A generator in any car, even a diesel one, is a real general manager of the engine. Without it, the car won't move. It can be a shame when the engine works well, but the electrical equipment begins to malfunction. If we talk about the six, then most likely it contains the G 221 generator, which was also equipped with the Fiat 124.

If you compare the electrical circuits of the VAZ 2101 and VAZ 2106 cars, it becomes obvious that they are almost the same. The six only has a few additional electrical devices. However, the generator there is the same. That is the problem. The fact is that initially the G 221 model was not intended to serve such a number of energy consumers. As a result, the relay-regulator receives insufficient current, the battery is undercharged and slowly dies.

The problem gets worse when the car owner installs additional devices, such as:

- Fog lights;

- Good audio system;

- Preheating before starting;

- second stove, refrigerator, TV, etc.

In general, any step that increases energy use can make the battery prone to drain even while you're on the road. If modifications are still necessary, then you will have to install a more stable and powerful generator G 222.

Electrical systems of VAZ 2106

The electrical circuit of the VAZ sixth model includes a number of systems that ensure the operation of consumers in different parts of the car. This:

- ignition system;

- control and lighting system;

- cigarette lighter operation system;

- engine starting system;

- carburetor solenoid valve control system;

- windshield wiper and washer system;

- heating system;

- sound signal system;

- component of the engine cooling system;

- system of indicators and status sensors.

The ignition system includes an alternating current generator, a rectifier unit, a current distribution system, spark plugs, fuses and a number of supporting elements. The system removes low voltage current from the generator brushes, converts it into high voltage current in transformers and, in accordance with the firing order of the engine cylinders, supplies it to the spark plug. The converted current must have enough energy to create electricity inside the engine cylinder and ignite the working mixture.

Control and lighting devices include all lighting devices, such as front and fog lights, interior lighting lamps, trunk lighting lamps, as well as additional lighting elements installed. This also includes turn signals, brake lights, side lights and others.

In general, these devices are an important part of ensuring compliance with traffic rules, and therefore are constantly powered either through the battery or through the generator and are turned off last. The same applies to the sound signal system, which provides clearer information to other road users about changes in the situation on the road.

The engine starting system includes a battery and a number of elements that supply high current to start all consumers and rotate the engine shaft to starting speed. When the crankshaft reaches this frequency, the alternating current generator comes into operation - now it powers all consumers and charges the battery.

For satisfactory operation of the fuel supply system at high speeds, the VAZ 2106 carburetor is equipped with a solenoid valve. It regulates the operation of the internal combustion engine at idle and operating speed. To control it and synchronize its operation with the operation of the engine, the electrical circuit has its own separate system. It is recommended to download the VAZ 2106 electrical diagram and familiarize yourself with its operation.

The engine cooling system fan control system ensures consistently normal thermal operating conditions for the internal combustion engine and increases the service life of the most expensive part of the vehicle. Indicators of the vehicle's operating status are connected to sensors installed in critical places on the VAZ 2106. The indicators take readings by converting physical quantities into an analog or digital signal, which is processed and sent to the indicators. From the latter, in turn, the necessary information can be read.

The VAZ 2106 has several electrical equipment systems designed to make life easier for the driver and increase driving comfort. These include windshield wipers, heater, defroster, cigarette lighter and others. Some of them are useful, others were created on the principle of “so it was.” Which one to use is up to the owner to decide, but the very fact that there is a choice is pleasing.

The electrical circuit of the VAZ 2106 car is very ramified and it is not possible to describe it all in one article. If there is a desire or there is a need to deepen and expand knowledge about the most popular car of the Union, it is strongly recommended that you familiarize yourself with special specialized literature or, at least, with a photo of the electrical circuit diagram.

How to connect a VAZ 2106 generator. Connection diagram for a generator on a VAZ Classic

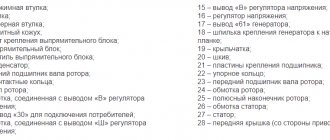

This generator connection diagram is useful for cars from 21214, 2110(12), 2108, 2107.

