If you don't take care of the timing drive

Emergency failure most often occurs when the timing belt breaks, and then, perhaps, the matter will be repaired by repairing the cylinder head. All this is provided that the motor is plug-in. This can happen as early as 70,000 km.

The Lada Granta and Datsun mi-DO with eight-valve engines that were used by our editorial team broke earlier than the replacement period stated by the manufacturer. In the car service book, replacement is prescribed at a mileage of 75,000 km. In the end - capital! The same effect can be caused by failed timing belt rollers and a cooling system pump.

To avoid problems, I advise you to check the belt at a mileage of 30,000 km and then at each maintenance. Force it to be changed every 60,000 km.

Box

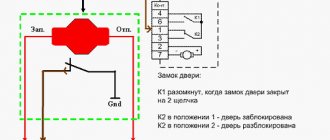

Howl in the gearbox, stiff gearbox when cold, freezing of the handle in the cold. In order to eliminate the problem, it is recommended to replace the oil in the box with synthetic 75w90.

Subscribe

to our channel in

Index.Zen

Even more useful tips in a convenient format

Changing the oil in a Lada Granta box

Over the course of 86,000 km, I changed 4 headlight bulbs. AND THAT'S ALL!

Thank you for the addition, we really appreciate it! We hope after another 15-20 thousand you will again add how your car performed, because the problem areas of the Grants described in the article are really only “diseases” of the first cars, and not all subsequent ones. Many who would like to purchase this car will undoubtedly be interested in knowing what problems may await next.

43,000 km. The headlight unit was replaced under warranty. I suppose it was my own fault - I didn’t notice the post, it crushed the wing, it pulled the headlight mount, so it depressurized. I can't find any other explanation. A squeaking clutch pedal can be treated by lubricating the rubbing parts in the passenger compartment and in the engine compartment. The rust on the frame does not spread further - it has rubbed off on the rubber. The paint no longer rubs. The generator tensioner pulley was replaced under warranty because... I didn't like the sound when it was cold.

I used a Lada Granta with automatic transmission for three years until problems started. First the fuel pump, then the lambda probe. Now it’s not at all clear what’s going on with the train. Shows the error of the first lambda probe. We remove the error. We start the auto check, no errors are on. After the replacement I drove 150 km. Doesn't hold speed and stalls. When starting off, it's as if someone is holding you by the tail. And for more than three years there were no problems. The machine has completed 35,000 miles. Who can tell me what the problem is and how to help my pet.

The car has already traveled 30,000 km. Of the shortcomings attributed to Grant, I only agree with: 1. the appearance of rust in the upper part of the frame, because it constantly rubs against the seal, erasing the paintwork, which is less than a millimeter wide. At the same time, the zinc coating layer is not touched, but there are only pinpoint areas of corrosion, less than a millimeter in diameter. This problem was found only on the rear left door; on the other doors the paintwork was not damaged. 2. The clutch pedal squeaks. 3. The front left headlight unit is sweating. Today, these are all the shortcomings that appeared at 30,000 km.

Car history

Today, the domestic model Lada Granta is a sales leader. Every year it becomes more and more popular, in demand and interesting to a wide audience, because the car was created using completely new technology, using original design solutions. Engineers have finally begun to move away from the outdated, established stereotypes of automotive design. The result of this search was Granta.

So, at the beginning of the 2000s, the AvtoVAZ plant reminded itself of itself with a good Lada Kalina project. Of course, this car still needed serious improvements and adjustments. But nevertheless, already from this car, new trends in the work of the enterprise emerged, which the press was quick to report and both critics and ordinary car enthusiasts noted. Now the plant management decided to continue the work line that had been started; the next project was to be even more daring, non-standard, combining such qualities as aesthetics, dynamics, comfort and low price.

Initially, the name of the new model was given a lot of words, Low Cost, which translated from English means “low price”. But later it was decided to replace this name with something more sonorous and bright. So, having selected one, Grant, from hundreds of thousands of items, AvtoVAZ began to establish serial production. In 2009, our compatriots saw the first copies of the Lada Grant.

Of course, she was strikingly different from Kalina, and even more so from previous projects. There was no longer that laconic modesty inherent in domestic developments; this car attracted attention with its alluring, elegant forms, an abundance of extraordinary design solutions, and an excellent technical component. It was no longer a shame to show such a car to a global audience, which is what they did.

