The adsorber is an element of the gasoline vapor recovery system (GPSU) of the injection engine of VAZ 2108, 2109, 21099 cars. This system is available in the injection systems of these cars designed to comply with EURO-2, EURO-3 toxicity standards, which prohibit contact of the gas tank cavity with the atmosphere and require afterburning existing fuel vapors in the engine.

Purpose of the adsorber

The adsorber in the fuel vapor recovery system is designed to collect and retain fuel vapors coming from the fuel tank when its pressure increases.

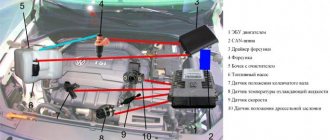

Location by car

On VAZ 2108, 2109, 21099 cars, the adsorber is located on the left side of the vehicle in the engine compartment, on the mounting studs of the left pillar.

Adsorber device

The adsorber is a plastic barrel-shaped container filled with activated carbon. In its upper part it has an inlet fitting for receiving fuel vapor from the gas tank (TANK) and a purge valve with an outlet fitting connected to the fitting on the throttle assembly. In addition, there is also a pipe for connecting the internal cavity of the adsorber with the atmosphere (air supply fitting for AIR purging).

Operating principle of the adsorber

In the SUPS of the injection engine of VAZ 2108, 2109, 21099 cars, when the pressure in the gas tank increases, fuel vapors enter the separator under the right rear wing, where some of them condense and return back to the fuel tank. The rest of the vapor from the separator, bypassing the safety (two-way), gravity and check valves of this system, enters the adsorber through tubes.

Here the vapors are heated and retained by the carbon filler of the adsorber.

When the engine operates at an increased speed, the control unit gives a command to open the canister purge valve (canister purge mode). In this case, additional air enters the adsorber through the purge air supply fitting (AIR). In the adsorber it mixes with fuel vapor. Under the influence of vacuum, a mixture of air and vapor is sucked through a tube from the adsorber to a fitting in the throttle assembly, and then enters the engine cylinders through the receiver. Where it is burned out.

The control unit regulates the degree of purge of the adsorber depending on the engine operating mode.

Adsorber malfunctions

Malfunctions of the adsorber include: its mechanical damage (for example, cracks), in which case the smell of gasoline will be felt in the engine compartment, fuel leaks on the adsorber are possible; overfilling with gasoline; failure of the purge valve installed on it; damage to hoses leading to the adsorber, etc. All this can lead to unstable engine operation at idle, a decrease in its power and throttle response, periodic spontaneous engine stalling, increased pressure in the fuel tank, and increased exhaust toxicity.

Adsorber applicability

In gasoline vapor recovery systems of injection 8-valve engines (ECM with control unit GM ISFI-2S 2111-1411020-10 (20, 21), BOSH MP7.0N (2111-1411020-50), BOSH M1.5.4N (2111 -1411020-60), VS 5.1 (2111-1411020-62), January 5.1 (2111-1411020-71)) of VAZ 2108, 2109, 21099 cars, an adsorber 2112-1164010 and 2112-1164010-10 is installed assembled with a pro valve blowers.

Notes and additions

— Adsorption – absorption of gases by solid or liquid bodies.

— Conditions for turning on the adsorber purge valve:

According to the Euro-3 European environmental standard, the release into the atmosphere of hydrocarbon vapors that arise during the evaporation of gasoline is prohibited. Taking this into account, scientists have come up with a device that allows them to capture and neutralize the vapors described above.

This “saving” device was the so-called adsorber or, as some call it, “absorber” (from the word absorbent - capable of absorbing, in part, this name can also be considered correct), it is installed in the fuel system of a car in order to eliminate harmful vapors that result from the evaporation of gasoline.

Today, we will try to answer the most popular questions related to the adsorber, so that you can find out what it is, what it is for, and how the fuel system adsorber works.

. As an example, we will take the VAZ 2110.

The absorbent that absorbs hydrocarbon vapors is coal, which is used to fill the adsorber tank. Where do the pairs come from? Vapors, as mentioned above, are released by gasoline due to heating of the fuel and constant agitation during movement; the vapors rise upward, then through the hole in the neck of the tank they enter the separator. In the separator, the vapors condense and flow back into the tank, and part of the gases that did not have time to go from a gaseous state to a liquid state or, simply put, to become a condensate, flows through the steam line into the gravity valve and directly into the adsorber, which it neutralizes with activated carbon. This process occurs when the motor is not running.

