In 1989, car enthusiasts saw the first copies of the VAZ 1111, which became the basis for the family. Three factories mastered the production of small cars: VAZ in Togliatti, KamAZ in Naberezhnye Chelny, Serpukhov, whose car plant specialized in the production of motorized wheelchairs for the disabled. This distribution of forces and resources made it possible to quickly begin production of this model without the construction of new production facilities.

Buyers were offered two versions of the car, which differed only in the power unit. The car has front-wheel drive, and replacing the Oka timing belt is carried out by analogy with VAZ 2108 and VAZ 21083 engines.

Timing for replacing timing belt

According to the regulations, car owners are recommended to check the condition of the timing belt, as well as its tension, every 30 thousand km.

It is recommended to replace the belt, despite its condition, after a mileage of 60-70 thousand km. If you do not change the belt in time, it may break, and this, as mentioned earlier, threatens very serious damage to the engine, and therefore expensive repairs. It is strictly prohibited to operate an OKA vehicle if even the slightest traces of oil are found on the surface of the timing belt. The leak must be identified and repaired immediately, and the belt must be replaced. If the timing mechanism is serviced on time and efficiently, then the car owner should not have any problems. If you follow all the tips given in this article, replacing the belt will seem like the simplest action possible.

In 1989, car enthusiasts saw the first copies of the VAZ 1111, which became the basis for the family. Three factories mastered the production of small cars: VAZ in Togliatti, KamAZ in Naberezhnye Chelny, Serpukhov, whose car plant specialized in the production of motorized wheelchairs for the disabled. This distribution of forces and resources made it possible to quickly begin production of this model without the construction of new production facilities.

Buyers were offered two versions of the car, which differed only in the power unit. The car has front-wheel drive, and replacing the Oka timing belt is carried out by analogy with VAZ 2108 and VAZ 21083 engines.

Checking and adjusting the ignition timing of VAZ "OKA" 1111 1988-2008

Ignition timing is a very important parameter on which the normal operation of the engine depends. If this timing (ignition timing) is set incorrectly, the engine will start poorly, operate unstably at idle, not develop full power, overheat and consume gasoline unnecessarily. In addition, if the ignition timing is too large (“early” ignition), detonation may occur - a very dangerous phenomenon, often leading to emergency engine damage.

In a contactless ignition system, ignition timing (ignition timing) can only be set using a strobe light

A strobe light is available to almost every motorist, as it can be purchased at almost every auto parts store at an affordable price.

The ignition timing is checked and set at engine idle (at a crankshaft speed of 820–900 rpm). The angle should be within 1°± 1° BTDC.

Check the ignition timing using the mark on the flywheel and the scale of the crankshaft rear oil seal holder (the rubber plug has been removed). When the marks on the flywheel are combined with the middle division (notch) on the scale, the piston of the first cylinder is installed at TDC. One division on the scale corresponds to 2° of crankshaft rotation.

The ignition timing can also be checked and set using the marks on the generator drive pulley and the front camshaft drive belt cover. The long mark corresponds to the installation of the first cylinder at TDC, the short mark to the ignition advance by 5° of crankshaft rotation. These marks are used to set the ignition timing on the stand.

Replacing timing belt Lada 2114 (Lada (VAZ) 2114) in Moscow - compare prices

1. For ease of operation, remove the air filter (see “Removing and installing the air filter”).

2. Disconnect the hose from the vacuum regulator.

3. To check the ignition timing, connect the “+” clamp of the strobe to the “+” terminal of the battery, and the “ground” clamp of the strobe to the “–” terminal of the battery.

4. Remove the tip of the high-voltage wire from the spark plug of the first cylinder and connect it to the strobe sensor in accordance with the instructions included with the strobe.

5. Remove the rubber plug from the clutch housing hatch.

6. Start the engine and direct the flashing strobe light into the clutch housing hatch.

The stroboscopic effect is based on the inertia of human vision. With frequent alternation of bright flashes, the eyes see objects only at the moment of the flash. If the frequency of repetition of flashes coincides with the frequency of rotation of an object, this object appears motionless. When adjusting the ignition timing, the flywheel with a mark on it appears motionless.

Illuminated by strobe flashes, rotating engine parts (crankshaft and generator pulleys, cooling system radiator fan), as well as the generator drive belt, appear stationary or slowly moving. Be careful not to get injured.

