May 11, 2017 Lada.Online 137 543 10

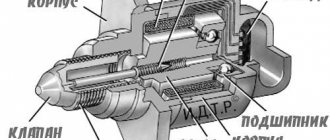

MD tuning stands for throttle modernization. There are quite a few ways to modify the throttle assembly, but this article will discuss the most popular scheme proposed by the American engineer Ron Hutton. According to him, correct MD tuning can increase engine power and reduce fuel consumption by up to 25%.

DIY throttle tuning

The price of MD tuning at a service station is from 3,000 to 7,000 rubles. As the experience of VAZ and LADA owners shows, it is possible to correctly modify the throttle assembly (CS) yourself, without having any special knowledge or precisely verified drawings. The only special tools you need are a 6 mm spherical cutter and a drill.

- Remove the throttle assembly.

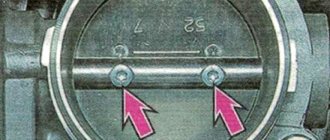

- Make two recesses around the damper (approximately 2-3 mm, no more than 5 mm), as shown in the drawing (great accuracy does not matter).

- Remove burrs with fine sandpaper.

The process is also shown in the video:

The process itself is not complicated and will not take much time. The advantage of MD tuning is that there is no need to flash the electronic engine control unit.

Improved cooling of VAZ-1118 “Kalina”

To reduce the likelihood of airing of the SOD due to jamming of the compensation valve of the expansion tank cap, readers suggested removing the valve from it as a temporary measure. We cannot recommend this method, because the risk of boiling and overheating of the engine increases. But if you decide to go this route, in order to prevent the antifreeze from boiling away at atmospheric pressure, we lower the fan start temperature to 98 degrees programmatically, or we cut an adapter into the radiator inlet pipe for sensor .

A more correct upgrade option has been tested several times and has shown its performance on cars with a cable-operated throttle. We put a plug in the pipe connecting the large cooling circle to the expansion tank;

- We connect the freed fitting to the lower heater hose through the tee from 2110;

- We plug the thin outlet hose (distant, if you look from the front of the car) of the throttle heating.

- We connect the free fitting through a tube of the appropriate diameter to the expansion tank. To do this, we cut an additional nipple into the upper plane, or connect through a tee to a thin input. Thus, we transfer the steam outlet to a small circle, while taking the liquid with air bubbles at the top point of the system.

Thus, we transfer the steam outlet to a small circle, while taking the liquid with air bubbles at the top point of the system. On a car with an electronic pedal (e-gas), we do the same.

- We connect the thin fitting of the thermostat to the upper part of the expansion tank (via a tee or an additional fitting). We turn off the standard thin tube from the thermostat.

- Disconnect and turn off the lower extension hose. tank, in the vacant space we connect a homemade line from a tee embedded in the “return” of the heater.

The problem of air removal is solved once and for all.

We wish our readers warmth in the cabin and stable engine temperature!

Reviews about MD throttle tuning

Advantages of MD tuning:

- The gas pedal becomes more informative (more responsive).

- Increase in power in the range from 1000 to 3000 rpm.

- Reduced fuel consumption.

Disadvantage of MD tuning:

1.

Checking the effectiveness of MD tuning in practice (

cable

):

- The gas tank was filled to maximum.

- We drove about 20 km.

- Once again we filled the tank to the maximum and got a consumption of 2.01 liters.

- We did MD tuning on a throttle body with a diameter of 46 mm.

- We drove along the same section of the road.

- We filled the tank to the maximum (gasoline consumption was 1.61 liters).

Thus, fuel savings after modification of the throttle assembly amounted to about 20%. During the experiment, an increase in low-end power was noted. Watch the experience in the video above from 12 min 30 sec.

2.

Testing the effectiveness of MD tuning in practice (

E-Gas

):

A similar experiment was carried out on a car with E-Gas. Fuel economy in this case was about 9% (was 1.5 liters, now 1.37). There is a faster response to the gas pedal. See also how to adjust E-Gas.

ps If after MD tuning there are problems with idle speed, then most likely the tightness of the closed throttle valve was broken (the chamfers were made too deep).

