Starter

The starter is a powerful DC electric motor. It can burn out for many reasons, for example, due to holding the key in the “start” position for a long time. If the starter does not turn or clicks are heard from it, you should not immediately buy a new one, you can try to repair it. Often, it is replacing the Bendix on the VAZ 2110 starter that helps solve everything. On a VAZ 2110, replacing the Bendix starter can be done with your own hands.

Replacing the bendix on the VAZ 2110 starter yourself

The starter is a powerful DC electric motor. It can burn out for many reasons, for example, due to holding the key in the “start” position for a long time. If the starter does not turn or clicks are heard from it, you should not immediately buy a new one, you can try to repair it. Often, it is replacing the Bendix on the VAZ 2110 starter that helps solve everything. On a VAZ 2110, replacing the Bendix starter can be done with your own hands.

What is Bendix for?

Replacing the Bendix starter for a VAZ 2110

Bendix is an integral part of the starter (see Repairing the VAZ 2110 starter - we do everything ourselves), without which the engine will not start. If a metallic sound is heard when starting, then the bendix must be replaced, and the starter must be dismantled in advance.

When identifying problems, many car owners turn to specialists, although the necessary measures can be taken independently. To begin with, it is recommended that you familiarize yourself with the car manufacturer's manual, as well as its tips for resolving such problems. In addition, before making repairs yourself, it is advisable to familiarize yourself with the recommendations for safe operation of the vehicle. Then you can follow the following tips to help you correctly identify starter problems and fix them without outside help. So:

With the help of a starter, the crankshaft is rotated, and the necessary pressure is created in the combustion chamber to ignite the combustible mixture (especially for diesel engines). If there is a lack of power, the engine will not start. For this reason, it is necessary to change the starter in a timely manner, assessing not only the suitability of the fasteners, but also the sufficient power to spin up the engine.

Bendix for VAZ 2110 starter

Caution. The starter should never be dropped, as it is a complex electrical device that is subject to damage to its internal components.

This device must be handled with care and attention.

Bendix replacement and starter repair

Bendix starter for VAZ 2110

To repair the starter, the following tools are required:

- spanners;

- heads in a set;

- several screwdrivers;

- insulating tape;

- new bendix.

When is it time to change the bendix?

During the operation of VAZ 2110 cars, sometimes drivers may notice low starter efficiency, which affects the functionality of the engine; as a result, the car simply does not start the first time.

For example, if, when starting the “tens” engine, the driver hears a slight crackling sound and feels the starter sticking, you cannot do without replacing the bendix, in other words, the overrunning clutch.

Useful tips

It is worth noting that when buying a new Bendix you need to have an old copy with you. Very often, different couplings differ from each other in small details that are not visually memorable. In the worst case scenario, you may end up purchasing the wrong mechanism.

Note! A cracked or worn plastic washer located on the starter cover can be replaced. If there is damage to the insulation on the mechanism pin, it can be repaired using electrical tape.

Today, any car repair can be performed at a service station, but in some cases you can do without this service. As a rule, this concerns minor repairs or replacement of components in mechanisms. Thus, with the help of video and photos, you can replace the bendix on the starter with your own hands. When disassembling the VAZ starter repeatedly, instructions are not needed, since everything can be done from memory. Self-repair is considered a profitable business, since the price of car service services is far from affordable.

Common starter problems and their causes

Regardless of whether 2106 or UAZ is installed, the problems are similar. If the car does not start, the VAZ 2106 is bad, first check the quality of battery charging. In addition, you should check how well the terminals are secured. If everything is fine with the charging and terminals, then the cause of problems with starting the engine may be in the starter.

The following malfunctions of the VAZ 2106 starter are possible:

- The device turns on, but the traction relay does not work: the traction wire is broken, the tips are not tightened well, there is a short circuit in the traction windings or to ground, the contacts have oxidized, the retractor armature is stuck.

- After switching on, a click occurs, the traction relay works, but the armature does not function or it rotates too slowly, the starter does not turn: the fastening bolts on the retractor are not tightened well, the brushes are worn out or stuck, the commutator plates are short-circuited or are burned out, the windings are damaged.

- When starting, the relay clicks, the armature works, but the crankshaft does not rotate: the buffer spring is broken, the clutch slips, slips out of the axle, or the clutch engagement lever is broken.

- The starter does not turn off when the engine starts: the relay or drive lever is stuck, the contacts are stuck together, the mechanism is skewed, the ignition switch return spring is faulty.

- Increased noise during startup: the unit is poorly secured, the bushings are worn, the teeth on the gears are broken.

Types of starters that are equipped with VAZ 2106

There are 2 types of such electric machines:

A car starter with a gearbox is more efficient and functional even with a low battery charging current. As a disadvantage, it should be noted that the rotation gear may be defective. Electric machines that are not equipped with a gearbox are simpler and provide almost instantaneous engagement with the flywheel ring. This significantly speeds up the ignition timing. The advantage is its high degree of reliability. As a disadvantage, the starter turns poorly in the low temperature range.

In the latest configurations of the “sixes”, the electrical system is equipped with starters of the ST-221 brand under the item number 35.3708 with an end receiver-collector. In some batches of vehicles, the installation of German or Belarusian electric vehicles is allowed. This starter is adapted to the performance characteristics of a standard product.

Basic tactical and technical data of the VAZ 2106 starter:

- The nominal power of the product is 1.3 kW.

- The nominal current value is 260-290 A.

- The maximum current value in non-operating conditions is 500-550 A.

- The maximum current value in idle mode without a relay is 35-60 A.

