Types of gearbox cushions

The existing gearbox on the VAZ 2110 is equipped with reliable spare parts, the interaction of which ensures smooth operation of the vehicle. It should be noted that it is maintainable. One of the elements of the transmission is gearbox cushions. These components can be of the following types:

In terms of price, the rubber-metal option is cheaper. As a rule, it is most often found on the 2110 model. The rubber can be made of polyurethane. This material is characterized by increased wear resistance and has good shock-absorbing properties.

Hydraulic options cope well with the loads placed on them and are able to effectively dampen vibrations that occur when movement occurs. The design of the present support is a housing that has two chambers with a special filler, between which there is a membrane.

Problems with box supports are rare. Long-term operation of the vehicle over rough terrain and temperature changes help reduce its service life. Because of this, the rubber of the cushions loses its elasticity and breaks down. As a result, there is a need for repair and restoration work.

Troubleshooting airbags

The metal base of the cushion provides good mechanical support for the gearbox. Thanks to her, this unit is securely fixed in its normal place. The gearbox support 2110 has good resistance to external loads, as well as temperature changes. The service life of this component depends on the operating conditions of the vehicle. The ingress of dirt, sand, etc. flying from the roadway helps to reduce their service life.

You need to pay attention to the condition of the pillows if the following manifestations are noted:

- vibrations at the beginning of the trip;

- extraneous knocking noises when braking;

- hum

In addition to this, it can knock out speed. Among the reasons for these manifestations may be deformation of the pillow as a result of strong temperature exposure. Also, the life of the gearbox cushion is negatively affected if oil or antifreeze gets on it.

Important! The presence of knocks and extraneous noise from the VAZ 2110 high-speed gearbox is not always due to the fact that the airbags have become unusable. These manifestations may be the result of broken gear teeth or loose threaded connections. Taking this into account, vehicles are subject to full professional diagnostics.

Thus, if the faulty consumables on the VAZ 2110 are not replaced in time, then the motorist may soon experience engine and gearbox breakdowns. As a result, vehicle control will deteriorate and there will be a need for serious repairs.

Design features

If you have a “ten” with an 8-valve engine, then the design provides two side and one rear support;

On a 16 valve engine there are two side mounts, one lower and one upper.

It is important to note that 8 valve engines on the 10 have a rear engine mount, while on the 16 valve there is none. But such motors can boast of having additional supports.

Regardless of the design, the replacement procedure is performed using a similar method.

Malfunctions

In fact, it is quite easy to detect failed airbags, since engine vibrations will immediately increase.

If the power unit is working normally, but the body is shaking, vibration is felt on the steering rack, pedals, and dashboard, then there is no doubt that the engine mounts are worn out.

The vibration peak occurs when the engine starts and when it is turned off. If the rubber elements are completely worn out, then a knocking noise will begin to appear. It is caused by contact of engine elements with the supports.

To make sure the cushions are worn, turn on the engine, lift the hood, and visually inspect the supports and cushions. By placing your hand on the engine, you will tactilely feel an increase in vibrations compared to the normal behavior of the car.

There may be several reasons for problems.

Causes

Peculiarities

Deformation of elements can occur during the life of the pillows, under mechanical or temperature influences

Rubber does not have a large margin of strength, so it ages over time. This effect increases when exposed to temperature changes.

Delamination and cracking

The pillow can literally fall apart and creep apart when exposed to chemically aggressive substances.

Is replacement required?

If you find that the rear airbag or any other airbag has begun to wear out, you should under no circumstances delay repairs.

When starting to repair engine mounts, you should think about whether it is worth changing the cushions separately, or replacing the mounts as a whole.

If the support is not damaged, it is not necessary to replace it. That is, in such situations it is enough to simply replace the pillow. A set of new pillows for a VAZ 2110 today costs about 1.3 thousand rubles. A set of supports will cost you 2.5 thousand rubles.

Doing the work yourself or contacting a service station is your choice. But you should know that you will be charged at least 300 rubles for replacing one pillow.

Features of replacing the VAZ 2110 box cushion

It is possible to carry out repairs yourself. Initially, it is worth purchasing suitable cushions for the gearbox for a VAZ 2110 car (produced by the Volzhsky Rubber Plant). Also, you need bolts, nuts, washers, and a casing bushing.

The main stages of replacing the VAZ 2110 gearbox cushion:

- The car starts up in the inspection hole.

- A beam is placed across the pit, on which the jack is installed (closer to the support).

- Visually you can determine the condition of the support. If it is deformed, the spare part needs to be replaced.

- To remove the pillow, you need to unscrew the nuts that secure it to the box.

- The through fastening bolt is unscrewed.

- The pillow is removed.

Installation of a new spare part occurs in the reverse order. Replacing a pillow on a box does not require any specific skills; this procedure does not require much time.