7. When the ignition timing is correctly set, mark 1 on the flywheel should be between the middle division 2 and the previous division 3 of the scale. Otherwise, it is necessary to adjust the ignition timing.

When to change the timing belt according to regulations and expert advice?

8. To set the ignition timing, loosen the three nuts securing the spark timing sensor.

9. To increase the ignition timing, turn the sensor housing clockwise (the “+” mark on the flange of the sensor housing is towards the protrusion on the auxiliary drive housing. In this case, one division on the flange corresponds to 8° of crankshaft rotation). To reduce the ignition timing angle, turn the sensor housing counterclockwise (the “–” mark on the flange of the sensor housing is towards the protrusion on the auxiliary drive housing).

10. Tighten the sensor mounting nuts, check and, if necessary, repeat the ignition timing setting.

11. Connect the hose to the vacuum regulator.

Source

The site is temporarily suspended

If you are the owner of this resource, then to resume the operation of the site you need to renew the hosting service.

If the suspension of the site is caused by a violation of the terms of the Subscription Service Agreement, then to resume work you need to contact the Support Service. We will be happy to help you!

| You will need | |

| |

Disconnect the wire from the “–” terminal of the battery. Setting the piston of the first cylinder to the top dead center (TDC) position of the compression stroke is necessary so that when carrying out work related to removing the camshaft drive belt, the valve timing is not disturbed. Set TDC according to the marks on the camshaft timing pulley.

When installed according to the marks on the flywheel, generator drive pulley or crankshaft toothed pulley, the piston of the 1st or 2nd cylinder may be in this position. Then be sure to make sure that the marks on the flywheel, or the generator drive pulley, or on the crankshaft sprocket (if the generator drive pulley is removed) match.

Ignition Features

Before we talk about how to set and adjust the ignition on the Oka with your own hands in accordance with the diagram, let's understand the features of the SZ.

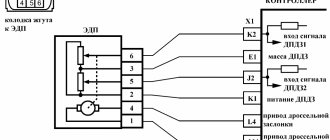

The ignition system on any car includes several different components, the main ones:

- Spark timing controller. This device is equipped with vacuum and centrifugal regulators. The device is designed to ensure the timing of spark formation, taking into account its standard installation, the number of engine revolutions, and the load on the motor. The signal reading procedure is based on the Hall effect.

- The switching device is designed to open the supply circuit of the primary winding of the short circuit, thus converting control signals into current pulses. When the ignition is activated, the connector of the switching device must not be disconnected under any circumstances, since this will lead to damage not only to this unit, but also to other elements of the SZ.

- Coil. In the ignition systems of Oka cars, in accordance with the diagram, a two-terminal short circuit with an open or closed magnetic circuit is used.

- Candles. This element is designed to transmit a high-voltage pulse, which contributes to the ignition of the combustible mixture in the cylinders of the internal combustion engine. The service life of spark plugs is about 10 thousand km, but this figure can be changed upward in accordance with the specifics of the spark plugs themselves. Or to a lesser extent, if for some reason the service life of the spark plugs is reduced.

- High-voltage cables designed to connect spark plugs to a distributor. In Oka, high-voltage circuits with distributed resistance are used. Do not touch them while the engine is running, as this may cause serious injury. It is also prohibited to start the power unit if the high-voltage circuit is broken (the wires may be broken or crushed, or the insulation on them may be damaged). If the insulation is broken, then other elements of the system may fail in accordance with the diagram.

- Egnition lock. According to the diagram, the lock is designed to start the engine by supplying voltage to an additional relay when the key is turned (video author - Nail Poroshin).

Typical system malfunctions

Among the malfunctions of the SZ, the following should be highlighted:

- Coil failure. This problem doesn't happen often, but it can happen nonetheless.

- Distributor failure. You can read more about distributor malfunctions, as well as troubleshooting, here.

- Spark plugs are worn out or have carbon deposits on them. This problem is relevant for many of our compatriots. Read about the reasons why soot appears and what ways to eliminate this problem exist in this article.

- Malfunction of high-voltage wires. The wires may be broken (broken) or their insulation may be damaged. Operating a car with such a problem is not allowed.