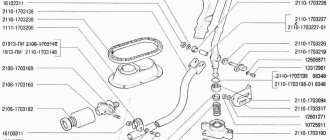

In the final modifications, some design changes were made to the VAZ 2106 starter device. In the last quarter of the twentieth century, when assembling the “six”, the ST-221 was mounted with a collector-receiver in the form of a cylinder, which had a different aft segment and a stator winding with a different set of shunt and serial coils. The basic design of the VAZ 2106 starter can be seen below:

1 – drive gear; 2 – overrunning clutch; 3 – leash ring; 4 – rubber rubber plug; 5 – drive lever; 6 – drive casing; 7 – relay anchor; 8 – relay winding; 9 – contact type plate; 10 – relay cover; 11 – bolts for contact; 12 – collector device; 13 – starter brush holder; 14 – anchor bushing; 15 – collector cover; 16 – protective cover; 17 – body part; 18 – pole element; 19 – anchor device; 20 – ring of intermediate fastening; 21 – limiter ring.

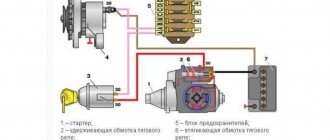

The electrical diagram for connecting the VAZ 2106 starter is located below:

1 – battery; 2 – winding of the starter relay; 3 – ignition key; 4 – winding of the relay retracting to the starter of the holding type; 5 – starter-starter; 6 – generator device.

When electricity is supplied to the VAZ 2106 starter, the price of which is quite high, the relay armature works to “retract” and, using a lever, moves the gear drive, engaging the gear with the flywheel. At the same time, the contact plate enters the circuit with the relay bolts, thereby contributing to the appearance of current in the starter windings.

When the starter electrical circuit is activated, current from the battery is supplied to the windings of the traction type starter relay. In this case, the winding that works to retract the bendix is de-energized, and the arrival of an energy pulse to the starter armature through the gearbox increases the electrical pulse several times.

Bendix is a device that guarantees long and trouble-free operation of the starter

In fact, to understand what Bendix is, you first need to have a good idea of what a car starter is. Let's try to understand the general features and consider the process of its operation, using the example of the Bendix starter device for the domestic VAZ 2110 car.

Everyone knows that in order to start an internal combustion engine, which is usually equipped with modern cars (including the VAZ 2110), it is necessary to crank the crankshaft. In order for a spark to “grab”, igniting the fuel-air mixture prepared by a carburetor or injector and fed into the internal combustion chamber. At one time, human engineering came up with a starter so that there was no need to turn the crooked manual start lever (remember, in those days these cars were equipped with just such a “starter”).

This device is just an electric motor powered by a car battery. It is the starter that gives the first impulse to the car engine shaft, which then, as they say, seizes.

- Device

- Principle of operation

- Interesting Facts

Device

So the role of the starter as a necessary functional unit is very large, otherwise you would have to run to the crooked handle every time you start the car. Can you imagine what it’s like to run with her to the hood of the modern triumph of the domestic automotive industry - the VAZ 2110? In such a situation, Bendix plays a peculiar role as an intermediary between the rotating shaft of the electric motor and the crankshaft of the car engine.

The design of the Bendix is such that it functions like a ratchet mechanism (or, as people say, a ratchet), while in good condition it:

- scrolls in one direction only;

- it stops when you try to rotate it to another.

How Bendix works can be found in the video below. » alt=»»>

Principle of operation

The principle of operation of the Bendix is as follows: torque is transmitted from the starter to the Bendix, which is a clutch. And from there, the movement is transferred to the engine of our VAZ 2110. Now let’s imagine what happens at the moment when the spark in the combustion chamber is “grabbed” by the scrolling transmitted to the shaft through the Bendix. The crankshaft of the high-speed engine immediately spun up at enormous speed, ahead of the starter's rotation speed. The speed of their rotation is two big differences. And if it weren’t for a device called Bendix, the spinning engine would immediately ruin the electric motor, known as the starter.

The principle of Bendix operation is that at the very moment the engine of our VAZ 2110 starts and the driver releases the ignition key to the return position, the starter stops and the clutch connection is disconnected.

That's it, the crankshaft of our VAZ 2110 car with a high-speed engine can rotate at an arbitrary speed, obeying only the will of the driver pressing the accelerator pedal.

And the starter, having fulfilled its function, froze in a motionless state. It is no longer threatened by excessively heavy loads that could damage the brushes, windings, bushings, and other parts of this rather expensive device. And this function is performed by a device known popularly by the name of its inventor, who first patented it, although in fact, its correct engineering name is an overrunning clutch.

Interesting Facts

The device is named after its inventor, Vincent Hugo Bendix. He made enormous contributions to the automotive and aviation industries. In 1907, at the age of 26, he organized the Bendix Corporation automobile company, and already in 1910 he received a patent for his invention - the overrunning clutch.

VAZ 2109 starter - how to assess problems and fix them as well as a mechanic?

For owners of domestic cars, self-repair or assembly of vital mechanisms is familiar and accessible; in this article we will try to improve our skill level and replace the VAZ 2109 starter with our own hands.

Starter circuit and purpose

On all cars, without exception, and therefore on the VAZ 2109, the starter is responsible for starting the engine, or rather, spinning the crankshaft. Essentially, it is a small electric motor. The VAZ 2109 starter device includes a movable rotor, two windings, and a bendix with a set of brushes. How does it all work? Magnetic fields of opposite values are created around the starter and rotor windings, which drives the moving element into dynamics. It is quite easy to apply voltage to the starter, but for the rotor you need an intermediary - brushes consisting of graphite and copper.

What about the Bendix starter of the VAZ 2109, this element transmits movement to the flywheel. The part consists of the following parts: a fork connecting the mechanism to the retractor relay, an overrunning clutch that ensures movement in one direction, and a gear. Many motorists are familiar with the situation when this part is erased. The slipping of the Bendix is clearly audible and indicates that the installation of a new kit is inevitable. And although the cause is often contamination of the mechanism, cleaning it is not recommended. Due to dust and soot, Bendix is subject to wear, often unevenly, and even after washing it will no longer perform its function at the proper level.

There is a gear starter and a simple one. The scheme for transmitting torque to the flywheel is excellent. The gear starter has an additional element between the armature and the bendix. Many consider this design to be more productive and less voracious. True, the gear unit is more difficult to repair.

