Jerking when changing gears or when starting the car. In some cases, adapting the throttle valve zero and adapting the misfire diagnostic function will help solve these problems. The adaptation process does not require special equipment and can be done with your own hands.

To remove the damper you need to perform the following operations:

- The wire is disconnected from the negative terminal of the car battery.

- The tightening that secures the ventilation hose going to the engine crankcase is loosened.

- The hose attached to the fitting of the air supply pipe is disconnected.

- The clamp connecting the pipe and the throttle becomes loose.

- The pipe is disconnected.

- The connector connecting the wires to the throttle assembly is disconnected.

- The bolts securing the throttle valve are unscrewed.

- The gasket located on the flange of the intake module is dismantled.

It should be noted that the gasket is disposable; when dismantling it, it is necessary to subsequently install a new element.

Tags

throttle valve.throttle valve essence the valve is the opening of the valve.throttle valve and the throttle valve.throttle valve time the valve laughs in the mechanism the valve is connected to the position of the valve is maintained is the throttle valve adapt the throttle valve.Purpose of the throttle valve throttle position hold adaptation of the damper. The need for adaptation of remote control adaptation. Adaptation involves adaptation without the peculiarities of adaptation and Cars

malfunctionsinstallationladatuninggaladegroupvasaz

Purpose of the throttle valve

Not a single car in the world can do without such a unit as a throttle valve. The mechanism is a transverse channel regulator that changes the amount of flowing liquid or gas. That is, at its core, the damper is an air valve. When it is closed, the pressure in the intake system is equal to vacuum, and when it is open, it is compared to external atmospheric pressure.

By pressing the accelerator pedal, the degree of opening of the damper is adjusted. Accordingly, how much air enters the engine cylinders depends on this. Almost every modern car is equipped with an injection engine, where all important responsibilities are assumed by the electronic control unit (ECU).

As some car enthusiasts know, the optimal ratio of gasoline to air is 1:14.7. By detecting the throttle position and the amount of air using sensors, the ECU regulates the operation of the injectors and fuel pump. This knowledge will be useful in deciding how to adapt the throttle valve.

In other words, the computer commands how much fuel needs to be supplied to the engine in order to maintain optimal proportions.

When and how to do it yourself

When to do it

adaptation of the throttle valve zero and adaptation of the misfire diagnostic function:

- After replacing the ECU controller or resetting the controller using a scan tool.

- After replacing the throttle assembly.

Throttle zero adaptation procedure

:

- When the car is stationary, you must turn on the ignition, wait 30 seconds, turn off the ignition, wait until the main relay turns off.

Adaptation will be interrupted

, If:

- the engine turns over;

- the car is moving;

- the accelerator pedal is pressed;

- engine temperature is below 5 °C or above 100 °C;

- Ambient temperature is below 5 °C.

Adaptation procedure

Misfire diagnostic functions:

- warm up the engine to operating temperature (parameter value “Coolant temperature” = 60.90 °C);

- accelerate the car in 2nd gear until higher crankshaft speeds are reached (parameter value “Engine crankshaft speed” = 4000 min-1) and perform engine braking (“Engine crankshaft speed” = 1000 min-1);

- Perform engine braking six times in one trip.

Via phone

Instructions:

- For an Android smartphone, download and install the ECU Tweaker application. We copy the ecu.zip archive to the root of the internal or external memory without unpacking it.

- Connect the ELM327 V1.5 adapter to the OBDII port of the car.

- Turn on the ignition.

- Launch the “ECU Tweaker” application on your smartphone

- In the search, select “BM LADA”

- Then "Automatic Transmission"

- Then "BVR_On_CAN_x52_JS3_v2.4"

- Then "After sales"

- Then "Diagnostic"

- Then the "Wrench" button

- Go back and select “Learnings information”

- Go back and select “Learnings Procedures”

- Complete the training (see “Training Procedure” above)

Throttle learning not at idle - what is this process?

When the throttle assembly of any modern vehicle operates, a lot of contaminants in the form of dust, soot, and oil gradually accumulate on the surface of the throttle. They form a layer of dirt, which makes the air gap between the damper and the car's air duct smaller than the established norm. This gap is important for the normal functioning of the “heart” of the car, since thanks to it the idle speed is maintained at the required level.