Granta Sport has repeatedly performed at major international competitions, taking prestigious places. This is how AvtoVAZ’s new idea debuted. But, in addition to the undeniable advantages, there are also flaws in Grant. Here and there there are annoying breakdowns, reminding us that we still have a domestic car in front of us, which is not fully thought out and is still far from ideal.

Creating a model

The Lada Granta was intended to replace not only the latest model of the “classic” VAZ 2107, but also the Lada Kalina, which, as many believe, turned out to be a marketing miscalculation of the Russian automobile manufacturer. However, it was the Kalina platform that became the basis for the design of the new car.

The developers set themselves a goal: to make a car that was budget-friendly but attractive in appearance. The designers changed Kalina's body greatly, and the created forms turned out to be exceptional for VAZ. The new model of a class B vehicle has very decent dimensions: length - 4260 mm, width - 1700 mm, height - 1500 mm, ground clearance - 170 mm. It is available in “standard” and “luxury” trim levels. Lada Granta is the first series of domestic cars produced with an automatic transmission (luxury equipment).

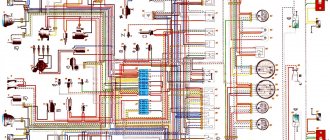

Lada Granta electrical system: main characteristics

The electrical circuits that supply the engine compartment control systems are designed using a multi-wire circuit and are connected to the vehicle ground only through an electronic control unit.

As a source of energy to power consumers, the standard Lada Granta electrical equipment scheme involves the use of a battery (when the engine is not running) and a generator (when the engine is running).

To connect (switch) the main consumers in the circuit of the Lada Granta car, the electrical equipment is equipped with a combined switch, namely the ignition switch, which in its design consists of a contact part, as well as an anti-theft device.

Processing details to pay special attention to

Lada Granta, whose factory anticorrosive protection is only a small part of the necessary measures to protect the body, requires additional protection

Anticorrosive Lada Granta is an event that requires a holistic approach, however, there are places where the Lada Granta body is treated that should be given special attention

So, for example, anti-corrosion treatment of Lada Granta thresholds is a paramount condition for protecting the car body. Susceptibility to corrosion thresholds is a consequence of the greatest physical impact compared to other parts of the body

Other elements to pay attention to include:

– bottom. It is on this that the protective function falls, which ensures that excess moisture does not penetrate. Even installed protection will not provide a complete guarantee of the absence of corrosion.

– wheel arches. Constant exposure to water and dirt from the wheels does its job.

Transmission

The manual transmission has been modernized more than once. It now has a cable drive, thanks to which the gears are engaged with less effort, and the accuracy of the selection mechanism has increased. This box has the factory index VAZ-2181. But the sound when its gears operate is still too loud. The problem with the second gear synchronizer has not been completely resolved. Poor engagement and rapid wear of the synchronizer, despite numerous upgrades, still occur. As well as oil leaks through the seals. The reason is the low quality of the seals themselves and the insufficient accuracy of the positioning of the seal relative to the shaft. All this fully applies to the VAZ-2182 robotic gearbox, because it was created on the basis of a mechanical one.

In the case of gearbox 2181, the clutch mechanism rarely lasts more than 100,000 km, especially if the car is used in a big city and often sits idle in traffic jams. In robotic gearboxes, the clutch lives even less.

The only truly reliable transmission in the line is a 4-speed automatic from the Japanese company Jatco.

Suspension

It handles all urban irregularities, so far there are no complaints about it. Those bumps that on the 2112 were crawled over at a crawl at 15 km/h, on the Grant they can be easily passed at 40-50 km/h. It’s possible faster, but why should I systematically kill components and assemblies? There will still be an opportunity to play around in the pits.

The only question about the suspension is that when high speed bumps pass at speeds above 30 km/h, a knock is heard in the front of the car, maybe the shock absorbers are working on rebound (which is unlikely), or maybe the Guarantor pin in the glove compartment rattles (which is more likely). But such crossings are so rare that I still don’t have time to clearly grasp the source of the sound.

The engine does not start.

Two possible malfunctions: 1. Fuel system malfunction

.

