Which engine mount is better than VAZ 2110 or VAZ

- Registration

- Entrance

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

Engine 2111. Changed engine mounts.

All three. A terrible vibration began. It feels like the engine is inside the cabin. I thought they would break in and soften in 1 thousand km. nothing changed. Are pillows faked too? Are there any secrets during installation? Which pillows are right, from which manufacturer?

Somebody installed these for themselves.

Well, everything is clear. The conclusion is this.

Under no circumstances should you change engine mounts until the old ones are completely torn.

Maybe one from a foreign car will be suitable?

It’s not too bad, but how much did it cost?

I can’t say for sure, I didn’t write it down, and I don’t remember. I picked it up in a store next to our official VAZ service center, maybe I was lucky.

It’s not too bad, but how much did it cost?

The guitar for 2112 cost 400 rubles. I’ve already changed the top one twice. There are no vibrations. If you move the inner boss, it seems that the rubber is very soft, even too soft. I vomit in this place periodically. Although my own one was also soft. If there is a roar on the body when starting with slipping, then I won’t open the hood. Need a new guitar

Source

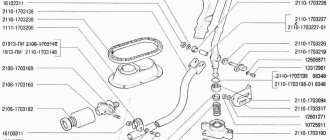

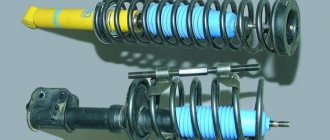

Reasons for replacing upper engine mounts

The standard upper supports of the VAZ 2110 are considered quite reliable and durable products. They must be replaced for the following reasons:

- defects in the rubber part due to aging of the original material. This leads to increased noise and impact during vehicle movement;

- failure of the upper support bearings.

Important: the knocking sound from the upper support with a faulty bearing is quite strong even with slight unevenness in the road surface. This negatively affects the driver and passengers; it is better to immediately replace the upper mounts of the VAZ 2110, which greatly influence the increase in engine vibration

Which engine mount is better than VAZ 2110 or VAZ

- Registration

- Entrance

- To the beginning of the forum

- Forum Rules

- Old design

- FAQ

- Search

- Users

I put a yellow piece of iron under the hood

I put a yellow piece of iron under the hood

vibration did not appear, well, maybe just a little.

I felt all the delights

after pushing on Dmitrovka. Where did my eyes go before?!

gears seem to be easier to disengage without pressing the clutch.

The engine fell on its side, the front cushion was intact, but apparently lost its elasticity. It stood for five years, I don’t know the manufacturer, it’s some kind of orange one.

I put SEVI (which is an Expert) and subjectively it immediately added pleasant impressions. Quite satisfied.

I put SEVI (which is an Expert) and subjectively it immediately added pleasant impressions. Quite satisfied.

In any case, there will be income from the new engine, the question is durability.

I put SEVI (which is an Expert) and subjectively it immediately added pleasant impressions. Quite satisfied.

The engine fell on its side,

In any case, there will be income from the new engine, the question is durability.

choose engine mounts

Diduh

If you're talking about the car from the profile, then it's a new model.

Will the new type support fit instead of the old one?

I have a feeling that there is no analogue of those supports that are installed on conveyors in stores.

How relatives died - leapfrog begins

I have a feeling that there is no analogue of those supports that are installed on conveyors in stores.

How relatives died - leapfrog begins

Information on icons and features

You can not

start topics You

cannot

reply to messages You

cannot

edit your messages You

cannot

delete your messages You

cannot

vote in polls You

can

attach files You

can

download files

Source

Preparing for repairs

There are several steps you need to take before:

- Place the car on a level surface.

- Install wheel chocks under the rear wheels.

- Open the hood and disconnect the battery.

- Place a jack under the engine. It is better to use a hydraulic one, it is more convenient to work with. Be sure to install a softening block between the jack and the engine.

You will also find this tool useful:

- Hydraulic type jack.

- Ratchet.

- Heads at “17”, “19”, “15” and “13”.

