If you are faced with the problem of how to unscrew the crankshaft pulley bolt, this article is for you. We will describe this process in detail so that you can quickly and easily remove the crankshaft pulley and then begin repairing it.

A knowledgeable motorist usually spends no more than a quarter of an hour on the process of dismantling the crankshaft pulley. But inexperienced drivers, when trying to remove this part on their own, are faced with many problems that they often simply cannot solve. The instructions for carrying out repair work and maintenance of any modern vehicle contain comprehensive information about the dismantling process, but, unfortunately, it does not help car enthusiasts.

First of all, difficulties arise with fixing the crankshaft. It is very difficult to dismantle it if the part is constantly rotating, “slipping” out of your hands. It is also not clear to many from which side to approach the bolt that holds the pulley. And its strong tightening usually makes the process of removing the unit very, very difficult, since dismantling under such conditions is fraught with damage to the body covering or elements of the car’s engine compartment.

All car manufacturers and car service specialists use great force to tighten the nut or bolt of the crankshaft pulley (on some vehicle models the mechanism is supported by a bolt, in others by a nut).

This is done specifically to avoid self-unwinding of this part during vehicle operation. If a bolt (nut) falls out while driving, it will not be easy to bring the car back to life in order to continue driving it, and the repair itself will cost, believe me, a pretty penny. In addition, the described fasteners increase their tightening level independently when the engine is running. And the final “indestructibility” of the bolt is given by the phenomena of coking, sticking, and corrosion.

Reasons for replacement

The crankshaft pulley is located on the right side of the engine compartment and is best accessed from below

Before proceeding directly to the process, it is necessary to consider the main reasons why it may be necessary to dismantle this part. In fact, everything is much simpler than it seems. So, let's look at the main reasons for dismantling:

- Major repairs will require removal of the pulley.

- Wear of the product (wear or broken teeth).

- Some repair operations will require dismantling the pulley ( setting valve timing , etc.).

Should we unscrew the crankshaft pulley?

So, when the reasons are considered, let's proceed directly to the process itself. It is worth noting that this operation cannot be completed alone, so you need to ask for help, in other words, you will need an assistant . Let's consider the immediate sequence of actions for removing the crankshaft pulley:

- We place the car on a pit or overpass.

- We dismantle the front right wheel. The car must be well secured in this position, since when unscrewed it may fall off the jack. Therefore, you need to install a stump under the threshold, and anti-roll bars under the rear wheels; you can use the removed wheel.

Car after wheel removal

Remove the plastic fender liner by unscrewing the 5 fastening screws

Generator drive circuit

We insert a crowbar into the flywheel so that it does not rotate when the nut is unscrewed

It is worth noting that the cutout on the crankshaft pulley, during installation, must coincide with the protrusion on the crankshaft itself.

Reverse actions

After removing the pulley, you can carefully examine it and put it aside for garage scrap metal. Take the new part in your hands and lubricate the key seat well with grease. Slightly tilting the key towards the hub, we slowly push the pulley onto the shaft. For this purpose, you should have a hammer in one hand, and in the other a piece of soft rubber, which is placed between the hammer and the body and prevents the hammer from damaging the crankshaft pulley.

Once the hub is in place, you need to tighten the fixing bolt. This must be done without any tricks: a wrench and a pipe will help tighten this bolt until it stops. To avoid turning the crankshaft when you begin to apply significant force to tighten the bolt, you need to lock it using a metal pin (large screwdriver), inserting the latter between the teeth of the flywheel ring. To do this, you need to open the clutch housing ventilation plug.

It is not recommended to tighten the bolt to the limit; you may miscalculate the effort and break it, and this is almost a disaster. To do this job correctly, you will need a torque wrench. As soon as the sensor shows a tightening torque of 400 N/meter, no further force is allowed.

Crankshaft pulley selection

The standard crankshaft pulley is steel. There are complaints about him. Therefore, when replacing it, many owners install a cast iron pulley. Moreover, cast iron is a little cheaper.

The cast iron pulley is on the left, and the steel pulley is on the right.

What's stopping you from removing the mechanism?

So, diagnostics showed that the crankshaft pulley needs to be replaced. In any book on car repair, this procedure is described very briefly, which makes you think about the simplicity of the operation. However, it is not.