Starter mechanism malfunctions

If any difficulties arise with starting the car, this unit is the first to be suspected, but now, knowing the design of the VAZ 2109 starter, you will quickly figure out where to look. Various sounds similar to metal grinding should also alert you; it is quite possible that your VAZ 2109 will need to disassemble the starter. The reason may lie in the flywheel, and its crown will need to be replaced. In this case, the car will most likely start, just not right away.

But if the car does not start and there are no alarming sounds, then you may have to replace the clutch. Disassemble the starter and dismantle it, try turning it in both directions. If it rotates freely, then calmly throw away the failed part. You can understand that it is necessary to remove and replace worn starter brushes installed on a VAZ 2109 by a characteristic click, after which the expected engine start will not take place.

Do-it-yourself Bendix starter repair (photos and videos).

What is a Bendix (overrunning clutch)?

Replacing the Bendix on a VAZ starter or do-it-yourself repair

In modern cars, the engine is started using an electric starter. The starter is a DC electric motor that transmits rotation to the engine flywheel through a special clutch.

This is what the starter looks like:

This is what the flywheel looks like:

Typically, the gear on the starter has 10-12 teeth, and the flange on the flywheel, with which the starter engages and starts the engine, has more than a hundred teeth.

If you exclude the overrunning clutch, then after the engine starts, even at idle, the starter will spin up to an incredible 100,000-200,000 rpm! Naturally, it will collapse.

To prevent this from happening, a special overrunning clutch is used, colloquially called a bendix.

It works on the principle of the rear hub of a bicycle, i.e. torque is transmitted only in one direction - from the starter to the engine.

Causes of Bendix malfunctions.

All malfunctions manifest themselves in the same way - the bendix fires every once in a while or does not work at all, while the starter spins.

Visually, a Bendix malfunction appears like this:

To repair a Bendix, you will need a screwdriver that can withstand blows from a hammer, a hammer, a yew, or a rag.

It is difficult to buy spare parts for Bendix, since Bendix is usually sold assembled. But there is one life hack - we buy a Bendix from a VAZ-2101 (the cheapest) and disassemble it for spare parts. The diameter of the rollers is almost always the same; if you don’t find the right diameter or if you have a large hole, you can cut it with a drill; springs are almost always suitable. The author of this article repaired the bendix on the Chery Amulet starter by replacing the rollers and springs with similar ones from VAZ.

The causes of failure are listed in order of likelihood, from most common to least common.

Loss of spring elasticity.

In the picture above, you can see that the rollers are pressed by springs. When the springs lose their elasticity, the bendix begins to slip, and the starter itself fires every other time.

Repair - we flare the starter bendix, carefully remove the inner part, replace or stretch the old springs, assemble without lubrication; if the bendix is lubricated, it will slip, and flare it.

Roller wear.

This is the second most common reason: the rollers do not spin during their operation and therefore only wear out on one side, sometimes they flatten and become oval.

Repair - we flare the bendix, carefully remove the inner part, turn the rollers over on the other side or replace them, assemble them without lubrication, and roll them.

Oiling.

This problem is relevant only for gear starters. Sometimes gear lubricant gets into the bendix, in which case it begins to slip constantly.

Repair - we flare the bendix, carefully remove the inner part, wipe all the rollers with gasoline or acetone, assemble without lubricant, and roll it. It is advisable to replace the lubricant in the starter gearbox with a more refractory one, or reduce its quantity.

If you prefer to watch a video, below is a detailed video on how to repair a starter bendix with your own hands:

That's all for me today. After reading the article, repairing the Bendix starter should not cause you any difficulties.

It is important to understand that Bendix is not such an expensive part and it costs 200-300 rubles, therefore, it is advisable to repair it only if there are no spare parts, or if the car is very expensive

Starting system for a modern car

Replacing a bearing in a VAZ 2110 generator yourself

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline!

Today, motorists have a much easier time than a few decades ago, when the car was started with a hand crank.

In those days, one could only dream of starting the engine from inside the car.

Today, motorists have a much easier time than several decades ago, when the car was started with a crank. In those days, one could only dream of starting the engine from inside the car.

Nowadays, it is enough to insert the key into the ignition or press a special button for the car to start. But problems also occur in this case, if the nodes, so to speak, “get sick.” No matter how modern a car is, over time it becomes outdated, and more and more problems arise.

One of them just implies poor engagement of the flywheel by the starter. Why does this happen? Experts, as soon as the topic comes up, mention the problem of the overrunning clutch or bendix.

Purpose of Bendix in a car

An overrunning clutch is a gear mechanism capable of transmitting anchor rotation to the engine flywheel. Thus, the engine starts.

Attention. A prerequisite for trouble-free operation of the components of the automotive system is the removal of the bendix after the engine has been successfully started. You should know that a clutch is not just a gear, but a mechanism that also develops malfunctions

You should know that a clutch is not just a gear, but a mechanism that also develops malfunctions.

To more fully understand the cause of the problem with the flywheel engaging, it will be useful to consider the general principle of operation of the entire starting system.

The starter is a DC electric motor. In some cases, it develops much more power than required. Thus, it becomes possible to run the internal combustion engine with maximum displacement.

In a modern starter, an important role is played by a relay - a special unit that brings the clutch into contact with the flywheel some time before the armature false start. Then only voltage is applied to the starter winding, after which it begins to rotate the crankshaft of the car engine.

The rotation of the crankshaft becomes a source of compression of the combustible mixture, followed by its ignition. As soon as this happens at the right moment, the internal combustion engine begins to function automatically.

At this very moment, the metonymic cycle of the flywheel begins to dominate the revolutions of the starter shaft (armature), and the bendix is already engaged. As soon as the driver turns off the car, the starter shaft no longer rotates, and the traction drive disengages the clutch.

