Even the most notorious admirers of the domestic automobile industry are infuriated when the gearbox lever of a VAZ 2114 dangles; as a dubious “bonus,” the motorist receives constant rattling. Owners of a strong nervous system put up with this situation. Soon even the all-metal psyche will not be able to withstand it; over time, the vibration will destroy the system. It will not be possible to engage the gear correctly; pairs second and fourth, third and fifth will engage with each other absolutely randomly.

Where does the vibration come from?

In this article we will popularly understand where the legs “grow” from and what to do. As expected, this is a mistake by the VAZ design bureau, sometimes it is the result of “tuning”, but we will consider all the reasons in detail, as well as methods for solving the problem.

- When moving, the bushing connecting the lever and the rod first begins to rub and then hit the edge of the rod. This vibration creates this sound. This is a pure engineering miscalculation, the length of the sleeve is worked out incorrectly, its length is longer than necessary and it is this extra edge that catches.

- Replacing the lever with a Kalinovsky one, here the rattling comes along with the positive effects of the replacement. Due to the imperfection of the design, Kalina's driveshaft produces vibration, which is subsequently transmitted to all structural elements. The vibration and sound remain even without the lever.

- The retaining spring is broken; the first symptom is that the VAZ 2114 gearbox lever dangles freely in neutral gear, absolutely not fixed in the position between third and fourth. If the problem suddenly appears, then the spring is to blame, and only repairing the gearbox will help here, otherwise the remains of the spring will break the entire box, then it will be really expensive.

- Sometimes this occurs due to general wear and tear of the car's shock absorbing parts, gearbox mounts and engine.

Car owners put off the problem until forever “later”, due to lack of time and money, but it’s worth knowing that the repair procedure is inexpensive, done with your own hands, and costs very little

Replacing the gear shift rod oil seal 2108 (our client still has front-wheel drive VAZs)

VAZ 2108 2109 Changing the gearbox rod seal Fundamental POINTS! Repair at home! Get .

VAZ 2108 with engine 21124 1.6 16 valves

Also pay attention to how Kalina_kardanchik looks!. VAZ 2108 2109 Changing the gearbox rod seal Fundamental POINTS! Repair at home! Get

VAZ 2108 2109 Changing the gearbox rod seal Fundamental POINTS! Repair at home! Get .

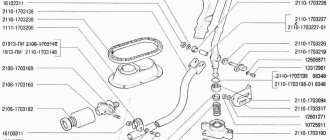

1. Get to the box stem; it is covered with a rubber boot. If the oil seal is faulty, it will be painful to find it simply by looking at the corresponding oil stain, see photo.

2.7. Bend the wide part of the boot; under it there is a cardan attached to the rod.

3. To gain access to the oil seal, you need to disconnect this popular rumor: the universal joint from the rod and gear shift lever. For this purpose, use the key at 13.

4. Unscrew the nut completely, this will loosen the connection between the cardan and the lever.

5. Remove the lever from the cardan shaft, then you will engage 1st or 3rd gear.

6. Disconnect the cardan from the rod using a 10mm wrench; for this purpose, move the lever to the side.

7. Remove the cardan.

See:

8. Next, remove the rubber boot, then you can see the very reason for the repair - the gearbox rod seal. The oil seal is placed in a recess - this is where the rod enters the box. It is impossible to remove the box seal without using a special tool, so take an awl and get to work. If necessary, use a screw, the usual principle is to screw in the screw and uncork the stem seal as if with a corkscrew.

9. When the old rod seal is removed, we proceed to change.

10. Without performing a high-quality installation of how to change the oil seal on a VAZ 2108-2109, what remains to be done is for our client to clean the landing area from oil, sand and other dirt.

11. If there is anything left for our client to do, press the new box seal into the seat.

12. Changing the VAZ 2108 gearbox seal is easier using a stopper from a plastic bottle. This is done in this way: the inner part of the plug is cut out and a new oil seal is installed through it. For example, I managed without it, in the end we can safely say - it’s the owner’s business.

13. After installing the new rod seal, begin assembly; it is done in reverse order.

Is it worth fixing the problem?