The process is complicated by the inconvenient location of this pulley under the hood of the car. The mechanism is hidden behind the generator. Access to it is severely limited. Pulleys can be damper or conventional - the former are equipped with an outer ring to dampen vibrations. In order to gain access to the pulley mounting, loosen the belt tension bolts on the accessory drives. When dismantling, care must be taken with regard to the application of force. It is important not to break the elements that surround the pulley.

When installing a pulley at the factory, it is clamped with a bolt or nut with great force to ensure reliable fastening. During operation of the internal combustion engine, the right-hand thread on the crankshaft and, accordingly, the nut or bolt of the pulley further strengthens the clamping. High temperatures, environment, time - all this accelerates the destruction process. It is also worth adding oil exposure and corrosion. It can be quite difficult to unscrew the crankshaft pulley nut without knowing special techniques.

If you disengage the clutch, you can easily turn the crankshaft with a key. Therefore, before trying to unscrew the nut, you need to securely fix the pulley - this will prevent rotation while unscrewing the nut. The service station has special devices for this - the element is screwed into the technological holes and a stop is formed against turning.

If there are no devices, then the problem is solved by reliable wheel chocks and engaging fourth gear at the gearbox. You can also secure the flywheel with a large screwdriver or pry bar.

Possible faults

Removal and, if necessary, replacement of the pulley may be required in the following cases:

- If the hub has turned. It must be said that most often this happens due to previous inept repairs. The fact is that the VAZ 2110 has a fixing sleeve in the seat for the damper, pressed into the gear. It tends to fall out of the gear, causing the hub to rotate;

- Oil leaked from under the front crankshaft oil seal;

- The lightweight crankshaft began to resonate strongly;

- The old-style pulley or damper is loose;

- The damper seat broke. In case of such a breakdown, a replacement is needed, preferably together with the crankshaft gear;

- If it is necessary to remove the crankshaft - for repairs, replacement of liners, half rings, converting it into a lightweight one, etc.

Installing a new timing belt

We check that the marks on the camshafts and crankshaft match. We install a new timing belt. If there are no directional arrows, put it so that the inscription is read from left to right.

The right, or descending, branch of the belt should be tight. You can turn the right camshaft clockwise a few degrees, put on the belt and turn it back. In this way we will stretch the descending branch. The tension roller has two holes for a special key. You can find it in any auto store. The issue price is 60 rubles. To tighten the timing belt, insert a special key and counterclockwise . Since there is a lot of controversy about tensioning the timing belt, let's write it this way: a tensioned belt should not have a sag between the camshafts of more than 5 mm when pressed and 7 mm on the longest branch (specially experimented).

Remember: an overtightened belt reduces the service life of the pump, and an undertightened belt can lead to cylinder head repair. (photo below)

We check all the marks. We turn the crankshaft two turns and check the marks again. If the pistons and valves do not meet and the marks coincide, then accept my congratulations. Then we put everything back in place in the reverse order of removal. Don't forget to tighten the bolts. We tighten the service belt roller with the same wrench as the timing belt tension roller. Fill with antifreeze and start the car. We wish the belt many years of service, but don’t forget to check it periodically; after all, it was made in Russia.

Removing the damper

On a VAZ 2110, the damper is removed in the following sequence:

- Disconnect the ground from the battery;

- Remove the radiator fan and fluid coupling;

- After loosening the bolts securing the fan pulley, remove the belt;

- It is advisable to remove the radiator, but if it does not interfere, you can leave it, protecting it from damage from the engine compartment with a sheet of plywood or cardboard;

- Remove the pulley from the radiator fan;

- We gain access to the damper, unscrew the bolts, dismantle it;

- When removing the hub, you need to secure it from turning (for which there is a special tool).

Next we proceed depending on the purpose of the analysis. If you only need to replace the damper, we do it and assemble everything in the reverse order.

You should know that replacing the liners on a VAZ 2110 can be done either with or without removing the crankshaft. But this requires a special device, and besides, it is better to entrust such work to an experienced mechanic - a mechanic.

conclusions

Dismantling the crankshaft pulley on a 16-valve VAZ-2112 engine is quite easy and does not require special knowledge. The only nuance remains safety precautions, since the car can jump off the jack both when unscrewing and when tightening the fixing nut.