Fig. 1 Shows a diagram of connecting a generator to a VAZ 2101 (G-221) car

_4 – ignition switch, 1 – battery, 3 – voltage regulator, 2 – generator, 5 – fuse block, 7 – RS-702 indicator relay, 6 – battery charge indicator lamp._

Fig. 2 According to this scheme, the generator of a VAZ 21214 car is connected if the wiring base is from a VAZ 2101

_1 – battery; 2 – generator; 3 – ignition switch; 4 – fuse block; 5 – battery charge lamp. 6 – diode (in5007) any diode will do. 7 - resistor 51 Ohm 5 W (5W51RJ)_The housing for the resistor and diode is made from an unnecessary RS-702 relay.

We don't need the orange wiring.

You need to bite off the (black and white) wire from the charge lamp, solder a new one instead, which connects to fuse 9 or 10.

How to install and connect a new generator on a VAZ 21012106

The reason for replacing a generator is the combustion of its windings, inter-turn short circuit, aging of the housing, which leads to its breakdown, etc. sometimes the power of the generator is low, and for this reason it needs to be changed.

There are situations when, when upgrading their car, they install powerful amplifiers and additional gadgets that consume energy; in this case, the standard generator is not enough, and it must be replaced with a new and powerful one.

Now let’s take a closer look at what you can replace the standard G-221 generator with:

- To begin with, you can use a generator with a VAZ 2105, which produces a current of 55 Amps, but this is not the most powerful option, it is good in cases where there is not a very large amount of equipment. But the good thing about it is that when installing it, you don’t need to redo the mount on the case; you just need to slightly alter the electrical system to accommodate it.

- The next option is to use a generator from a VAZ-2106, which produces 55 Amperes, which is again sufficient when there is not a lot of additional electronics.

- The third option will be a standard generator, for the VAZ 21074 generator, it is marked 372.3701-03. It can produce approximately 73 Amperes, where there are many more accessories than in the previous two options; the installation does not differ much from the previous version of the generator.

- The fourth option is to install a generator from a car like a Niva, its power is about 80 Amps, and it can satisfy a very large number of electronics, additional amplifiers, and LEDs. Installation requires more changes than in other cases.

- The last option is that the standard generator can be replaced with other models of foreign cars, hybrids, but most often Chinese generators. These five methods are considered the most common.

- Now let's talk more specifically about installing a generator from a VAZ 21074 on a VAZ 2106 (2101). Quite often they choose model 2107-37011010; it is good because you can easily find spare parts for it. Quite a lot of bad things are written about the K1216Eh2 relay-regulator; it is bad because the relay does not change the charging voltage to a dependent ambient temperature.

What is needed for maintenance

Very often a malfunction occurs such as excessive wear of bearings. As a rule, the one located in the front cover fails. You can even detect a breakdown by hearing. A loud whistle indicates its failure. The reason that it is in the front cover that the bearing fails is that it is subjected to a very large load. After all, it is on this side that the belt is located.

The 2106 generator's brushes, made of graphite, are in constant contact with the rotor. Their strength is quite high, but despite this, the effect of friction makes itself felt. Therefore, they need to be replaced with new ones from time to time. If this is not done, the field winding will not work.

No power is supplied to it, and the magnetic field that is necessary to generate electricity is not created. It happens that the excitation winding, or one of the stator windings, begins to “short” to ground. To verify this, it is necessary to completely disassemble the VAZ 2106 generator, and then use a multimeter to test all windings without exception.

You should have at least an idea of how to check the windings for breakdown. Please note that there must be a certain resistance in the stator, depending on the generator model. If there is no resistance, there is a short circuit to the device body.

Choose your own way out of this situation. You can either rewind the stator winding, replace it completely, or install a new power source. The price of a new one, of course, is rather high - about 3000-3500 rubles. You can buy it at a dealership for three times the price, but will it work properly?

Understanding the reasons for charging problems on the VAZ 2106

To check the electrical circuit of a car, you need a simple multimeter or voltmeter. The most common reasons for low charging voltage are:

- The generator belt tension is too weak or too worn;

- generator malfunction (worn brushes, faulty diode bridge, broken or burnt stator or armature coils);

- voltage regulator malfunction;

- shaving in charging area.

