- home

- /

- Car brands

- /

- VAZ car service (Lada)

- /

- VAZ engine repair

The Auto Maxima car service center in the Southern Administrative District of Moscow offers repair services for VAZ and LADA engines.

We guarantee that once you visit our car service center, you will become one of the regular customers who appreciate the quality and speed of our work.

The basis of our successful work is utmost attention to every detail, consideration of the individual characteristics of the engine, deep knowledge and extensive practical experience.

This approach allows us to repair the VAZ engine with a guarantee of its subsequent long and trouble-free operation.

Modern cars are equipped with technically complex power units that require competent maintenance and professional repairs.

If earlier a car engine could be repaired with improvised means, today this requires special knowledge and high-precision equipment.

The main signs of a VAZ engine malfunction

You can determine that a VAZ engine needs repairs based on the following characteristic signs:

- Traces of engine oil leakage appeared;

- Oil consumption has increased. This may indicate a malfunction of the piston group parts. If the malfunction is confirmed, the element will need to be replaced;

- Extraneous noises, grinding noises during engine operation;

- Unnatural color of exhaust gases.

If at least one of these signs appears, you must immediately contact the specialists of our auto center, who, using specialized diagnostic equipment, will accurately determine the breakdown and take measures to eliminate it.

Ignoring the problem can lead to more serious troubles, including major repairs.

Tuning

Simple firmware or chip tuning for 124 engines will not change the technical characteristics. To significantly increase power, it is necessary to modify the engine.

- The simplest and most common tuning of the 21124 engine is the installation of sports camshafts, a direct-flow resonator, an increased throttle - in this way you can increase the power to 120 hp. Installing a lighter piston engine can add some power to this. This, at the same time, will reduce the fuel consumption of the VAZ 21124.

- About 150 hp can be ensured by modification of the cylinder head and installation of camshafts with increased valve opening phases.

- Installing a compressor has approximately the same effect; it is installed on eight-valve and sixteen-valve engines.

- Stable engine operation at any speed is ensured by installing four chokes, one for each cylinder. According to popular experience, the most suitable option is to install an injection system from ToyotaLevin. To do this, a set is assembled from the chokes themselves, an adapter manifold, a zero-resistance filter, injectors, an absolute pressure sensor and a fuel pressure regulator. Due to the fact that the speed exceeds the limit, it is necessary to install lightweight piston and wide-phase camshafts. With this modification, engine power can reach 200 hp. But such modernization sharply reduces the service life of the engine, is fraught with frequent breakdowns and the need to carry out serious repairs of the VAZ 124, due to the fact that the engine easily and often spins up to 9,000 rpm.

VAZ engine diagnostics

When carrying out computer diagnostics, disassembling the motor is not required. The unit is connected to a specialized computer and, using a scanner, malfunctions in the functioning of all engine components are detected. However, conventional scanners do not always detect all problems. To ensure high-quality and comprehensive diagnostics, our specialists use licensed software and special scanners from AvtoVAZ. Such diagnostics of a VAZ engine allows you to obtain the following information:

- Throttle valve opening value in percentage;

- Engine speed;

- Engine temperature;

- Voltage of on-board electrical network;

- The temperature of the air supplied to the engine;

- Ignition timing;

- Data from the air flow sensor;

- Fuel injection time by injectors;

- Motor load level;

- Oxygen sensor data.

Before starting diagnostics, our service technicians “listen to the engine.” Then they scan with computer equipment, and only after identifying faults, our specialists can determine the required amount of work to eliminate them.

Design and principle of operation of the ignition module

Some old-school motorists call the modules double-spark coils, which makes sense. After all, the coil is the predecessor of the ignition module in the technical evolutionary chain. The module is a paired design consisting of two pairs of windings (primary and secondary) and a switch that alternately switches low-voltage current from one coil to another. In some models of double-spark coils, the commutator is structurally located outside the block.