- Socket and open-end wrenches.

- Pliers.

- Penetrating lubricant such as WD-40.

Treat all connections with penetrating lubricant in advance, this will allow you to complete all the work more quickly. Be sure to use new bolts and nuts during installation. There should be a plastic insert on the threads of the nuts.

What signs indicate a torn engine mount?

The engine support (engine mount) is designed to reduce vibration loads and oscillatory movements of the internal combustion engine in the engine compartment, as well as to minimize the transfer of such loads to the vehicle body. In other words, the engine is attached to the load-bearing elements of the car body not directly, but with the help of special supports, which are also called cushions.

Next, we will talk about what signs indicate that the power unit mount is torn, as well as how to diagnose and check engine mounts.

Airbag malfunctions

You can tell that the airbags have become unusable by the amount of engine vibration. If it operates in normal mode, and the body begins to rattle, transmitting vibration to the steering rack, pedal block, and instrument panel, you can be sure that the reason for this is the wear of the pillows.

The greatest vibration is usually observed when the engine starts, as well as when it is turned off. When the rubber cushions are completely worn out, a knocking noise may appear caused by the contact of the engine elements and its supports.

To be more convincing, start the engine, open the hood and visually inspect the engine mounts and the cushions themselves. Place your palm on the motor and feel how much it vibrates.

The causes of failure of engine mounts can be:

Engine mount: what it affects and how it works

On various domestic and foreign cars until the 80s, the engine mount was actually a thick rubber that was screwed to the engine and body. This solution was widely used on cars, which at that time were overwhelmingly rear-wheel drive. At the same time, simple supports coped well with their tasks.

However, later the bodies became lighter, the thickness of the steel decreased, the requirements for passive safety changed, etc. As a result, pillows evolved into more complex products made of metal and rubber. Elite car models now have hydraulic engine mounts that can provide maximum comfort compared to other analogues.

As for the internal combustion engine, it is customary to highlight the right airbag, as well as the front and rear. The right engine mount is attached to the front right side member. This support is located on top. The front engine mount is often attached to the front beam, located below. The rear cushion is also located at the bottom and can be attached to the underbody or to the subframe. By the way, on many models the rear support is structurally absent.

If we talk about the design, rubber-metal engine mounts may differ in shape and materials of manufacture, but often they are based on a metal cylinder into which a silent block is pressed.

The main task is to securely, but not rigidly, fix the internal combustion engine, while the cushion simultaneously absorbs vibrations and dampens the resulting vibrations. As a result, vehicle controllability improves, the engine itself is less vibration-loaded, attachments suffer less from vibrations, vibrations are not strongly transmitted to the car body, etc.

Signs and causes of fastening wear

Accelerated wear of the cushions is observed in the following cases:

- when there is deformation of artificial rubber as a result of reaching its maximum service life;

- loss of adaptive qualities (elasticity) as a result of frequently changing climatic conditions;

- cracking and changes in structure as a result of chemical interaction with various technical fluids.

In general, when a breakdown is already evident, its causes are secondary. Important only in cases where operating conditions are violated.

Torn engine mount: signs

Like any other part, the power plant support also has a limited service life and eventually fails. On average, airbags on modern cars are designed to last at least 100-120 thousand km, although in practice these elements may need to be replaced both earlier and much later than this period.

Usually the cause of problems is the rubber insert, which simply cracks and breaks under load. Less often, cracks appear in the metal part of the support, the installation sites of fasteners are broken, etc.

One way or another, the following symptoms usually indicate a malfunction of the engine mounts:

- The engine itself runs smoothly, but the driver feels a clear increase in vibrations in the body, on the steering wheel, on the gearshift knob, etc.;

- When you start moving from a standstill, as well as during braking, you can hear clicking or muffled knocking in the engine compartment;

- When driving on an uneven road, impacts are heard from the front of the car; in many cases such impacts are felt on the gearshift lever; shifting gears with a manual transmission at this moment can be difficult;

To check the engine mounts, it is not necessary to immediately go to a service station and drive the car to a stand. Usually, a fault can be identified and localized on your own, even if you do not have much experience in car repair and maintenance.