If there is a spare pulley, then the old one can be torn off with screwdrivers, a chisel, etc., otherwise our services usually don’t have anything in stock, they will pull off the old pulley anyhow, damage the teeth on it, and then they put it back and the timing belt starts crawl and get eaten. I had such a case recently in Autoworld. The universal puller looks flimsy, but everything is made of steel, which will tighten no worse than screwdrivers. As for the new method, I doubt it will work, and it’s not clear what kind of hole in the gear we’re talking about? If the hole is a seat for the crankshaft, then no tap will be able to be driven there. If the hole is a hole from which the landing tube under the generator pulley sticks out, then it still needs to be freed, and then the hole there is only 4-5 mm, and the thickness of the pulley in the place of this hole is no more than 5 mm, then the internal cavity. Accordingly, the machine tap will be short and its threaded part will come out of the hole without having time to rest not only on the end of the crankshaft, but on the silumin cover of the oil pump. And if you manage to find a super long tap with a threaded part of 15-20 mm (which is unrealistic), then it will either damage the pump cover or may itself break off in the gear. In any case, the gear is already thrown away. It’s easier then to cut two holes in the gear, drive the studs there, put a plate with a bolt on the studs, and resting the bolt against the generator pulley bolt screwed into the crankshaft, tighten the gear. But this turns out to be actually a one-time homemade puller made directly on the body of the gear. The gear is still thrown away. Now, when I change the crankshaft oil seal or pump, I buy a new pulley (price 50 rubles) so as not to be gentle with the old pulley and at the same time change the crankshaft pulley.

Source

Video

This video contains useful tips on how to unscrew the nut securing the pulley to the crankshaft of a car engine.

An option for unscrewing the crankshaft pulley bolt using a poly V-belt.

How to remove the crankshaft pulley on a VAZ (2108, 2109, 21099, 2110, 2111, 2112, 2113, 2114, 2115).

How to remove the crankshaft pulley bolt. Bolted connection.

How to tighten a crankshaft pulley very quickly.

Removes the crankshaft pulley on a Honda car without a special key.

We unscrew the crankshaft pulley on a VAZ-2112 16 valves with our own hands

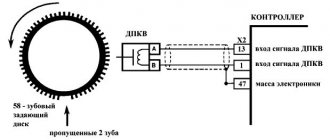

The crankshaft pulley serves to transmit rotation from the crankshaft to such important vehicle components as the generator, power steering and air conditioning. In addition to this function, in the injection engine there are special teeth on the damper-type pulley, which are read by the crankshaft sensor.

This is one of the most important indicators for the electronic motor control system, which is responsible for the correct operation of the entire unit.

If it fails (beating and deformation, cracks and tears), the VAZ crankshaft pulley will most likely need to be replaced. This part of the car can be repaired, but in very rare cases (if minor defects are detected).

It is not necessary to go to a specialized car workshop; if you have free time and skillful hands, you can do the replacement yourself, which will not only save money, but also increase your self-esteem.

What problems might you encounter?

There is a possibility that you may not immediately notice the characteristic disc part under the hood of your car. It may also be difficult to access. It will be difficult to fix the shaft. Over a long period of time, the joints of fasteners will “stick” and you will have to use special liquids.

To perform all the necessary steps step by step, you will need the following tools:

- impact wrench;

- puller set;

- jack;

- a set of wrenches or other tools for removing bolts;

- presence of an inspection hole.

Tools for work

In the case of a manual gearbox, the crankshaft pulley bolt can be unscrewed using a spanner or socket. It's better to take a regular wrench. In most cases, the ratchet cannot withstand such a load (even if it is the strongest) and as a result falls apart. It is not recommended to use an open-end or gas wrench when dismantling the crankshaft pulley.

The first tool may break, but the second will only damage the edges of the bolt, and next time it will be even more difficult to unscrew it. In case of severe damage to the edges, it will have to be drilled out and removed in parts, which will be unpleasant for the car owner. This will increase the time it takes to replace the element.

Source

Purpose

The crankshaft pulley serves to transmit rotation from the crankshaft to such important vehicle components as the generator, power steering and air conditioning. In addition to this function, in the injection engine there are special teeth on the damper-type pulley, which are read by the crankshaft sensor.

This is one of the most important indicators for the electronic motor control system, which is responsible for the correct operation of the entire unit.

If it fails (beating and deformation, cracks and tears), the VAZ crankshaft pulley will most likely need to be replaced. This part of the car can be repaired, but in very rare cases (if minor defects are detected).

It is not necessary to go to a specialized car workshop; if you have free time and skillful hands, you can do the replacement yourself, which will not only save money, but also increase your self-esteem.