Thus, replacing the VAZ 2110 gearbox cushion can be done independently. When carrying out this procedure, you need a set of keys and a jack. In normal condition, the products should be solid; components should be periodically checked for integrity. There are many signs that the gearbox cushions have become unusable, for example, vibrations of the gearbox lever, knocking noises when switching from 1st to 2nd gear. The car must be equipped with original spare parts only.

VAZ 2110: replacing the gearbox cushion on your own

Replacing the box cushion

If the car has been in use for more than three years, it starts to knock somewhere and a squeak comes out somewhere. When accelerating or driving on broken roads, a knocking sound begins under the bottom of the car. A knock can also be heard at the location of the gearbox. For a VAZ 2110, replacing the gearbox cushion, which will be discussed in the article, can completely solve the problem. Replacing the VAZ 2110 gearbox cushions is a simple matter that anyone can handle.

Signs of Wear on Engine Mounts

When operating a vehicle, engine mounts break for a variety of reasons. The most common defect is a break in the rubber component of the cushion. And although these parts serve for quite a long time, as a result of high load, the rubber cannot withstand it and breaks. The heaviest loads occur when starting a vehicle and during braking. If a car owner prefers high-speed driving with a sharp start, then his engine mounts will not last long.

The rubber on the pillow can lose its elasticity and dry out. Sometimes the aluminum bracket breaks off when hitting an obstacle. If oil from the gearbox or engine gets onto the rubber block of the support, the rubber is corroded by the oil, and the support fails earlier than necessary. Brake fluid and antifreeze also have a detrimental effect on the support. In any situation, operating a car with a faulty engine mount will be uncomfortable and, sometimes, unsafe.

The following signs indicate a faulty airbag:

- When driving on uneven roads, there is kickback on the gear shift lever.

- The appearance of vibration.

- Driving on uneven road surfaces is accompanied by impacts in the front part of the body.

- When braking and starting, knocking and clicking noises occur in front of the car.

Do-it-yourself repairs and preparatory work

Replacing the VAZ 2110 gearbox cushion

The knocking starts when the gear is switched from 1 to 2 or from 3 to 4. The knocking also occurs when driving on country roads at one speed. One thought immediately arises: the checkpoint is buzzing. What to do? Contact a car service center or look for the cause yourself. A car enthusiast, not a specialist, needs to know a simple truth. At service stations, minor repairs are taken on reluctantly or even refused due to workload. They may, of course, offer to repair the gearbox. Since such repairs will bring financial profit. But the result is the same. The knock under the bottom will remain. Therefore, there is no need to despair. You need to visit a car store and buy the necessary spare parts:

- 2 assembled pillows (choose from the Volzhsky Rubber Plant or Balakovo);

- 2 bolts M12x75; 4 washers dia. 12 mm;

- 2 nuts - 12 mm with nylon insert;

- 2 bolts M10x25; 6 wide washers - 10 mm;

- 2 engraving washers - 10 mm;

- 1 VAZ-2108 timing case bushing.

Note: it is advisable to buy all rubber cushions for repairing VAZ and other car models from these manufacturers, since they use natural rubber in their production. This is not advertising, but years of practice.

- Drive the car into the garage into the inspection pit:

- Connect the lamp with the lantern closed;

- Visually inspect the attachment points of the box cushions. The knock can be produced by the rocker (see Replacing the rocker on a VAZ 2110 on your own), hitting the transverse rod. All due to the fact that the gearbox sagged. The gap from the link to the rod should be more than 5 mm.

Note. You can temporarily eliminate this defect. Take a piece of rubber hose, cut it lengthwise and put it on the drawstring. But this is only for temporary use.

When there is enough time, it is necessary to replace the gearbox mounting pads. It is advisable not to delay this. If the box is sagging, you need to find the cause and eliminate it. First, try tightening the left mount nut on the gearbox. Due to its spontaneous unscrewing, the engine and the gearbox sag. If this operation does not help, then you need to change it.

Price issue

Engine mounts are produced by several manufacturers. The most popular among our compatriots are the products of the BRT company. Provided that this is a truly original product and not a fake, of which there are many on the market.

The cost of the front engine mount from BRT ranges from 500 to 600 rubles. The rear airbag is somewhat more expensive, approximately 700÷800 rubles . At car dealerships you can find pillows much cheaper. But most likely it will be a fake, from which there will be no result other than harm.

The original cushion uses a special type of rubber SKI-3 of the first group and high grade. This rubber is made from natural rubber. Special glue and high-quality steel are also used to make the side plates. This pillow is designed for use at temperatures from -45°C to +70°C.

Diagram, design of the VAZ 2110 gearbox. Replacing the airbag, signs of malfunction.

