The gearbox in VAZ 2110 cars is one of the most involved dynamic elements. Because of this, the unit often becomes loose, which makes operating the car inconvenient. A shaking gear shift lever is a fairly common occurrence in domestic cars. There are two ways to combat this defect: constantly adjust the gearbox or make the rocker short-stroke - the process can be done independently. You can also purchase a gearbox repair kit from another VAZ model, which initially comes with a short-throw driveshaft.

What is so good about a short-stroke rocker? Firstly, it guarantees reliable operation of the gearbox over a long period of time. Secondly, the short-stroke version helps to increase the clarity of VAZ gear changes, including in the 2110 model. This is quite enough to make the operation of the power plant more comfortable, because smoothness, stroke and clarity of gear shifting are important for the gearbox.

Differences between a short-stroke link

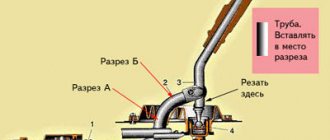

The main differences can be seen even in photographs. We see that the short-stroke rocker has smaller dimensions, namely length. To reduce the stroke length at startup, the length of the transmission under the hinge should be increased. Due to this, we can not only get shorter gears, but also maintain the traction axis in its original position.

It is worth understanding that after such tuning, you will need to put more effort when changing speeds. After upgrading, switching will resemble joystick control, which is undoubtedly a plus. In addition to the rocker, you can install a backlash-free cardan, which will also have a positive effect on the smooth operation of the gearbox.

Is it difficult to change the slide yourself?

In order for the short-stroke rocker to feel the beauty of the absence of play and vibration in the lever, it must be installed correctly. If the installation is carried out in a car service center, you don’t have to worry, but if you replace it yourself, you should take this with full responsibility. The whole procedure is reminiscent of replacing the rocker seal - almost half of car owners face this operation. The need to replace the oil seal is very eloquently indicated by the characteristic crunch that is constantly present when switching gears.

If we analyze the process of self-installation of a short-stroke rocker in more detail, we can highlight the following main stages of work.

- The interior cover of the lever along with the handle is removed with a simple sharp jerk upward.

- Using a 13 key, the clamp is loosened and the lever rod is removed from the propeller shaft.

- The reverse speed locking ball is released, for which you will need to remove the ring blocking it.

- The retaining ring and lever are removed along with the ball and spring, located in a separate housing.

- Now it will be possible to remove the lever along with the rod through the interior. If necessary, they can be previously disconnected.

- Next, the cardan is removed, from which the boot is first pulled off and the bolt located on the left side is unscrewed.

- The new cardan is lubricated with lithol; when tightening the fastening, you should not be too zealous.

- The rod is also mounted from the interior. It will be much more convenient to carry out this work together.

Further assembly is also not difficult. The rod is put on the cardan rod, after which it will be necessary to assemble the reverse gear locking mechanism. It is better to lubricate its ball first. After this, before the final tightening of the mounting clamp, the final adjustment of the lever and the reverse gear locking system is carried out - in some cases the mechanism often does not coincide with the plate, then it will have to be removed and the existing hook adjusted. The process of installing a short-throw rocker on a Priora can be seen in the video:

Most car owners who, for one reason or another, decide to replace the standard linkage with a short-throw one, remain satisfied with the speed and clarity of gear shifting

If we take into account the very low cost of such an upgrade, which can also be done with your own hands, the advantages of a short-stroke rocker increase

Even if the driver does not particularly care how long it takes to engage the gear, the almost complete absence of extraneous noise and play is inevitably noted by every driver

Making a short-stroke slide with your own hands

So, let's begin the modernization process:

- We raise the place of attachment of the piece of iron that goes from the gearbox to the lever inside the VAZ 2110 interior.

- You can do without dismantling the rocker, the main thing is to disassemble the ball joint.

- Now we need to ensure that the plastic paws release the ball. To do this, you need to unclench the metal ring. We disconnect the rod and carefully drag it inside through the cover, which is responsible for protecting it from dirt. It will be much more convenient to work if the clamp near the gearbox is loosened.