If the engine is running, the control system purges the adsorber by opening the solenoid valve, after which harmful vapors along with air are emitted into the intake pipe, where they are burned.

The benefit of such a system is double, because first of all, there is no pollution of the atmosphere with harmful fumes, in addition, fuel savings occur, since gasoline does not evaporate, but is returned through the separator to the tank.

What is an adsorber, what is it used for and how does it work? Replacing the VAZ 2110 adsorber with your own hands

According to the Euro-3 European environmental standard, the release into the atmosphere of hydrocarbon vapors that arise during the evaporation of gasoline is prohibited. Taking this into account, scientists have come up with a device that allows them to capture and neutralize the vapors described above.

This “saving” device was the so-called adsorber or, as some call it, “absorber” (from the word absorbent - capable of absorbing, in part, this name can also be considered correct), it is installed in the fuel system of a car in order to eliminate harmful vapors that result from the evaporation of gasoline.

Today, we will try to answer the most popular questions related to the adsorber, so that you can find out what it is, what it is for, and how the fuel system adsorber works. As an example, we will take the VAZ 2110.

The absorbent that absorbs hydrocarbon vapors is coal, which is used to fill the adsorber tank. Where do the pairs come from? Vapors, as mentioned above, are released by gasoline due to heating of the fuel and constant agitation during movement; the vapors rise upward, then through the hole in the neck of the tank they enter the separator. In the separator, the vapors condense and flow back into the tank, and part of the gases that did not have time to go from a gaseous state to a liquid state or, simply put, to become a condensate, flows through the steam line into the gravity valve and directly into the adsorber, which it neutralizes with activated carbon. This process occurs when the motor is not running.

If the engine is running, the control system purges the adsorber by opening the solenoid valve, after which harmful vapors along with air are emitted into the intake pipe, where they are burned.

The benefit of such a system is double, because first of all, there is no pollution of the atmosphere with harmful fumes, in addition, fuel savings occur, since gasoline does not evaporate, but is returned through the separator to the tank.

Disadvantages of the device

Despite the fact that the absorber has on board almost every car sold on the market, this does not mean at all that it is without disadvantages:

- The dimensions of the device are quite significant, which is why it occupies quite a large usable space in the front of the machine;

- Significantly expensive installation. Installing this device on an old car is quite an expensive pleasure, which is unlikely to be offset by some fuel savings. All vehicles coming off the assembly line include an absorber fee as a markup on the cost.

- There is a widespread opinion among car enthusiasts that the device “strangles” internal combustion engines and significantly reduces the dynamics of the car. Also, the speed and response time of the gas pedal allegedly drop. All this, however, does not find any confirmation in modern research.

- In the event of a breakdown, the driver should urgently go to the nearest technical center, otherwise a broken absorber will cause a lot of trouble. The least you will have to deal with is a drop in engine power. In advanced cases, the fuel pump breaks down. In addition, there are known cases of accidents caused by a gas tank cap flying off at high speed under vapor pressure.

Where is the adsorber located on the VAZ 2110?

In order to find the adsorber, you need to lift the hood and look in the near left corner, there you will see a small black cylindrical jar.

Replacing the VAZ 2110 adsorber is a simple procedure; it consists of buying a new adsorber, removing the old one and connecting all the hoses in accordance with how they were connected.

That's all for me, the article about the adsorber has come to an end, whoever liked it, comment and share the article on social networks using the special buttons at the bottom of the article. Thank you for your attention, see you again at VAZ Repair.

Source

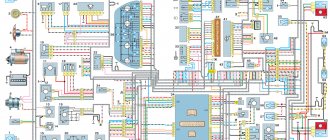

Pinout DS 2109, 2110, 2112, 2114, 2115

If you understand how to connect the speed sensor, then there is the following pinout that you should follow

At the same time, it is important to understand the essence of the operation of the DS to study the circuit diagram of the sensor, which is attached to this article

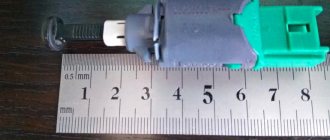

The factory speed sensor of VAZ cars is manufactured with some differences in connections to the block connector. The square-shaped connector is used in Bosh electronics systems. The circle-shaped connector is used in electronic systems such as January 4 and GM.