Manual gearboxes have proven themselves to be reliable and unpretentious devices, but even such “hardware” can have faults. Finding the problem can be quite difficult, since there are a lot of parts in the VAZ 2110 gearbox. After reading this material, motorists will be able not only to identify a defect in the operation of the gearbox, but also to independently study how the circuit is designed, the design of the VAZ 2110 gearbox and solve the problem. As an example, we will consider the most common malfunctions that owners of “cans” have to face.

Gearbox - device and location

The VAZ 2110 has a five-speed manual transmission with two shafts. There are two main tasks of the checkpoint:

- Speed change - due to a change in torque, speed modes are switched.

- Direction of movement - shifting to reverse gear causes the crankshaft to spin in the opposite direction, as a result, the car goes backwards.

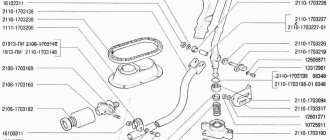

The box in the VAZ 2110 car consists of two shafts - the drive and driven, which are also called the primary and secondary. Each ox has a block of gears, due to which the torque is adjusted. Also in the gearbox housing there is a main gear (using a clutch it is connected to the crankshaft) and a differential. The mechanism for changing speeds is a lever that goes into the car interior. To get to the box, you need to remove the fasteners both in the hood and under the car. Together with the engine, the transmission forms the power plant.

Basic faults

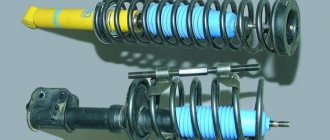

The service life of the front engine mounts for the VAZ 2107 is approximately 150÷200 thousand km. The rear airbag lasts a little less, about 80÷100 thousand km. Over time, the rubber cushion damper dries out and becomes less elastic.

This may cause more engine vibration. The rubber element of the cushion may crack or even tear. This leads to increased vibration and possible engine misalignment.

The metal elements of the pillows fail somewhat less frequently. Although there are cracks on the mounting bracket or on the plate itself.

The main sign of a faulty airbag is, first of all, increased engine vibration. Moreover, this vibration is felt not only at idle, but also at high speeds.

Unnatural shaking of the entire body is a good reason to check the condition of the engine mounts. The vibration is especially noticeable on the steering wheel. Moreover, its frequency depends on engine speed.

If the cushion is particularly damaged, the transmission in the box may be switched off. In addition, a torn rubber part of the cushion or a broken mount causes the engine to skew relative to the horizontal and vertical axes.

This in turn leads to intense wear of the drive axle and accelerated destruction of the gearbox bearings and clutch system. The installation angles of the exhaust system elements are violated. This can cause increased noise when the engine is running, and even the penetration of exhaust gases into the vehicle interior.

Diagram of the VAZ 2110 gearbox: faults and solutions

Some defects can be eliminated with your own hands, but to do this you need to learn to determine which defect is interfering with the normal operation of the gearbox. The main faults are listed below:

- The lever is loose. The cause may be worn-out gearbox and motor cushions. Also, other parts may be the “culprits”. Below are instructions for replacing the cushions and lever.

- Noise in the VAZ 2110 gearbox when switching. There may be several reasons: parts are worn out, poor lubricant is used or its level has dropped below the minimum, or water may have gotten into the working fluid. In the case of worn parts, only replacement will help. As for the lubricant, its quality and the presence of water in it can be checked with a dipstick.

- The gears are switched off randomly. This defect appears when parts wear out - an inspection is necessary to determine the cause of the spontaneous shutdown. The malfunction also appears due to incorrect operation of the drives that need to be adjusted.

Advice! In order not to waste a lot of time searching for faults, it is recommended to take the car to a service station, where professionals perform diagnostics. Subsequent repairs and replacements can be done by yourself.

Reviews after installing the rear gearbox support

The purpose of the rear mount of the power unit with the engine is to reduce the load on the front and rear engine mounts and reduce the rolling of the gearbox. In other words, after installing the additional gearbox support:

- The engine jerks less when starting to move, when changing gears or when you sharply press/release the gas pedal;

- The rattling of the gearshift knob has decreased;

- Shifting into gears has become clearer, especially 2nd.

Many Lada Priora car owners notice that after installing an additional airbag, vibration appears at idle, the reasons may be the following:

- the engine mount is made of low-quality rubber, it is better to choose another manufacturer, for example, BRT;

- The gearbox cushion is not installed correctly (in tension), as a result of which it does not dampen vibration from the power unit;

- other engine mounts are worn.

Have you installed an additional gearbox cushion on your Priora? Share your feelings after revision. Let us remind you that body reinforcements/struts are also very popular among car enthusiasts?

