Many car enthusiasts, when problems arise with electrical wiring, immediately begin frantically looking for a familiar auto electrician to solve the problem, citing the fact that they do not understand electricity. In fact, there is nothing difficult about carrying out electrical diagnostics yourself. To do this, you will need a multimeter and a little knowledge, which we will try to outline for you in this article. Read the information below and you will not have any questions about how to find a short circuit in a car or, conversely, how to find a broken wire in a car.

Signs of faulty wiring

Before diagnosing the car's electrical system, you need to make sure that the problem is with the wiring. We list the main types of electrical wiring faults and their symptoms:

- Short circuit. One of the most dangerous problems with wiring, which can cause hazardous smoke and even fire - these are actually signs of a short circuit in the car. It is important to immediately stop using the car, since overheated wires from a short circuit can melt the insulation of adjacent wires and only worsen the situation. Most often, such problems end with a blown fuse or relay.

- Broken wiring. This is a safer malfunction, the consequences (and, at the same time, signs) of which can only be the failure of a certain electrical unit (in some cases, the entire electrical system).

Elimination of short circuit consequences

If the search for the short circuit was successful, then it’s time to exhale and start eliminating it. What to do next depends on the extent of the damage to the electrical wiring. Regardless of the situation, before starting any repair work, you should definitely turn off the power to the apartment and make sure there is no voltage.

It is necessary to assess how much the cable insulation was damaged at the time of the short circuit. If there are swelling, darkening or melting, the wire must be replaced. If possible, it is necessary to assess its condition along its entire length.

Connecting wires in the distribution box using terminal blocks

If the wire covering is in order, then the immediate location of the short circuit is removed. The surviving ends of the current-carrying conductors are stripped and connected using Wago terminal blocks, welding, soldering or crimping. In low-current circuits, you can use regular fast twisting at your own risk. However, the PUE (7th edition, clause 2.1.21) does not provide for and does not approve of this method of connecting cables.

Short circuit in the car

To answer the question of how to find a short circuit in a car, first check all the fuses and relays - as a rule, if there is a short circuit, one of them should fail. After finding such a fuse or relay, find out from the description (on the cover of the fuse box) which unit it belongs to. Next, start examining this unit - visually inspect all the wires running from it to the fuse box.

If external signs of a short circuit are not found in the car, then set the multimeter to resistance measurement mode, and then disconnect the “plus” of the unit being tested from the fuse box and from the device powered by it. Then connect one contact of the multimeter to the positive wire, the second contact to ground. If there is no short circuit, then the resistance on the multimeter will be equal to one. Otherwise, the “plus” somewhere touches the “minus”.

Another way

Also, when searching for a short circuit, auto electricians often use a regular incandescent lamp. In this case, instead of a blown fuse, we connect a lamp to the circuit, I usually use H4, there are a lot of them lying around with a burnt-out low beam filament.

For example, we have an MMC Pajero 4 with non-working reverse lights and a blown fuse. You can look for a fault as in the previous case, but it will be easier and faster to connect a lamp instead of a fuse, turn on the ignition, reverse gear, and this lamp flashes at full intensity, but there are no reverse lights. This means that there is a short circuit in the reverse lamp circuit. Our lamp limits the current in this circuit; it will not be more than what the lamp consumes and at the same time serves as an indicator that a short circuit is present.

At the same time, we immediately note that the lamp lights up only after we engage reverse gear, that is, there is definitely no short circuit in the area from the fuse to the gear selector (and by the way, there are two connectors and branches there, quite a few have already been cut off). Next we go and disconnect the connectors from the rear lights. The lamp continues to light, that is, the short circuit is not in the lamps. Next, working from simple to complex, we climb under the car and find the gear selector connector S-05 on the box (let’s say we have an automatic).