- Broken ignition switch. Wear on the inside of the lock will result in the driver being unable to start the engine with the existing key. Replacing the lock cylinder will solve the problem (the author of the video is Mikhail Burashnikov).

When should adjustment be made?

The valve clearance on the Oka, according to the manufacturer’s recommendations, should be adjusted every 30 thousand km. But this is far from an accurate indicator, since much depends on operating conditions. Thus, lubricants, fuel, climatic conditions, features and intensity of use of the car can significantly affect the operation of the timing belt, and work on adjusting the thermal gap will have to be carried out earlier.

There are a number of signs indicating a change in the thermal gap:

- Increased engine noise (the sound of the unit is similar to a diesel unit);

- Power drop;

- Poor launch;

Some note that fuel consumption also increases. This is true, but the Oka uses a carburetor power system (except for the latest models equipped with a Chinese 3-cylinder unit), so it is simply unrealistic to determine the amount of fuel consumed, and such a sign of a change in the thermal gap can be ignored.

This type of maintenance can be done with your own hands, since the whole process is not complicated, but you need to know how to properly adjust the valves on the Oka.

The main thing you need to know is what valve clearance on the Oka is considered normal. Here it all depends on what kind of valve it is: for the intake valve it is 0.2 mm (an error of 0.05 mm is allowed), and for the exhaust valve it is 0.35 mm (the same error).

What will you need?

The only problem with timing belt adjustment is the shims. The fact is that a professional set of them is quite expensive, since it includes washers with a thickness of 3.0 to 4.5 mm (in increments of only 0.05 mm).

Which timing belt is better to choose for a VAZ-2112 16 valves

But many auto stores sell these washers separately, so the price of one washer is low. Only in the process of carrying out the work will you have to make all the necessary calculations, go to the auto store, purchase the required sized elements and download the assembly.

In addition, you will also need special devices - a tool for squeezing the valve and retainer. Since this specialized tool is practically not found on Oka, you can buy a regular one - for the VAZ-2108, and modify it a little.

The squeeze tool consists of a tube with holes for attaching to the valve cover studs, and a handle with a curved lever (pointed at the end) connected through an axle, allowing the lever to move freely.

The tool works simply: a handle with a lever is put on the tube. It is then secured to the valve cover studs. The handle moves freely along the tube, allowing it to be positioned exactly opposite the cam. The lever is installed between the cam and the pusher; when you press the handle, it compresses the valve spring, and all that remains is to install a clamp to hold the pusher in the depressed position. You can see how everything happens in the photo below.

As for modifying the tool from the VAZ-2108 to work with the VAZ-11113, you just need to drill two through holes in the tube, the distance between which corresponds to the position of the valve cover studs of the Oka engine (it is 17.8 cm).

In general, to make the adjustment you will need:

- Set of keys (open-end, socket);

- Screwdrivers;

- Punch and tweezers;

- Tool for squeezing pushers;

- Retainer;

- Set of probes;

- A tool for accurately measuring thickness (at least a caliper);

- Washers;

- Rags;

- New valve cover gasket;

Sequencing

All work is performed on a cold engine. The whole process is done like this:

Remove the air filter housing from the car. Cover the carburetor with a rag;

We disconnect the pipes from the valve cover and move them to the side;

Unscrew the nuts securing the valve cover and remove it;

We set the TDC. To do this, rotate the crankshaft until the marks on the generator drive pulley and the timing belt cover align (since there are two marks on the cover, you need to install it on the long one);

The order of adjustment of the cylinders on the Oka is not important, since in the engine of this car they run synchronously. That is, start adjusting on any cylinder

It is only important to remember that the outer valves are exhaust, and the inner ones are inlet (exhaust-inlet-inlet-exhaust). This is necessary in order not to confuse the thermal gaps

For example, we will consider a cylinder located closer to the camshaft gear;

We measure the gaps on the valves of the selected cylinder using feeler gauges and write them down;

The pushers have special slots for removing the washer. Use a screwdriver to turn the pusher to turn one of the slots towards you;

We install a squeezing tool on the valve cover studs and secure it with nuts;

We place the handle opposite the first valve, place the lever between the camshaft. shaft and pusher, press the handle, overcoming the force of the spring;

Install the retainer between the distributors. using the pusher shaft, remove the lever and move it to the side;