— Fuel lines are clogged. Possibly caused by low-quality gasoline or debris getting into the fuel lines (extremely rare). It is necessary to wash the fuel tank and fuel lines, dry them and fill with high-quality gasoline. It is possible to identify the malfunction by measuring the pressure in the fuel rail, after first making sure that the fuel pump is fully operational. — Fuel pump malfunction. The presence of power can be determined by ear. It should work when the ignition is turned on (do not forget that after 3-4 ignition starts the fuel pump will no longer turn on. Remove it from the gas tank and check it in the tank by turning on the power and measuring the output pressure. It should be at least 2-3 atmospheres. - The fuel filter is clogged. When removing the fuel pump, visually inspect the filter. It may be clogged with dirt, which results in insufficient pressure in the fuel rail. - The pressure regulator in the fuel rail is faulty. On new engines, the pressure regulator can be installed directly in the fuel pump linkage and be located in same housing. In this case, check the pillar assembly. The output pressure should be normal. 2. Ignition system malfunctions

. - There is no spark on the engine spark plugs. The ignition system of the new Granta engine no longer contains high-voltage wires. Perhaps the malfunction arose in the spark plugs or individual coils (break). Replace both with a known good engine. - Throttle assembly is faulty. This is the so-called electronic pedal, which replaces two components of the old engine (throttle valve and idle speed control) with one. In this case, it is an electrically driven throttle assembly. In the event of a malfunction, the composition of the fuel-air mixture may be incorrect, as a result of which the engine will not start. — DPKV is faulty. The crankshaft position sensor counts pulses on the engine crankshaft. If there is no signal from this sensor, the controller does not receive information about crankshaft rotation and, accordingly, does not issue commands to the spark plugs and injectors. — The injectors are faulty. A very rare occurrence, usually one of the 4 injectors fails, but the engine can be started on 3 cylinders. If none of the above reasons solve your problems, then you should contact a specialist.

Rare breakdowns

Experts say that 90% of all “Rich mixture” errors are related to injector adjustment. It's easy to fix

The main thing is to pay attention to improper operation of the car engine in time.

The rarest and most exotic are considered to be malfunctions of the engine control unit, as well as poor condition of the contacts. Sometimes there are cases of oxygen sensor poisoning. An experienced specialist can identify such deviations. In this case, not every car owner can solve the problem on their own.

Having considered what a rich mixture is, you can understand the danger of such a situation. If unforeseen situations arise, it is better to contact the service center. At service points there is the necessary tool with which you can perform diagnostics. This will save the car's engine.

While the vehicle is moving, the Pilot converter records the operation of the oxygen sensor and air flow sensor. At the same time, you can see on the computer monitor in real time which mixture is lean or rich.

What is an "engine management system"?

This system is key to the operation of the car. Read more about where it is here!

M74CAN is the “brain” of the Lada Granta car in disassembled form.

It starts and turns off the fuel pump, constantly monitors the volume of air (the air filter is also indirectly involved in this process), which enters the working cylinders, and also directs the same amount of fuel into the intake manifold which is needed at the moment.

In addition, the process of spark formation on the spark plugs is controlled, the ignition timing is adjusted and the frequency at which the crankshaft moves at idle is adjusted.

Engine radiator fan assembly

Additionally, this system controls an electric fan, which is directly related to the engine cooling system. Due to a malfunction in the ECU, the fan may constantly work or not turn on at all.

Let's sum it up

There are many reasons why you can purchase a Grant, but there are no fewer reasons why you should refuse such a purchase. On the one hand, this car is one of the cheapest on the market, and also offers good ride comfort, a large trunk, and a relatively interesting interior design. On the other hand, we can recall the many childhood illnesses that force people to contact the service. But remember that for the first 100,000 kilometers or three years you will drive under the protection of a good warranty service.

The engine runs unsteadily and stalls at idle.

— Insufficient pressure in the ramp. For a description of the solution to the problem, see above in the paragraph “The engine does not start.” — Malfunction of the electronic gas pedal. For a description of the solution to the problem, see above in the paragraph “The engine does not start.” — There is an air leak. The suction is possible through the crankcase ventilation hoses connecting the intake pipe to the vacuum brake booster. Tighten all fastening clamps and, if necessary, replace the hoses with new ones. — Valve clearances are broken. If you have an 8-valve engine, then periodically (every 15-20 thousand km) it is necessary to adjust the timing valves. — Malfunction of the ignition system. For solutions to problems, see above, in the paragraph “Engine does not start.”