When it decreases, the vehicle's electronic control unit (car computer) slightly opens the damper by introducing coefficients that take into account changes in its cross-section. Up to a certain point, the ECU manages to maintain the air gap at a constant level, but sooner or later the throttle valve will still have to be cleaned of dirt. After flushing this unit, the engine speed will certainly increase due to the fact that the cross-section of the throttle, freed from the contaminant layer, will become larger.

The procedure for returning to the initial (set by the manufacturer) position of the damper is usually called training or adaptation.

Mechanical throttle

Currently, a mechanically driven damper can only be found in budget car configurations. In such a mechanism, the damper is connected to the accelerator pedal via a metal cable, fixed to the shaft and placed in a housing on which sensors are also located:

- idle air controller (IAC)>;

- throttle position (TPP).

All this looks like a separate block. Various pipes also lead to it; coolant is supplied and discharged through one, and through others the crankcase is ventilated and fuel vapors are captured.

Thanks to the IAC, the required number of crankshaft revolutions is maintained when the damper is closed. The regulator itself consists of a stepper motor and a special valve. Together they regulate the amount of air, regardless of what position the throttle valve is in. Usually there are no problems regarding how to adapt the throttle valve in the case of a mechanical drive.

Dismantling

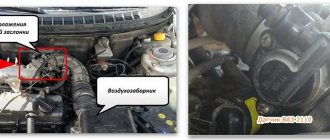

On a VAZ 2110, the throttle assembly is removed in the following sequence:

- Disconnect the connectors of the sensor that regulates the position of the throttle valve, its drive cable and the XX regulator;

- We partially drain the coolant;

- Next is the removal of the air hose located on the body of the mass air flow sensor. Why do you just need to loosen the clamp;

- We also loosen the clamps: where the throttle pipe is attached to the air hose; where the hose of the 2nd crankcase exhaust circuit is attached to the cylinder head cover pipe. We remove the connected hoses - the air and 2nd crankcase ventilation circuits;

- Having loosened the clamp, remove the hose of the 1st crankcase gas exhaust circuit from the throttle assembly fitting;

- Having loosened the clamps, we remove the hoses supplying and discharging coolant;

- You will need a wrench with a 13mm head, with which you need to unscrew the nuts securing the throttle assembly to the receiver on a VAZ 2110;

- It is now possible to remove the throttle assembly from the studs;

- It remains to remove the sealing gasket and, if your VAZ 2110 has a system that traps gasoline vapors, disconnect the hose for purging the adsorber.

Signs of throttle adaptation

The throttle valve in its modern form is one of the last components to undergo electronic modernization. Instead of mechanical rods, a compact electric motor is installed on it, which serves as an actuator.

The signal to it comes directly from the throttle sensor. Together, this system allows you to control the engine correctly, supplying the required volume of fuel mixture to the combustion chambers in a timely manner. There are several signs by which you should start adjusting the throttle position.

For example, when you suddenly release the gas pedal, the engine does not go to idle and stalls; the following can also happen:

- Unstable engine operation at idle;

- a significant “freezing” of revolutions around the 1.5 thousand mark;

- drops in speed when gaining power;

- the “CHECK ENGINE” indicator lights up on the dashboard;

- difficult start at ;

- lack of response when pressing the gas pedal.

Depending on the engine type, there may be a slight loss of power, for example with engines with a V8 configuration. Also, fuel consumption almost always increases. These signs appear especially often on cars with a mileage of 30 thousand km or more, equipped with turbocharging.

– dancing with a tambourine, battery and ignition

Warm up the engine to operating temperature. Usually 80-90 degrees is enough and we turn off the engine.

Disconnect the battery, remove the terminal from it

. This is necessary to reset the parameters in the control unit. In a simple way - reset the ECU to factory settings. This will allow the unit to retransmit the damper values in the closed position.

To calibrate the throttle you need to remove the battery terminal

To calibrate the throttle you need to remove the battery terminal

We wait five minutes

. This is enough for the control unit to be completely de-energized. We connect the terminal to the battery. Don't forget to tighten it to make better contact.

Turn on the ignition and wait 30-40 seconds

without touching or pressing anything. At this time, you may hear a buzzing noise under the hood. This adapts the throttle, the motor moves the damper, determining its position and recording this data in the ECU. This is typical only for electrical and electromechanical remote sensing devices.

Turn off the ignition and wait 15 seconds

. After this time, we turn on the ignition, wait until all the indicators on the dashboard go out and start the car. We check the engine at idle speed, the speed should be normal.