The simplest method of initial diagnosis is to rock the engine with your hands in the engine compartment, after which you can localize a torn or cracked support by knocking.

To carry out a more detailed check, you first need to find out in advance where exactly the supports are located on a particular model. Then the elements available for review will need to be pre-inspected. Cracks, breaks and other damage are usually visible and easily visible.

For a full visual assessment of the lower airbags, you need to be prepared for the fact that the car will need to be parked in a garage with an inspection hole, driven onto an overpass, or using a lift.

If a superficial diagnosis shows nothing, then the assistant should be used again. One person uses a pry bar to move the support, while the other watches for tears in the rubber insert at the very moment the support moves. It happens that some cracks are not immediately visible without rocking.

As for the replacement itself, replacing the top cushion is quite simple. The car needs to be jacked up, the old cushion removed and a new one installed. If you have to change the lower supports, it is also important to consider that the engine goes down after removing this cushion. This means that you will need an additional support that supports the internal combustion engine, allowing you to direct the cushion and properly secure this element.

Do I need to change

There are no recommendations for replacing pillows depending on their service life, but once you determine that they are faulty, you should not delay replacing them. Vibration processes can not only worsen the comfort of the driver and passengers, but also lead to destructive processes in the engine or gearbox itself.

Having decided to repair the engine mounting elements, you need to decide whether you will change the cushions themselves or the mounts assemblies. In principle, if the metal support itself is not damaged, it can be left, replacing only the pillow.

The price of a set of pillows for a VAZ 2110 costs around 1,300 rubles. The cost of a complete set of supports is about 2,500 rubles.

For the work of replacing engine mounts or mounts at a service station, you will be charged at least 300 rubles for each.

For eight-valve engines

- Prepare the car for repair: place it on a flat surface, place stops under the rear wheels, remove the engine protection.

- Unscrew the generator belt tensioner bolt and remove the belt (key 13).

- Place the jack under the engine, place a thick wooden beam or board under its upper part. Raise the engine to remove the load on its mounts.

- Unscrew the nut of the central fastening of the right pillow (15 wrench).

- Unscrew the bolts securing the pillow to the bracket (key 13).

- From the bottom side of the right arch, unscrew the 3 bolts securing the bracket to the spar (17 key).

- Remove the bracket and replace the old cushion with a new one.

- Carry out installation in reverse order.

- Move the jack under the gearbox and lift it up.

- Unscrew the nut of the central fastening of the left pillow (15 wrench).

- Unscrew the two bolts securing the support and remove it (key 13).

- Replace it and reassemble the structure in reverse order.

- Unscrew the two 17 nuts securing the cushion to the body, and then two more nuts securing it to the gearbox (removal and replacement of the rear support is carried out from the bottom of the car).

- Remove the rear support.

- Unscrew the nut securing the pillow to the bracket (19mm wrench). Remove the old pillow and install a new one.

- Install the rear support in reverse order.

For sixteen-valve engines

Removing and replacing side airbags is done in the same way as for 8-valve engines.

Work to replace the front lower airbag is carried out from underneath the machine.

- Unscrew the bolt securing the front lower support rod to the front suspension cross member (15 wrench).

- Unscrew the nut of the bolt fixing the support to the engine bracket (2 wrenches x 15). Remove the bolt.

- Remove the support, replace the pillow or the entire structure.

- Carry out installation in reverse order.

- In the engine compartment, unscrew the bolt securing the upper front support to the body, holding its nut with your hand (17 wrench).

- Remove the bolt and nut.

- Unscrew the bolt securing the front upper support to the engine bracket (15mm wrench). Remove the bolt and nut.

- Remove the support, replace the pillow or the entire structure.

- Install it in reverse order.