How to reset the error without using an adapter

The first solution to the problem is to remove the terminal from the battery for 5 minutes. This is necessary to reset the memory in the power supply, as well as to reset the on-board computer.- Apart from this, there is another option. To do this, remove the cigarette lighter fuse, which is responsible for the backlight and the cigarette lighter. As a rule, the fuse location diagram is on the cover.

Devices for diagnostics of electrical equipment

The set of basic diagnostic instruments includes a circuit tester or voltmeter (although it is quite possible to use a banal 12-volt test lamp equipped with a set of connecting wires). If available, you can use an open circuit indicator, which includes a lamp, an independent power source and connecting wires.

In addition, you should always carry a set of cables in your car to start the engine from an alternative source (usually the battery of another car). These wires are equipped with alligator clips.

It would be a good idea to have an electrical circuit breaker, since this equipment can be used to connect circuit elements and bypass electrical equipment during diagnostics.

Weaknesses of the Lada Granta:

The interior is clearly the weakest side of the car. Already from the first minutes of using the car, you can notice a number of its shortcomings. The first is associated with the handle responsible for adjusting the seat. It is quite fragile and breaks quickly. In addition, the gear lever boot also leaves much to be desired. The material is of low quality and cracks quickly. During operation, it constantly crawls out from under the knob.

Almost immediately, the light that controls the operation of the airbags begins to blink. It indicates their malfunction. Soon the power windows fail. They begin to jam and make an unpleasant sound when the glass is lowered.

The car has air conditioning, but the quality of its operation is quite poor. He doesn't cope well with the task. During the day, in the heat, his work is almost invisible. Especially if the car is stationary.

Lights, electronics, thermostat

The weak point is the rear lights. They sweat quickly and are poorly secured. There are large gaps on the lamp side, where dust and dirt quickly accumulate. It will be necessary to carry out measures to remove it.

As for electronics, it became a drawback on the first cars of this model. Quite often the ECU floods the wiring harness. In addition, generator malfunctions occur. The problem lies with its bearings and belt.

In principle, the cooling system has no complaints. Problems appear only with the thermostat, and not in all models. This problem is mainly typical for cars manufactured before 2012.

Body

The above disadvantages are minor and relatively harmless. If we talk about the body, then this is a serious disadvantage of the vehicle. The paint on it wears off quickly. As a result, the body is left without a protective layer and begins to rust. This indicates that the vehicle was installed incorrectly. At the same time, the plastic bumpers are not painted at all, which many buyers do not really like.

Chassis, gearbox, brake pads

The car's chassis became its important drawback. Over time, the front struts begin to make an unpleasant sound. It manifests itself in the form of a knocking sound after 6 thousand kilometers. Over time, the traction control brackets located on the front suspension can burst.

The appearance of a whine in the gearbox indicates a malfunction of the gearbox. This problem often worries car owners. In addition, when cold, this part has a tight movement. It does not tolerate low temperatures well. In winter, there is a high probability of the handle freezing. This problem can be solved by simply changing the gearbox oil to synthetic.

The brake pads that the Lada Granta is equipped with are of low quality. Over time, they make an unpleasant creak and squeal. In addition, brake discs wear out quickly.

The handbrake cable is not very well secured in the car. Experts advise starting to operate the vehicle with extreme caution. It will take time to get used to this feature.

Salon

- The gear lever cover cracks and comes out from under the knob.

- Fragile seat adjustment handle.

- The airbag malfunction lamp is often an eyesore. The problem could be sensors in the belts, airbag control unit, or wiring.

- The taillights are sweating.

- The rear lights have open and quite large holes on the side of the lamps, and in the future, all the dirt from the trunk will be inside the lights.

- Unreliable fastening of headlight covers.

Main types of faults

So, as you can see, there are more than enough places for potential breakdowns. In case of errors, the “check engine” indicator will light up on the instrument panel screen.

This is what the engine warning light icon looks like

All engine modifications of the Lada Granta are controlled by an electronic control system.

Problems with the fuel pump

Location of the fuel pump in Grant (I apologize for the dirty interior, there were rogue kids driving before the shooting)

In this component, two parameters must be monitored, among which the operating pressure, as well as performance during operation, stand out. In most cases, the problem can be resolved through repair work rather than completely replacing the part.