And we begin to actively move the wiring on the box, and at the same time we see that our lamp has started to blink, that is, the short circuit disappears, then everything is simple, we find the place of damage and repair it. It will look something like this

Of course, you will say, it’s easy to look for such short circuits, just try to find a short circuit that appears once a week, or even less often. It happens, in this case, we check the most likely places and if we find nothing, we separate the different circuits hanging on one fuse with our own fuses, as in this Lexus, by the way, that Lexus is still driving to this day, the short circuit no longer appears.

Successful repairs and no harmful clients to all. If you have interesting cases from practice, write in the comments.

Source

Finding broken wiring in a car

In order to check a car for current leakage with a multimeter, you will need to perform the same steps. Measuring resistance is an indicator of the presence or absence of contact. In the absence of contact, the resistance tends to infinity (or the number “1” on the device). If there is contact, the resistance should ideally tend to zero (the lower the better). So, to check for a break in the wiring, you need to connect a multimeter to two contacts suspected of a break and measure the resistance; we repeat - a unit on the multimeter screen will indicate a break.

Thanks for subscribing!

To avoid a repeat break, do not twist the wires with your hands. Use only a soldering iron and special heat shrink. If there is a break in the terminal, be sure to clean it before repairing.

Optional equipment

During operation, car owners often install additional electrical equipment:

Integrating them adds wiring to the vehicle and also puts stress on the electrical system. Moreover, a number of “new” electricity consumers cannot be switched off, for example, alarm systems, which means that the likelihood of rapid battery discharge becomes very important.

Current leakage is also determined using a multimeter

If your car begins to have difficulty starting after a long period of parking, then you should determine the cause of the current leak. A multifunctional device switched to ammeter mode will also help you find a leak.

Tip: Don’t forget to set the measurement range to 10 Amps, since the current in the car’s on-board network is constant.

How to check a car battery with a multimeter

If you suspect that the battery is not working well, then again, a multimeter will help you. So, arm yourself with a multimeter configured to measure voltage (20V):

- Disconnect one terminal and connect the red contact to the positive and the black to the negative. Normal voltage should be between 12.4 - 12.8 Volts. It is important to take measurements at least an hour after stopping the engine.

- Measure the voltage under a load equal to twice the capacitance. For example, if the capacity is 75 Am/hour, then the load should be 150 Am. If the voltage drops below 9 Volts, it means something is wrong with your car’s battery (undercharging or failure). After disconnecting the load, the voltage should be restored within 5-10 seconds.

Recommendations

First, decide on the type of short circuit:

For example, let's take a simple car. You noticed that the left front parking lamp began to spontaneously go out and light up. Find the wiring diagram in the instructions and familiarize yourself with it. Now look at what wires are connected to your lamp. Start disassembling the problematic circuit, disconnect the lamp itself and check the power. If the problem is not power, then look for the adjacent connector in the circuit; in your car it is located near the left fender of the car. Disconnect this connector, if the power to the light bulb disappears, then connect the connector and after the lamp lights up, it will become clear to you that a short circuit of two phases occurs between the next connector and the lamp.

Now take care of the connector on the left wing, open the circuit and remove the winding from the wiring, take a close look at the wire leading from the connector to the lamp, if you notice a burnt spot on it after a short circuit, start replacing this section of the wiring with a new one, you should have a soldering iron and just solder the required section and insulate it, protecting it from condensation, check the operation of the car.

A self-powered test lamp helps to detect a short circuit. You just need to disconnect the wiring from both ends of the circuit and also inspect the wires to visually determine the place where the burnt wire is. This lamp can detect a ground fault if you disconnect the battery.

Continuity of wires

Before starting any measuring work, it is imperative to check the serviceability of the tester itself.

It happens that the measuring system itself is faulty. To check, the ends of the probes of the measuring device are in contact. If the device is operational, the indicator will display zero or deviate slightly. A slight deviation indicates that the probes and terminals have their own small resistance.

If the multimeter has a sound signal, then the device is set to buzzer mode. This is done by placing the switch on the corresponding icon on the tester body.

The probes are brought to the ends of the part being tested.