The most common cause of charging failure is a malfunction of the voltage relay. In order to verify its usefulness, it will be enough to remove the grudge from the grudge, put it together, and start the engine. Because of the fact that all other elements of the lance are attached, the voltage in the lance is close to 17 or more. If the voltage does not increase, then it is necessary to check the presence of 12 V at the terminal connected to pin 15 of the relay regulator. If necessary, check the lance, which confirms the lance and the very integrity of this lance.

If the device is connected to this terminal, it is necessary to check the connection in the generator wake-up circuit. Connect the test lamp between the 12 V rechargeable battery and the dart, which connects to connection 67 of the voltage regulator relay. In this way, you can check the voltage relay-generator circuit, as well as check the generator brushes and armature windings. If there is no voltage at the lamp pins, worry about a malfunction of the direct bridge.

Next, check the serviceability of the conductor from the generator to the relay regulator. For such verification it is necessary to disconnect the terminal from the generator and connect it to -12 Art. The indicator light is on to indicate faulty brushes or broken armature windings. If a malfunction of the generator is suspected, it should be removed from the vehicle and examined further. Next, check the integrity of the diode in the diode bridge of the generator, check the continuity of the stator coils and armatures for damage or burnout. Faulty elements must be repaired or replaced.

The VAZ 2106 battery charging circuit shows a constant voltage of 13.5 to 14.3, regardless of engine speed. However, there are breakdowns when the voltage on the middle turns of the engine noticeably “sags” when the additional voltage is turned on. If such a phenomenon occurs, it is necessary to check the tension of the generator belt and adjust it. Weak contact at the battery terminals can also lead to this effect.

Since the voltage at the battery terminals is higher than the specified values, you need to check all contacts, starting from the positive terminal of the battery to the voltage regulator relay. If all contacts are normal, then the relay regulator prompts replacement.

Keeping an eye on your car's electrical system, the contacts and terminals of the battery, regularly checking the belt tension and the level of the electrolyte in the battery will allow your car's engine to run smoothly and without problems, and you will avoid a bug atoch malfunctions in dozі.

Diagnosing charging relay faults

First of all, it is necessary to check the integrity of fuses No. 9 and 10, as well as their secure fastening in the fuse block.

If, after replacing the fuses, the VAZ 2106 still does not charge the battery, then you should continue troubleshooting.

Next, you need to check the integrity of the generator drive belt and its tension. If the belt is not torn and its tension is normal, then you need to check the condition of the drive pulleys. When the inner surface of the pulleys wears out, the alternator belt simply begins to slip, which will also contribute to the incomplete charging of the battery or there will be no charging at all. You can check this visually by looking at the inside of the pulley. If it shines, it means the belt is slipping and it was he who polished the inside of the pulley.

The next reason why the battery may not charge is poor contact at the battery terminals or their oxidation. The unreliable contact is tightened, and the oxidized terminals must be treated with a solution of soda and water. Soda neutralizes the oxide, after which the terminal must be rinsed with water and wiped well. To ensure that the remaining oxide is removed with fine sandpaper. Then the terminal must be lubricated, for example with Litol 24 grease. A similar operation must be done with the terminals themselves. There is no need to sand the terminals or scrape them with a knife. They are very malleable, since they are cast from lead, and three or four such procedures will noticeably reduce their diameter, which will make it impossible to properly tighten the terminals, and therefore there will be no reliable contact between them. Entrust this issue to soda and it will perfectly clean the terminals of oxide.

Replacing the generator yourself

Typically, the VAZ 2106 generator must be replaced only in the most exceptional cases, and in case of most malfunctions it is simply repaired.

But if this device on your car has completely failed and cannot be repaired, then it is necessary to replace it.

To make this repair procedure as simple as possible, below is a list of necessary tools that will help make this operation easier:

- Keys for 17 and 19

- Heads for 10, 17 and 19

- Ratchet handles and knobs

- Extension with universal joint

The procedure for removing and installing the generator on a VAZ 2106

Before attempting this repair, disconnect the negative battery terminal. Then you need to disconnect all power wires from the generator itself. First you need to unscrew the terminal securing nut:

Now you can pull out all the other wires and plugs, just pull them to the side with a little effort:

Loosen and completely remove the alternator belt.