First, you need to check the voltage at the connector that supplies power to the gasoline pump. This comes from the on-board energy system. If possible, this value should be 12 V or even slightly higher. In addition, during operation, slight noise during operation of the pump is considered normal.

The difficulty with this testing method lies in the fact that it can be very difficult to detect an unreliable contact in an electrical circuit on the way to the connector.

If we talk about control relays, then they are all located inside the car. And, if they do not work correctly, they can give themselves away with characteristic clicks. But, this malfunction is quite easy to fix, since replacing the relay is accompanied by monitoring the symbols, which will tell you where and what component needs to be mounted.

Problems associated with starting the Lada Granta engine

Naturally, many other problems are possible that are directly or indirectly related to its management system. These include wear on the injection elements of the fuel pump. Problems may also relate to the fuel supply process, as we already discussed in the previous section.

Relatively poor build quality is the bane of Russian cars

Lada Granta was no exception to the general rule. The build quality of the car is only slightly better than the layout of the “Tenth” family of cars. The company made significant changes to its production capabilities, consulting with experts from Renault and Nissan to look for problems in the assembly lines. But it was not possible to significantly improve the quality of the layout, welding and tightening of bolts for the Lada Granta. This car has its own serious problems associated with not very high-quality assembly:

- when driving you have to listen to a symphony of hard plastic, which rubs against other elements of the cabin with not very pleasant sounds;

- some fasteners have to be tightened every 5-10 thousand kilometers so that no components and assemblies fall off along the way;

- We recommend that you pay special attention to the engine compartment; if you hear rattling or vibration in this place, you should arm yourself with a wrench and a screwdriver;

- welding work at the plant was also not carried out using the latest technologies; sometimes Granta owners report the need to weld the car in the first year;

- in the cabin you can find a lot of shortcomings in the assembly process, but most of these problems can be fixed with your own hands without any effort.

It seems that the car does not undergo any certification at all. Lada Granta is one of the hopes of the domestic automobile industry; today it is the concern’s best-selling car, as well as one of the most popular participants in the Russian vehicle market. And even taking into account all these factors, the plant does not care too much about the quality of the car. It’s time to equip the assembly process with inspectors who will find every minor flaw and send the car back to the assembly shop for revision. True, in this case the Lada Granta will significantly lose its attractive price.

Generator - the main childhood disease of the first modification Grants

Every third owner of a Lada Granta car in the very first issue became a victim of a low-quality generator. Today, these components manufactured by Bosch are installed on cars, but the first cars rarely reached 15-20 thousand kilometers with an old generator under the hood. So this is one of the most serious and frequent “bugs” in the work of Russian VAZ engineers.

The engine does not develop full power.

— The engine is new, has not yet been run-in. The new Granta engine needs an initial run-in of up to 6-7 thousand km. During this period, the engine does not develop full rated power. The crankshaft revolutions during the break-in period should not be raised above 3000. — Malfunction of the electronic gas pedal. For a description of the solution to the problem, see above in the paragraph “The engine does not start.” — Insufficient pressure in the ramp. For a description of the solution to the problem, see above in the paragraph “The engine does not start.” — Valve clearances are broken. If you have an 8-valve engine, then periodically (every 15-20 thousand km) it is necessary to adjust the timing valves. — Malfunction of the ignition system. For solutions to problems, see above, in the paragraph “Engine does not start.” — Low compression in the cylinders.

Insufficient oil pressure.

1. Using oil that is not suitable for the engine. Use only oils and specifications recommended by the manufacturer. 2. Oil dilution/foaming as a result of fuel/antifreeze entering the engine crankcase. It is necessary to identify leaks and eliminate them. After this, be sure to replace the oil with a new one, with flushing. 3. Worn oil pump. The oil pump resource is quite long. Its failure is rare. If damaged, replace with a new one. 4. The oil filter is clogged. Replace with a new one, along with an oil change. 5. Damage to the crankcase. Check for external damage to the engine crankcase. It may be damaged by the road surface, which will reduce the gap between the oil receiver and the bottom of the oil sump. 6. Clogged oil channels and lines. May be caused by contaminated oil over a long period of time. The system needs to be flushed. 7. Cracks, uninstalled oil channel plugs. Carry out a visual inspection and install missing plugs.