Replacement is carried out according to the same scheme. Only instead of welding, a freelance short-stroke rocker from another car is installed. Replacement is a more expensive solution, so doing it yourself is problematic. If you have experience working with gearboxes, then replacing and purchasing a new part will cost about 1,000 rubles.

The VAZ 2109 gearshift lever is loose, what needs to be changed? | Topic Author: Taichi

In general, the problem is this... the fact that the gearbox lever dangles, I can’t control the speed... at any speed the lever dangles like in neutral... but I can’t catch 5 at all... I only drive in 4 all the time... what do I even need to change?? clip? backstage? cardan, or does something need to be changed there in this rubber band at the bottom (where is the cardan)? What needs to be changed..so that the gearbox and speed are turned on normally? ! help me please

Roman (Dhruv) is also loose on my tweeter (I changed the ball joint of the lever, it didn’t help!!!). On the new ones it’s also loose!! it's a disease!! I read an article, a guy from the inside under the lever casing stretched the usual rubber bands from his underpants, the lever stopped hanging!!! Nikita (Borys) had the same problem. I changed the backstage. and everything seems to be fine now Tima (Husam) installed a driveshaft from the viburnum, half an hour of work and everything is fine) but before it was also loose, the rear from first and fifth were generally difficult gears. Vladimir (Philipi) change the rocker Evgeny (Hawa) you need to change the choice Viktor (Aldonza) Nikolay, Exactly the same for me on 9. I installed a Kalino cardan, nothing has changed. Most likely the linkage needs to be changed. Danil (Oceanus) First, check it, put it on the lift and see, maybe the nut that secures the rocker is just loose, I had this happen, take the key to 13 and tighten it, judging by the symptoms, it is, but you need someone to hold the gearshift lever Oleg (Ebrilla) +1 The bolt on the driveshaft often comes loose, the symptoms are exactly the same, I had it on both the Pyatakh and Kalina, you pull the cover off the driveshaft and turn it to 13 with the key. For 2 minutes. Stanislav (Eris) Change the gearbox hinge and install from the viburnum Pavel (Melisenda) the linkage needs to be changed! ) Dimka (Kadin) my drawstring is the same crap Nikolay (Gavriella) should I change the assembled drawstring and everything will be fine? Vyacheslav (Maurizia) change the link, there is a bolt on the crosspiece that is constantly unscrewed and the shaft on the box may come loose Alesha (Dashratha) Nikolay, the link is assembled =) the price of the issue is less than a thousand... )) Danil (Oceanus) So, first check what you mean I wrote to you, why don’t you immediately throw away the money? Nikolay (Gavriella) the nut on the rocker is normal... I already looked at Mikhail (Setara) I just tightened the bolt on the cardan and everything stopped Stanislav (Eris) My bolt securing the gear shift mechanism and the rod inside the box has come loose. It was also dangling until it completely unscrewed :) Vladimir (Philipi) I have the same problem ((in any gear like in neutral, replacing the rocker didn’t solve the problem!!!! I just started catching gears a little better, but I feel like I’ll tear the hell out of everything there soon because that you shift from 3rd gear to 1st, and the same 3rd gear gets stuck, you panic, get nervous, and there is such a crunching sound, in short, it’s scary, what should I do????? Thanks in advance, I’m a newbie with the pelvis)

Installing a short-stroke cardan

The first step is to purchase the cardan itself. The best choice would be a part from Priora or Kalina. Usually it is included in the repair kit with a boot, so the standard boot from a VAZ 2110 will not fit here.

Work is performed only if there is an overpass, inspection hole or lift. It is also recommended to call an assistant for help, since at the end of the process it will be problematic to independently adjust the position of the gearshift lever.

The work proceeds according to the following scheme:

- Armed with two 13 keys, we need to loosen the clamp on the drive rod and then pull it off the rod.

- The next step is to dismantle the boot. Next, use the 10th key to unscrew the bolt, which is a lock on the standard cardan. Now you can remove the cardan with gentle blows of a hammer.

Important: it is necessary to check the condition of the oil seal. If this is the first intervention in the gearbox, then it is most likely in a worn condition, so it is recommended to change the boot.