When connecting a sensor, you should choose devices with contact group digitization such as “-”, “A”, “+” (internal designation on the block contacts) instead of digital designations such as “1”, “2”, “3”. In addition, preference should be given to devices with a metal-type rod, since plastic rods are very short-lived.

Signs of malfunction of the adsorber valve (absorber)

According to the requirements of new environmental standards that limit the content of harmful substances in exhaust gases, vehicles must be equipped with an EVAP system. This equipment prevents harmful fuel fumes from entering the atmosphere. The main function in the fuel vapor recovery system is performed by the adsorber. Some people underestimate the importance of this element in the operation of a car. However, a malfunction of this seemingly minor component can lead to damage to the fuel pump and affect the operation of the entire engine. Therefore, experts recommend checking the adsorber valve when signs of engine malfunction appear.

Purpose and principle of operation of the adsorber purge valve

The EVAP system is installed on gasoline internal combustion engines to prevent fuel vapors from entering the atmosphere. The canister purge solenoid valve is an element of this system. Therefore, to find out what the canister valve is for and how it works, it is important to understand the operating principle of the entire system.

The design of the adsorber is a container filled with an adsorbent, most often activated carbon. The device is connected to the fuel tank and the control valve of the vehicle using special tubes.

Brief information

Adsorption is the process of absorption of one substance (more rarefied) by another (more dense)

. In this case, the transformation of one chemical substance into another does not occur. This principle finds application in various spheres of human life - from medicine to industry.

The following are used as absorbent substances:

- A carbon-containing substance of organic origin that has pores;

- Dried gel;

- Calcium and sodium aluminosilicates;

- Various minerals found in the natural environment.

Starting from the second generation of the Euro series environmental standard, all manufactured cars must have a special capacity to absorb gasoline or diesel fumes. European manufacturers who flout these rules are fined. Foreign violating factories are losing the European market.

The absorber is a small cylindrical container located under the hood of the car in close proximity to the engine.

Car enthusiasts often make a mistake in spelling the word “adsorber”

, replacing the letter “d” with “b”.

The erroneous option is very common, but adsorber is still normative .

Operating principle

When the fuel is heated in the engine, the same hydrocarbon vapors appear, which, according to the laws of physics, rise upward into the separator, where most of them condense (return to a liquid state and flow back into the fuel tank, i.e. fuel savings occur). Residual gases are transferred through a steam line to an adsorber filled with activated carbon, which neutralizes them.

While the engine is running, there is another option for getting rid of harmful vapors - by redirecting them from the intake pipe. The temperature there is quite high, and the gas simply burns.

How can I do it without having to deal with dirty gaskets?

The largest absorbers seem to be found in Epson printers.

It was for them that clever users first came up with the idea of storing “spit” in a separate container outside the printer.

This requires partial disassembly of the printer.

The tube through which the waste is discharged into the absorber is extended using a tube from a medical dropper and an adapter from the refill of a ballpoint pen.

This tube must be taken out through a slot in the back wall of the printer or through a specially made hole and inserted into any suitable container (for example, an ink bottle).

Now there is no need to wash the absorber, you just need to remove waste from the external container in a timely manner.

Therefore, it must be honestly washed (or changed). But, if a service station needs to be serviced, then most likely the interior of the printer and the encoder strip are dirty, the grease on the carriage guide has dried out, etc.

In other words, the printer needs full maintenance.

Replacing the adsorber

You can replace the adsorber on a VAZ 2110 without any difficulties. It is enough to study its fastening and connecting the hoses to it. Buying a new adsorber is a minimal investment. We disconnect the hoses and tubes one by one (to begin with, you can mark them with a felt-tip pen or colored tape), remove the old adsorber, and install a new one. Then we connect the hoses and tubes in the same order. Attention to your car is always justified: timely replacement of the adsorber will help you reduce fuel consumption, reduce the risk of breakdowns in the fuel system, and ensure the safety of you and your passengers.

What is an adsorber, what is it used for and how does it work? Replacing the VAZ 2110 adsorber with your own hands

According to the Euro-3 European environmental standard, the release into the atmosphere of hydrocarbon vapors that arise during the evaporation of gasoline is prohibited. Taking this into account, scientists have come up with a device that allows them to capture and neutralize the vapors described above.

This “saving” device was the so-called adsorber or, as some call it, “absorber” (from the word absorbent - capable of absorbing, in part, this name can also be considered correct), it is installed in the fuel system of a car in order to eliminate harmful vapors that result from the evaporation of gasoline.