It is important to understand that the bendix itself consists of 2 parts: upper and lower (HFB and LFB). The latter acts in the form of a hollow shaft having two different calibers. One of the parts of the shaft is equipped with splines that transmit rotation of the starter, and the other part contains a cage with rollers

One of the parts of the shaft is equipped with splines that transmit rotation of the starter, and the other part contains a cage with rollers.

There is no interaction between the videos and the NCB initially. It occurs only after, when the first revolutions appear. The rollers are brought to the middle, thereby limiting the shaft. This happens in such a way that the shaft can only rotate in one direction. The rollers, thanks to their springs, do not allow them to rotate in the other direction.

Once the flywheel gains speed, it will be able to rotate the bendix. In this case, the rollers move apart, opening the stopper. The gear mechanism returns to its primary position.

Bendix often freezes in the mornings when it is cold. Experienced drivers recommend cranking the starter several times, thereby heating the bendix and enabling its operation.

What do car mechanics advise?

Before removing the starter and changing the bendix, make sure that the battery is charged. There are funny cases when the problem was not in the overrunning clutch, but only in a discharged battery.

Don’t skimp on small things - be sure to install only a new washer and retaining ring.

Before installing the bendix, thoroughly rinse and lubricate all rotating parts and armature splines.

When disassembling the starter, write down the sequence of actions. This will make it easier to assemble the unit.

Before installing the starter, check it. To do this, take two wires that are used to start cars in cold weather. Connect the “minus” to the body, the “plus” to the contact on the solenoid relay. If the starter is working properly, a characteristic click will be heard and the overrunning clutch will move forward.

How to replace the mechanism on rear-wheel drive cars?

Here the algorithm of work is simple and accessible to everyone. Unscrew the bolts that secure the starter to the gearbox housing. The starter is secured with three bolts. If you have never removed it, you will have to work under the car. The last bolt from under the hood cannot be unscrewed.

Then, turning the starter to the right, remove the terminal on the solenoid relay and the thin wire. After this, the starter can be removed. They clean it, unscrew the solenoid relay, and unscrew the bolts holding the starter together. Take out the back cover, winding and middle part. They also pull out the cotter pin and knock out the stopper. Now you can get the anchor and overrunning clutch. They immediately check the brushes and replace worn parts. The new bendix is installed in its place on the anchor. After this, the stopper is hammered in, a cotter pin is installed, and the assembly is assembled. This completes the replacement of the Bendix VAZ-2107. You can install the starter and check it already on the car.

How to remove bendix

First you need to dismantle the starting device itself, having first disconnected the positive terminal from the battery, and from the starter - the wire going to the solenoid relay. Removing the starting device (most often it is fixed with three bolts) is possible from the top or bottom (you will need an inspection hole) - it all depends on the make of the car. At the same time, inspect the flywheel teeth: if they are very worn, you will have to replace the ring gear or the entire flywheel. After the starter is on the workbench, dismantle (if necessary, here everything again depends on the model of the machine) the solenoid relay. Next comes the removal of the bendix:

- Unscrew the nuts securing the vertical studs (usually there are three of them) and, lightly tapping with a rubber mallet, separate the starter housing. Take this opportunity to visually assess the condition of the brushes and windings.

- Hook the bendix by the “ears” with a flat-head screwdriver and pull it out of the fork.

- Take a hammer and an open-end wrench that fits the diameter of the overrunning clutch shaft and remove the first retaining ring; the second can be moved with a flat-head screwdriver.

- Now we remove the starter bendix itself.

Features of mechanism diagnostics

The starting unit is checked using a tester. After turning on the device, the voltmeter reading should not be higher than 8V, and the current should not exceed 23A.

You can check the windings using a tester; if it lights up, it means there is a short circuit. To perform a visual inspection of the starting unit, it must be removed and cleaned of dirt (video author - Irina Kuzilova)

When disassembling the device, each part should be visually inspected. Scores and scratches can be removed using sandpaper. Broken and worn parts must be replaced. It is also necessary to replace the VAZ 2106 starter bushings if they are badly worn.

A faulty collector cannot be repaired; it is advisable to replace it. The height is checked on the brushes. More than 12 mm is considered optimal, otherwise the brushes must be replaced.

Replacing the starter on a VAZ 2108-VAZ 21099

Removal

1) Disconnect the negative terminal from the car battery to cut off the power supply to the starter. Having trouble disconnecting? – See the article: “Replacing the battery in a car,” point one.

2) Now think about which part of the car will be easiest for you to remove the starter from the car (top/bottom). Advice: with carburetor engines, in the absence of an inspection hole nearby, it is easier to remove from above. For injection machines, it is also possible to remove it from above, but in addition it is necessary to remove the air filter housing. Please note that it is much more convenient to shoot from below, using a pit. Unscrew the bottom bolt without any problems (by the way, you most likely won’t even be able to unscrew the bottom bolt without a special tool). If there is a crankcase protection, remove it (not present on all cars, because protection is not installed from the factory, but a mudguard that protects the engine from contamination is always installed, be sure to remove it, instructions are “here”).

3) Having removed all the obstructing parts, we proceed to removing the starter itself:

- disconnect the wire block by pulling it (photo 1);

- proceed to unscrewing the nut securing the battery terminal and unscrew this nut completely (photo 2);

- remove the terminal from the starter stud where it is located (photo 3);

- Remove the three nuts securing the starter to the car engine.

Installation

The new part is installed in the reverse order of removal.

Note! We recommend sanding the terminal connected to the starter if there is rust or ingrained dirt. A clean terminal will ensure better contact, and to prevent it from rotting and oxidizing in the future, lubricate it with grease or Vaseline.

Bendix replacement

Regardless of whether you are going to replace the bendix or rebuild it, you will first have to remove it from the starter. There are two types of starters:

- With a “beak”, where the front support of the starter shaft is made in its housing.

- And without the “beak” where the front starter support bushing sits in the crankcase.

The most common mechanisms are of the first type, the “beakless” ones are familiar from the VAZ of the “eighth” family.