The operation of the module is controlled from an electronic unit that collects and analyzes information from various working components of the engine. The block, unlike the classic coil, has 4 sockets for connecting high voltage wires going to the spark plugs. The pulse occurs in pairs, first at terminals 1 and 4, then 2 and 3. That is, each of the built-in coils is responsible for the operation of two cylinders. A spark occurs simultaneously, as a pair.

This is what one of the ignition module models looks like. The connector for connecting incoming wires is visible at the top.

At the input, the ignition module has a connector with four terminals. Usually most models have markings opposite them. Pulses from the Hall sensor alternately arrive at contacts A and B, serving as a signal to switch the commutator from one primary winding to another. C and D – ground and power supply (12 V), respectively.

VAZ engine repair in Moscow

Car service center "Auto Maxima" offers repair of VAZ engines in Moscow at affordable prices. Experienced specialists carry out high-quality repairs of both gasoline and diesel power units. We carry out work of any complexity: diagnostics, maintenance, local and major engine repairs. The car service is equipped with the necessary modern equipment for diagnostics and high-precision settings, which significantly speeds up the work process.

Repair of gasoline and diesel engines

The legendary reliability of VAZ cars has earned them wide fame and popularity among Russian car enthusiasts. However, harsh operating conditions, poor quality roads and fuel can damage even the most reliable mechanism. Sooner or later, every car owner may need VAZ engine repair in Moscow.

The Auto Maxima service center provides prompt and high-quality repairs of both gasoline and diesel power units. We carry out work of any complexity: diagnostics, maintenance, local and major repairs of VAZ engines.

What is this?

Engine overhaul refers to the work of a master aimed at returning the engine to a state as close as possible to its original state. In this case, most of the nodes are changed or restored. This type of repair is resorted to when there is a lot of wear on the parts of the unit.

The list of work may include grinding the crankshaft journal and camshaft, installing new pistons and springs, and honing the cylinders. If too many engine components are faulty, then it is more advisable to completely replace it.

The following signs indicate that it is time to overhaul the engine on the VAZ-2114:

- The appearance of red, black or dark gray carbon deposits on the spark plugs.

- Increased oil consumption.

- The occurrence of knocking in the engine.

- Increased fuel consumption.

- The appearance of smoky exhaust.

- Bad traction.

- Engine overheating.

- At idle, the engine runs unevenly.

- Reduced power.

Major repairs proceed approximately according to this scheme:

- Preparing the engine for dismantling (disconnecting wires, hoses, gearbox).

- Removing the engine.

- Removal and inspection of the cylinder head.

- Disassembling the unit for diagnostics and cleaning.

- Block boring. Grinding the crankshaft. Application of hone to the cylinder walls.

- Weight distribution of connecting rods, pistons.

- Block assembly.

- Restoring the head (replacing caps and guides, straightening seats).

- Assembling the engine and installing it in the engine compartment.

- Connection.

- Functionality check.

VAZ petrol engine repair

If there are extraneous noises in the operation of the engine, the consumption of gasoline and oil has increased - this is a clear reason to contact a car service center.

Repair may result from:

- Failure to comply with oil change schedules;

- Severe filter contamination;

- Use of low-quality oil and gasoline;

- Neglect of regular maintenance, with replacement of consumables (belts, rollers, etc.)

Timely repairs or maintenance of a gasoline engine using professional equipment will cost much less than replacing it. Naturally, all work on the main component of the car should be carried out only by experienced mechanics.

At the Auto-Maxima car service center, the repair procedure includes the following types of work:

- Motor diagnostics to detect all problems;

- Engine removal, partial or complete disassembly;

- Establishment of the repair method and direct repair;

- Assembly and installation of the engine.

What spare parts are needed

- repair size pistons with rings (70ue);

- connecting rod and main bearings (15ue);

- camshaft 21213 (for the best “low-end” 35ue);

- split gear (in order to correctly set the 20ue marks) and a new chain (12ue);

- valves, guides and seals (20ue);

- valve springs (15ue), the purchase of which is often neglected;

- rocker depending on condition;

- cylinder head bolts (3ue);

- automatic chain tensioner (11ue);

- set of gaskets and seals (10ue);

- oil pump assembly (30ue);

- gear tensioner shoe (25ue);

- thermostat, pump and cooling pipes (20ue);

- BSZ (45ue) to provide a powerful spark, respectively + new wires with spark plugs (15ue);

- carburetor repair kit (4ue);

- filter (oil, fuel, air (5ue);

In total, work with parts and liquids, on average, will cost 470, provided high-quality spare parts are used, which will ultimately give a well-functioning engine with a long service life, as well as a power of about 85 hp.