Then we tear off the upper mount of the generator with an ordinary open-end wrench 17, and after that we throw on the head with an extension and a cardan joint to unscrew this nut quickly and without unnecessary effort:

Next, you need to crawl under the car from below and tear off the nut with a spanner wrench and unscrew it completely using the ratchet handle:

After the nut is completely unscrewed, you need to knock the bolt out. To do this, you can use a wooden block, pointing it at the bolt and hitting it several times with a hammer. The photo shows it without a block, but keep in mind that the backing must be present so as not to damage the thread:

After which the bolt can be pulled out by hand. If it is difficult to move, you can resort to penetrating lubricant, spraying it a little in the right place.

Then you can remove the generator from below, as this is more convenient. If it doesn’t give in right away, you can turn it a little in the right direction so that nothing gets in the way when removing it. This is roughly what it looks like in practice, as shown in the photo below:

The price of a new generator for a VAZ 2106 varies from 2,500 rubles and above, it all depends on your wallet. The replacement process is not complicated and installation occurs in the reverse order of removal.

Source: https://vaz2106-remont.ru/zamena-generatora-svoimi-silami/

VAZ 2106 car charging diagram

The VAZ 2106 charging circuit consists of a fairly small number of parts:

- three-phase synchronous generator with excitation winding;

- diode rectifier (combined in the same housing with the generator);

- accumulator battery;

- voltage regulator relay (mechanical or electronic);

- charging indicator lamp relay;

- battery charging indicator light.

The generator is driven from the crankshaft via a V-belt drive. A rectifier built into the generator converts its current into direct current. Next, the voltage regulator relay maintains its value in the range from 13.5 to 14.3 V. Old type relay regulators worked on the principle of mechanical closing and opening of contacts depending on the generator voltage. Such devices required additional adjustments during operation.

The modern VAZ 2106 charging relay circuit includes an electronic voltage regulator, built entirely on discrete elements, and does not require additional intervention in its operation throughout its entire service life. However, the use of such devices requires additional safety measures. Thus, when the engine is running, it is prohibited to remove the terminals from the battery in order to avoid damage to the new model relay regulators.

The warning lamp relay, which provides an indication when the battery charging voltage is lost, is a conventional electromagnetic relay with normally closed contacts. One terminal of the relay coil is connected through the ignition switch to the positive terminal of the battery. The other contact is connected to the +12 V terminal of the generator. The normally closed relay contacts are respectively connected to the +12 V battery (via the ignition switch contacts), and to the warning light.

When you turn the key, battery voltage appears at the relay contacts and the charging lamp lights up. When the engine is running, voltage appears at the output of the generator, which is supplied to the terminals of the electromagnetic relay. When a value of about 7.5 V is reached, the magnetic field of the solenoid increases so much that it attracts the armature, and the contacts through which voltage from the battery is supplied to the charging lamp open. The warning light goes out.

Generator belt

Of course, the G-221 will not work without a drive belt. The belt for the VAZ 2106 generator is 10 mm wide and 940 mm long. It is wedge-shaped and toothed in appearance, which allows it to easily cling to the teeth of pulleys.

The belt resource is designed for 80 thousand kilometers.

The belt is made of high-strength rubber and is designed for a long period of operation.

How to tighten a belt

Tensioning the alternator belt after installing it is considered the final stage of work. For fast and high-quality work, you will need to comply with the factory tension regulations:

- Loosen the self-locking nut (on the top of the generator).

- Loosen the lower generator fixing nut.

- The body of the device should move slightly.

- Insert a pry bar between the generator housing and the pump housing.

- Move the pry bar to tighten the belt.

- Without releasing the mount, tighten the self-locking nut.

- Then check the belt tension.

- Tighten the bottom nut.

Eliminating the causes of charging failure on the VAZ 2106

To check the electrical circuit of a car, you need a simple multimeter or voltmeter. The most common reasons for loss of charging voltage are:

- the generator belt tension is too weak or it is worn out;

- generator malfunction (brush wear, diode bridge malfunction, break or burnout of stator or armature coils);

- voltage regulator malfunction;

- break in the charging circuit.