Have you modified your car this way? What feedback can you leave about MD tuning?

Let us remind you that we previously talked about other modifications that can improve engine performance. For example, installing a PCV valve in the crankcase ventilation system, as well as installing capacitors in the car’s ignition system.

The simplest way to carry out adaptation

Now the question of whether it is necessary to adapt the throttle valve after cleaning should definitely not arise if there were still doubts. The easiest way to carry out the operation is to simply reset the battery terminal. Just to begin with, it is worth warming up the engine well to operating temperature, for which you should take a short trip. Then, turning off the engine, disconnect the negative terminal of the battery and wait. Depending on the brand of car, the waiting time can be 10-30 seconds or 15-20 minutes.

During this period, all ECU parameters should return to the original (factory) settings. Next, all that remains is to connect the terminal and start the engine - the speed should return to normal.

MD throttle tuning

MD-tuning (MD - Tuning) of the throttle valve is nothing more than Modernization of the Throttle. The development of a technological improvement of the unit that regulates the supply of the air-fuel mixture belongs to Ron Hutton from the American company Gadgetman Technologies LLC.

It consists of the following: air, which is usually supplied evenly, is swirled into a vortex flow, which helps create a truly homogeneous working combustible mixture. Fuel and air are intensively mixed with each other, resulting in an almost ideal ratio. Gasoline in this form burns almost completely in the engine chambers without burning out in the catalyst. As a result, the engine power becomes greater, fuel consumption and the content of harmful substances in the vehicle exhaust decreases, and at the same time the dynamics increase.

A vortex air flow is created due to pressure differences in the intake manifold. In the throttle assembly of injection cars or in the mixing chamber of carburetor cars, chamfers of a certain size and shape are made at the desired angle, which create this “hurricane”. This modification does not affect the car’s electronics; the sensors themselves record new data, forcing the car to operate in a new mode (we are not talking about very complex cars stuffed with sensors).

MD tuning can be done on many cars, including Russian VAZ 2110, 2114, Priora. If you try, the groove can be done even on GAZ and ZIL, but there are few instructions for such work, and the owners of such cars are unlikely to be interested in upgrading the throttle assembly. VAZ throttle modifications are popular among car enthusiasts.

A little practice

Those who have already resorted to similar tuning of the VAZ 2112 throttle valve note a change in the dynamics of acceleration. In addition, due to greater oxygen filling of the cylinders, and at the same time an increase in power, fuel consumption is reduced. The savings are insignificant, about 0.5 liters, but subsequently this accumulates into a rather noticeable result. Again, the main achievement of tuning is the increased engine power.

Relatively recently, a new throttle valve appeared on sale, the diameter of which is no longer 54 mm, but 56. This means, in theory, that the engine can become even faster.

The downside of such tuning of the throttle valve of a VAZ 2114, or other models, is the need to reflash the control unit for a new throttle valve. However, what can’t you do to make the car at least a little sportier.

Signs of trouble

The problem with many VAZ 2110s is that until a serious increase in speed, the car remains, as motorists say, in a “sluggish” state, it does not pull, and becomes more or less playful only when the revolutions reach approximately the 3000 mark.

This is very often associated with improper throttle operation. Moreover, the main culprit may be the manufacturer, but more on that later. And now - about some more signs of malfunction:

- engine speed fluctuates;

- there is no clear response from the car when you press the gas pedal;

- when changing gears, jerking can be observed;

- vibration is observed when the car is idling;

- stalls when changing speed;

- The engine does not start well if the car is already warmed up and then turned off.

TaTaPuH031 › Blog › Refinement of the Throttle Unit on the VAZ

During the operation of VAZ cars, many points are revealed that the designers ignored.

For example, the throttle assembly (TS) on some vehicle trim levels has a defect, which can cause a number of problems, such as: the engine stalls when changing gears, the engine starts poorly when the car is warm, engine vibration at idle, etc. A similar omission exists on engines with a metal receiver. If you think logically, then there should be a flow of air from the space in front of the remote control to the space behind it. For this purpose, it has a channel with a diameter of approximately 2.5 mm. There is a hole in the gasket between the throttle assembly and the receiver for this channel. But the problem is that the channel abuts the wall of the receiver. It turns out that at the factory the designer of the throttle assembly foresaw the leakage, but the designer of the receiver simply forgot about it.