Use a punch to pry up the washer, and then remove it with tweezers;

The washer has its size marked on it (if it is worn, we change its thickness with a caliper);

We calculate the required thickness of the new washer. To do this, take the thickness of the removed washer, add the measured thermal gap to the value and subtract the nominal value. Let's take the intake valve as an example. The measured gap was 0.28 mm. We removed the washer, measured it and got a value of 3.80 mm. We combine these indicators - 4.08 mm. We subtract the nominal gap (0.2 mm) from it and it turns out that you need to install a washer 3.88 mm thick. Since there is no element with this value in the set, we select the closest one to it (for this we need an error of 0.05 mm). As a result, to restore the thermal gap, a washer with a thickness of 3.90 mm is needed.

We install the selected washer and move on to the next cylinder valve. We calculate the thickness in the same way, but taking into account the fact that the exhaust valve has a nominal gap of 0.35 mm;

After making adjustments on one cylinder, move on to the other. But to do this, it is tedious to rotate the crankshaft 360 degrees. And then all work is performed in the same way as indicated above;

After adjustment, we install the removed elements from the engine, and the valve cover gasket must be replaced;

Finally, we note that this operation is also carried out in the case of work related to the removal of the camshaft, for example, when replacing valve seals.

Article on the topic - Adjusting the valves of the VAZ "Classic"

Oka gas distribution mechanism

If you compare old VAZ classic engines with a timing chain drive, you will notice significant differences in the design of the drive. The bulky metal chain was replaced with a timing belt. The design of the cylinder block has become shorter and lighter, since the opening for the chain in the timing drive mechanism has disappeared. The designers changed the principle of opening valves, it became simpler. If on old engines the camshaft cam pressed on the valve stem through the rocker arm, now it acts on it through the adjusting washer. The thermal gap is set on a cold engine by selecting a washer of the required thickness. Manufacturers make them in different sizes, the values of which are marked on the ends of the washer. If the driver adjusts the thermal gap independently, he will have to purchase a certain number of such washers, which is not always economically feasible.

The design of the timing mechanism drive is such that the belt drives the pump in the Oka engine cooling system. Often it is because of the breakdown of this pump that the toothed belt drive fails. Therefore, car manufacturers recommend that the belt drive and pump in the engine cooling system be replaced at the same time

When inspecting, you should pay attention to the condition of the tension roller in the timing mechanism.

Belt replacement procedure

The process of replacing a timing belt on Oka is not very difficult. If you carefully study the process before doing this, you can do it yourself. The work can be done on any level surface.

Before starting the operation, install wheel chocks under the rear wheels and tighten the hand brake cable. The front wheels are turned to the right as far as possible (all the way), and the battery is disconnected. The further procedure will be something like this:

In the engine compartment, remove the spare wheel and the windshield washer fluid reservoir. You will also have to dismantle the air filter housing and ignition coil. After loosening the tension on the generator set drive belt, remove it from the pulleys. After this, you can remove the protective plastic timing case. Next, rotate the crankshaft clockwise until all the timing marks in the timing drive are aligned. It is not yet possible to remove the toothed belt; the generator set drive pulley on the engine crankshaft is in the way. There is a hole on the right mudguard in the direction of travel of the car. A 19mm socket wrench is inserted into it to unscrew the bolt on the crankshaft pulley. Before doing this, you should secure the motor from turning. This can be done through a hole in the top of the flywheel housing by inserting a strong screwdriver or suitable pry bar between the flywheel teeth. An assistant should hold it. Unscrew the bolt securing the generator pulley and remove it from the shaft. Next, loosen the tension of the timing belt. To do this, you need a 17mm wrench to loosen the tension roller nut. If it is replaced, then completely remove it from the axle. There is an adjusting washer in front of the roller on the block side. If the pump in the engine cooling system is being replaced, drain the antifreeze and then remove it from the engine block. Remove the timing belt

Important! The engine cannot be cranked after this, so as not to bend the valves. Carefully inspect the condition of the timing drive pulleys, clean them of possible contamination and traces of engine oil. Installing a new timing belt is done in the reverse order. Before this, carefully check once again how the timing marks in the timing drive mechanism match. At the end of the work, manually turn the engine several times, and again check how the marks match.

At the end of the work, manually turn the engine several times, and again check how the marks match.

