Only in recent years has the Russian automobile industry begun to produce products that are in many ways similar to their foreign counterparts. Servicing such cars is mainly the work of service centers. With classic models everything is different. It just so happens that most of the work with the classics is done with one’s own hands. In relation to the VAZ 21093, repairs also became a concern for the car owner.

General concept of VAZ 21093

VAZ 2109 is a classic domestic car produced by AvtoVAZ for a total of 19 years: from 1987 to 2006. The base model with a 1.3-liter carburetor engine has undergone a number of changes to obtain various modifications with relevance in different time periods.

- VAZ 2109 - carburetor, 1.3 liters (1987-1997).

- VAZ-21091 - differs from the base model only in engine capacity, which was 1.1 liters (1987–1997).

- VAZ-21093 - with a 1.5 liter carburetor (1988–2006).

- Modification 21093i - the same 1.5 liters, but with an injector (since 1998).

- The universally recognized 21099, or “ninety-nine,” received a number of export names and was also produced in two variations: with carburetor and injection engines (1990–2006).

Lada Samara, or VAZ 21093, is one of the variations of the widespread model, popularly called simply “nine”. The five-door front-wheel drive hatchback was released in two variations: VAZ 21093 and VAZ 21093i: with carburetor and injection engines, the volume in both cases was 1.5 liters.

Samara is a classic domestic car, and do-it-yourself VAZ repairs have become the generally accepted norm. In addition, this option is a good choice for beginners who want to get to know their iron horse better and get acquainted with its “under the hood world.” But before you roll up your sleeves and grab a wrench, it's still worth a little preparation.

Printed publications such as the “Repair Manual” and “Operation Manual” will become indispensable assistants for a beginner.

The main requirement for them: color illustrations. And the question here is not about better perception or aesthetic beauty. The VAZ 21093 is a structurally complex unit with a complex electrical circuit, the color designation of the elements of which will help you understand the identity of the wire you found.

An important point when operating any vehicle is strict compliance with the prescribed operating and maintenance requirements. But even if all points are observed, there inevitably comes a time when the car will require additional intervention. And here it is already necessary to accurately determine and localize the breakdown, or at least narrow the scope of troubleshooting as much as possible. Some issues can be solved yourself by making repairs, as they say, with your own hands. But there are also problems that will still require contacting specialists to resolve.

Lada/VAZ-2108/ -09/ -099 operation, maintenance and repair manual

VA3-2108, -2109 and their modifications are five-seater passenger cars with a front, transverse engine. The body is a load-bearing structure, all-metal, welded. Engines are four-cylinder, in-line, four-stroke, gasoline, with a displacement of 1.5 liters and a power according to GOST 14845-89 (net) 51.5 kW (70 hp), carburetor or with a distributed fuel injection system. To reduce exhaust toxicity, some cars with fuel injection are equipped with a neutralizer in the exhaust gas system (previously, some carburetor cars in the export version were also equipped with a neutralizer). Previously, cars of the “eighth-ninth” family were equipped with carburetor engines with a displacement of 1.1 and 1.3 liters, with a power of 39.7 kW (53.9 hp) and 47.0 kW (63.7 hp), respectively.