Possible tester behavior options:

- A zoom will sound if the wiring is not damaged.

- The cable may be fine, but it is very long. In this case, the resistance of the conductor will be much greater than that at which the sound signal is triggered. The display will come to the rescue and display the resistance value.

- If the indicator shows one, then the resistance value is higher than the permissible range of the multimeter scale. You need to switch to another range and repeat the measurement.

- If the conductor is faulty, the multimeter will not perform any action.

When taking measurements with a multimeter, do not allow the human body to come into contact with probes and wires where there is no insulation.

Operating principle

The analog type of the device does not require its own power supply . Its operating principle is the same as that of an ammeter, and an analog device works best in the range of radio waves and electromagnetic fields. There are induction coils inside the device body, and when the probes touch the conductor, a current begins to form in the coils. The created magnetic field deflects the indicator needle to a certain angle. The magnitude of this angle depends on the strength of the current generated, and the arrow on the drawn scale indicates the measurement value.

Digital devices contain a textolite printed circuit board on which a digital chip , which is responsible for processing the received data. To operate the electrical circuit and screen, digital devices are powered by batteries or an external power source.

Digital multimeters have lower measurement uncertainty and are more accurate than their analog counterparts.

There is a switch on the front panel of the multimeter that selects the measurement mode. The switch sets the scale factor that determines the value on the device scale.

Analog instruments have two types of scale:

- Uniform display.

- Logarithmic exponents.

The uniform scale is very sensitive to overloads, so the switch is first set to a large scale factor value, which is gradually reduced. The logarithmic scale does not have this drawback and has a range of values from zero to infinity.

Thus, the main components of multimeters are:

- Display for showing measured values.

- Connectors for probes and probes themselves.

- Switch for different modes and ranges.

Second hands

New cars are a separate category: all automakers, without exception, pay maximum attention to the cars they sell.

Therefore, their share in fire chronicles is negligible, because:

And it’s a completely different matter for cars that have been in use - who did what with them, how correctly they followed all the instructions, etc. no one can guarantee .

It is quite possible that the car's wiring was treated this way

But even without the “playful hands” of the previous owner, there are a lot of places in a used car that require control:

- High-voltage wiring of older cars often suffers from problems associated with violation of the integrity of its insulation. If in the evening under the open hood in the area of the wiring you notice bright flashes of electrical discharges, replace all high-voltage wires, including the tips, as quickly as possible.

Note! Simply replacing these wires will improve engine stability. Don't forget about the center wire. The instructions will tell you the order of execution and warn against erroneous actions.

Possible reasons

The entire electrical system of a modern car can be divided into circuits of sensors, as well as actuators (drives), which include lighting devices and electric motors. In the first case, some sensor is connected by wiring to the electronic engine control unit (ECU). It is from here that a voltage of 5 Volts is sent to the sensor, which is analyzed and changes depending on the measured parameters.

The consumer circuit includes wiring from the battery, relay, switch, fuse, lamp or other consumer. Each of these circuits only works fully if it is intact.

During the operation of the car, the wires can be damaged due to the following reasons:

- damage from rodents;

- unprofessional installation of wiring;

- mechanical damage, moisture ingress;

- physical wear of wires.

History of development

The appearance of wires in cars is directly associated with three inventions:

- High power rechargeable battery;

- Electric starter;

- Battery ignition.

For reference: The battery and electric starter are a trial-and-error solution for easy engine starting. They simultaneously brought each other under the hood of the car, paving the way for battery ignition and other consumers of electric current.

The modern generation of car enthusiasts, who start the engines of their cars with a half-turn, are unfamiliar and incomprehensible to the problems of age-old motorization. And for the first car owners, the main difficulty was starting the engine.

Today's engine starts at the touch of a button

To say that these were temporary difficulties means to hide a century-old layer of history.

In particular:

- Starting the engine took longer than the trip itself;

- All proposed easy starting schemes - springs, flywheels, compressed air, etc. only made the structure heavier;

- A “crooked starter” caused more injuries to drivers than road accidents.