VAZ 11113

For ease of operation, remove the windshield washer reservoir, ignition coil and air filter housing (see the relevant sections).

- Remove the generator drive belt (see "Replacing the generator drive belt").

- We remove the front cover of the gas distribution mechanism (see "Adjusting the tension of the timing belt (timing belt)").

- Turn the front wheels all the way to the right.

- Through the hole in the front right mudguard, using a 19mm head (with an extension), turn the crankshaft clockwise by the bolt securing the generator drive pulley until the mark on the camshaft timing pulley aligns with the mounting lug on the rear cover.

- Having removed the rubber plug in the upper part of the clutch housing, we make sure that the mark (mark) on the flywheel is located opposite the central slot of the scale of the crankshaft rear oil seal holder (the coolant supply hose to the radiator has been removed for clarity).

- We fix the crankshaft from turning by inserting a screwdriver through the hole in the clutch housing between the flywheel teeth.

- Unscrew the bolt securing the generator drive pulley.

- Remove the generator drive pulley.

- Use a 17mm wrench to loosen the tension roller nut.

- Turn the tension roller to a position in which the belt will be loosened as much as possible.

- We remove the timing belt from the camshaft and crankshaft pulleys and the coolant pump. ATTENTION! On a VAZ-1111 engine with the belt removed, turning the crankshaft or camshaft is unacceptable - this will lead to engine damage.

- When replacing the tension roller, unscrew the nut securing it and remove the roller from the stud.

- A spacer washer is installed under the roller.

- Install the timing belt in reverse order. We check that the alignment marks of the shafts match.

- With the generator drive pulley removed, it is convenient to control the position of the crankshaft by aligning the marks on the crankshaft toothed pulley and the oil pump cover (for clarity, the operation is shown on a disassembled engine).

- We put the belt on the crankshaft pulley. Then we put the rear branch on the coolant pump pulley and place it behind the tension roller. We put the belt on the camshaft pulley.

- Using a special key with pins, turn the roller counterclockwise and slightly tighten the belt. Tighten the tension roller mounting nut.

- We screw the bolt securing the generator drive pulley into place and using the 19-inch head, turn the crankshaft two turns clockwise by the bolt.

- We check the alignment marks of the crankshaft and camshaft. If the marks do not match, repeat the operation to install the belt. When the marks are in the correct position, we adjust the belt tension (see Adjusting the tension of the timing belt).

Which timing belt to choose

To make it easier for you to find the answer to your questions about which belt to choose or which belt is suitable, we have prepared a table for selecting timing belts for different brands and models of cars:

| Brand, model | Original code | Code analogue |

| Renault timing belt | ||

| Timing belt Logan | 7701477024 130C17480R 130C10178R | K015662XS 130C17529R |

| Timing belt Logan 2 | 130C17480R 130C10178R | K015662XS 130C17529R |

| Timing belt Largus | 130C17480R 130C10178R | K015662XS 130C17529R |

| Timing belt Duster | 130C11551R 7701477028 130C13130R 130C10178R | 130C17529R |