In most cases, this method of adapting the throttle valve gives positive results.

It may not work on cars: Audi with a 1.8 liter ADR engine, Opel Corsa, Octavia Tour 1.6 akl engine, 4th generation Golf, Audi A4 ADL B5 body. All cars have non-volatile memory, which cannot be reset by removing the terminal from the battery.

Torque

To change the amount of torque, the electronic control unit can change one or more parameters:

- throttle opening angle

- boost pressure (if the engine is turbocharged)

- ignition timing

- fuel injection timing

- turning on/off cylinders

The amount of torque is constantly adjusted and depends on the following factors:

- engine starting conditions

- stable idle speed

- O2 content in exhaust gases

- restrictions on power and number of revolutions

- Automatic transmission (when shifting gears)

- traction control when braking

- forced idle when braking

- equipment operation (climate control, air conditioning)

- cruise control (whether the mode is on)

Features of the Lada Granta throttle assembly

The throttle valve is turned by an electric motor through a gearbox. Both are built into the throttle body. When starting and warming up the engine, as well as during idling, the flow of air into the cylinders is regulated by opening the throttle valve. The throttle position is controlled by two sensors built into the throttle body.

The throttle valve opening angle is set by the electronic control unit (ECU) depending on the estimated amount of air that should enter the engine cylinders. This takes into account the operating mode of the engine (starting, warming up, idling, and so on), the temperature of the ambient air and the engine, and the position of the gas pedal.

Control commands are sent to the throttle assembly to the electric motor. At the same time, the ECU monitors the opening angle of the damper and, if necessary, sends appropriate commands to adjust its position. As a result of the fact that the ECU simultaneously regulates the amount of injected fuel and incoming air, the optimal composition of the combustible mixture is maintained in any engine operating mode.

The electric throttle body is sensitive to deposits that may accumulate on its inner surface. The resulting layer of deposits can interfere with the smooth movement of the throttle valve, jamming it (especially at low opening angles). As a result, the engine will operate unstably and even stall at idle, start poorly, and failures may also appear during transient conditions. To avoid this, as a preventive measure, deposits should be removed with special detergent compounds during regular vehicle maintenance. A large layer of deposits can completely block the movement of the damper. If flushing fails to restore the throttle assembly to operability, it must be replaced.

A malfunction or incorrect operation of the throttle assembly may be caused by a broken contact in its electrical circuit (oxidized terminals in the wiring harness connection block). In this case, it will be possible to restore operation by treating the terminals with a special compound for cleaning and protecting electrical contacts. There are other possible causes of the malfunction:

— no supply voltage is supplied to the throttle assembly;

— signals are not received from both throttle position sensors;

— The computer cannot recognize signals from the throttle position sensors.

In these cases, the engine control system goes into emergency mode. At the same time, the car retains the ability to independently move a short distance at a slow speed, which, in extreme cases, will allow it to be moved to a safe place

The fact that the throttle assembly is operating in emergency mode may be indicated by a burning indicator lamp for a malfunction of the engine management system and an increased speed of the crankshaft at idle (about 1500 min-1, despite the fact that the engine is warmed up to operating temperature), the engine at this will not respond to pressing the gas pedal.

Each of the throttle position sensors is a potentiometer. During operation, gradual wear of conductive paths and moving contacts occurs. Over time, wear can reach such an extent that the sensor cannot function correctly. The presence of two sensors increases the reliability of the entire unit.

If only one sensor fails, the warning lamp will light up, but the engine management system will switch to backup mode. In this case, the engine will respond adequately to pressing the gas pedal, but with worse performance parameters

The reserve mode allows you to drive your car to the repair site under your own power.

Why does the car jerk when driving at low speeds?

If the defect is noted when the vehicle is driven at low engine speeds, the reasons can also vary greatly. More often we are talking about failures of the fuel supply system, but the breakdown may lie in other components.

Supply system

This unit most often suffers when the wrong air-fuel mixture is supplied. If the car jerks when driving at low speeds, you will need to check the following:

- Condition of the throttle body: there may be cracks in it.

- Serviceability of idle speed sensors.

- Tightness and cleanliness of injectors.

- Condition of air ducts, percentage of wear.

If the diagnostic steps reveal that there are problems with these parts, it is recommended to immediately install new parts. After servicing, it is necessary to check the quality of connections, tightness, and pressure level in the fuel unit.