- We install the driveshaft from the Priora in the reverse order: put on the boot and install the new driveshaft, securely tighten the fixing bolt, and then tighten the boot. All that remains is to put the drive rod on the cardan rod, but the clamp should not be tightened.

- Now the assistant gets behind the wheel and places the gearshift lever in the optimal position. At this time, the clamp is tightened. Done, the replacement is complete, all that remains is to test the switching.

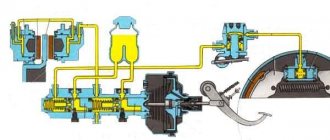

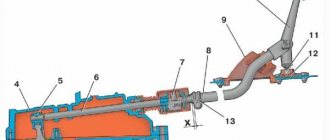

Gearbox slide: device and principle of operation

Let's start with the fact that the name backstage is common. In fact, experts call this element the gearbox control drive rod. The rocker itself is a fairly strong part, but the design consists of several components, which somewhat reduces reliability.

The main purpose of the gearbox linkage is to connect the gearshift lever (switch) with the rod, which is connected to the gearbox. The slide is located between the gear shift lever in the cabin and the gearbox. The location may be different, that is, it depends on the ground of the car (under the gearshift lever, under the bottom, closer to the driveshaft, etc.).

At the same time, the linkage in a manual transmission can wear out quite quickly, since driving a manual transmission, unlike an automatic transmission, involves constant work with the gear shift lever. Typically, the service life is about 100-150 thousand km, but problems may appear earlier.

As mentioned above, the slide consists of several parts, and the wear or breakdown of any of them leads to the fact that the performance of the entire mechanism will be impaired. Also, the rocker in a car suffers from factors such as dust, dirt, moisture, insufficient lubrication, etc.

It should be added to this that if the driver himself works aggressively with the gearshift lever, or operates a car in which shifting gears is difficult, for example, due to problems with the clutch, etc., this also has a direct impact on the linkage and shortens the service life of the mechanism.

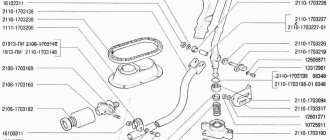

Let's move on to the design of the gearbox backstage. Let us note right away that each manufacturer strives to increase reliability, as well as achieve clarity and ease of gear engagement, reduce backlash, etc. As a result, the design of this mechanism may differ on different cars. However, we can highlight the main (basic) elements in the design of the gearbox rocker:

- gear lever;

- gear traction;

- fork and fork finger;

- fork seal;

- oil seal retainer;

Also in the device you should highlight the backstage body, cable, and spring. Normally, thanks to these parts, gear shifting occurs smoothly, without unnecessary effort, gears are engaged clearly, and backlash is minimal.

If problems arise with the mechanism, signs of a faulty link appear quite clearly. As a rule, problems with the clutch lead to certain difficulties when shifting gearboxes.

Among the main problems it is worth highlighting:

- gear shift lever play;

- difficulties when changing gears, when more effort needs to be applied to the lever;

- knocking or crunching when operating the lever;

- gears do not engage or the wrong gear is selected by the driver (gear shifting is no longer clear);

Let us immediately note that some play is acceptable due to wear, but a significant increase in it not only reduces operating comfort, but can also cause more serious damage.

In other cases, when the required gears are engaged with great effort or the gear cannot be engaged, maintenance of the rocker and adjustment, replacement or repair is necessary, since driving with a damaged rocker can be considered extremely unsafe.

Video instruction

Many inexperienced drivers begin to panic and talk about a breakdown of the gearbox, although in fact the culprit of the problem is the rocker.

Practice shows that replacement and repair are rare and not very common measures. Much more often, the current situation forces you to simply adjust the scenes.

But today we will talk not only about adjustment, but also talk about the features of modification, repair and replacement of this element.

Element location

Sports

We noted that for the VAZ 2114 you can install a sports short-throw rocker. Outwardly they are quite similar, but the difference in work is felt immediately. On a sports unit, gears shift faster and smoother. It's all about the design of the backstage itself. Unfortunately, it is precisely because of this that the process of independent replacement becomes almost impossible.

Sudden changes in the weather? Is it uncomfortable to drive on winter tires? Find a quick replacement where they sell used tires.

