cannot be felt by a finger are allowed. To determine cylinder wear...

...we measure the diameter of the cylinder with a bore gauge. We measure the diameter of each cylinder in four zones - at different distances from the upper plane of the cylinder block and in two directions (parallel and perpendicular to the axis of the crankshaft). We carry out measurements in three zones at distances from the upper plane of the cylinder block, approximately corresponding to the positions of the compression and oil scraper rings when the piston is at TDC. Measurements in the fourth zone are carried out in a direction parallel to the axis of the crankshaft, at a distance (from the upper plane of the cylinder block) corresponding to the position of the piston pin axis when the piston is at BDC. The cylinder in the area of the fourth belt (in the direction parallel to the axis of the crankshaft) does not wear out. Therefore, by the difference in measurements in the fourth and other belts, the wear of the cylinders can be determined. We evaluate the condition of the pistons. The pistons are not allowed to have cracks, burnouts, scuffs or chips. To determine the wear of the piston skirt, use a micrometer to measure its maximum diameter in a plane perpendicular to the piston pin axis. By comparing measurements of the diameters of the cylinders and piston skirts installed in these cylinders, we determine the gap between the piston and the cylinder, which should not exceed 0.15 mm. If the gap exceeds 0.15 mm, it is necessary to bore and hone the cylinders at a service station for oversized repair pistons. In this case, the piston rings will need to be replaced with new, repair size ones. After machining the cylinders, we wash them with kerosene and blow out the oil lines in the cylinder block with compressed air...

...and piston cooling nozzles. Inspect the crankshaft. Cracks anywhere on the shaft are unacceptable. On the main and connecting rod journals of the shaft, as well as on the surfaces mating with the working edges of the oil seals, scuffs, scratches, nicks and risks are not allowed. To assess shaft wear...

...with a micrometer we measure the diameters of all main... ...and connecting rod journals of the crankshaft in two diametrically opposite planes. If the wear or out-of-roundness of the crankshaft journals is more than 0.03 mm, and also if there are burrs or marks on the journals, then the journals must be ground at a service station to the nearest repair size. After grinding the crankshaft journals, it is necessary...

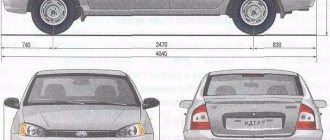

Technical data VAZ 11183 1.6

- VAZ 11183 1.6 is a four-stroke gasoline engine, the four cylinders of which are arranged in one row.

- Power supply of the power unit, injection, distributed fuel injection.

- The cylinder block of the Lada Kalina internal combustion engine is made of especially durable cast iron. The gas distribution mechanism is single shaft, has 8 valves. The timing mechanism is driven by a toothed belt from the crankshaft pulley.

- The engine piston has a stroke less than the cylinder diameter of 75.6 mm and 82 mm, respectively. The compression ratio of the internal combustion engine is 9.6. The fuel used is AI 95. It is permissible to use AI 92, for which you need to change the ignition timing.

- Power VAZ 11183 1.6, at 5200 rpm min., 81 l., sec. Torque at 3000 rpm, min., 125 Nm.

- Environmental compliance standards: Euro 2, Euro 3.

Fuel consumption

Fuel consumption when driving around the city is 8.8 liters per 100 km, mileage. When driving on the highway 6.2 liters. Total consumption is 7.6 liters per 100 km, mileage.

Oil consumption

The permissible consumption of motor lubricant is 50 grams per 1 thousand km. Types of oil used: 5W40, 10W40, 5W30, 15W40. The volume of engine lubricant in the VAZ 11183 1.6 engine is 3.5 liters. When changing, fill in 3.2 liters. Manufacturers recommend changing the oil every 15 thousand km.

Resource

Engine operating life according to factory data is 150 thousand km. In reality, in the right hands, the VAZ 11183 1.6 can last up to 300,000 kilometers.