The most common cause of charging failure is a faulty voltage relay. In order to check its functionality, it will be enough to remove both wires from it, connect them together, and start the engine. Provided that all other elements in the circuit are good, the voltage in the circuit will reach about 17 V or more. If the voltage does not increase, then it is necessary to check the presence of +12 V at the terminal connected to pin 15 of the relay regulator. If it is missing, check the fuse responsible for the circuit and the integrity of this circuit itself.

If there is power at this terminal, then you need to check the connections in the generator excitation circuit. Connect a test lamp between +12 V of the battery and the wire that is connected to terminal 67 of the voltage regulator relay. In this way, you can check the voltage relay-generator circuit, as well as the serviceability of the generator brushes and its armature windings. If there is no voltage at the lamp terminals, an assumption is made that the rectifier bridge is faulty.

Next, check the serviceability of the conductor from the generator to the relay regulator. To do this check, you need to disconnect the terminal from the generator and connect it to -12 V. The glow of the control lamp indicates faulty brushes or broken armature windings. If a generator malfunction is suspected, it is removed from the vehicle and completely disassembled. Next, the serviceability of each diode in the diode bridge of the generator is checked, and the stator and armature coils are tested for breakage or burnout. Faulty elements are repaired or replaced.

The VAZ 2106 battery charging circuit provides for a constant voltage of 13.5 to 14.3 V, regardless of engine speed. However, there are cases when, at medium engine speeds, the voltage noticeably “drops” when an additional load is turned on. If such a phenomenon occurs, it is necessary to check the tension of the generator belt and adjust it. Poor contact at the battery terminals sometimes also leads to this effect.

If the voltage at the battery terminals is higher than the specified limits, you need to check all contacts, starting from the positive terminal of the battery to the voltage regulator relay. If all contacts are normal, then the relay regulator must be replaced.

Timely care of the car’s electrical equipment, the condition of the battery contacts and terminals, and regular checking of the belt tension and electrolyte level in the battery will allow your car’s engine to operate for a long time and without problems, and you will avoid many malfunctions on the road.

Repair of under-hood power plant

Removing the generator is a simple procedure. However, to perform it you will have to crawl under the car. In addition, it is better to remove the battery in advance, as it will interfere with unscrewing the nut securing the device to the adjustment bar.

- We roll the car into a hole or lift the right front part of the car with a jack and place bricks under it. Don't forget to put the car in gear or put the handbrake on.

- We remove the crankcase protection if it interferes.

- Slightly unscrew the nut of the lower mounting of the generator.

- We get out from under the car and loosen the nut on top that secures the unit to the adjustment bar.

- We push the generator towards the engine and remove the drive belt, first from the pump pulley, and then from the generator and crankshaft pulleys.

- We finally unscrew the nut securing the unit to the adjusting bar and remove it together with the washer.

- We climb under the bottom again, unscrew the cap of contact “30”, then disconnect the remaining wires and remember where to plug them in later. If the memory is bad, we mark everything with a marker.

- We finally unscrew the nut securing the generator from below, remove the bolt with one hand, and support the device with the other so that it does not fall.

- We pull the generator down, after tilting it.

It must be remembered that when installing a new device, it is extremely important not to mix up the wires. It should be noted that pin “67” and the wire leading to it do not have insulating pads.

Repairing a VAZ generator is not a very simple matter. To overhaul the unit, you need to have many special tools for disassembly and diagnostics. Therefore, it is better to entrust such an operation to specialists who have all the necessary equipment.

Without special knowledge and pullers, only replacing the generator brushes is possible. To perform this operation, you need to find contact “67” on the back cover of the unit. Directly below this contact there is a brush holder secured with just one screw, which must be unscrewed. Now we pull out the brush holder, check the condition of the brushes and the distance at which they protrude from the device. If this indicator is less than 12 mm, the brushes must be replaced.

Attention! Before reading and using this wiring diagram, read THIS BZ entry. It describes a problem that arose after six months of using this scheme.

The idea of replacing a generator on a six is as old as the world because the native 42-amp G-221 is no longer enough for everyone who installs more energy consumers on their car than a weak Chinese radio. And those who don’t install it are probably annoyed by the dim low-beam headlights at idle and poor battery charge. So, let's begin: There are many alternatives to a native generator, since with the proper skills, means and desire, you can install any generator. In this article I am considering only “budget” VAZ generators from other models, because: a) They are the cheapest. b) They are the most common, so you will not have problems replacing them, finding components for their repair, and searching for them themselves. c) They are easier to replace - you don’t have to look for or make all sorts of specific fasteners and completely redo the electrical system.