Tips and tricks

It is important to understand that the airbags experience the heaviest loads when the car suddenly starts from a standstill, as well as during heavy braking. The service life of the supports is also reduced by driving through potholes when the body and engine sway, especially at high speed.

As for diagnostics and repairs, it is necessary to check and change engine mounts in a timely manner, since increased vibrations not only affect comfort, but also have an extremely negative impact on the engine itself, the body and the equipment. In other words, even if one airbag is torn, it is strongly not recommended to further operate the car with such a malfunction.

Car engine mounts: purpose. Types of power unit supports and design differences. Signs of malfunctions of engine support cushions and inspection.

Why might the engine vibrate at idle? Causes of malfunction, diagnostics. Tips and recommendations for reducing engine vibration levels.

The engine twitches at idle: why does this happen? Engine jerking in idle mode, diagnostics of possible malfunctions, recommendations.

Replacing engine mounts: what are the signs that indicate that the cushions need to be changed? Types of support cushions, how to change engine mounts with your own hands.

Causes of vibration and unstable operation of a diesel engine in idle mode. Possible causes and fault diagnosis.

Ways to check the engine when choosing a used car: diagnostics by appearance, sound of operation, condition of spark plugs, color of exhaust gases, etc.

Source

What can happen if faulty supports are not replaced?

What happens if you do not pay attention to possible malfunctions of the engine mounts? At first, when vibration and knocking are unnoticeable, nothing critical will happen. But with the destruction of the engine mounts, the power unit will begin to transmit vibrations to chassis parts and they will begin to fail much faster; this could have happened under the same operating conditions. Also, the engine can hit elements of the engine compartment and lead to damage to various pipes, hoses, wires and other parts. And the condition of the engine itself may suffer due to constant impacts that are not dampened by anything.

How to extend the life of engine mounts

Engine mounts work hardest when the engine vibrates the most. This is primarily starting from a stop, accelerating and braking. Accordingly, a driving mode with a soft start and less sudden acceleration and stopping prolongs the life of the engine mounts.

Of course, these parts last longer on good roads, but this factor is very difficult for us to influence. As well as for launches in sub-zero temperatures, when the rubber hardens and tolerates vibrations less well. But in general, we can say that a careful and quiet ride can extend the life of many parts, including engine mounts.

Source

How to replace engine mounts on a VAZ 2110?

Each individual VAZ 2110 engine mounting mount and all of them together are designed to provide reliable mounting while simultaneously vibration isolating the engine and gearbox on the vehicle.

Therefore, if, while driving over bumps, when changing gears or during other actions, you begin to feel vibrations and characteristic tapping and creaking in the engine area, as if the pieces of iron are hitting each other, indeed, it is the motor mounts that should be suspected.

Engine support cushion

On the VAZ 2110, the cushion is a rubber-metal part such as a silent block. On one side this part is attached to the body, on the other - to the engine cylinder block. They hold not only the engine, but also the gearbox.

This design has proven itself well - it is reliable and not expensive. But - as long as the pillows are not destroyed.

Testing

After carrying out the replacement work, it is important to check the result.

To do this, start the engine and check the vibration level. With low vibration and quiet operation, removal and replacement were done correctly. If not, it means the fastenings are not firmly fixed enough. You need to check the installation of the supports again and possibly secure them. Obviously, if there are excessive vibrations when the engine is running, it is worth checking the engine mounts and the condition of the rubber on the mounts. Timely replacement will at least restore the level of comfort in the cabin.

Design difference

On a VAZ 2110, the engine is usually held by three or four points at the bottom, and two or three at the top. But you should know that the 8 valve engine has a rear engine mount. The 16 valve does not have it, but it has additional supports.

Rear support cushion for 8-valve engine

But in general, their replacement is similar.

By the way, if desired, additional support can also be installed.

Possible problems

Replacing the transmission of a VAZ 2110 photo instructions on how to remove and change the gearbox on a VAZ 2110

There are several situations when the crankcase hits the road surface. Their consequences can be very different.

Therefore, let's look at the most common situations and determine what you, as the driver and owner of the car, should do.