Engine tuning 11194 1.4 16V

City tuning Kalina engine 1.4

The 11194 viburnum engine is not the best choice for tuning; boring the 11194 to 79 mm or 82 mm is fraught with the appearance of shells, and modifying a low-volume engine is ineffective. Installing sports top camshafts with a receiver means squandering the already non-existent low end. The most rational thing to do would be to start tuning by replacing the block with a Priorovsky one and build according to already proven options. But what to do if you want to slightly improve performance without major changes... let's install a 4-2-1 spider straight-through exhaust on our viburnum with 51 pipes or a 4-1 spider ( replacement of the catalyst), simple Nuzhdin 8.7 camshafts (a wider shaft will not work well on a sluggish engine), a 54 or 56 mm throttle body, a receiver and all this is properly configured, this set will provide us with up to 110 hp. at the top, at the bottom the engine will be worse than standard, which is not very convenient in the city. This problem is solved by selecting the main pair and choosing a suitable range of gearboxes. To get even greater output and at the same time tighten up the bottom end, you need to bore the cylinder head channels, install larger valves, etc., but such procedures are a waste of time on an initially non-running engine. In general, despite 16 valves, engine 11194 is unsuitable for tuning.

Compressor for Kalina 1.4 16 valves

Unlike other VAZ engines, the Kalinovsky 194 engine has a high compression ratio and it will not be possible to painlessly install a St. Petersburg compressor on a standard engine. It is necessary to reduce the compression ratio by installing a tuning piston; with such an investment, the return will not live up to expectations.

Engine Kalina turbo 1.4

By analogy with the compressor, we change the piston to a forged one with a reduction in the coolant to 9, Nuzhdin shafts 8.7 or 8.85, install a small turbine like a Garrett 17, a turbo manifold, a Walbro pump for 450 liters/hour, BOSCH 431 injectors with a capacity of 360cc, switch to DBP with DTV, blow-off, 51-pipe exhaust, intercooler and consumables. Approximately 150+ hp we will get it, but the same thing on the prior block will give a greater increase. It's up to you to do it or not.

For this car, the best tuning is to replace the block with a !

ENGINE RATING: 3+

General design features of internal combustion engines

The VAZ 11183 1.6 engine is a modified version of the already well-known carburetor power unit VAZ 21083. Most of the design elements are borrowed from this model. The cast iron cylinder block also has four in-line cylinders. But the aluminum cylinder head is adapted for distributed fuel injection. It has an overhead camshaft. The valves are driven by fists through pushers. Hydraulic compensators are not provided on this engine model. Because of this, periodic adjustment of the valves is required. Which you can do yourself by selecting the required number of steel washers.

The 11183 1.6 engine block is very similar to the VAZ 21083 power unit block. The only thing that has changed is the height of the cylinder block. As a result of these changes, the stroke of the piston group increased. It became 75.6 mm, instead of the previous 71 mm. Accordingly, engine capacity increased from 1.5 liters to 1.6 liters.

Design features of the VAZ 11183 timing belt

The camshaft of the gas distribution mechanism is driven from the crankshaft pulley using a toothed belt. Belt tension, unfortunately for drivers, is manual and brings a lot of trouble. Therefore, the belt often has to be tightened manually. A very important and pleasant point for owners of such an internal combustion engine is that when the timing belt breaks, the pistons do not meet the valves. This is possible thanks to the special design of the pistons, which has a recess in the upper part.

Maintenance

According to AvtoVAZ recommendations, the 11183 engine must be serviced according to the regulations:

| Maintenance object | Time (month) or mileage (10,000 km), whichever comes first |

| Timing drive | 36/ 1 |

| Battery | 12/2 |

| Valve clearance | 24/2 |

| Crankcase ventilation | 24/2 |

| Belts that drive attachments | 24/2 |

| Fuel line and tank cap | 24/2 |

| Engine oil | 12/1 |

| Oil filter | 12/1 |

| Air filter | 12 – 24/4 |

| Fuel filter | 48/4 |

| Heating/cooling circuits | 24/4 |

| coolant | 24/4 |

| Oxygen sensor | 10 |

| Spark plug | 12 – 24/2 |

| Exhaust manifold | 12/1 |

By default, the cooling system has a volume of 7.8 liters. Red Felix Carbox 40 antifreeze is usually poured on the conveyor. Replacement is made with any coolant, taking into account the temperature range of 85 degrees. Since the internal combustion engine device is quite simple, the maintenance operation can be performed on your own.