The principle of operation of electrical equipment of the VAZ 2106

The ignition switch has 4 positions, when each of them is activated, certain connectors and contacts are switched:

- In position “0”, the battery current is transmitted only to connectors 30 and 30/1, the others are de-energized.

- In position “I”, current is supplied to connectors 30-INT and 30/1-15, while the “dimensions”, windshield wiper, and fan heating system of the heating complex are energized.

- In position “II”, contact 30-50 is additionally connected to the previously used connectors. In this case, the ignition system, starter, panel sensors, “dimensions” and “turn signals” are included in the circuit.

- In position “III” only the “dimensions”, horn and windshield and stern wipers are activated. In this case, the current is available only to connectors 30-INT and 30/1.

A number of cars of this brand are equipped with such devices as a rear window heating complex, an electric windshield washer, a light relay, etc. The power supply to these gadgets is supplied via a separate line through the ignition switch at the key positions “I” and “II”.

Important: because The washer tank is made of PVC material and is a dielectric, then the electric motor is additionally equipped with a negative wire and when working with it it is necessary to use dielectric protection on the connectors

In the “six”, the following power circuits operate continuously under current: horn, brake lights, emergency lights, cigarette lighter socket, “carrying” plug, instrument lighting. The leading circuits of the electrical equipment of vehicles are subject to protection by fuses, which are located in two special blocks (main and spare), located on the driver’s side under the dashboard.

One of the elements of the VAZ 2106 wiring diagram is a safety block, the design of which does not meet modern requirements for the maintenance of electronic equipment. Flaws:

- an unstable connection between the fuse and the socket leads to the appearance of burnt spots;

- during operation, the safety element is subject to heating, which negatively affects the nearby fastening sockets;

- the low cost of replaceable fuses does not guarantee their reliability, so checks of this unit should be carried out regularly.

Using the so-called "bugs" can lead to a vehicle fire, because there is a high probability of committing a short circuit. There is a completely safe option for upgrading standard products, in which blade fuses must be installed, the seats of which are perfectly integrated into the safety block.

Advantages of blade fuses:

- stable contact of the product with the mounting location;

- the fusible type element is sealed in a transparent PVC casing;

- dynamic heat dissipation due to the increased contact area.

Important: the “six” generator unit, the wiring to it, as well as to the battery, starter, bobbin, optics relay and some other elements are not equipped with safety elements

Regulator replacement

- The regulator is located on the left mudguard. Unscrew the fastening nuts and remove the device.

- Disconnecting the wiring

- We install the new regulator, connect the wiring to it in the same way as they were installed on the previous device. Tighten the fastening nuts.

Electrical equipment of the VAZ sixth model

If you look at the electrical diagram of the VAZ 2106 in its complete form, you will immediately notice the connection made according to the single-wire principle. That is, all equipment is connected to the current source in series from its “plus”, and the role of “minus” is taken by the car body or “ground”. This became possible due to its large mass and large capacity. The body has become a kind of conductor connected to the “minus” of the battery. This approach made it possible to increase the level of safety when operating electrical equipment, and also significantly saved on wiring, because it was now needed in half.

Now this will not surprise anyone, but this was not always the case. Yes, the VAZ 2106 was not the first car in the world with such an electrical circuit, but it was the first truly mass-produced one in the USSR. A battery and an alternating current generator are used as a current source for the operation of VAZ electrical equipment. The current from the battery is used when starting the engine to crank the crankshaft and to create a spark in the spark plugs. The current from the alternator is converted by a rectifier system into a current acceptable for the vehicle according to its characteristics and is supplied to the system to consumers during engine operation, as well as to the battery to compensate for losses when starting the engine.

Unfortunately, this design removes some of the payload from the crankshaft, reducing power output. However, you have to get electricity from somewhere, right? After all, the battery, due to a number of purely physical reasons (slow charging, unstable current strength, huge disproportion between capacity, weight and size, and so on), is not capable of providing all consumers with current.