Many people don’t even try to fix the gearshift lever of a VAZ 2114, but this task is completely solvable, it doesn’t require skills, and the undeniable advantages are worth an hour of time. The difference is so noticeable that if a breakdown has been present in your life for a long time, you will constantly remember that there is not enough noise.

The main thing to remember is that a machine is like a person, what “cured” one is not the fact that it will help the other, and don’t get upset.

The repair will take very little time, you can get away with a small sum, and in return you will receive a number of huge advantages, such as:

- the unpleasant sounds accompanying the increase in speed will disappear;

- the gearshift lever will be fixed;

- switching will become smooth;

- At idle, the lever will stop “dancing the lambada” under your hand.

Let's get started

The most common factor influencing the “inadequate” behavior of the gearshift lever in the VAZ 2114 is the first reason described above. Therefore, this is where we should start solving the problem. To do this, you will need the following tools: electrical tape, sandpaper (grinder), ruler, 13mm wrench and lubricant.

Actions are performed in the following order:

- Remove the handle cover.

- Unscrew the nut and remove the handle and rod.

- We take out the bushing.

- We remove the plastic bushings and clean the metal bushings from dirt.

- We measure 2-3mm from the edges with a ruler, draw a line, glue electrical tape under the line for convenience, cut off the excess with a grinder (you can use sandpaper, but this will be a serious test).

- We put everything in place, lubricate it if necessary, don’t forget to tighten the nut, and put on the casing.

- Enjoying the silence.

There is a second way. It's a little more complicated. Washers are cut out of the plastic cover, or special rubber (plastic) nuts are purchased. You need to screw them on both sides of the drawstring, then you may not have to grind it down (although usually you still have to). The method is designed to reduce rattling by dampening vibration with rubber or plastic.

Replacement instructions

Before starting work, we advise you not only to purchase a new spare part, but also to watch training videos on replacing the slide. The procedure is not very complicated, but a visual aid will never be superfluous. Especially if you do not have much experience in repairing a car and transmission in particular.

Replacement procedure

The process involves performing several sequential steps.

- Remove the housing from your gear shift knob.

- Raise the car using a jack. In some cases, an inspection hole will do, if you have one in your garage.

- Now you should dismantle the console, which will give you access to the backstage.

- The element is held in place by six bolts, which can be removed using a regular 13 mm wrench.

- But it's not that simple. You won’t be able to unscrew the top two bolts with a wrench, so don’t even try. They are specially planted as tightly as possible, so to dismantle them you simply need to cut them down with a grinder.

- Now you can safely remove the remaining two bolts in the lower fastening of the rocker, for which your effort and a 13 key will definitely be enough.

- The next step is to remove the clamp and move the boot. You will need to remove the hinge. At the same time as replacing the link, we recommend changing the hinge. It would be a good idea to replace the oil seal and cardan shaft. These elements have a limited service life, and since you decide to change the slide itself, there are objective reasons to do everything as efficiently as possible.

- After this, install the new unit in place of the old one. Act carefully so that the rubber bands of the slides fall on the welded bolts, which you previously sawed off using a grinder.

- The assembly is now reassembled, operating in the opposite sequence to disassembly. It is not necessary to seat the top mounting bolts tightly, but try to tighten them firmly.

Let's sum it up

Vibration after “Kalinovsky tuning” is inevitable, and all artisanal methods are ineffective. As for replacing vibration-damping elements, a repair kit will help, which is initially better to buy for the slide. If its installation does not help, then it’s worth purchasing new pillows. Another option is to install an additional locking spring directly on the lever. The solution is good if the problem is not a broken spring in the gearbox, otherwise the time to buy a new gearbox is just a matter of your luck.

Backstage

The gearbox is a multi-lever assembly mechanism that connects

the gear shift lever

and the rod that fits the gearbox. It is located under the bottom of the car, as a rule, near the cardan or under the gearbox lever located in the cabin. In any case, dirt and water get there, which over time deteriorate the quality of lubrication of the rubbing elements of the slide, which is why they begin to wear out, leading to various problems.