| Timing belt Renault Clio | 7701469776 7701472726 130C10178R | 130C17529R |

| Timing belt Sandero | 130C17480R 130C10178R | K015662XS 130C17529R |

| Timing belt Sandero 2 | 130C17480R | K015662XS |

| Timing belt Sandero Stepway | 130C10178R | 130C17529R |

| Timing belt Sandero Stepway 2 | 130C10178R | 130C17529R |

| Timing belt Symbol | 7701477024 | |

| Timing belt Megan | 7701469776 7701472726 130C10178R | 130C17529R |

| Timing belt Megan 2 | 130284231R 7701063999 130C13130R 130C13191R | CT977 |

| Timing belt Megan 3 | 130C13191R 7701477028 | |

| Ford timing belt | ||

| Timing belt Focus 2 | 1672144 | VKMA04226 |

| Timing belt Focus 3 | 2045356 | KTB764 CT881K5 VKMA04226 530049510 KD452.24 |

| Fusion Timing Belt | 1672144 1672143 | |

| Daewoo timing belt | ||

| Timing belt Nexia | 1987948226 530 0332 10 5900270 | |

| Timing belt Opel | ||

| Timing belt Opel | 95516740 | |

| Chevrolet timing belt | ||

| Timing belt Lacetti | 93185845 93746917 | |

| Timing belt Cruz | 95516740 | |

| Hyundai timing belt | ||

| Timing belt Accent | 24312-26001 | |

| Solaris timing belt | 24321-2B200 | |

| Timing belt Elantra | 24321-2B200 | |

| Timing belt Skoda | ||

| Timing belt Octavia | 06A198119D | |

| Timing belt Fabia | K035565XS | |

| Kia timing belt | ||

| Rio timing belt | 24321-2B200 | |

| Timing belt Soul | 24321-2B200 | |

| Timing belt LED | 24321-2B200 |

Timing belt options for VAZ

If you can’t decide where to buy a timing belt in Volgograd, Volzhsky or another city in the region, contact us, you can’t go wrong.

Pay special attention to how to set the timing marks. We suggest taking a little more time to watch the video of replacing the timing belt on a VAZ with a 16-valve engine

Replacing the timing belt and rollers on 16 valve VAZ 2110, 2111 and 2112

The gas distribution mechanism (GRM) of a car fills the cylinders with a new portion of fuel and is also responsible for removing exhaust gases. This process occurs in the engine cylinders using overhead valves.

The camshaft controls the operation of the valves. It is located at the very top of the valves and rotates from the crankshaft using a toothed belt, which in addition to them also drives the water pump (pump).

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline! Read more"

Where is the timing belt located?

First, let's remember where the timing belt is located and what it looks like. Its location is in front of the engine, but do not forget that motors come in longitudinal and transverse locations. In most cases, gas distribution mechanisms use a toothed rubber belt, but in a considerable number of car models from different manufacturers, a steel chain is also used for this.

Engine cylinders can be equipped with two or four valves with one and two camshafts (CV), respectively. The kinematics of the gas distribution mechanisms of such engines differ. We will show them using the example of 8- and 16-valve power units for the VAZ 2110, 2111 and 2112.

The scheme with two shafts is more complicated, and in it, in addition to the pulley of the second RV, a support roller is added. This also complicates the belt replacement procedure. It is most difficult to perform this operation after a break or severe stretching of the belt, when the factory timing settings can be completely lost. Replacing in normal mode is not so difficult that you can’t try to do it yourself.

About the engine

For these models, engines 2108 and 21083 were taken as the basis. They are 2-cylinder engines with an in-line vertical arrangement of cylinders. The camshaft is installed in the cylinder head. The working volume is 649 cm 3 and 749 cm 3. The increase in volume is obtained by increasing the diameter of the pistons from 76 mm to 82 mm. The cylinder blocks of these engines, heads, flywheels, and pulleys are different.

Many spare parts are unified with their 4-cylinder variants. The power supply system is carburetor, but with changed calibration data. In 1990, the timing belt on the power unit was replaced. If the previous product had semicircular teeth, then on the new one they began to have a trapezoidal shape with a groove at the top of the tooth. The pulleys were changed to match the tooth profile, but the belts themselves are interchangeable; you can use both new and old parts.

It is possible to obtain maximum efficiency from using an internal combustion engine only with the correct adjustment of the valve timing. There are marks on the timing drive for this purpose. One of them is the protrusion on the rear cover for the drive belt protection, which should coincide with the mark on the camshaft pulley. The second mark is located at the bottom of the cylinder block, and it coincides with the mark on the crankshaft pulley. The piston of the first cylinder should be at top dead center at this time.

Are the valves bending?

This question worries many owners, since after such an “incident” a costly overhaul of the power unit will follow. Mechanics know of cases where, after the pistons met the valves, in addition to bent valves, the piston heads were damaged and the guide bushings in the cylinder head were destroyed. The engine, based on the VAZ 21083 engine, is free from such shortcomings. The pistons of this internal combustion engine have recesses that prevent the valve head from meeting the upward-moving piston.

This problem can occur in two cases:

- Cutting teeth on the timing belt.

- The alignment marks on the engine being repaired are not aligned correctly.

To avoid this, you should carefully study the process of replacing the belt, or seek help from service center specialists.

DO IT YOURSELF! Adjusting idle speed and ignition on the road! Ignition distributor for Oka. DOWN. Replacing the ignition coil on an oka

Will the valves bend?