The first step is to remove the throttle assembly of the VAZ 2110. To upgrade the throttle assembly you will need a file. Using it you need to make a 2-3mm groove in the indicated location. throttle body VAZ place for grooving in the throttle body; grind the gasket of the throttle body; finalizing the remote control

As a result, this modification of the remote control eliminates some injector diseases, for example, when it is difficult to start when hot. By reducing the vacuum in the receiver, the run-out increased. That is, now you can ride 500m on the highway with zero fuel consumption, and at the same time the speed will drop by 7-10 km/h. In addition, low-end thrust has increased and engine vibrations at idle have disappeared.

Comments 5

… During the operation of VAZ cars, many points are revealed that the designers ignored. For example, the throttle assembly (TS) on some vehicle trim levels has a defect, which can cause a number of problems, such as: the engine stalls when changing gears, the engine starts poorly when the car is warm, engine vibration at idle, etc.

…

This is exactly what they provided for... only during operation, many people change the factory throttle assembly to a new one (not adjusted) and then problems begin (as I had). Perhaps someone's throttle assembly was not adjusted from the factory (and it MUST be adjusted).

… A similar omission exists on engines with a metal receiver. If you think logically, then there should be a flow of air from the space in front of the remote control to the space behind it. For this purpose, it has a channel with a diameter of approximately 2.5 mm. There is a hole in the gasket between the throttle assembly and the receiver for this channel. But the problem is that the channel abuts the wall of the receiver. It turns out that at the factory the designer of the throttle assembly foresaw the leakage, but the designer of the receiver simply forgot about it.

... There is no “omission” there and never has been.

There were receivers for the VAZ-2111 engine of the old model (mainly for the old ECM 2111-1411020-00 Bosch M1.5.4 (without the letter N

); 2111-1411020-21 GM and 2111-1411020-22 January 4 for them and it was yours that was developed throttle pipe) and were of a new type, mainly with ECM 2111-1411020-40, -50, -60, -61, -62, -70, -71, -72. External differences are in the “diamond” and additional fitting (on the s/o) and the absence of these on the s/o. There is a “overflow” and it is adjusted using the throttle valve stop screw. But the channel is needed for completely different purposes and it should NOT be used for you. I wrote a little about this myself.

… As a result, this modification of the remote control eliminates some injector diseases, for example, when it is difficult to start when hot. By reducing the vacuum in the receiver, the run-out increased. That is, now you can ride 500m on the highway with zero fuel consumption, and at the same time the speed will drop by 7-10 km/h. In addition, low-end thrust has increased and engine vibrations at idle have disappeared.

... This is not an “injector disease”, but simply an unadjusted throttle assembly. AvtoVAZ even once sent out a mailing to officials (it mainly affected owners of 2112 engines), which instructed them to either adjust with an adjusting screw or install a special spacer on the stop. But because From the factory, the adjusting screw is “set” on the varnish (I just “set it” on the thread lock), and the adjustment is very complicated; it was prescribed to install the “spacer” on the stop. Your run-out has increased, but your engine braking has worsened, which means you use the brake pads more often. The low-end thrust is unchanged, simply due to the “pre-opening” of the throttle, the “transient processes” change and subjectively the dynamics improve, the mass air flow remains unchanged (the IAC will close for the required number of steps). The revolutions should also remain at the same level.

Correction of a factory miscalculation

It is quite common for a throttle assembly to come out of the factory with something that cannot even be called a defect, but can still be attributed to design errors. In theory, air should flow into the space behind the throttle, for which a channel of approximately 2.5 mm is specially made.

But the whole problem is that this channel was pressed against the wall of the receiver, thus blocking the possibility of air flow. A slight modification of the throttle assembly can help in this case.