Since you can change the Bendix on the starter only by removing the starter itself, first the battery ground is disconnected, and the power cable and the solenoid relay control wire are removed from the starter. Having unscrewed the fastenings of the starter to the crankcase, we pull it out.

Regardless of the design of the starter, the solenoid relay is first removed, since its plug later interferes. We unscrew the nut on the power terminal of the starter winding, remove the terminal, then unscrew the screws connecting the retractor to the housing. We take out the relay winding, after which the core can be easily disengaged from the Bendix fork.

Then we disassemble the starter. Having unscrewed the longitudinal coupling bolts of the covers, remove the “beak” or front cover of the starter. After this, you can easily remove the fork from the Bendix and pull the rotor towards you.

A thrust bushing is installed on the rotor, limiting the stroke of the bendix. Before removing the bendix from the starter, you need to compress this bushing. In garage conditions, an open-end wrench is used, the mouth of which fits onto the rotor shaft, but rests against the bushing with its jaws. Having firmly fixed the key in a vice, we rest the thrust sleeve against its jaws and apply a sharp blow to the end of the shaft through a drift made of durable wood, copper or aluminum, so as not to damage the shaft itself. After this, the retaining ring installed inside the bushing jumps off the groove and releases it. After removing the bushing, pull the retaining ring off the shaft by prying it off with a thin screwdriver.

After this, we take out the Bendix assembly. Installing the Bendix is done in the reverse order, and the main difficulties are caused by pressing the thrust bushing back. It should be taken into account that it is asymmetrical - on one side there is a wide chamfer, which makes it easier to enter the locking ring. When removing the bushing, the retaining ring is deformed; it must be straightened before assembly. The thrust bushing must be seated on the retaining ring without distortion, otherwise the edge may be squeezed out of the groove on the rotor, the ring will bend and will not allow the thrust bushing to be pressed into place.

Something else useful for you:

Replacing the bendix on a VAZ starter or do-it-yourself repair

Replacing the bendix on the starter is a simple procedure. However, it also requires certain knowledge and skills. The replacement process takes about 1 hour and is no different on the VAZ-2110, 2109, VAZ-2114 and other front-wheel drive models of the Tolyatti Automobile Plant.

- What is Bendix, and in what cases is it required to be replaced?

- Bendix replacement

- Performance evaluation

- VAZ 2114 with gearbox (video)

- Do-it-yourself Bendix repair (video)

What is Bendix, and in what cases is it required to be replaced?

Bendix is a clutch used to engage the starting electric motor and flywheel when starting the engine. Externally, the element is an oblique gear and is located on the starter shaft. At the moment it is triggered, it moves forward with the help of a solenoid and connects to the flywheel.

When the power supply stops, the gear returns to its place, disconnecting from the flywheel. The amplitude of movement of the clutch is about 10 cm. The bendix is protected from excessive displacement by locking rings.

Signs of a malfunctioning clutch are clearly visible, so the question of how to check the starter bendix usually does not arise. The “symptoms” of a malfunction include:

- a grinding noise in the flywheel area when trying to start the engine;

- the starter rotates idle, without transmitting torque to the flywheel;

- a characteristic knocking sound at the moment the solenoid relay is activated, after which the shaft does not rotate.

» alt=»»> A faulty gear is usually not repaired, but replaced. Repairing the element is possible, but such actions are not justified in terms of financial and time costs. Therefore, if the coupling breaks, it must be replaced. If you still want to repair it, a detailed video will be at the end of the article.

This method is not a repair method, but it allows you to start the engine and get to your home or auto repair shop.

Bendix replacement

Replacing the Bendix VAZ-2110 and other front-wheel drive models begins with dismantling the starter.

To do this you should:

- remove the “-” terminal from the battery;

- Using a 13 key, unscrew and remove the power terminal from the electric motor;

- unscrew the starter mounting bolts with a 13mm wrench (2 on top and 1 on bottom);

- remove the starter.

It is worth noting that the electric motor mounting bolts often become so sour that it becomes difficult to unscrew them. In this case, you should not try to unscrew the bolt by force. This may cause it to break. It is necessary to tap the heads with a hammer, fill them with WD-40 liquid and wait 15-12 minutes.

With the electric motor removed, the retaining ring is removed from the shaft. To do this, you need to knock it out of its seat with a special mandrel (if you don’t have one, a high 15 socket will do) and remove it using pliers. After this, the part can be easily removed by hand.

The above procedure answers the question of how to remove the bendix from the starter. In general, at this point the main part of the repair can be considered complete, since replacing the bendix on the starter after the old element has been dismantled is a matter of one minute.

The new spare part is put on the shaft, after which the electric motor is assembled in the reverse order. They put on the retaining rings, install them on the car, secure the starter itself and the power terminal with bolts, and return the removed terminal to the battery.

Performance evaluation

After completing the work, you should check how the engine starts. The starting engine should run smoothly, without knocking and grinding noises characteristic of a faulty overrunning clutch. This is a sign of a high-quality replacement of the Bendix on VAZ-2109-2115 cars.

In some cases, changing the bendix is not enough. Prolonged operation of a faulty clutch leads to wear and damage to the flywheel teeth. In this case, the symptoms of failure that existed before replacing the gear may become weaker, but do not disappear completely. In such cases, it is necessary to replace the flywheel.

Performance evaluation

After completing the work, you should check how the engine starts. The starting engine should run smoothly, without knocking and grinding noises characteristic of a faulty overrunning clutch. This is a sign of a high-quality replacement of the Bendix on VAZ-2109-2115 cars.

In some cases, changing the bendix is not enough. Prolonged operation of a faulty clutch leads to wear and damage to the flywheel teeth. In this case, the symptoms of failure that existed before replacing the gear may become weaker, but do not disappear completely. In such cases, it is necessary to replace the flywheel.

”alt=””>

”alt=””>

In the starter, important importance is given to the bendix, if it breaks down it will not be possible to start the engine. And, if a characteristic metallic sound is heard during startup, this indicates an immediate replacement of this part.