A dent has formed, but the breakdown is not visible

There is a high probability that as a result of such damage the breather, that is, the oil receiver, has broken.

You should not rejoice prematurely if no traces of oil leaks are found after the impact.

The breather for the “ten” is often made of plastic or aluminum. Its design includes an oil pickup tube. It is located slightly above the tray - about 5 centimeters. Therefore, the place where the tube breaks may be higher than the existing oil level.

If such an impact occurs, immediately turn off the car and stop.

Next, you should check the breather for a break:

- Start the engine by performing a test run. If the oil sensor light does not go out, there is a high probability that the breather will break;

- Turn off the power unit;

- Add oil to the crankcase, then start the engine;

- If at the same time an oil stain appeared under the car, the breather still broke. You will have to call the evacuation service;

- If the oil pressure sensor light goes off, you can hope that nothing happened to the breather after the impact. You can continue moving on your own. Only to a service station.

In such a situation, often the repair consists of simply replacing the breather. This is not so easy to do, but it is still easier compared to overhauling the engine.

The dent on the block is insignificant, there are no signs of breakdown

With such impacts, the breather breaks off extremely rarely. But the gap between it and the pallet may decrease. Because of this, the performance characteristics of the car are reduced, and the car may not withstand heavy loads.

What could cause such a nuisance? Oil hunger. For the engine, this is no better than a broken breather, and maybe even worse. You will not be able to get the necessary information from the ECU, since the control system for the systems on the “tens” is quite primitive. It is far from a fact that the corresponding error code will appear on the on-board computer.

It’s good if the oil pressure warning light on the dashboard does not light up. In this case, continue driving on your own and head to the nearest service station. You will need to remove the pan, level it, or replace it completely. At the same time, be sure to check the current condition of the breather.

Carter struck

If the standard mudguard has a hole, oil flows out of the sump and forms a whole puddle of lubricating fluid under the car, this is bad.

IMPORTANT! Under no circumstances should you attempt to start the engine if you find a puddle of oil under the crankcase. If you are in motion and see traces of oil following you, stop as quickly as possible and turn off the engine.

Call a towing service

If you are in motion and see traces of oil following you, stop as quickly as possible and turn off the engine. Call a towing service.

Functionality check

Before changing pillows, you should check the functionality of the old ones. It may happen that the cause of vibration and knocking is not in them.

- We put the VAZ 2110 on supports;

- We install a jack with a backing made of board or timber under the oil pan and jack up the engine until the cushions are freed from its weight;

- We check all the pillows, namely: • Are there any cracks on them; • How easy it is to separate them from the substrate (it is made of metal); • Are they still hard? • If no obvious deficiencies are found, and replacement is not yet necessary, check the play between the frame and the plates; • Lubricate the cushions with a protective compound, lower the motor, tighten the fasteners and nuts.

Replacement features

If the vibration from the engine is very noticeable, then you need to change the pillow. Some car owners neglect this procedure, believing that the vibration can be tolerated, but this will not make the car drive any worse. This is a fundamentally wrong position , since constant vibration will lead to the destruction of engine attachments, as well as to breakdown of the gearbox.

On the VAZ-2110 you can change either individual cushions or complete with supports. It is not necessary to change entire supports.

When replacing engine mounts, you can go to a service station, but it will cost a decent amount. For those who want to save money, it is recommended to replace the engine mounts yourself.

Checking the performance of engine mounts

The engine mounts must not show any visible damage.

Before you begin work on replacing the engine mounts, you need to make sure that they are the cause of the engine vibration. To do this you need to do the following:

- The car must be placed on special supports.

- Place a jack under the oil pan. To avoid breaking through the oil pan, you need to place a board or timber on the jack platform.

- Next you need to lift the engine up. Lifting must be continued until the cushions are completely freed from the weight of the engine.

- To avoid injury, you need to place another support next to the jack. This will hold the engine if the jack comes off.