This material will help you install engine crankcase protection yourself: https://vazweb.ru/desyatka/dvigatel/zaschita-dvigatelya.html

Bored channel for air flow in the throttle

To do this, just take a file and use it to make a small groove in the indicated place. 2 - 3 mm will be enough. But before doing this, it is necessary to remove the throttle.

Self-cleansing procedure

If the damper is electronically actuated, then it is better to remove the negative terminal of the battery. Next, you can do everything according to simple instructions:

- dismantle the air filter by unscrewing the pipe clamp;

- disconnect all connectors of the throttle module and other pipes;

- move the air filter receiver to the side so that it does not interfere, and begin cleaning the damper;

- upon completion, reassemble the damper module in reverse order, checking that everything is in place;

- After assembly, start the engine and check the idle speed.

In some cases, before you begin to adapt the throttle valve on a Toyota, Nissan or Skoda, it is necessary to remove the throttle itself, which allows you to completely clean the valve. To do this, you will need a 5 mm hexagon to unscrew the 4 fasteners. Removing the throttle should be done with great care, as there is a risk of damaging the gasket.

If, after cleaning the throttle body, increased idle speed is observed, it means that the damper needs to be adapted. What this is is further in the topic of the article.

Dismantling

On a VAZ 2110, the throttle assembly is removed in the following sequence:

- Disconnect the connectors of the sensor that regulates the position of the throttle valve, its drive cable and the XX regulator;

- We partially drain the coolant;

- Next is the removal of the air hose located on the body of the mass air flow sensor. Why do you just need to loosen the clamp;

- We also loosen the clamps: where the throttle pipe is attached to the air hose; where the hose of the 2nd crankcase exhaust circuit is attached to the cylinder head cover pipe. We remove the connected hoses - the air and 2nd crankcase ventilation circuits;

- Having loosened the clamp, remove the hose of the 1st crankcase gas exhaust circuit from the throttle assembly fitting;

- Having loosened the clamps, we remove the hoses supplying and discharging coolant;

- You will need a wrench with a 13mm head, with which you need to unscrew the nuts securing the throttle assembly to the receiver on a VAZ 2110;

- It is now possible to remove the throttle assembly from the studs;

- It remains to remove the sealing gasket and, if your VAZ 2110 has a system that traps gasoline vapors, disconnect the hose for purging the adsorber.

Cleaning

Even if the purpose of removing the throttle was to modify it, still do not forget that for stable operation it also needs periodic cleaning. To be honest, there is nothing complicated in this procedure, but it will help the engine run better, which is quite important.

For cleaning you will need:

- short and long screwdrivers;

- toothbrush (soft, or just old);

- cotton buds;

- cleaning agent;

- rubber or cotton gloves.

For cleaning to give the desired result, it must be carried out very carefully. First, you can go through all the cavities with a toothbrush, at the same time cleaning the idle speed control (it must also be removed). Further, more delicate, cleaning is done with cotton swabs. Pay special attention to the area where the throttle valve is located and the place where the XX regulator fits.

Please note that cleaning the crankcase ventilation duct with conventional means is not possible, but it can be easily done using the foot pump available in each trunk. The diameter of the fitting is similar to the wheel one, you just need to add cleaning agent and pump your foot several times.

Let's sum it up

Taking into account the above information, it becomes clear that the throttle valve is an important element of a fuel injection engine. At the same time, it is a mistake to believe that the throttle assembly does not require regular maintenance.

Moreover, although the manual recommends cleaning the damper every 35 thousand kilometers, it is important to make allowances for the operating conditions of the vehicle. As a rule, even in cities, roads in the CIS countries are not clean, and the air is quite heavily polluted. If a car drives on dirt roads, air pollution increases significantly.

It is also necessary every 30-40 thousand km. completely remove the throttle assembly, deep clean it, at the same time clean the sensors and electrical connectors, check the condition of the corrugations, pipes, etc.

Finally, we note that you need to constantly monitor the condition of the throttle and regardless of whether there are any problems with the engine. This approach will allow not only to achieve stable operation of the internal combustion engine, not to lose engine power and not to consume excess fuel, but also to increase the service life of the power unit.

Source: krutimotor.ru