Replacing the pillow

The important point here is to look for a worn-out pillow. To find out which one to change, the VAZ 2110 must be jacked up and then placed on supports. Next, the jack needs to be placed under the pallet. To protect yourself while working, you need to place a wooden block between the jack and the pallet. The motor must be removed from the support and hung. Now you can inspect his pillows and find the defective one. Due to a damaged cushion, not only the lever dangles, but the entire interior dangles - the level of comfort drops noticeably. A new pillow will cost about 200 rubles.

Replacement proceeds as follows:

- The negative terminal is disconnected from the battery. The VAZ 2110 must be lifted with a jack;

- Next, the engine needs to be raised so that you can get to the damaged cushion;

- The next step is to unscrew the through bolt that holds the support;

- Once removed, the mount can be disconnected from the power plant. Before installing a new cushion, the bolt must be treated with a fixing sealant, and then secured in its original place. Done, replacement complete.

Replacement

The replacement procedure should not cause much difficulty for those who have independently repaired their car more than once, especially the suspension and chassis.

If you have no experience, then we recommend contacting a service station. Only proven and reliable.

Dismantling works

Replacement has its own nuances depending on the pillows for each engine in question. We will separately talk about the repair of 8 and 16 valve engines.

8 valve engines

- Select a flat surface for repairs, place chocks under the rear wheels, and turn on the handles.

- Remove the engine protection.

- Unscrew the bolts of the generator belt tensioner, after which this belt must be removed. You will need a 13mm wrench.

- Place a jack under the car, place a strong wooden board on top and lift the engine until it releases the load from the supports.

- Using a 15 wrench, unscrew the central fastening nut of the worn pillow.

- Now use a 13mm wrench to unscrew the airbag fixing bolts mounted on the bracket.

- From below, near the right arch, 3 more bolts are unscrewed. They are responsible for connecting the bracket to the spar. You need a 17mm wrench.

- The bracket is removed, the pillow is removed and replaced with a new one.

- Next, perform assembly in reverse order.

- Place the jack under the transmission and then lift it up.

- Using a 15 wrench, unscrew the nut of the central fastening of the left pillow.

- Using a 13mm wrench, unscrew a pair of bolts securing the support, after which it is removed.

- Replace the damaged element, and then carry out the reassembly procedure.

- Remove a pair of nuts with a 17mm wrench. They secure the cushion to the body. Then a couple more nuts connecting the cushion to the gearbox are unscrewed.

- Remove the rear support.

- Using a 17mm wrench, remove the fastening nut connecting the bracket to the cushion. A new rubber part is installed in place of the old element.

- The rear support is returned to its original state by reassembly.

16 valve engine

If you have a 16 valve engine under the hood, then there are some nuances for replacement.

On 8 and 16 valve engines, dismantling and replacing the side cushions is carried out in a similar manner, there is no difference. But the front lower ones change differently.

To change the front lower mount on a 16 valve engine, you need:

- Unscrew the front lower support rod fixing bolts in relation to the front suspension cross member. For these purposes, arm yourself with a 15 key;

- Unscrew the fastening nut that holds the support to the engine bracket. You will need a pair of keys at once and both are 15. The bolt is removed;

- Remove the support, change the cushion on it or replace the entire assembly;

- Reassemble;

- In the engine compartment, unscrew the fastening bolt of the upper front support to the car body, while holding its nut by hand. This is where the key for 17 comes in handy;

- Remove the bolt and nut;

- Remove the fastening bolt of the front upper support in relation to the power unit bracket using 15mm wrenches. The bolt and nut are removed;

- The support can now be removed, the pillow or the entire assembly can be replaced;

- Assembly is performed in reverse order.

Assembly of the unit

Additional support

To make movements in the longitudinal direction smaller, you can install an additional support. It is also called a suspension bar. Mostly they can be found in online stores.

Additional support

To mount an additional support on the 8-valve power unit installed under the hood of your VAZ 2110, you will need to purchase a special bracket used to transfer the ignition module.

Reviews from those who have performed such operations claim that when starting off the car does not jerk, the engine does not become loose, which has a positive effect on the wear of the cushions.

An important useful property of modification by installing an additional support is to prevent the lower pipe from falling off the radiator, which seriously affects dozens of people.

There are a lot of opinions regarding reducing vibrations. Some consider this a useless exercise, while others, on the contrary, note significant improvements in the behavior of the car.

Prevention measures

To prevent breakdowns, it is best to carry out periodic maintenance. This way you will spend much less effort and time on repairs.

Preventive measures include:

- Periodic check of bolt tightness;

- Removing dirt and oil traces from the rubber elements of the engine mounts with a dry rag;

- Regular repetition of these activities every 4 months.

In practice, even a relative beginner in the field of do-it-yourself repairs takes no more than 5 hours to replace engine mounts. But this allows you to develop your own skills, as well as save a decent amount of money on the services of service stations.