VAZ diesel engine repair

Repairing a VAZ diesel engine usually costs much more than repairing a gasoline engine, because the complexity of the unit is higher. Entrust the repair of your VAZ diesel engine to car service employees who have the necessary knowledge, tools and equipment to perform the repairs with high quality.

Common reasons for repairing diesel engines are:

- Problems in the fuel system;

- Failure to comply with oil change schedules.

The most common cause of problems is a malfunction of the fuel system; natural wear and tear of parts is also common.

Frequent signs of diesel engine problems:

- Difficulty starting the engine;

- Unstable operation, poor acceleration, jerking;

- Increased consumption of diesel fuel and oil.

The diesel engine repair process at the Auto-Maxima car service includes the following steps:

- Diagnostics;

- Disassembly of the motor and repair of components;

- Checking tightness and eliminating leaks in cooling and lubrication systems;

- Boring, lining, honing;

- Installation and configuration.

Due to the complexity and specificity of these works, they can only be performed in a serious professional car service center, for example, like ours.

Cleaning valve channels

To remove any valve, you will need to remove the camshaft. All screws on the bearing housing must be unscrewed evenly and tightened with a force of 10 N*m. The hydraulic compensator can be removed with a magnet, and then the valve is desiccated by compressing the spring with a puller (see photo).

How to remove the valve

There may be carbon deposits in the valve channels. It is cleared:

- Flat screwdriver;

- Sanding felt.

Grinding is carried out as follows: a rubber pipe is placed on the valve, a paste with diamond chips is applied (one drop), then the valve is pressed into the channel and scrolled. It will also be possible to change the valve stem seals (2112-1007026). You can’t do this without a special puller.

Cap puller

On any car, including the VAZ-2112, cylinder head repair comes down to cleaning and checking, as well as correcting geometry defects. In the latter case we are talking about milling. The presence of cracks and chips is a reason for replacement, not repair.

A small photo report

A burnt valve is immediately visible.

One valve burned out in cylinder 2

Carbon deposits were found in each valve channel.

Carbon layer in the cylinder head channels

Repair: cleaning all channels, replacing the valve with lapping. Direct repair of the VAZ 2112 cylinder head will require several operations that require some special equipment. Of course, this is not possible at home, and car enthusiasts simply replace worn parts. Next, we will consider the process of repairing the block head, as well as some of the nuances associated with this work.

Overhaul of VAZ, LADA engine

A major overhaul of a VAZ engine , due to the high complexity and responsibility of the event, can take several days and consist of the following stages:

- Removing and disassembling the engine, thoroughly washing and cleaning all elements;

- Defeating – identification of parts and assemblies that cannot be restored;

- Restoring the working condition of the cylinder block, cylinder head, crankshaft, etc.;

- Engine reassembly;

- Cold running and engine tuning.

Employees of the Auto-Maxima car service strictly control each stage of work, and only with positive results do they proceed to the next one. Thanks to this approach, we perform major repairs of a VAZ engine with consistently high quality and ensure further trouble-free and long-term operation of the vehicle after its repair.

Dismantling the cylinder head

First of all, to get to the cylinder head, you need to remove the cylinder head cover. For different 16-valve engines, this operation is different, and the cover part numbers also look different: 2112-1003260 (-10) and 21124-1003260.

Engine cover VAZ-21124 (1.6 l)

You will also need to remove the timing belt - there are no differences between different engines.

Let's look at how the exhaust manifold can be detached from the cylinder head. On engine 21120:

- Remove the exhaust pipe of the muffler: unscrew two nuts 1 (key “13”), remove the clamping bar, unscrew six nuts 2 (key “14”) and dismantle, not forgetting to turn off the oxygen sensor. The photo shows three of the six nuts.