Modifications of the internal combustion engine VAZ 11183 1.6

This engine underwent a major modernization in 2011. On the new model, the receiver has been enlarged, and the throttle valve has received an electronic control system. The type of throttle control is called E-gas. The new engine acquired its own VAZ 11183-50 index, and its power increased to 82 hp. What is also important is that the VAZ 11183-50 began to comply with European compliance standards Euro 4.

It should be noted that in parallel with the VAZ 11183 engine, the VAZ 21114 engine was produced. By and large, this is the same engine. Most systems, components and mechanisms are identical.

However there are some differences:

- in the power system of the VAZ 21114 engine they used a completely different generator 5132.3771 for 90 Amp hours;

- a new fastening method was used to mount the generator;

- To drive the generator, a new belt with a thickness of 882 millimeters was used. The mechanism for tensioning the belt has also been changed.

All other components, systems and mechanisms of the engine are completely the same, despite the fact that the motors were produced in different production shops.

Do-it-yourself car repairs

“Kalina” is a simple car, so the driver can eliminate most of the damage himself. For example, you can fix the following problems on your own:

- change the engine air filter;

- remove air from the cooling system;

- change the water pump;

- eliminate the rattling of the gear knob;

- change the ignition module;

- replace the generator diode bridge;

- install a brand new outer CV joint to replace the crackling old one.

Repairing the LADA Kalina car yourself must be carried out in accordance with the instructions, using only good car mechanic tools, if you need to use special equipment and pullers for repairs.

Recommendations for servicing the Lada Kalina engine

The service life of any engine depends on proper maintenance from the very first days of operation; the VAZ 11183 1.6 engine is no exception to the rule.

The manufacturer recommends servicing this engine in the following order:

- During the first kilometers of driving, the entire car undergoes grinding in of parts, including the engine. The grinding-in period is called the running-in period. It lasts about 1.5 thousand kilometers. After it expires, you need to replace the engine lubricant and the oil filter element.

- The next stage of maintenance must be performed after a mileage of 10 thousand kilometers. The engine oil and oil filter must be replaced. Also, at this stage it is necessary to change the air filter, measure the compression in the cylinders and adjust the valves.

- After 20,000 kilometers, it is necessary to diagnose all mechanisms and systems of the internal combustion engine. Naturally, you need to change the engine oil, since it must be replaced every next 10,000 kilometers.

- After 30 thousand, you only need to change the engine lubricant and filter element

- After a mileage of 40 thousand km, many engine elements and parts must be replaced:

- replacing the air flow filter element;

- replacing the fuel filter element;

- replacing the timing belt and roller;

- replacing the alternator belt if necessary;

- replacing the pump at the slightest play in the fuel pump pulley;

- replacing the valve cover gasket;

- other parts requiring replacement;

- In addition to replacing parts, during this period of operation the valves should be adjusted and diagnostics of the internal combustion engine systems should be carried out.

Subsequent maintenance must be carried out in accordance with points 2 and 5. The exception is motor oil and filter. They need to be replaced every 10 thousand kilometers.

Oil change video

Advantages and disadvantages

The advantage of the 11183 engine is the cylinder head of the original design. However, it was subsequently further modified into the ICE 11186, adding volume to the combustion chambers. The downside is the generator belt tensioner - the drive is constantly over-tightened, a deflection of 10 mm is not ensured without slipping, so the belt life is reduced and it has to be changed more often. This defect was corrected only in the next version of the motor 11186.