- Next you need to check the condition of the engine mounts. Both the metal base of the pillow and the condition of the rubber are checked.

- If everything is visually in order, you need to check if there is any play between the frame and the plates.

If you're lucky, the repair may be limited to tightening the fastening nuts. In more complex cases, the pillows will need to be replaced, since they cannot be restored.

8 valve engine

If you need a replacement on an 8-valve valve, then proceed as follows:

- Right pillow. It is necessary to unscrew: • The upper nut; • Bolts for fastening to the bracket; • Bolts under the wheel arch securing the bracket to the side member. We remove the bracket and install a new pillow, reassembling it in the reverse order.

- Left. After unscrewing the top nut, lower the motor onto the prepared support and pull out the top washer from the support. We unscrew the fastening bolts, remove the washer, after which you can replace it;

- Rear (8-valve only). Unscrew the nuts that secure the airbag to the body, then the bolts securing it to the gearbox. The new part may come with a bracket. But if it is not there, install it with the removed one and assemble all the parts in place.

How the engine is mounted in a VAZ2110 car

The engine of a VAZ 2110 car is mounted in the car in the engine compartment. The supports are three elastic elements. The right support is attached to the engine bracket, and the left and rear supports are attached to the gearbox housing brackets. The last two supports are similar in design.

How to replace the right engine mount of a VAZ 2110 car

- The top nut securing the engine mount is unscrewed.

- The two bolts holding the element to the bracket are unscrewed.

- The bolts that connect the bracket to the side member are unscrewed under the wheel arch.

- The bracket for the right engine mount of a VAZ 21103 is pulled out of the car.

- The old cushion is replaced and a new one is installed in the reverse order of disassembly.

How to replace the left engine mount of a VAZ 2110 car:

- As in the first case, the upper nut fixing the pillow is unscrewed. But the engine on this side needs to be lowered.

Tip: Before starting work, you need to prepare a stand on which the gearbox will rest.

- The engine is lowered onto the prepared support.

- The upper washer of the pillow is pulled out.

- The bolts securing the element are unscrewed.

- The left cushion under the VAZ 2110 engine is removed.

- The lower washer is removed along with the pin.

- The left engine mount of the VAZ 21102 is replaced with a new one, and assembly is performed in the reverse order.

- Using a socket, the nut that secures the rear cushion to the body is unscrewed.

- The mount of the engine mount on the VAZ 2110 to the gearbox is unscrewed.

- The pillow is removable.

How to replace the rear airbag of a VAZ 2110 car

Removing the rear cushion of a VAZ 2110

The rear airbags can be equipped with or without a bracket. The part is a one-piece cast element, which has all the necessary holes for mounting the pillow. To increase reliability and rigidity, ribs are located on the inside of the bracket. The upper motor mount bracket is an intermediate link between the engine support pad and the flexible rod. With its help, you can change the angle of fixation to the body and strengthen the fastener design.

Tip: If the pillow was purchased without a bracket, you need to move the part from the old device. To do this, its bolt is unscrewed and the bracket is placed on a new pillow.

- Installation of the new part is carried out in the reverse order.

- The assembly of the unit is performed in reverse of its disassembly.

Tip: You need to start assembly by fixing the pillow to the body.

To correctly replace VAZ 2110 engine mounts, you can watch the video.

Tuning engine mounts for VAZ 2110

A fairly affordable tuning element with which you can make the engine mount more rigid is to replace the factory standard mount with an element with a more rigid body and a rubber support part. This device allows you to:

- Reduce engine movement as much as possible when braking, abruptly starting the car, or hitting bumps.

- Increase the service life of the exhaust system and drive wheel drives.

- Protect against self-switching gears.

- A bright tuning part will be installed under the hood.

Tuning part for VAZ 2110 engine mount

To increase engine rigidity, you can install a fourth support for the car’s power unit. It connects the cross member of the front suspension of the VAZ 2110 car and the clutch housing. Such a device can be installed both for mounting an 8-valve and 16-valve engine. When installing an additional support, you need to find another place for the ignition module and purchase a new bracket. The general view of the device is shown in the photo.