Making a knot yourself

If you wish, you can make a CC yourself, and it will be perfect for any car, including the VAZ 2114. To work, we will need the following:

- a small tube with a diameter of exactly 15 mm;

- RPP from the VAZ 2114 model;

- ball nut;

- steering cardan;

- VAZ 2114 axle and bushings (repair kit for backstage).

The work takes place in several stages. First, you need to cut off the ball from the RPP and adjust the lower edge so that you can then install a pipe here. Scalding is carried out. A nut is attached to the pipe from the bottom edge and welded. Then comes the installation of the ball. The cardan is mounted to the gearbox lever.

Having carried out such an operation once under the supervision of an experienced car mechanic, you will understand that in fact there is nothing impossible or complicated here. The entire process of manufacturing the CC takes about two hours and is almost the same as replacing the rocker seal. And every second car owner performs such work almost with his eyes closed.

The CC device is quite simple. Easier gear shifting is achieved by reducing the lever travel, and this depends on how long the lever is. In order for the standard rocker to become short-stroke, you just need to lift the fastener of the “piece of iron”, which extends from the gearbox towards the lever. In this case, you do not have to dismantle the standard rocker, which allows you to significantly save both time and effort.

Signs of a malfunctioning rocker

Most often, problems with the rocker are eliminated by adjustment

or

replacing a repair kit

, less often the unit needs to be replaced.

In most car models, the gearbox linkage is a fairly reliable unit that can easily last up to 100 thousand kilometers without repair. The exception is cars that are not initially distinguished by high build quality - anything can happen to them. Wear of the link can be determined by the appearance of such signs as:

- increased play in the gear shift lever;

- problems with gear shifting;

- impossibility of adjusting the mechanism.

If the gears begin to engage excessively slowly, or the wrong gear is engaged that should be engaged, first of all you should try to adjust the drive if it is visually in normal operating condition. If the joints of the hinges work with a lot of play, the link will have to be changed.

So, from all of the above, we can conclude that the gearshift rocker, also known as the gearbox control rod, is a fairly simple mechanism, but it also requires maintenance for comfortable driving.

Subscribe

to our channel in

Index.Zen

Even more useful tips in a convenient format

Over time, almost everywhere possible, backlash begins to appear on cars produced by AvtoVAZ. The gearbox is no exception. It is not surprising that replacing the rocker on a VAZ 2114 has become a routine procedure familiar to all owners of this model.

Set

Determining the malfunction is quite easy:

- Gear shifts with problems, indistinctly;

- The gearbox is loose.

Some masters argue that it is not always wise to completely change. It is more profitable from a financial point of view to purchase a repair kit. But in fact, such repairs do not give the desired result, and after a while the link will still have to be changed.

Short walker

We change the CV joint and its boot on a VAZ 2114

Many people are still wondering whether it is worth changing their standard factory long-stroke linkage to a short-stroke one.

Short walker

Make your decision purely on the basis of individual reflections and do not “be fooled” by statements regarding a significant increase in dynamics with the transition to a short-stroke.

The real difference between short-stroke and long-stroke is shown in the table.

Backstage type

Peculiarities

Draw your own conclusions from here - do you need such a drawstring or not. There is nothing complicated in terms of replacement. The only question is the purchase.

The VAZ-2109 rocker is a simple mechanism used to change gears. The driver, applying force in one direction or another, acts through the rocker on the gearbox. This switches on the required speed. Very rarely, the mechanism breaks down and requires partial or complete replacement. Most often the cardan shaft fails. Changing it won't be difficult. But if the rocker itself is broken, you can think about a little tuning - make a short-stroke one. This will require less effort to engage the desired gear.

Price issue

Short walker

Actions on your own, you only have to purchase the necessary parts and ordinary consumables. If you contact a car service, the minimum cost of the service will be 800-1000 rubles. That is, the savings are obvious.

The curtain itself costs about 400 rubles. From here it becomes clear why we did not advise buying a repair kit, but rather completely replacing the part. There will be no savings as such, but the difference as a result of the repair will be significant.