Elements of the exhaust pipe

Everything important is under the screen

Now we will talk about engine 21124:

- Disable both oxygen sensors. We unscrew the three nuts securing the protective screen (with a 10mm wrench) and disassemble the bracket by unscrewing the four nuts with a 13mm wrench.

How to disassemble the mounting bracket

Operation with additional muffler

Here we believed that the VUT hose was disconnected from the intake module. Finally, the spark plugs are unscrewed on any of the engines (a “16” tubular wrench).

The order of unscrewing (left) and tightening the mounting screws

High-quality VAZ engine repairs in the Southern Administrative District of Moscow

The Auto-Maxima car service center offers highly professional VAZ engine repairs. In our work, we are guided by the interests of our clients, so we try to minimize costs.

What do you get by contacting the Auto-Maxima car service:

- One of the lowest prices in the region;

- Excellent quality and efficiency of work execution;

- Professionalism of the staff, constantly improving their skills;

- Free consultations;

- Performing work on new equipment that ensures high accuracy and quality;

- Repair of any engines, regardless of brand and year of manufacture;

- Use only high-quality components.

We value our reputation, so we always do quality work. We will be glad if you become our regular customers. If you need VAZ maintenance, diagnostics or repairs, call us, we are always ready to help.

Lubricating parts

Combined engine lubrication device for the VAZ-2109 (2110). Oil is supplied to the main and connecting rod bearings, as well as to the camshaft supports under pressure; the cylinders, pistons, pins and rings, camshaft cams and pushers are lubricated by splashing; all other associated parts are lubricated by gravity.

A gear-type oil pump with a bypass valve is installed at the front of the block. The oil receiver is mounted using bolts on the cover of the second main bearing and the pump housing. The oil filter is non-separable and has bypass and anti-drainage valves. The design of the lubrication system and other engine systems is discussed in detail in separate articles.

Crankcase ventilation is forced, gases are removed through the oil separator.

Prices for repair of VAZ, LADA engines

| Petrol engine repair | Price, rub. |

| ICE repair gasoline 8 valves | from 20 000 |

| ICE repair gasoline 16 valves | from 25 000 |

| Engine repair gasoline V6 | from 50 000 |

| Engine repair gasoline V8 | from 55 000 |

| Engine repair gasoline V10 | from 60 000 |

| Engine repair gasoline V12 | from 70 000 |

| Detection of an internal combustion engine defect (with the cylinder head removed) | from 5 000 |

| Removing the internal combustion engine | from 8 000 |

| Installation of internal combustion engines | from 10 000 |

| Diesel engine repair | Price, rub. |

| Repair of internal combustion engine diesel 8 valves | from 55 000 |

| Repair of internal combustion engine diesel 16 valves | from 65 000 |

| Repair of internal combustion engine diesel 5 cylinders in-line | from 75 000 |

| Repair of internal combustion engine diesel 6 cylinders in-line | from 75 000 |

| Engine repair diesel V6 | from 85 000 |

| Engine repair diesel V8 | from 90 000 |

| Engine repair diesel V10 | from 95 000 |

| Detection of an internal combustion engine defect (with the cylinder head removed) | from 5 000 |