Nobody argues that it is better to own a new car. Everything is good, it works well, all the functions included in this car by the manufacturer are present, nothing rings, does not knock, etc….

But after a few years of active use, problems begin, small at first, then more and more. But today, I would like to talk about such a thing as play in the gearbox of a VAZ car. This “disease” plagues cars of the entire front-wheel drive family. For a more convenient location of the gear shift lever you have to pay by adding new parts to the design of this unit, and accordingly more parts means more breakdowns :).

For VAZ models of the classic family, the gear shift lever is installed directly on the gearbox, or more precisely on the drive mechanism of the gearbox forks. This option eliminated any play in the backstage, since it was not there at all. In models with front-wheel drive, such a gearbox arrangement was impossible, so a rocker mechanism was used. It allows you to move the gear shift lever during design, which is a big plus in designing the comfort of a car.

Adjustment

Now let's talk about how you can adjust the link if it shows primary signs of malfunction.

- First of all, try by hook or by crook to engage first gear.

- Place the car on an overpass, turn on the handbrake, place additional supports under the wheels to avoid the car moving.

- Do not turn off first gear on the transmission.

- At the bottom, find the clamp that holds the rocker and secures it. To do this you will have to crawl under the hood. You shouldn't have any problems finding the gearbox. The clamp needs to be loosened.

- Now return to the salon. Your task is to move the box lever as far as possible to the left. If you start to pull the handle forward or backward, the drawstring will most likely come off. You don't need it.

- Get back under the car and tighten the clamp back.

- In many cases, simply shifting the rocker relative to the cardan shaft by literally a few millimeters is enough.

When adjusting, pay attention to the condition of the cardan shaft. It may require replacement if worn.

Work is in full swing

Finalization

Now many owners of the VAZ 2110 are discussing the possibility of refining and improving the gearbox by replacing the rocker from a standard one to a short-throw one.

The short walk is the result of independent tuning. Decide for yourself whether to carry out such work or not. But from the point of view of the efficiency of the gearbox, installing a short-throw rocker is only beneficial, since gears begin to shift more clearly.

Short walker

To install a short walker for yourself, it is not necessary to completely dismantle the standard version.

To do this you need to perform several operations:

- You just need to disassemble the ball joint from the outside;

- Next, the metal ring of the support is opened and the legs made of plastic are spread apart;

- This is how the ball will come out;

- Now the rod is disconnected from the support, and a small piece of pipe and a piece of sheet metal of good strength are welded to the rod;

- Be sure to lift up the hinge with the hook, otherwise erroneous switching of speeds will not be avoided.

Installing a short drive will entail the need to apply more force when engaging a particular gear. But on the other hand, switching becomes clear and smooth. Therefore, decide for yourself which option would be better for you - standard or short-stroke.

Tuning

Many VAZ 2110 car owners, even having purchased a completely new car, strive to change the scenes. This can make it more comfortable, but only if done carefully.

The fact is that the short-stroke rocker is, in fact, a homemade product, a modification. If you have a short-throw shifter, the gearbox wears out less, and in general this is not bad for the gears - they engage more clearly.

In order for the short-stroke rocker to replace the standard one, it does not have to be completely removed. It is enough for the ball joint to be disassembled from the outside. It is necessary to unclench the metal ring of the support and spread the plastic legs so that the ball comes out.

Next, you need to disconnect the rod from the support and weld a small piece of pipe to the rod, as well as a piece of durable sheet metal. Do not forget to lift up the hinge, which has a hook, to prevent the gears from being engaged by mistake.

Although the short-throw rocker requires more effort to engage, it increases the smoothness and clarity of gear engagement. But, in principle, choosing which is better for him - short-stroke or full-time - is the right of every VAZ 2110 owner.

Repair

Regardless of what exactly you do with the rocker - repair, adjust or change, you will still need to disassemble this unit.

Disassembly is performed as follows.

- Remove the cover from your gear shift knob.

- Place the car on a pit, or raise the front end with a jack.

- Remove the front console. It is held in place by mounting bolts.