Qualified craftsmen are not recommended to even try to repair the Bendix; according to them, it is much more advisable to replace the old worn-out part with a new Bendix. Such a timely replacement of the bendix, rather than repairing it, will prevent imbalance of internal parts with the prospect of increased wear on the starter motor.

Content

Purpose

Bendix is otherwise called an overrunning clutch, which refers to the working body located in the car starter. Torque is transmitted by a gear from the starter motor to the flywheel of the internal combustion engine. But the gear cannot be in long-term engagement with the flywheel, since the starter should operate for a short time, after which it must cool down. And in order to protect the starter motor from the effects of the internal combustion engine, Bendix is designed.

Diagnostics

Even with extensive experience, it is difficult for a technician to immediately figure out problems in the starter.

After all, the reason for replacing the Bendix can be not only worn-out teeth of the Bendix gear, it can also be worn-out bushings on which the starter shaft is mounted, or there may be a common reason - damage to the solenoid relay. So, in order to identify the cause of this damaged part, experience is needed. Some technicians carry out diagnostics on special stands under several loads:

- Under load;

- Without load.

And for some, it is enough to move their hand to understand the need to replace the Bendix.

Self-replacement

Replacing a bendix yourself is not as simple as it seems at first glance. To change it, even on the simplest domestic car, you will need to remove the starter, and this work can be accompanied by a number of difficult moments. Still, you can try to make the replacement yourself. So what needs to be done:

- Remove the starter. To do this, open the hood and disconnect the negative cable from the battery. The car must be driven into the inspection hole. Using a wrench, unscrew the fastening of the positive battery cable to the solenoid relay. Then the two terminals are removed, paying attention to the condition of the insulation on the wires. Unscrew the bracket using a hexagon. Then, using a spanner, unscrew the bottom bolt that holds the starter. This process is quite troublesome. After this, the upper mounting bolt is turned out and the bracket is unscrewed, with the help of which the starter is attached to the block. After this work, the starter is carefully removed.

- By unscrewing the studs along the entire starter and those that secure the cover, separate the starter into two parts. After removing the brush assembly and rotor, it is recommended to clean all parts of the starter.

- Then you need to remove the retaining ring from the rotor shaft and remove the worn bendix, replacing it with a new one. Immediately check the condition of the bushings and forks. To remove the plug, you need to carefully remove the rubber plug and remove the required element.

- The bushing is pressed out using a head of a suitable size. If these parts wear out, they should be replaced immediately with new ones. The bushings are driven back using a hammer. It is worth remembering that the blows should not be strong and should be carried out through a special wooden lining.

- The starter is assembled in the reverse order, after which its functionality is checked.

Is it necessary to make repairs?

From a theoretical point of view, there is no problem in changing the bendix, but from the practical side of things, it is somewhat burdensome and difficult, but quite doable.

But what about Bendix repair? In principle, according to professionals, conversations about repairing this part should not even arise.

This is explained by the fact that modern machines have almost the same wear resistance of parts located in a single unit. This means that you can be sure that if one gear wears out, then after it, almost immediately, the next one will deteriorate, and so on. Therefore, it is much more practical to completely change the bendix, and besides, the cost of the part itself is low.

What is the sequence of actions

So, to change the bendix you should do the following:

- Removing the starter;

- Starter disassembly;

- Replacing the old bendix with a new part;

- Reassemble the starter in reverse order.

When starting work on replacing the Bendix, it is advisable to completely remove the battery, since even a short circuit can lead to serious consequences. If you have any questions or doubts, you should seek professional advice.

–> Masters VAZ / Starter

Starter

How does the bendix starter work?

Bendix performs two functions simultaneously. When starting a car engine with a starter, it provides a rigid kinematic connection between the starter electric motor and the flywheel of the engine crankshaft. After the internal combustion engine has been successfully started, its speed increases significantly. At this moment the bendix breaks the rigid connection, otherwise it will spin. In this way, the starter motor is mechanically disconnected from the rotating flywheel. This process allows:

- avoid overload on the starter shaft and its premature failure;

- reduce the level of mechanical noise;

- prevent flywheel damage and increase engine load.

Structurally, the Bendix is made in the form of two combined units: a gear that is mechanically connected to the engine flywheel, and a direct overrunning clutch. A special feature of the gear is the presence of bevels on the outer ends of the teeth. They are designed to facilitate the alignment of the working areas of the bendix and flywheel at the moment the starter is activated.

The overrunning clutch of most used bendixes is designed in the form of two rings with cavities, inside of which there are thrust cylinders or balls. They are jammed by springs when the flywheel gear rotates in one direction and does not interfere with mutual rotation in the opposite direction.

This type of overrunning clutch is known to many cyclists as a “ratchet”. However, bicycles usually use a different, ratcheting, overrunning clutch mechanism.

Signs of a Bendix malfunction

During vehicle operation, Bendix is subjected to extreme loads during engine starting. Photo: avtomag22.ru

The service life of Bendix engines, especially “non-native” ones, is no more than 20 thousand engine hours in the urban rhythm of traffic.

A possible Bendix malfunction can be judged by the following signs:

- mechanical grinding noise in the area of the starter or flywheel when starting the engine;

- continuous metallic sound after starting the engine (stop the engine immediately);

- starter activation, engagement with the flywheel “every other time”;

- the presence of a mechanical sound like a “ratchet” at the time of startup.

In these and other cases, the serviceability of the bendix should be assessed. There are no indirect methods for 100% determination of a Bendix malfunction. In any case, dismantling of the starter, visual inspection and bench testing are required.

The main causes of Bendix malfunction

Bendix malfunction is usually caused by the following reasons:

- natural mechanical wear;

- foreign objects entering the gear-flywheel contact zone;

- malfunction of other starter elements: plug, solenoid relay;

- improper operation of the vehicle at the time of starting;

- a malfunction of the car's electrical equipment, causing unintentional activation of the starter while the car is moving;

- failure to carry out routine maintenance in a timely manner.