| Removing the internal combustion engine | from 15 000 |

| Installation of internal combustion engines | from 18 000 |

| Other engine repair work | Price, rub. |

| Oil pressure sensor - replacement | from 800 |

| Crankshaft position sensor - replacement | from 800 |

| Speed sensor - replacement | from 800 |

| Coolant temperature sensor - replacement | from 800 |

| Throttle valve, idle air valve 8V - replacement, cleaning | from 2000 |

| Throttle valve, idle air valve 16V - replacement, cleaning | from 2000 |

| Ignition coil - replacement | from 900 |

| Valves - replacement | from 8000 |

| Exhaust manifold - replacement | from 4000 |

| Valve seals 8V - replacement | from 12 000 |

| Valve seals 16V - replacement | from 16 000 |

| Piston rings - replacement | from 15 000 |

| Muffler lambda probe - replacement | from 1 000 |

| Exhaust manifold lambda probe - replacement | from 1 500 |

| Oil pump - replacement | from 5 000 |

| Rear engine mount - replacement | from 1 500 |

| Left engine mount (gearbox) - replacement | from 2 000 |

| Right engine mount - replacement | from 1 300 |

| Heater stove (radiator) - replacement | from 5 000 |

| Engine sump - replacement | from 3 000 |

| Muffler cushion - replacement | from 600 |

| Intake manifold gasket - replacement | from 2 000 |

| Exhaust manifold gasket - replacement | from 2 500 |

| Camshaft replacement | from 6 000 |

| Rear crankshaft oil seal - replacement | from 12 000 |

| Front crankshaft oil seal - replacement (with the timing belt removed) | from 400 |

| Front crankshaft oil seal - replacement | from 2 000 |

| Camshaft oil seal - replacement | from 850 |

| Generator pulley - replacement | from 4 500 |

| Replacing the engine cooling radiator | from 3 000 |

| Replacing the thermostat | from 1 500 |

| Replacing the engine cooling fan | from 1 500 |

| Replacing the pump | from 2 500 |

| Replacing the expansion tank | from 1 000 |

| Replacing the cooling system pipe | from 1 200 |

| Replacing the cooling system pipe clamp | from 300 |

Specifications

VAZ 2114 car

The technical characteristics of the VAZ 2114 engine are quite typical for the 2113-2115 series of cars. In addition, this power unit is developed on the basis of the “eight” engine, which has declared itself to be reliable and easy to repair. The car was produced from 2001 to 2013. During this period, the vehicle received five valuable power units.

VAZ 2114 engine structure

As was said earlier, the 2114 was equipped with five different power units, which differed in power and valve mechanism. Three of them had 8 valves, and the other two had 16. The gas distribution mechanism had a belt drive. Until 2007, the engine was equipped with a simple on-board computer, which did not regulate the operation of the engine based on sensor readings. Therefore, the motorist had to regulate the processes the old fashioned way, manually. Since 2007, an ECU was installed, which, receiving data from sensors, independently adjusted many processes.

Design features of the engine.

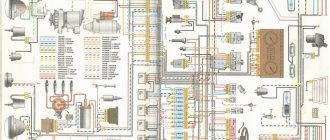

Since the second generation had a so-called two-way electronic engine control unit, it is worth considering what electrical circuit was installed.

Electrical diagram of a VAZ 2114 car.

Main characteristics of the motor

All engines that were installed on the vehicle had approximately the same characteristics and design features. So, the motor is easy to service and repair with your own hands. Let's look at the main technical characteristics of the VAZ 2114 engine:

VAZ 2111

| Name | Index |

| Volume | 1.5 liter (1499 cm3) |

| Number of cylinders | 4 |

| Number of valves | 8 |

| Fuel | Petrol |

| Injection system | Injector |

| Power | 77 hp |

| Fuel consumption | 8.2 l/100 km |

| Cylinder diameter | 82 mm |

VAZ 21114

| Name | Index |

| Volume | 1.6 liter (1596 cc) |

| Number of cylinders | 4 |

| Number of valves | 8 |

| Fuel | Petrol |

| Injection system | Injector |

| Power | 81.6 hp |

| Fuel consumption | 7.6 l/100 km |

| Cylinder diameter | 82 mm |

VAZ 11183

| Name | Index |

| Brand | 11183 |

| Marking | 1.6 8V |

| Type | Injector |

| Fuel | Petrol |

| Valve mechanism | 8 valve |

| Number of cylinders | 4 |

| Fuel consumption | 9.6 liters |

| Piston diameter | 82 mm |

| Resource | 200 – 250 thousand km |

VAZ 21124

| Name | Index |

| Volume | 1.6 liter (1599 cc) |

| Number of cylinders | 4 |

| Number of valves | 16 |

| Fuel | Petrol |

| Injection system | Injector |

| Power | 89.1 hp |

| Fuel consumption | 7.0 l/100 km |

| Cylinder diameter | 82 mm |

VAZ 21126

| Name | Index |

| Volume | 1.6 liter (1597 cc) |

| Number of cylinders | 4 |

| Number of valves | 16 |

| Fuel | Petrol |

| Injection system | Injector |

| Power | 97.9 hp |

| Fuel consumption | 7.2 l/100 km |

| Cylinder diameter | 82 mm |

Engine VAZ 2114.