General view of additional support elements for VAZ 2110

Installation instructions include:

- Removal of spark plug armored wires.

- The wire connectors from the car's ignition module are disconnected.

- The fastening to the cylinder block and clutch housing of the ignition module is turned out.

- The last three nuts securing the module are unscrewed, which is then removed.

- A new fastener is screwed in and the ignition module is installed in a different place.

- The fourth support bracket is screwed onto the front suspension cross member.

- A bolt is inserted into the hole in the terminal clamp, a nut is installed and tightened two turns.

- The lower head of the rod is placed in the support fixation eye.

- A bolt of the appropriate size is inserted into the hole of the eye and the cushion, and the nut is tightened.

- The size of the rod is adjusted until the hole in the clutch housing matches the hole on the upper head.

- Another bolt is inserted.

Tip: Adjustment is made by turning the upper head relative to the lower one, without tightening the locknut.

Installation of the fourth engine mount VAZ 2110

- The clutch housing shield and the rod head are attached through a spacer sleeve on the support.

- All bolts are tightened.

- When installing another mount for the ignition module, bolts are screwed into the threaded hole on the cylinder block.

- The bottom and top of the bracket are attached, all bolts are tightened.

When installing the fourth support, the price of the engine mounts will increase, but the reliability of mounting the engine of the VAZ 2110 will also increase.

Additional support

In order to reduce engine movement in the longitudinal direction, an additional support (suspension rod) can be installed. They are mainly purchased in online stores. An additional support is installed on all types of VAZ 2110, but it has its own characteristics.

For an 8-valve model, you also need a special bracket that is used to carry the ignition module. Those who installed such a bar claim that when the car starts moving, the engine does not wobble, the cushions do not wear out as much, and the lower hose does not come off the radiator (which is what dozens of people “suffer from”).

Opinions differ regarding the decrease/increase in vibrations.

Source

Choice of protection

How to change the ignition switch on a VAZ 2110

To ensure proper protection for your own engine on a VAZ 2110, you must first decide which element will be installed on the bottom of the car.

Today, manufacturers offer many options. Let’s identify the most popular solutions in the case of the domestic “ten” and discuss their features. This will help you make the final decision specifically for your situation.

Type of protection

Peculiarities

Aluminum alloy guard

Lightweight, quite reliable and durable. No special mounting brackets are required for installation. Typically, the available fasteners are excellent for fixing

Steel protection with powder paint

Such elements are durable and have good corrosion resistance. However, they are characterized by a significant drawback - the metal is too thin, so do not expect reliable protection

Protection of KAMAZ production

This is the thickest protection option, where metal is used with a thickness of about 4 millimeters. They are distinguished by reliability and heavy weight. Due to the mass, a serious drawback arises - the fasteners can simply break out with all the consequences. Therefore, for installation it is imperative to use special high-strength brackets

Be sure to choose steel that is at least 2 millimeters thick. At the same time, the presence of stamped stiffeners is also strongly recommended.

When purchasing protection, be sure to pay attention to the presence of special technological holes through which oil is drained from the crankcase and airflow is provided to the power unit. Fasteners only in full compliance with the holes provided on the VAZ 2110

Design and technological features

Since in the “fourteenth” model the entire load from the engine falls on the front suspension, accordingly, the chassis is made of materials with an increased margin of safety, and its design must strictly comply with established standards. Durable rubber mounts of the VAZ-2114 engine are used as a damper for vibrations of the power unit under various loads.

Since high demands are placed on this part, it is extremely important to purchase only original and certified supports, since only they are suitable for use in our conditions.

In the design of the front part of the car frame and its suspension, the engine mount is one of the important elements, while its independent replacement is quite within the capabilities of a car owner who has even the most minimal concepts in plumbing.

The main thing in the repair process is to complete the entire technological sequence of actions, then the installed part will serve for a long period of time.