VAZ-2111 engine management system The VAZ-2111 engine uses a distributed fuel injection system (a separate injector for each cylinder). The injectors are turned on in pairs (for cylinders 1-4 and 2-3) when the pistons approach top dead center (TDC). Some engines are equipped with a feedback injection system (oxygen sensor) and a neutralizer in the exhaust system. This system does not require adjustment or maintenance (if exhaust gas toxicity standards are exceeded, failed components are replaced). The oxygen sensor and converter are not installed on the other part of the engines. In this case, the toxicity of exhaust gases is regulated by a CO potentiometer using a gas analyzer. INJECTION SYSTEM CONTROLLER It is a special-purpose mini-computer. It contains three types of memory—random access memory (RAM), programmable read-only memory (PROM), and electrically programmable memory (EPROM). RAM is used by the computer to store current information about engine operation and process it. Codes of any faults that occur are also recorded in RAM. This memory is volatile, i.e. When the power is turned off, its contents are erased. The PROM contains the actual computer program (algorithm) and calibration data (settings). Thus, the PROM determines the most important parameters of engine operation: the nature of the change in torque and power, fuel consumption, etc. The PROM is non-volatile, i.e. its contents do not change when the power is turned off. The EPROM is installed in a connector on the controller board and can be replaced (if the controller fails, a working EPROM can be replaced with a new controller). VEPZU records immobilizer codes when “learning” the keys (see “Car anti-theft system”, p. 11). This memory is also non-volatile. INJECTION SYSTEM SENSORS Provide the controller with information about engine operating parameters (except for the vehicle speed sensor), on the basis of which it calculates the torque, duration and order of opening of the injectors, the torque and order of spark formation. If individual sensors fail, the controller switches to bypass operating algorithms; in this case, some engine parameters may deteriorate (power, throttle response, efficiency), but driving with such malfunctions is possible. The only exception is the crankshaft position sensor; if it is faulty, the engine cannot run. CRANKSHAFT POSITION SENSOR Installed on the oil pump cover. It provides the controller with information about the angular position of the crankshaft and the moment the pistons pass the 1st and 4th cylinders TDC. The sensor is of the inductive type and reacts to the passage of the teeth of the drive disk on the generator drive pulley near its core. The teeth are located on the disk at 6° intervals. To synchronize with TDC, two teeth out of 60 are cut off, forming a cavity. When a depression passes by the sensor, a so-called synchronization reference pulse is generated in it. The installation gap between the core and the teeth should be within 1±0.2 mm. COOLANT TEMPERATURE SENSOR Screwed into the exhaust pipe on the cylinder head. It is a thermistor that changes its resistance depending on the temperature: Temperature, °C - Resistance, Ohm 100 - 177 80 - 332 60 - 667 40 - 1459 20 - 3520 0 - 9420 -20 - 28680 -40 - 100700 The controller supplies The sensor uses a stabilized voltage of +5 V through a resistor and, based on the voltage drop, calculates the engine temperature, adjusting the mixture composition. THROTTLE POSITION SENSOR (TPSE) It is installed on the throttle valve axis and is a potentiometer. A stabilized voltage of +5 V is supplied to one end of its winding, and the other is connected to ground. The signal for the controller is removed from the third output of the potentiometer (slider). To check the sensor, turn on the ignition and measure the voltage between ground and the slider terminal (do not disconnect the connector - the wires can be pierced with thin needles connected to the voltmeter terminals) - it should be no more than 0.7 V. Turning the plastic sector by hand, fully open the throttle flap and measure the voltage again - it should be more than 4 V. Turn off the ignition, disconnect the connector, connect an ohmmeter between the slider terminal and any of the two remaining ones. Slowly turn the sector by hand, following the arrow readings. There should be no jumps throughout the entire working range. Otherwise, replace the sensor. If the TPS fails, its functions are taken over by the mass air flow sensor. In this case, the idle speed does not fall below 1500 min-1. MASS AIRFLOW SENSOR Located between the air filter and the intake hose. It consists of two sensors (working and control) and a heating resistor. The passing air cools one of the sensors, and the electronic module converts the temperature difference between the sensors into an output signal for the controller. In different versions of injection systems, two types of sensors are used - with a frequency or amplitude output signal. In the first case, the frequency changes depending on the air flow; in the second case, the voltage changes. If the mass air flow sensor fails, its functions are taken over by the TPS. KNOCK SENSOR One contact knock sensor is screwed into the upper part of the cylinder block, a two contact sensor is mounted on a stud. The operation of the sensor is based on the piezoelectric effect: when a piezoelectric plate is compressed, a potential difference occurs at its ends. When detonation occurs, voltage pulses are generated in the sensor, according to which the controller regulates the ignition timing. OXYGEN SENSOR (LAMBDA PROBE) Installed in the exhaust pipe of the exhaust gas system. The oxygen contained in the exhaust gases creates a potential difference at the sensor output. On the currently produced “January” and Bosch controllers, self-diagnosis is not provided, and the connector is used to connect a diagnostic device of the DST-2 type. If the system is working properly, then when the ignition is turned on, the “SNESK ENGINE” lamp lights up, but goes out immediately after the engine starts. If the lamp lights up while the engine is running, there are malfunctions in the engine management system, the conditional codes of which the controller records in memory (RAM). Even if the light then goes out, these codes remain in memory and can be read using a scan tool or self-test mode (if equipped). To erase codes from the controller’s memory, you must disconnect the battery for at least 10 seconds. However, the failure of some components of the injection system (fuel pump and its circuits, ignition module, spark plugs) is not detected by the controller and, accordingly, the “SNESK ENGINE” lamp does not light up.

A book in a series of full-color illustrated guides to do-it-yourself car repairs. The manual describes the design features of components and systems of VAZ-2108, -2109, -21099 vehicles with engines 2108, 21081, 21083, 2111. The main malfunctions, their causes and solutions are described in detail. Color photographs, annotated, show in detail all maintenance and repair operations. Recommendations for tuning car components are outlined. The Appendices contain tools, lubricants and operating fluids, lamps, lip seals, bearings, tightening torques for threaded connections, as well as electrical diagrams. The book is intended for drivers who want to maintain and repair a car themselves, as well as for service station workers.

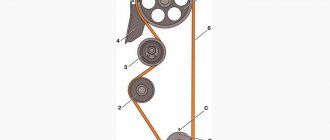

Location of elements of the VAZ-2108, VAZ-2109, VAZ-21099 engine control system: Diagram of the VAZ-2111 engine control system

Problems that arise at the beginning of the journey

The most unpleasant breakdowns are those that occur on the road when you are not expecting them at all. Therefore, it is important to carry at least a minimum set of tools in the trunk, as well as a jack and a tow rope. Then you can fix a minor breakdown on the spot with your own hands, and with a major one you can get to the nearest main repair point.