Today, we will try to answer the most popular questions related to the adsorber, so that you can find out what it is, what it is for, and how the fuel system adsorber works . As an example, we will take the VAZ 2110.

The absorbent that absorbs hydrocarbon vapors is coal, which is used to fill the adsorber tank. Where do the pairs come from? Vapors, as mentioned above, are released by gasoline due to heating of the fuel and constant agitation during movement; the vapors rise upward, then through the hole in the neck of the tank they enter the separator. In the separator, the vapors condense and flow back into the tank, and part of the gases that did not have time to go from a gaseous state to a liquid state or, simply put, to become a condensate, flows through the steam line into the gravity valve and directly into the adsorber, which it neutralizes with activated carbon. This process occurs when the motor is not running.

If the engine is running, the control system purges the adsorber by opening the solenoid valve, after which harmful vapors along with air are emitted into the intake pipe, where they are burned.

The benefit of such a system is double, because first of all, there is no pollution of the atmosphere with harmful fumes, in addition, fuel savings occur, since gasoline does not evaporate, but is returned through the separator to the tank.

There are problems, but everything is whole

Having the above symptoms, and having checked the integrity of the hoses, we move on to the adsorber valve. How to check it?

1) First of all, disconnect the negative terminal from the battery;

2) Remove the absorber (in most cases it is located on the right side of the engine near the car’s air system);

3) Now turn off the electrical power to the valve itself;

4) Remove the hoses (inlet and outlet);

5) Then we try to blow air into the system through the valve (into the holes for the hoses);

6) If it is working, then when the power is removed from it, it will be blocked, i.e. You won't be able to blow it out;

7) Check further. We connect two wires from the battery to the power contacts on the valve. At the same time, you should hear an opening sound (click);

8) When connected to the source, we try to blow air into it. It should work without problems, if not, then it is closed;

9) Reset the power, if it closes again, then it is 100% working.

By checking the adsorber valve in this way, you can determine its performance at almost 100%. Of course, there may be nuances in which this will be more difficult, but the principle is the same everywhere. Thus, we have described in detail how to check this device.

If it is faulty, then you need to buy a new one - the cost is about 2000 rubles, so before you immediately change it, check it. If the problems lie in the operation of the electronic control unit, then this is a completely different story and everything becomes much more complicated.

Now a short video of a VAZ engine.

I’ll finish here, read our AUTOBLOG.

(

10 votes, average: 4.10 out of 5)

Similar news

Do-it-yourself windshield polishing. In different ways + pass.

Different compression in the cylinders. Why and what to do? Let's figure it out.

Source

Where is the adsorber located on the VAZ 2110?

In order to find the adsorber, you need to lift the hood and look in the near left corner, there you will see a small black cylindrical jar.

Replacing the VAZ 2110 adsorber is a simple procedure; it consists of buying a new adsorber, removing the old one and connecting all the hoses in accordance with how they were connected.

That's all for me, the article about the adsorber has come to an end, whoever liked it, comment and share the article on social networks using the special buttons at the bottom of the article. Thank you for your attention, see you again at VAZ Repair.

Working with EVAP elements

To repair the EMS, you will need a file, a set of wrenches and a screwdriver. It is very easy to get to the adsorber itself - it is located under the hood. Sometimes it is fixed with special fasteners, sometimes not

Pull the part out and carefully unscrew the cap. This is where the work begins

Carefully start sawing the part from the bottom. You can make several cuts of 10 millimeters each from the wide part of the body

These cuts are sealed with tape. Next, after the bottom has been sawed off, the adsorber needs to be turned over and the tape removed. Now it is enough to disassemble the lower part of the part, pull out the filters and springs inside. The coal inside spills out. You are interested in filters: they should not be damaged. If the filters are foam rubber, it is better to replace them with felt pads, since this material is more durable. Such gaskets are applied to the walls of the automobile adsorber and treated with high-quality sealant. It is better to replace the spilled coal with new one and dispose of the old one.

Spare parts for Renault 10

Steering rack/mechanism oil seal (see standard sizes) Now the adsorber remains to be assembled. To connect the two parts of the adsorber, the upper part is lubricated with epoxy resin and applied to the lower one. Some car enthusiasts recommend wrapping the device with tape for better fixation.

Of course, the above method is very crude. However, it will allow the car enthusiast to save a lot. The best option would be to buy a new device, since no repair or replacement of filler will allow the adsorber to be brought to marketable condition.