- Now remove the curtain itself. To fix it, AvtoVAZ used 6 bolts in the case of the VAZ 2110 model.

- When carrying out dismantling work, be sure to examine the condition of all elements.

- By bending the boot, you will gain access to the support, oil seal and cardan shaft.

Changing the boot

Now regarding the repairs. There may be several recommendations in this regard, depending on the current state of the node and its components.

- At best, repairs will require the use of a repair kit for the backstage. It doesn't cost much.

- If the bushing is deformed, it will need to be replaced with a new one.

- Check the lever shaft bore for wear.

- Make sure there is no play in the driveshaft. Otherwise, a regular repair kit will no longer be enough, that is, a complete replacement of the entire backstage will be required.

- Often the culprit of extraneous noise and rattling when shifting gears in gearboxes is the rocker pad. Changing it is quite simple, and even a beginner can perform the operation.

Replacing the oil seal

Quite often, VAZ 2110 owners are faced with a situation where, after parking under the car, they find traces of oil. There are two options here - the oil filter has worn out or there are problems with the oil seal.

Replacing the rocker rod oil seal

The normal condition of the oil seal determines whether the oil “disappears” from the gearbox, so if you notice oil stains on the asphalt after parking, you should think about whether it is the oil seal or the oil filter.

Therefore, after checking the filter, it’s the seal’s turn. A malfunction of the VAZ 2110 oil seal can also be suspected if a crunching sound is heard when changing gears.

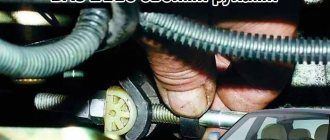

The oil seal can only be replaced in a hole, overpass or other device that allows you to get under the car:

- First of all, we pay attention to the rubber boot. If oil escapes from the VAZ 2110 gearbox through the oil seal, then the entire boot will be in its drops;

- We bend the boot and disconnect the cardan, gaining access to the cuff;

- We remove the cardan from the lever, and then from the rocker;

- Having removed the cardan, we get to the oil seal;

- Using an awl and a hook, remove the cuff on the gearbox;

- Now you need to press in the new oil seal. Traditional craftsmen usually install it using a plastic bottle cap;

- If the replacement was successful, we return everything to its place, install the boot, and we can consider this minor repair complete.

Remember that any rocker repair will not be successful if it is not adjusted correctly. It is best if the setup is done with an assistant, since it is problematic to do this on a VAZ 2110 yourself.

Adjusting the scenes of the VAZ 2110: do-it-yourself modification

Even such an element as the gearbox linkage can be modified. Most car enthusiasts prefer to change the standard rocker to a short-throw one. Such tuning in the future involves performing such an operation as adjusting the scenes of the VAZ 2110.

If this procedure is not completed, you will experience problems with gear shifting in the future. It is best when adjusting the rocker is done with an assistant, otherwise you need to be patient.

Do-it-yourself repair should reveal the cause of the problematic shifting of rear and fifth gears. Setting up the VAZ 2110 backstage is done in several ways.

Option one is rear speed adjustment. To do this, you need to switch the box to move backward, loosen the clamp a little and switch the lever to the position in which it should be when the reverse gear is engaged. Tighten the clamp and the problem disappears.

The second method becomes relevant in the case when there is no possibility of switching reverse gear. In this case, the adjustment of the VAZ backstage is performed in first gear. We switch to first speed, loosen the rocker clamp (it is located at the bottom of the car), turn the rocker drive counterclockwise until the gearbox lever rests against the reverse gear lock, made of plastic. All that remains is to tighten the clamp, and the adjustment is complete.

Setting the neutral position of the gearshift knob is done by calculating the depth of fit of the rocker on the driveshaft of a VAZ 2110 car.

It often happens that do-it-yourself modifications cause unpleasant rattling sounds in the area of the gearshift lever. Of course, you can ignore this, but we do everything as a businessman. The easiest way out of this situation is to install a spring, which will help hold the gearbox and prevent unpleasant noise from occurring.

Be that as it may, you need to work not with the symptoms, but with the cause of the malfunction; we hope that adjusting the VAZ 2110 rocker will not cause you any problems.