Restoring Bendix performance

During the period of total shortage of auto parts for domestic cars, “Kulibins” easily repaired some Bendixes. Photo: driving24.ru

The following may be subject to repair, replacement and restoration:

- “eaten” gear teeth;

- cracked thrust rings or balls;

- worn springs.

In case of more serious damage to the structure, repair of the bendix is impossible. But even in situations accessible for repair, it is more advisable to make a unit replacement. Bendix is a starter consumable. On the auto parts market there are modifications for almost any starter model. Its cost is low - from 600 rubles. Starter repair stations have a full supply of ammunition for all cars.

Professional replacement of a bendix takes no more than an hour, costs from 1000 to 3000 rubles, depending on the make of the car and the complexity of installation and dismantling work. At the same time, most auto repair shops carry out starter diagnostics, routine maintenance, and assess the degree of wear of the fork, solenoid relay, and flywheel teeth. This significantly increases the service life of the engine starting system.

There are workshops that restore the performance of exclusive Bendixes, for example, for vintage cars.

To replace the bendix yourself you need:

- metalwork skills;

- availability of tools for installation and dismantling work;

- the ability to access the car from below (a pit or a lift), if dismantling the starter from above is impossible;

- Basic knowledge in the field of electrical engineering.

The sequence of work to replace the bendix:

You will find another DIY replacement option in this video:

Causes

There are many reasons for the failure of the overrunning clutch, both indirect and direct. It may seem to you that my reasoning is not objective, but I will list some:

If we go in order, I'll start with the big starter. Drive failure ended with its removal and replacement of the bendix. At the same time, the starter bushings in the middle part and the nose part (starter cover) were changed.

With the purchase of a small starter, there were more serious breakdowns. The lid broke, the teeth of the crown licked. But here, on the advice of the master, I made some modifications to the lid and the problem was solved.

Some UAZs have been in use for years and do not have such problems. This in itself suggests some kind of defect in the engine. And he himself would have been at a loss until one master gave a possible solution to the causes of the breakdowns and advice on repairs. Although I haven’t determined the exact cause of the breakdown, I think the way of thinking is correct.

Frequent breakdowns of the bendix and bushings are associated with heavy loads on them due to the starter being incorrectly positioned relative to the crown on the flywheel. A small tooth engagement height leads to licking of the teeth. Rapid wear of the bushings and even when a tooth hits a tooth, the front cover breaks.

Why does this happen? As the master said, these are displaced mounting studs on the clutch housing or guides of the flywheel housing itself.

But if you take into account that if you move the crankcase itself, there will be problems with installing the box. Then the first option remains, there was a defect in the flywheel housing. But he still explains the reason for the small engagement of the teeth relative to each other.

The buffer spring is broken

How to check starter bendix

If the starter bendix does not turn, then you can check its operation in two ways - visually, by removing it from the car, and “by ear”. Let's start the description with the latter, as it is simpler.

As stated above, the main function of the bendix is to engage the flywheel and spin the engine. Therefore, if, at the moment of starting the engine, you hear that the starter motor is spinning, and characteristic metallic clanging sounds are heard from the place where it is located, this is the first sign of a Bendix malfunction.

So then it is necessary to dismantle the starter and disassemble the bendix in order to inspect it in detail and determine the damage. The removal and replacement procedure is described below.

And so, the bendix was removed, it is necessary to inspect it. In particular, check whether it rotates only in one direction (if it turns in both, it means it needs to be replaced) and whether the teeth are eaten. Also check to see if the spring is loose. You should also remove the fork from the Bendix, check its integrity, signs of wear, and if necessary, replace it. In addition, be sure to check if there is any play on the armature shaft. If this occurs, then the bendix should be replaced.

Operating principle

The principle of operation of the Bendix is the inertial effect on the gear coupling until it engages with the flywheel. When the driver turns the ignition key, current from the battery is supplied to the solenoid relay, and from it to the windings and starter armature. This sets the anchor in motion. Due to the presence of helical grooves on the inside of the bendix and the rotational movement of the armature, the coupling is able to slide along the splines until it engages with the flywheel crown.

Under the influence of the drive gear, the driven cage and gear are driven. If the teeth on the flywheel and the clutch gear do not match, the clutch rotates to create a rigid engagement. The Bendix design has a buffer spring - it serves to soften the engine starting. It also helps to avoid breaking the gear teeth on the overrunning clutch at the moment of clutch.

When the internal combustion engine has already started, the angular speed of the flywheel is significantly higher than the one with which the flywheel rotated the starter. Therefore, the clutch rotates in the opposite direction and slides along the splines in the opposite direction, disengaging with the flywheel.

Main symptoms of a malfunction

You can find out that the VAZ 2114 starter bendix has failed by the following series of indirect signs:

- the starter turns the flywheel, but its power is insufficient to start the engine;

- the starter works, but rotation is not transmitted to the crankshaft flywheel;

- The sound when the starter operates is different from normal, the engine starts with difficulty.

All these signs may indicate that the bendix itself or its gear is damaged and does not provide good adhesion to the flywheel gear, making it impossible to start the engine. In some cases (for example, with weak rotation transmission), both the bendix and the solenoid relay may be to blame. In order to establish the exact cause, as well as to eliminate it, you will need to dismantle the starter and completely disassemble it.

We unscrew the starter; if there is no gearbox, then carefully knock the washer off the armature and remove the retaining ring. Remove the bendix from the axle. We replace it with a new one, which we install in the reverse order. The most difficult part is installing the washer and retaining ring. For this, craftsmen use clamps, special wrenches, and sliding pliers. Replacing the bendix on the starter requires some practice.

Sometimes a malfunction occurs due to dirt getting into the mechanism and there is no need to disassemble the starter; you can try to revive it. To do this, the anchor with the overrunning clutch is dipped in a container of gasoline for 5–7 hours and the gear is periodically turned. Afterwards, the starter needs to be dried thoroughly and tested. If it does not work, then disassembling the unit cannot be avoided.