The most common problem with most domestic cars: the engine will not start.

It is impossible to immediately answer the question “why”, because there may be several reasons.

| Why | What to do |

| The malfunction is directly in the ignition system. | The presence of a spark on the spark plugs, the stroke sensor, the reliability of the connection of contacts and high-voltage wires, especially the central high-voltage cable (for a carburetor model), are checked. In the case of the 21093i injection variation, first of all you should check the functionality of the sensors, of which there are five in the system. |

| Problems with the fuel system. | After making sure that there is fuel in the tank, you should check the supply of fuel by manually pumping the fuel pump (in the case of a carburetor) or make sure that the above is working by listening when you turn on the ignition (for an injection engine). |

| Banal blockage. | It will also block the flow of gasoline into the system and may prevent the engine from starting normally. |

Such problems most often await us along the way. This is a list of the main points, but it is far from complete. There may be many more reasons.

Heart examination

Any edition of the manual says that the most important part is the engine. The driver knows that each vehicle has its own resource. In this case we are talking about 150 thousand kilometers. In most cases, the machine lasts longer, but proper care is important for this.

First of all, you must follow the maintenance rules. The manual provides detailed advice on when and how to change each part. You can handle almost all consumables with your own hands.

The second point is driving style. The engine is strictly prohibited from operating for a long time at low or high speeds. The driver should change gears in a timely manner.

Recommendations include restrictions on towing, cold starts, and the use of poor fuel.

The main way to extend the life of the machine's heart is to maintain it regularly. It consists of a planned replacement of technical fluids and consumables. Depending on the mileage, but on average approximately once a year, it is necessary to inspect the car and consult the manual for preventative repairs and identification of problems.

A knock under the hood should immediately alert you

The second unpleasant moment: unexpected knocking sounds. This type of malfunction can be very dangerous and may even cause an accident. In some cases, it is much safer to have the vehicle towed to a workshop using a rope.

Among the unpleasant knocks that threaten only the cost of repairs, we can highlight: knocking of worn pistons and cylinders, valve knocking, knocking of piston pins. In this case, moving independently does not pose any threat to others, except, of course, for worsening the condition of the car itself. But extraneous sounds of detonation, connecting rod bearings, suspension and transmission and main bearings can become a problem both for the general condition of the car and for others.

Another set of faults, such as vibration and shock in the steering wheel, as well as problems with the brake system, should force you to immediately stop and fix the problem, or simply have the car towed for maintenance. Movement in this case can simply be life-threatening.

Instructions illustrating the location of all these elements will help you navigate and localize the source of the sound.

Auto highlight

First of all, you need to study the brake system. This includes regular replacement of pads and brake cylinders. The repair and operation manual for a VAZ 21099 carburetor or injector describes in detail how to disconnect the fasteners, dismantle the old part and install a new one.

The literature allows you to competently bleed the brake system. This is a simple action if you follow all the steps step by step:

- It is necessary to open the reservoir on the master cylinder.

- You should find and clean the bleeder fitting. It is located on one of the brakes, specifically for troubleshooting and prevention.

- Brake fluid is poured using a special hose. The cable is immersed in a bottle with it and the brake is pumped.

- The buddy must press the pedal all the way down several times and then hold it down.

- The fitting is unscrewed with a key, the liquid merges with the air.

For a more detailed description of the procedure, download the manual. This process is repeated several times until no more air bubbles come out.

Known modernizations of VAZ 21099

In 1997, the model was restyled and received the name VAZ-2115. She became the first representative of the new Samara-2 family . This is what AvtoVAZ continued to produce after it stopped producing the VAZ 21099 in 2004.

As for the aforementioned Lada Victory model, at the time of assembly it had a rear spoiler, 14-inch alloy wheels, and a 1.6-liter engine . Thanks to its excellent characteristics, it was exported to Europe.

Repair features

This model, like all other Ladas, loves repairs. Unlike their foreign counterparts, they break down more often. But the cost of servicing this car is much lower than foreign cars. Replacing the same racks will be several times cheaper.

Experienced car owners improve and tune their cars. Thus, they correct some of the manufacturer's flaws.

Maintenance of this car for a novice driver is divided into 3 types:

- Do-it-yourself problems.

- Malfunctions that can be fixed at home, but with the help of a specialist.

- Repairs carried out only at service stations.

The last type includes:

- camber - toe;

- wheel balancing;

- recovery after a serious accident;

- some types of body repair;

- electrical diagnostics by computer;

- engine boring;

- flashing the on-board computer;

- resetting errors on the computer;

- vulcanization, etc.

The second type includes work that the owner himself can only partially do. If the driver is a beginner, he does not yet know how to weld, repair wiring, carry out work on engines, and does not know the structure of the car well. In such cases, experienced car owners or mechanics are called to help.