It would seem that such an element as the backstage cannot be modified or modernized, because everything here is extremely simple. However, tuning is also possible here, we’ll talk about this in this article, and as an example we will have a VAZ-2110 car. Many car owners prefer to change the standard rocker because it has too long a stroke; instead, they install a short-stroke one. This is good because the clarity of switching improves and less time is spent on it, but at the same time, car enthusiasts for some reason forget that the rocker needs adjustment.

If there is no adjustment, the driver will soon feel difficulty changing gears. It is recommended to do the work together with an assistant, although, if desired, you can do everything alone.

In this case, the owner of the “ten” replaced the rocker, did not adjust it, and had problems when shifting from reverse to fifth gear. The adjustment can be done in different ways; we will consider several options with you.

Symptoms of a malfunctioning rocker

There are certain signs indicating that it is the gearbox linkage that has become unusable, and not the transfer case itself.

The most common signs:

The first gear is driven correctly, but after a while the reverse gear is set independently;

As soon as the listed symptoms, even one of them, are noted while driving a car, you need to contact the service to fix the problem. If experience and desire allow, you can fix the breakdown yourself.

The most common symptoms of a link failure and possible cause:

- The play in the gearbox lever can be clearly felt: the cause could be physical wear of the linkage, the problem can be solved by completely replacing the part.

- The box slide rings when gears are changed: sometimes the sound indicates a poorly performed repair or a factory assembly defect.

- Speeds are switched with great effort: adjusting the VAZ 2110 rocker will fix this; if the problem persists, you will need to replace the element.

- When you engage the first gear, the lever shifts to reverse gear: the reason is precisely in the gearbox, a mandatory replacement is required. The situation can be corrected by a repair kit, but this depends on the severity of the damage or the detected wear of the assembly elements.

- When the engine is running, strong vibration is transmitted to the gearshift knob: the hinges need to be checked, the cause could be play.

Self-adjustment of the rocker on a VAZ 2110. Adjustment of the gearbox rocker with your own hands

The gearbox linkage, like everything else in a car, requires care and timely adjustment. misadjusted gearbox linkage can cause discomfort while driving. For example, the gear knob may rattle, the gear shift may become inaccurate, the speeds may “knock out” from time to time, and the lever itself may begin to “play.”

To get rid of all this, you need to carry out a simple procedure for adjusting the gearbox rocker, especially since adjusting the rocker will take you no more than half an hour.

The gearbox slide is necessary to prevent random switching of gears due to the simultaneous movement of the sliders. Often, the entire transmission suffers from an incorrectly adjusted rocker, and as a result, you are at risk of malfunctioning the entire gearbox. In our previous articles, we have already talked about this detail several times, for example, in the article: About how to install a short-throw rocker on a Lada Priora. and also in the article: Installing a short-throw rocker on a VAZ 2109. In addition, the issue of engaging gears and gearboxes is addressed in this article.

Adjusting the gearbox slide requires the presence of an assistant, in which case the result, and the work itself, will be of better quality. It is fashionable to adjust the slide in several ways; below we will talk about each of them in more detail.

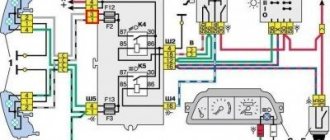

Installation of the backstage from "Kalina"

Replacing the VAZ 2110 gearbox shifter On a VAZ 2110 you can successfully install a Kalina shifter:

- To do this, it needs to be modified a little.

- The cardan from the new model is 20 mm longer than the original “tenth”.

- Therefore, it needs to be cut, to do this, use a lathe.

Note: when cutting manually, you can ruin the part, since when the temperature of the metal increases, it loses its strength.

- The replacement of the slide must be carried out in the garage from the inspection hole.

- Remove the plastic tunnel from the car interior.

- Also remove the boot.

- Remove the old rocker, unscrew all the fasteners from under the bottom of the car.

- Install a new link and adjust it.

Note: adjustment must be carried out in order to later avoid troubles that arise during operation of the vehicle.