Ignition system

The malfunction may lie in premature ignition of the air-fuel mixture, or less often we are talking about low voltage on the spark plug elements. During diagnostics, the following is checked:

- Serviceability of the ignition coil.

- Condition of the candle set.

- No mechanical defects in wiring.

- Distributor functionality.

- The camshaft and crankshaft sensors are correct.

- Switch health.

Often twitching is caused by installing candles of the wrong size or by violating the installation technology. Replacement will help get rid of the unpleasant phenomenon.

Transmission

If the owner performs gearbox maintenance too rarely and does not observe the lubricant change interval, the car begins to twitch when driving at low speeds. The malfunction is especially typical for cars with automatic transmission and robotic gearbox. With a total mileage exceeding 150–200 thousand, noticeable jerks often appear. As a result, the oil in the gearbox begins to foam, the solution becomes thicker or, on the contrary, thinner. It is better to restore the gearbox at a service center; it takes an average of 3–4 hours. It’s better not to carry out the work yourself: you don’t always have the right tool at hand, and besides, this task is not an easy one, especially if the box has an automatic design.

Accelerator

When a driver quickly presses on the gas, the number of revolutions of the power unit immediately increases, which can cause a decrease in the efficiency of the vacuum regulators. After this, if the engine starts to operate at low speeds, its distributor falls, and the vehicle moves jerkily. With continuous combustion of fuel, the driver strives to increase the speed of the internal combustion engine; this cannot be done quickly if the regulators malfunction or fail completely. As a result, if the oxygen flow is not supplied synchronously and the damper is opened, the fuel does not burn immediately, which can damage the advance angle bearing.

During repairs, the regulators are first diagnosed: the hoses with pipes are removed, covering them manually. If there is no vacuum during engine operation, the reason is a damaged throttle valve. The part should be replaced, and then the car should be tested.

Conditions for carrying out the idle speed adaptation process

Before starting training, a number of prerequisites must be met:

- travel by car for 10 minutes;

- ensure that the battery voltage at idle is at least 12.9 V;

- warm up the gearbox;

- The wheels of the vehicle must be straight, the steering wheel must be in the middle position;

- engine temperature – 70–95 °C;

- all devices that put a load on the car’s electrical network (heated windows, headlights, etc.) should be turned off;

- The automatic transmission selector is set to N or P.

Causes

The most common reason for an adaptation to be made is the consequences of throttle valve maintenance. As a result of operation, a large amount of deposits forms in this unit, therefore, after flushing, the position of the throttle valve changes, and the ECU continues to send signals about its condition until maintenance.

Over time, natural wear occurs on the resistive layer of the sensor potentiometer and the moving elements of the throttle valve; in this case, after adaptation, it will most often require replacement. It is necessary to conduct training if changes are made to the ECU settings (chip tuning), especially if operations have been performed to increase engine power.

The procedure is performed using special programs on computer equipment or without them (a strictly defined procedure, which will be discussed below) depending on the brand of car. Auto electricians must take into account the features of the model, year of manufacture, and type of ECU installed on the vehicle.

Self-cleansing procedure

If the damper is electronically actuated, then it is better to remove the negative terminal of the battery. Next, you can do everything according to simple instructions:

- dismantle the air filter by unscrewing the pipe clamp;

- disconnect all connectors of the throttle module and other pipes;

- move the air filter receiver to the side so that it does not interfere, and begin cleaning the damper;

- upon completion, reassemble the damper module in reverse order, checking that everything is in place;

- After assembly, start the engine and check the idle speed.

In some cases, before you begin to adapt the throttle valve on a Toyota, Nissan or Skoda, it is necessary to remove the throttle itself, which allows you to completely clean the valve. To do this, you will need a 5 mm hexagon to unscrew the 4 fasteners. Removing the throttle should be done with great care, as there is a risk of damaging the gasket.

If, after cleaning the throttle body, increased idle speed is observed, it means that the damper needs to be adapted.

Adjusting opening angles in Mitsubishi Lancer

My secret How to adapt the throttle Complete instructions

The air valve should be open and the throttles should turn freely. Permissible gaps range from 0.06 mm. replacing front brake pads on a Mitsubishi Lancer 9 - The adjustment is carried out at low idle speed. The Lancer engine will gradually warm up to 90 degrees and only then will it be possible to tighten the screw, which will change the composition of the combustible mixture (two and a half turns are enough to enrich it). After starting the engine, you should make sure that there is minimal throttle opening, but the engine itself is running well. Then, using the adjusting screw, we achieve the highest speed (the throttle must be open). In this way, we ensure that even after sharply opening the throttle, the engine will still run and quickly gain speed.