Sports

We noted that for the VAZ 2114 you can install a sports short-throw rocker . Outwardly they are quite similar, but the difference in work is felt immediately. On a sports unit, gears shift faster and smoother. It's all about the design of the backstage itself. Unfortunately, it is precisely because of this that the process of independent replacement becomes almost impossible.

Sports model

4 / 5 ( 1 voice )

How to adjust the rocker on a VAZ 2114, varieties, repairs

The VAZ-2109, 2114 rocker is a simple mechanism with which gears are changed. The driver, applying force in one direction or another, acts through the rocker on the gearbox. This switches on the required speed.

Very rarely, the mechanism breaks down and requires partial or complete replacement. Most often the cardan shaft fails. Changing it won't be difficult. But if the rocker itself is broken, you can think about a little tuning - make a short-stroke one.

This will require less effort to engage the desired gear.

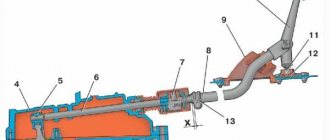

1-gearbox housing, 2-gear selection mechanism housing, 3-gear selection mechanism, 4-clutch housing, 5-rod lever, 6-gear selection rod, 7-rod hinge, 8-gearbox control rod, 9- rod protective cover, 10-shift lever, 11-spherical lever pin, 12-ball lever support, 13-clamp, X-distance between the ends of the clamp and the link

Varieties of backstage

Despite the different design models, only two types can be distinguished:

- Long-stroke (standard, previously installed on cars of model 2109 and similar).

- Short-wheel drive (installed on Kalina cars).

Structurally they are very similar, only different in size. The advantage of short-throw ones is that with their help, gears are engaged easier and faster.

True, many myths have formed around the gear shift: some claim that the dynamic characteristics of the car are significantly improved. This is all wrong; there is no connection between the dynamics of the car and the view of the backstage. But still, the short-stroke one has advantages over the standard one.

Why change the backstage

There are situations when it is necessary to intervene in the gear shift mechanism due to the failure of a component. But there are cases when an extreme measure is required - replacing the VAZ-2109, 2114 rocker.

In these cases, replacement is required:

- An oil leak appeared due to damage to the oil seal. Only the oil seal can be replaced.

- Complete failure of the scenes.

- You have realized the advantages of a short-stroke design and you have the funds for this kind of tuning.

Symptoms of gear shift mechanism failure:

Increased gearshift lever play

Please note that this behavior may also be caused by a loose cardan. Sometimes the bolt securing it gets screwed out, so to reduce the backlash it is enough to tighten it, and first apply a drop of thread locker. Difficulty shifting gears

Sometimes extraneous sounds are heard. Gear shifting is not possible. Inconsistency between the position of the lever and the selected speed. For example, the back one disappears, and the first one is in its place.

If a slight play appears, it is advisable to carry out diagnostics and identify the breakdown of the unit. Make repairs immediately, otherwise one or more speeds will disappear at the most inopportune moment.

Short-throw slides for "nine"

Such designs were developed exclusively for sports models, but are widely used in production ones.

Advantages of the VAZ-2109, 2114 short-stroke rocker over the standard one:

- Easier gear shifting.

- The backlash of the gearshift lever is reduced, especially when using a cardan from Kalina.

Disadvantages:

- You need to either buy it or make it yourself.

- It takes a lot of force to change gears. Despite the smaller stroke, this type of backstage is more suitable for people who are not only strong in spirit.

But you don’t have to buy a rocker for a VAZ-2109, 2114 in stores; you can make a short-stroke from a regular one with little welding skills.

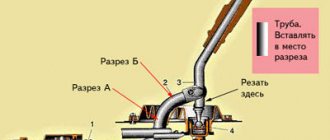

To do this, cut the old rocker in two places and weld pieces of a metal plate to lengthen the arms. The main thing is for the new drawstring to fit into place, so first carefully study the drawing, which shows the locations of the cuts.

Didn't find the information you are looking for? on our forum.

, please select a piece of text and press Ctrl+Enter.