Why is it recommended to install a cardan from the new Kalina? On VAZ-2110 models, universal joints made of less resistant material are installed, so they quickly fail. This causes premature play in the rocker, which usually affects the quality of gear shifting while the vehicle is moving. After purchasing a new link, a visual comparison should be made of the old cardan and the purchased one.

The comparison will be entirely in favor of the new acquisition. The Kalina cardan is made of better quality material, it is much more wear-resistant.

After installing a new link, the lever may rattle. Since this link completely eliminates play, that is, the vibration is transmitted completely to the lever.

How to adjust the rocker on a VAZ 2110 with your own hands

Before adjusting the gearbox linkage, it is necessary to perform a number of preparatory work:

- Drive the car into the pit.

- Tighten the handbrake and install the wheel chocks.

Method No. 1 - adjusting the rocker according to the rear speed.

- Loosen the clamp.

- Engage reverse gear and position the lever as you would like it to be in this position.

- Then tighten the clamp and check how the rocker works, whether you are satisfied with the current position of the lever and the operation of the rocker.

Method No. 2 - adjusting the rocker at first speed.

This method is used, as a rule, when the first method did not produce results.

- Turn on first speed.

- Loosen the rocker clamp.

- Turn the rocker drive counterclockwise until the gearshift lever begins to rest against the plastic reverse speed stop.

- Tighten the clamp and check how everything works.

Method No. 3 - adjusting the scenes in neutral.

If you do not have a plastic stopper, the adjustment is made in neutral gear.

To adjust the neutral position of the gearshift lever, you need to accurately calculate the depth of the shift of your gearbox to the driveshaft of the VAZ 2110. Sometimes such manipulations result in the appearance of annoying rattling of the lever.

If adjusting the rocker does not lead to anything and there is still a problem with switching, replace the rocker completely or ask for help from specialists.

Diagnosis of the problem

The gearbox linkage in a car is necessary so that the unit cannot independently change gears as a result of the simultaneous movement of the sliders. This mechanism requires careful care, as well as periodic and high-quality adjustments. If the adjustment is performed poorly or some time has passed, this may manifest itself while the car is moving and the driver will feel discomfort.

VAZ 2110 car

In practice, as a result of constant use of a car with a rocker drive that requires adjustment, the vehicle may be at risk of breaking the entire transmission system. Therefore, attention should be paid to the quality of the unit’s operation and problems that arise during operation should not be neglected.

To understand that in your VAZ 2110 you need to adjust the rocker shaft, you just need to pay attention to the operation of the gearbox unit. Symptoms of the malfunction will be as follows:

- There were problems with engaging first gear. In particular, it will be impossible to turn on the gearshift lever, and sometimes it will be impossible to switch from first speed to second.

- Instead of first gear, reverse gear is engaged. Imagine: you are about to start moving and engage first gear, but instead your vehicle starts moving backwards. Perhaps after switching to “neutral” the problem will disappear, but over time it may happen again. In this case, in 98% of cases the problem lies precisely in the rocker shaft, that is, this has nothing to do with the speed lever.

- There may be problems with engaging first and fifth speeds. At the same time, all transmissions will work normally.

New component of the VAZ 2110 transmission system

- A large amount of play has appeared in the gearbox selector, that is, when switching the lever, you noticed that a gap has appeared. Apparently, the rocker in your vehicle is out of order and adjusting it will no longer help: you will have to repair the mechanism.

- A new extraneous noise has appeared, uncharacteristic of the gearbox of your VAZ 2110. In particular, the rocker began to ring, that is, you feel a distinct ringing from under the unit. This problem can be called the VAZ 2110 disease, since many car enthusiasts have encountered it. In this case, the cause of the breakdown may be an inaccuracy made during the assembly of the car at the enterprise or errors made by the car owner or a mechanic at a service station when adjusting the mechanism. It is also worth noting that the ringing often appears after repair work has been carried out on the chassis.

- The speed may simply jump out. That is, you have engaged a gear, but when accelerating, the car immediately loses power because the gearshift lever automatically engages neutral speed. This will require some fine adjustments.

- Vibrations of the gearshift lever. If the linkage is faulty, the driver may feel increased vibration of the gearbox selector. Often this indicates the appearance of a small gap in the hinges of the gearbox unit.