This question is sometimes almost the main one. Some motorists refuse to buy a car if the valves on the engine bend when the belt breaks. This is understandable, since after this you have to completely repair the cylinder head. And this pleasure is not very cheap. It must be said right away that on engines based on 21083, the valves do not bend. There are recesses at the top of the pistons that prevent them from hitting the valves (arrows point to them in the photo).

But on the 2108 motor there is a bending problem and it can arise in the following cases:

- If the teeth on the drive belt are cut off.

- If the marks on the shaft pulleys are set incorrectly.

To prevent breakage, you need to change the belt correctly. Any motorist who knows how to handle wrenches can replace the timing belt on the Oka.

OKA ignition system

Ignition system of Oka, VAZ 2109.

How to set the ignition on Oka

If Oka's car does not start the first time, then you need to set the ignition correctly. Also, the proper functioning of the ignition affects fuel consumption and the overall dynamics of the vehicle.

First, remove the air filter. You only need to check the ignition timing when the engine is idling. The crankshaft rotation speed should be 820–900 rpm. The advance angle should not deviate more than 1° from top dead center.

Other announcements on the topic:

The ignition system is one of the main systems of a car. If the ignition timing is set incorrectly, the engine will begin to overheat, will not develop full power, fuel consumption will increase significantly, and detonation will appear. To check the ignition timing, you can

Read

Correct setting of the ignition timing in a contactless ignition system makes it possible to operate the car in comfortable conditions. Otherwise, the engine does not develop full power and fuel consumption increases. You can set the contactless ignition not only to 100, but

The normal operation of a car engine depends on the correct ignition timing. Otherwise, fuel consumption increases, the vehicle's thrust decreases, and pistons, connecting rods and piston pins are destroyed. You should inspect its installation from time to time in order to always be

https://youtube.com/watch?v=jXTcxsl8ON0

Troit Oka

.

Setting the ignition on the Oka

.

Oka

carburetor .

https://youtube.com/watch?v=Kcomcxmgf3g

We set the timing marks

In this video

I'll tell you in detail how to

set

the timing marks on

the eye

. If anyone wants to help develop the channel, here's a qiwi.

The operation of a car engine is impossible without correctly set ignition timing. This is noticeable not only when starting it with the starter, but also when driving. Increased discomfort is created from uneven operation, a drop in engine power, increased fuel consumption and, most importantly, the car

The car's ignition system is one of the main ones. Without it, there is no way to start the engine and start driving. In addition, incorrectly set ignition timing not only causes discomfort when driving a car, but also contributes to increased fuel consumption, and in some cases

Read

Ignition problems quite often occur on VAZ cars. That is why experienced motorists have developed several methods with which you can quickly and easily adjust the ignition of a VAZ. Since adjustment can take a long time, quite often it is only done

Perhaps, one of the ways to most accurately determine for yourself the correctness of the ignition timing set in a car engine is to determine the specified parameter using a strobe light, which is always available for sale in any store that sells vehicles.

The ignition timing in a car is determined by the angle of rotation of the crankshaft from the moment the spark appears at the spark plug to the position of the piston at top dead center. The ignition angle is lost due to a poorly tensioned chain or a twisted belt. For good engine operation it is necessary to set the angle

For reliable operation of the Buran snowmobile engine in difficult operating conditions, it is necessary to correctly adjust the ignition system. The most important parameter that has to be taken into account when adjusting is the ignition timing setting. As a rule, even the factory setting

>

Replacement timing

The vehicle operation regulations recommend that owners check the condition of the belt drive and belt tension after a run of 30 thousand km (more often). It is recommended to replace it after 60 thousand km. If the car owner does not change the belt within this period, it may be destroyed.

It is not allowed to operate the Oka with traces of engine oil leaks in the area where the toothed belt operates. It has a bad effect on the belt material and accelerates its destruction. Engine oil leaks should be repaired and the toothed belt replaced with a new spare part. If you carry out maintenance work on the power unit in a timely manner and with high quality, then there will be no problems for the owner.

That's how the pump makes noise. Oka VAZ 1111

How to change the timing belt on an Oke video

Do not bend or twist the belt!

After removing the timing belt, do not rotate the crankshaft and camshafts to avoid damage to the internal components of the engine as a result of the valves hitting the piston bottoms!