All engines were equipped with 5-speed manual transmissions. Engine volume ranges from 1.5 to 1.6 liters. This car was not equipped with a large power unit. The average engine power of the VAZ 2114 is 85 horsepower.

Where to start if you want to service your car yourself?

Do you want to learn how to repair a car yourself?

Can you imagine how cool it will be to fix the problem yourself? But at the same time, you are not confident in your abilities, do you think that you are not capable of learning the science of auto mechanics? Put your doubts aside, if you really want to learn how to repair a car, you can do it! You need to start step by step. Of course, you shouldn’t immediately try to remove the engine or gearbox from the car and try to repair them, this will not lead to anything good. It’s the same as if in middle school they start teaching you the Laplace transform instead of elementary mathematics. Illogical, unreasonable, you simply won’t understand anything and will waste many hours.

If you really want to learn how to repair cars, start with the basics.

To get started you will need:

Patience and perseverance. Study the material you will have to work with. Step by step, each step, one after another.

Buy tools. Not necessarily expensive professional kits, entry-level tools are enough (not outright junk, of course, but decent cheap tools). Maybe in the end you won’t like climbing around in the oily insides of your iron friend. In this case, why overpay?

And lastly, but most importantly, where to start? We invite you to familiarize yourself with five interesting and at the same time easy repair options that will teach you the basics of working with a car, in case of incorrect actions will not cause serious damage to the car and will certainly give you moral satisfaction from the fact that you were able to do it yourself. All the weaknesses of a used BMW 3 Series (E90)

All the weaknesses of a used BMW 3 Series (E90)

If you get involved in the process and with constant practice (for example, you don’t have a new car that requires constant repairs), then in a couple of years you will know the structure of your car quite well, realize which bolt is responsible for what, which lock nut performs which function, and what parts do certain systems consist of?

And it can all start with five simple renovations.

Volume of disasters

Capital can be partial or full. To determine what kind of repair the engine needs, it is necessary to carry out control measurements and troubleshooting - start with the condition of the cylinders and the piston play in them, inspect the liners and measure the diameter of the crankshaft journals, evaluate the gaps in the piston pins. With partial capitalization, they are usually limited to replacing piston rings, liners, seals, and gaskets. With a complete overhaul, the list turns out to be much longer, and the amount of work is significantly greater. The cost of repairs is correspondingly higher.

Full capital

The sequence of actions with full capital is as follows. First, the engine is removed from the car. This operation is most expensive on all-wheel drive vehicles with automatic transmissions.

Next - disassembly, washing, troubleshooting and micrometering. Only at this stage can a more or less accurate cost of repairs be determined. If the verdict is rendered earlier, there is reason to be wary. Most likely, you ended up with incompetent specialists, or they will try to deceive you.

After measurements and troubleshooting, the main parts are sent for machining - many workshops do not maintain expensive equipment for boring blocks and grinding crankshafts and send the parts to related suppliers. The cost of work greatly depends on the volume of machining. Then the engine is assembled, installed on the car and filled with working fluids.

Now about spare parts - in the overall calculation they usually make up half of all capital costs. All gaskets, rubber and rubber-metal seals are replaced. Timing drive elements are always replaced if it is a belt drive, and almost always if it is a chain drive. During any overhaul, new piston rings and crankshaft liners are installed. The pistons of modern engines are very loaded and most often also need to be replaced.

Parts that are replaced based on diagnostic results include valves, oil pumps and even crankshafts if it is not possible to grind to a repair size. They are trying to repair the main parts - the cylinder block and heads. In this case, the cylinders are either bored to the repair size or relined to fit standard pistons. In the head, sometimes it is necessary to restore the camshaft beds and change the valve bushings, mill the mating plane and almost always machine the valve seats.