The integrated catalytic collector assembly in the engine was initially unfinished:

- the tubes of the four channels are short;

- flows converge inside the block at almost one point;

- exhausts collide and create opposition to each other;

- the shape of the block did not allow changing the arrangement of the tubes.

When installing the engine on the Lada Granta, the cabin heat exchanger was connected to the thermostat in series. All the coolant passed through it along a small circuit, the response temperature error was 5 degrees instead of the required 2 degrees.

Possible malfunctions of VAZ 11183 1.6

The VAZ 11183 engine is an improved version of the VAZ 21083. Most of the possible malfunctions for these engines are similar:

Flow sensor

For cars, a number of VAZ models, including Lada Kalina and Lada Granta, stopping the engine while driving is popular. Experienced drivers know that the culprit of the breakdown is the sensor responsible for mass fuel consumption. When replacing this sensor, the engine will start without problems.

Oil leaking

A popular problem is engine lubricant leaks. Oil can leak through the valve cover gasket, gaskets and seals. Sometimes a leak can be so critical that complex repairs cannot be avoided. Critical failures include oil leakage through the crankshaft seals.

Overheat

Overheating of the VAZ 11183 power unit occurs due to the thermostat. Unfortunately, the quality of domestic spare parts leaves much to be desired. A newly installed thermostat may not work. The motor may overheat, or on the contrary, it may not heat up.

Engine knock

Knocks in the power unit are a real problem for many VAZ cars. It is necessary to take into account the fact that the engine knocks when cold. If the engine has already warmed up and the valve clearances have been adjusted, the problem may be more serious. To determine the problem, you will need to diagnose the internal combustion engine.

ECU

The control electronics on the VAZ 11183 1.6 engine is one of the sore spots. Most drivers have encountered its replacement. There may be several reasons for this. For example: increased fuel consumption, the engine cannot develop full power, idle speed failure.

Engine tripping

If the engine starts to stall, you need to check the spark plugs. If the spark plugs are OK, then the ignition coil has failed. Very rarely a valve can burn out.

The revolutions are floating

If the engine speed fluctuates, then with a high probability it can be said that a dirty throttle valve is to blame. Often the cause may be a failed electronic sensor.

Crankshaft bearings

If, when accelerating, you can hear the sound of metal in the engine, then there is a high probability that the crankshaft liners are rattling. Further operation of the vehicle is not advisable until the problem is resolved. Otherwise, scuffs may form on the crankshaft journals.

As can be seen from everything described above, the VAZ 11183 power unit has many weak points and possible malfunctions. However, given the simplicity of the engine design, drivers fix most internal combustion engine problems themselves. Here, it must be said that spare parts for the VAZ 11183 are low in cost. Thanks to these circumstances, many domestic drivers fell in love with this engine. They consider it a reliable, easily repaired power unit.

Cooling system

The Kalina engine must be operated at a given operating temperature; overheating of the engine or insufficient temperature leads, first of all, to a decrease in the performance characteristics and operating parameters of the station wagon and hatchback. This is why it is so important to monitor the cooling system, maintain it on time (we are talking, first of all, about the planned replacement of antifreeze) and repair it.

The fact that the Kalina 8 and 16 valve thermostat is a sore point of the VAZ is not an open secret. Namely, the same Kalina 8-valve thermostat is responsible for distributing antifreeze over a large and small circle; the engine temperature directly depends on its condition. Based on this statement, replacing the Lada Kalina 2 thermostat if it breaks down or malfunctions (the unit is not repairable) is quite critical.

Other components of the cooling system, the radiator and cooling fan of the Kalina 2, the associated radiator and fan of the Lada stove, and other parts may also break. All these breakdowns and a number of other malfunctions of the cooling system often lead to engine failure due to overheating. In this regard, it is so important to replace the fan , the Lada Kalina 2 pump replace the Kalina 2 cooling radiator and replace the Lada Kalina 2 heater radiator , as well as replace the Kalina 2 air conditioner radiator and other types of work.