Before installing the belt, thoroughly clean all timing gears, completely removing dirt, grease and moisture from them!

The timing belt must be installed on a cold engine!

Timing drive components installation details

- Apply the parking brake, support the rear wheels with wheel chocks, then jack up the front of the car and place it on stands (see illustration Diagram of setting up the stands to secure the vehicle in a raised position

). If equipped accordingly, remove the crankcase protection. - Drain the radiator - try not to let coolant get on the drive belts.

- Remove the radiator.

- Remove the cooling fan and water pump pulley.

- Remove the drive belts for the steering pump, AC compressor and generator.

- Remove all spark plugs.

- Remove the distributor protective screen.

- Remove the support bracket for the intermediate roller of the AC compressor drive belt.

- Remove the tube connecting the timing cover to the air intake hose.

- Remove the coolant hose connected to the thermostat.

- By turning the crankshaft by the bolt of its pulley, bring the engine to the TDC position of the end of the compression stroke of the piston of the first cylinder.

- Remove the crankshaft pulley bolt and remove the crankshaft pulley using a suitable puller.

- Remove the upper and lower sections of the front timing cover.

- Make sure that the dot alignment mark of the left camshaft gear is aligned with the matching mark on the upper section of the rear timing cover.

Replacing the timing belt VAZ 11113 Oka

Replacing the timing belt VAZ 11113 Oka

now there are a lot of left belts

on the market, so buy only brands and there will be no problems. Although I came across that.

Good evening everyone. It’s slowly freezing outside, today it was 20 degrees in some places. The window was whispering slowly, in the evening I decided to warm it up, it started up normally, the panel showed -15 degrees. Who knows why this happened with the timing marks. The 1st photo shows how it should be, the 2nd photo shows how my timing marks are at the moment. The discrepancy turns out to be 2 teeth, I do it as expected and it won’t start. If anyone has encountered this, I would be glad to hear comments on this issue. Good luck everyone with your cars.

Price tag: 0 ₽ Mileage: 111805 km

A few words about the Oka engine

The engines used as the basis were models 2108 and 21083. There are only two cylinders in Oka engines, they are arranged vertically in a row. The camshaft is located in the cylinder head, engine capacity is 649 and 749 cc. cm respectively. The increase in volume was achieved by increasing the diameter of the pistons by 6 mm (from 76 to 82). As you can understand, motors have different blocks, flywheels, pulleys, and heads.

But it should be noted that most of the parts are unified with the 4-boiler options. The engine is powered by carburetors. On cars after 1990, they began to install not semicircular teeth on the timing pulley, but trapezoidal ones.

To increase the efficiency of the motor, you need to properly configure the timing mechanism. To do this, you need to align all its pulleys strictly according to the marks on the rear cover opposite the camshaft and on the crankshaft pulley.

Occasionally, the timing belt breaks at 10,000 km. Replacing the timing belt and rollers on 16 valve VAZ 2110, 2111 and 2112. This is how the pump knocks. Oka VAZ 1111

How to replace the belt on the Oka?

Difficulties should not arise when replacing the timing belt on the Oka if the procedure was always carried out in a timely and correct manner. All repair work must be carried out on a flat surface. First, place wheel chocks under the rear wheels to prevent the car from rolling.

Next you need to perform the following manipulations:

- Remove the spare tire and washer water tank from the engine compartment. You will also need to remove the air filter housing and the ignition coil.

- Loosen the tension on the alternator belt and remove it.

- Remove the plastic casing that covers the drive.

- Rotate the crankshaft clockwise to align all marks.

- Install the socket 19 through the hole on the right mudguard onto the crankshaft pulley bolt. To unscrew it, you need to secure the engine from turning. To do this, put an assistant in the car, he must press the brake pedal with 4th and 5th speed engaged.

Springs

Springs (outer 16 and inner 17) press the valve to the seat and do not allow the valve pusher to come off the actuator. The lower ends of the springs rest on the support washer 18 springs. The upper support plate 15 of the valve springs is held on the valve stem by two valve nuts 14, which when folded have the shape of a truncated cone. The cotters have three internal flanges that fit into the corresponding recesses on the valve stems. This design provides both a reliable connection and the ability to rotate the valves during operation, so they wear more evenly.