Alternative to overhaul

Many people prefer not to repair a worn-out engine, but to take a so-called contract (used) engine. Not a bad option, you can even save a lot of money - a complete overhaul sometimes costs twice as much. For example, the price of a “live” engine for Granta is 25–30 thousand rubles, for Logan – 45 thousand rubles. For more complex multi-cylinder engines they ask from 80 to 200 thousand rubles or more.

But the euphoria is inappropriate: still, you must not forget that you are not buying a new, but a used unit! And this is a lottery that you can lose. Therefore, before making a final decision, we advise you to scour the Internet. Read reviews about sellers of used units and about the design advantages and disadvantages of your motor. For example, you should not buy used 2-liter G4KD aluminum engines installed on many Hyundai and Kia models. Typically, these units do not survive up to 150,000 km - scuffs appear on the cylinder walls, which causes a sharp increase in oil appetite. Such motors are restored by re-lining.

And further. The engine number does not appear in the registration documents, but a replacement engine still needs to be registered with the traffic police.

Compression test, troubleshooting

One of the main reasons for engine repair is decompression. Actually, the troubleshooting itself must be done every 30 thousand km, combining it with valve adjustment.

Signs of the need for early technical inspection of the engine are:

- power surges;

- increase in fuel consumption;

- engine tripping.

Compression measurement

If you experience similar symptoms, you need to do the following:

- Check the starter and charge the battery.

- Find a compression gauge and warm up the car.

- Remove the spark plugs and fuel supply hose.

- Insert the compression gauge into the spark plug socket of the first cylinder and depress the accelerator.

- We turn the key in the ignition and turn the starter for 10 seconds, watching the device, it must be interpreted as follows: a. if the pressure stops at 0.8 mPa and then stops growing or does so slowly, then the cylinder head is broken or there is a leak in the valve; b. if it just grows slowly, it means that the rings have exhausted their service life (by the way, this fact can be checked by adding oil and measuring again, if the pressure returns to normal - the rings are 100% to blame).

After the procedure is repeated for all cylinders, it is necessary to analyze the records. So, in a working engine, compression should not fall below 1 MPa and should not have a spread between the cylinders of more than 0.2 MPa. Otherwise, you will have to repair the engine.

Design

VAZ-21053 is the progenitor of the “seven”. Externally, it is very similar to the VAZ-2107, with the exception of the radiator grille. It became the first model in which they strongly decided to abandon chrome (in order to reduce the cost of the design). Thus, the radiator grille was completely black, and the shiny moldings usual for the “Classics” were absent on the body. Other differences include new rectangular headlights with integrated turn signals. Also, other bumpers appeared on the “five”. They were also metal, but more voluminous and lacking “fangs”.

The design of the front side windows has also changed. Previously, the Classic had windows. With the advent of the “five”, the door received solid glass. The design of the rear lights has changed. Otherwise, the body structure remains the same. By the way, initially only 13-inch stamped wheels were offered for the Zhiguli. In the 2000s, 14-inch alloy wheels became available for the VAZ-21053.

Among the disadvantages of this car, owners note the quality of corrosion protection. The car is rotting badly. Therefore, it is not surprising that the “five” could be repainted several times. And touch-ups are completely normal for her. The weak points of the “five” are the sills, bottom and arches. There is no protection against corrosion here. In order to somehow protect against rust, the owners themselves coat the bottom with mastic, treat the thresholds with anti-gravel and other means. Plastic fender liners are also often installed on the car.

Advantages of Superstore

1. Fast service 2. Quality of work thanks to our experience 3. Own availability of new and used parts from disassembly. 3. Compliance with the previously agreed cost and deadlines in the Order - work order 4. Providing a guarantee for work, discounts on all work performed.

Timely identification and elimination of faults significantly saves your money and helps to avoid emergency situations. Diagnostics, scheduled seasonal maintenance, and service maintenance in accordance with regulations contribute to safe operation.