Electrics and body

The generator bearings have insufficient life. They can begin to hum by 80,000 km. Power windows often squeak and raise the windows slowly due to glass jamming in the seals. Electric window motors often fail. You can also note the leakage of the rear lights of sedans: not only water, but also insects penetrate inside.

The paint on the body can be easily damaged by stones flying from under the wheels of other cars. The resulting paint chips “bloom” quite quickly. The paint layer is so thin that it is sometimes rubbed off by the door seals. The seat adjustment knob often breaks off.

Malfunctions of electrical equipment in Lada Granta - a guide to action

Although the car has a fairly reliable electrical system that powers consumers, from time to time electrical equipment malfunctions still appear on the Lada Granta.

Before you begin troubleshooting any faults in an electrical circuit, you should carefully study a specific electrical circuit diagram in order to understand the functional purpose of such a circuit as clearly as possible.

Potential fault locations are usually eliminated by identifying and eliminating properly functioning components of the same circuit.

In the event of simultaneous failure of several elements or circuits, the likely cause of failure may well be the blown fuse responsible for these elements. The cause of electrical equipment malfunction in a Lada Granta car may well be a violation of contact with ground.

Failures of electrical equipment are very often explained by the most elementary reasons, among which the most common are:

– corrosion of contacts on connectors; – failure of the safety element; – burnout of fuse links or damage to contact groups and relays.

You should visually check the functionality of all fuses, wiring and connectors in the circuit immediately before proceeding with a more scrupulous check of its components.

If you use diagnostic devices to find a breakdown, plan in detail exactly which points of the circuit circuit and in what sequence (the Lada Granta Norma electrical diagram will help with this) you need to connect the measuring device for more effective detection of the fault.

Rear suspension

It has an independent suspension with wishbones and a stabilizer bar. Damping of vibrations is carried out by hydraulic shock absorbers. The main structural element is the stand. It includes a swivel bearing, shock absorber and spring.

The pillar support has also been improved. Suspension creaking on the Lada Granta appears much less frequently than on Kalinas and Priors. To reduce roll, the design includes a stabilizer bar. It is made of spring steel. The stabilizer is installed with its ends to the lower suspension arms. Its middle part is fixed to the body.

The steering angle of the steering wheels was also increased. Caster angle is now 2° 45'. This move significantly increased the vehicle's directional stability at high speeds. However, the steering wheel became heavier. This is especially noticeable on models without an electric amplifier. By the way, the steering uses a short rack.

Unlike the front, it has undergone virtually no changes. Here, just like on the first Soviet G8s, a semi-independent beam is used. It is attached to the body on hinges (fortunately, there are no “crabs” in the design). A helical spring with constant stiffness is used as an elastic element.

To dampen vibrations and prevent swinging, two shock absorbers are used. The elements come from the factory are oil type. The spring is fixed together with the shock absorber. This greatly simplifies maintenance work, but has a negative impact on handling.

- High reliability. The design does not have additional levers, which, in addition, can bend when falling into a large hole.

- Energy intensity. The Lada Granta absorbs all bumps perfectly, especially if oil shock absorbers are installed at the rear.

- Cheap maintenance. Due to its simple design, this pendant can be rebuilt even with your own hands. And the cost of new rubber-metal elements is unlikely to empty the pockets of even the most stingy car owner.

conclusions

Most of these problems are caused by improper operation of the vehicle, including the use of low-quality fuel and oil, as well as prolonged operation at high speeds. It would be a good idea to carry out preventive maintenance from time to time to identify shortcomings in the form of leaks in the fuel channel, where air can get in.

Sources

- https://www.zr.ru/content/articles/922289-skolko-km-realno-proekhat-na-lada/

- https://1LadaGranta.ru/remont/problemy-neispravnosti-osmotr.html

- https://la-granta.ru/lada-granta-sxema-elektrooborudovaniya-ustranenie-neispravnostej.html

- https://www.zr.ru/content/articles/922561-5-problem-lada-granta/

- https://vgrante.ru/?cat=1&pcat=1

- https://carfrance.ru/osnovnye-neispravnosti-sistemy-upravleniya-dvigatelem-lada-granta/

- https://PolomkiAuto.ru/slabye-mesta-i-nedostatki-lada-granta.html