Let's sum it up

Bendix is an important starter part. It transmits rotation from it to the engine flywheel. If the support clutch fails, the car will not start. You can determine the breakdown by ear. If the starter turns, but the gear starts to slip and does not rotate the engine, then it is the overrunning clutch that has failed. You can remove and repair it yourself. But if wear appears on the surface of the rollers, outer race or gear, then it is better to install a new bendix.

Sources used:

- https://znanieavto.ru/fire/kak-pomenyat-bendiks-na-startere.html

- https://autodont.ru/jelektro/kak-samostoyatelno-provesti-zamenu-bendiksa

- https://masteravaza.ru/starter-2/zamena-bendiksa-na-startere-vaz-2110-587

- https://carfrance.ru/menyaem-bendiks-na-vaz-2110-svoimi-rukami-artikuly/

- https://swapmotor.ru/ustrojstvo-dvigatelya/bendiks-startera.html

Starter repair

In order to remove the starter, you will need the following set of tools:

- slotted screwdriver;

- crosshead screwdriver;

- socket wrenches (or heads) for thirteen and 10.

The replacement of the Bendix VAZ 2114 itself is done as follows:

- Disconnect the ground terminal from the battery.

- Using a 13mm wrench, remove the pair of mounting screws that secure the starter to the crankcase.

- Using the same key, unscrew the nut that secures the “positive” wire to the solenoid relay housing.

- Using a Phillips screwdriver, remove the pair of mounting screws located in the starter cover and holding it in place.

- Remove the starter cover.

- Using a 13mm wrench, unscrew the nut securing the contact of the solenoid relay winding.

- Using a flat-head screwdriver, remove the washer-bracket (this should be done carefully).

- Using a 10mm wrench, unscrew the pair of bolts holding the halves of the starter housing together and then remove them.

- Separate the starter housing into two halves (if you cannot do this by hand, you should stand it vertically and tap the lower part with an aluminum, rubber or wood hammer).

- Using a flathead screwdriver, remove the bendix ears from the fork.

- Place the wrench on the shaft, then knock out the first locking ring with hammer blows.

- Remove the 2nd retaining ring using a slotted screwdriver.

- Remove the bendix.

After the electric starter has been completely disassembled, you should inspect all its parts that are subject to active wear, and specifically:

- bushings;

- graphite motor brushes;

- Bendix gear.

If necessary (if they turn out to be very worn), they should be replaced with new ones. It should be noted that when inspecting the Bendix, serious deficiencies indicating its breakdown should be not only obvious chipped teeth, but also their abrasion, loss of their original shape, which is one of the circumstances of poor engagement with the flywheel gear.

After all elements of the starter have been inspected and faulty ones have been changed, it should be reassembled. It is carried out in exactly the same order as disassembly, but in the reverse order (with all this, before reassembling, you should remove all dirt, clean oxides from the relay contacts and lubricate the moving parts).

Thus, replacing the Bendix on your own is a task that virtually every car owner can do. The only thing you should keep in mind is that it should be done when the first signs of a malfunction occur, without waiting for a more severe breakdown and possible damage to other parts of the starter.

The sequence of work performed when replacing a relay:

First, you should turn off the power from the battery, because while the electrical circuit is connected, it is prohibited to dismantle or disassemble the starter, otherwise a short circuit may occur and you will burn all the wiring.

- Before disassembling, thoroughly clean the starter from dust and dirt so that dirt does not get inside.

- Unscrew the brush assembly nut from the traction relay bolt and remove the contact from the bolt.

- We unscrew the coupling screws securing the relay to ground and pull it out.

- Unscrew the nuts from the end and divide it into two parts

- We take out the old core and replace it with a new one

- Reassemble everything in reverse order and install the retractor

- We check the entire mechanism and install it on the car

After all the parts have been installed on the car, we check them again for functionality, to be sure that we did everything correctly and everything is working properly for us.

How does a starter bendix work?

The design of the element includes a gear, which meshes with a flywheel located on the shaft of the power unit to rotate it. For normal engine starting, the rotation speed of the starter shaft should be in the range of 50-100 rpm. It makes no sense to develop high speed, since the starter operates at maximum load for only a few seconds. During this period of time, the load on all elements of the starting system and the power unit increases to the limit, and if the starter does not stop working in time, the consequences can be unpredictable. This will help prevent the Bendix from starting up in a timely manner.

Among the functional and structural features of the element, it can be noted that it is aggregated with the car’s crankshaft only to start the engine, rotates in one direction and begins to scroll as soon as the speed of the power unit increases significantly in comparison with the starting shaft.

What is the design of the gear-six starter?

The VAZ 2106, produced after the 1980s, has a starter with an end manifold model 35.3708. Earlier cars from the Volzhsky plant had a different gear mechanism installed - ST-221, which was equipped with a cylindrical manifold. Their structure is approximately the same, so they are completely interchangeable.

Let's take a closer look at the design of the mechanisms that interest us, using model 35.3708 as an example. The “six” gear starter consists of the following main parts:

- field winding (i.e. stator) and housing;

- electric drive with anchor;

- three special covers;

- electromagnetic traction relay with two windings (one of them is retracting, the other is holding).

Using bolts, the starter housing is secured into one block with three covers. The armature of the mechanism we are interested in has a core, a commutator and a shaft. The last of these elements rotates in metal-ceramic bushings (there are two of them structurally provided). These bushings are pressed into the covers and must be impregnated with a lubricant. The starter drive is located at the end of the shaft. It includes a gear and a roller clutch, which is necessary to transmit torque to the flywheel.

On the front cover there is a relay consisting of a yoke, several flanges and a core. When the gear mechanism is turned on, two processes occur simultaneously: the armature is retracted, and the drive and gear mesh with the flywheel; a special contact plate closes the bolts. The result of these processes is the start of power supply to the windings of the device we are considering. As you can see, the circuit for switching on and operating the “six” starter is quite simple.