A popular automobile magazine in the 19th century covered all the more or less noteworthy inventions for starting an engine.

Note! The first component in a car that had wires in its design can be considered a magneto, which was installed on the internal combustion engines of the first cars.

Magneto-electric ignition (magneto in the photo below), discovered in 1864 by inventor Marcus, combined:

- Generator;

- Ignition coil;

- Relay interrupter.

Single spark magnetto

Moreover, in 1875, Marcus himself assembled a car with a gasoline engine and electromagnetic ignition. Today, its only surviving copy is considered the oldest car in Europe, having competed for this role with the car of Karl Benz, which was considered the first-born.

In general, the inventors of those years had to solve a lot of questions and problems. For example, Henry Leland, CEO, also needed to replace the wiring in the car with a more functional one.

School physics course

Any consumer of electric current, powered from an outlet, be it a kettle, an iron or a TV, represents a certain source of resistance, which simultaneously converts the electrical energy of the circuit, which it closes when the plug is plugged into the outlet, into thermal or mechanical energy. If for any reason the circuit closes without the participation of the above devices, a condition will arise for the operation of the so-called Joule-Lenz law, according to which in the section of the circuit where the short circuit occurred, an instantaneous release of thermal energy of enormous magnitude will occur, significantly exceeding the strength of the current flowing through the circuit. damaged area. It is this thermal energy that leads to mechanical and thermal destruction of the area under discussion.

Among other things, serious reasons for a short circuit may be damage to the electrical wiring, the device itself.

A short circuit will be caused by failure to take precautions in time, negligence, or improper use of devices.

Source

Where to begin?

Many drivers, finding themselves in an unpleasant situation, simply do not know where to start looking for a short circuit in the car. For a complete diagnosis, you will need special equipment, which is almost never at hand, so at the very beginning you should perform the simplest steps.

Before checking anything serious, you first need to open the hood and carefully examine the wiring sections located in the engine compartment. Since a short circuit occurs between wires or on the housing, the location of the accident can be easily calculated by visible damage, which serves as the main sign. The identified areas are the first to undergo extended diagnostics.

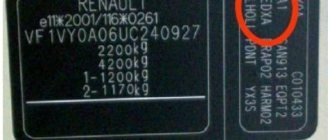

Next, all fuses are checked one by one. They are often the weak link in the chain. In the event of a short circuit, they immediately burn out, protecting the devices connected to this line. The fuses are compactly placed in a special block covered with a lid. Checking the serviceability of each of them is carried out using a multimeter, since visual inspection does not give accurate results.

Before starting to check the elements, the ignition must be turned off and the driver must know how to determine a short circuit with a multimeter. If a faulty fuse is detected, it cannot be categorically stated that the fault has been completely detected. Quite often, the cause of a short circuit is faulty wiring in some part of the circuit.

Device structure

Devices may differ in appearance, but multimeters are fundamentally divided into analog devices and digital devices.

Analogue devices are already gradually being replaced from the market by digital ones, but in the homes of many home craftsmen you can still find analog devices.

Such devices are equipped with an indicator screen with a scale and arrow. The advantage of these models is the clarity of display of measurements. The deflection of the needle is visually easier to assess than the flashing of numbers on the electronic display of digital instruments. Often, when making a call, it is necessary to evaluate approximate resistance indicators or, in general, its presence or presence, so analog devices are suitable for most practical work.

Digital multimeters have more complex electronics and a digital display. This type of device is used mainly in production and industry.

The housings of all multimeters have outputs for two probes. These are two insulated wires ending in needle-like metal tips. In some cases, special clips, so-called “crocodiles,” are put on the nozzles. When choosing a device, you need to pay special attention to the quality of the probes. The correctness of measurements depends on them.

The wires must be flexible with strong soldering and fit well into the device sockets. It often happens that outwardly spectacular probes are of unsatisfactory quality and have poor technical characteristics.