After properly carried out repairs or preventive maintenance, you will only need to make sure every 15-20 thousand kilometers to ensure that excess dirt does not accumulate and that the Mitcubishi Lancer 9 throttle valve is working properly. This will help you save money and not spend money on new spare parts for a long time.

Do you still think that diagnosing a car is difficult?

If you are reading these lines, it means you are interested in doing something in the car yourself and really saving money, because you already know that:

- Service stations charge a lot of money for simple computer diagnostics

- To find out the error you need to go to specialists

- The services use simple impact wrenches, but you can’t find a good specialist

And of course you are tired of throwing money down the drain, and driving around the service station all the time is out of the question, then you need a simple CAR SCANNER ELM327, which connects to any car and through a regular smartphone you will always find the problem, turn off CHECK and save a lot of money.

This is interesting: Flushing a car radiator - note to the owner!

Throttle learning idle

After flushing the unit or reflashing the ECU, the throttle valve should be trained to idle. To do this, fulfill the following conditions:

- check the voltage on the battery with the engine off, it should be at least 12.9 V;

- the coolant temperature should be in the range from 70 to 100 degrees;

- the steering wheel must be in a neutral position;

- The gearbox oil must be warmed up;

- all electrical consumers are turned off;

- automatic transmission handle in position P.

Failure to comply with the above requirements will lead to incorrect operation of the engine, so they must be followed. After warming up the engine, you must:

- turn off the ignition for 10 seconds;

- make sure that the accelerator pedal is in the up position;

- turn the key to the ON position for 3 seconds (do not start the engine);

- Press the gas pedal all the way 5 times within 5 seconds and release it for the last time;

- after 7 seconds, press the gas pedal all the way and wait until the “CHESK ENGINE” display lights up continuously;

- After pausing for 3 seconds, release the gas pedal.

Try to start the car, the attempt can be repeated several times. During stable operation, rev the throttle several times and the idle speed should return to the acceptable range.

The procedure for learning the throttle using a PC and car programs has its own specifics, depending on the brand of car, etc. Therefore, it makes no sense to describe the entire process in detail. But first you need to install special software on your PC, for example, VAG-COM for a VAG car group (or other) and drivers. The following is the standard connection order for all:

- turning on the ignition;

- connecting the PC to the car diagnostic connector with an information wire;

- launching software on a PC;

- conducting a test;

- receiving information about readiness for further work - the inscription: “The adapter is ready for work.”

Following a special algorithm, you will be able to coordinate the remote control and the ECU in the “throttle fully open/fully closed” modes for cars with both an electronic and mechanical gas pedal. In this case, the throttle valve training is carried out when the car is warm and the above requirements are met.

- Features of the Lada Granta throttle assembly

- Electronic gas pedal Lada Granta

- Malfunctions of the electronic gas pedal

- Cleaning the electronic throttle valve E-Gas Lada Granta 16V

Owner reviews

Owners of LADA XRAY who independently performed the throttle valve zero adaptation procedure note that the car stopped twitching and acceleration became smooth.

Some reviews from Drive2.ru (link to post):

It really works! This morning I did this operation and the car drove much better, especially at low speed. Why is this not done during pre-sale preparation?

I’ve been suffering with this problem for half a year, but here it’s 3 minutes! I even wrote to AvtoVAZ, they sent me... to the dealer.) Now, after carrying out the above mentioned manipulations, I’m driving for the second day without twitching!

In the morning I carried out these manipulations at an ambient temperature of -10 and an engine temperature of 50 degrees. The car is unrecognizable - all the twitching is gone. Acceleration became smooth, and fuel consumption seemed to drop slightly. I rode all day long.

Let us remind you that we previously published an information letter from AVTOVAZ, which tells us what to do in case of vibrations and jerks when starting off a LADA car.

Key words: ECM Lada XRAY | ECM Lada Vesta | ECM Lada Largus | ECM Lada Priora | ECM Lada Granta | ECM Lada Kalina | ECM 4x4 | esud niva | universal article

Share on social networks:

Welcome! Throttle cable - thanks to this cable, the throttle opens to the angle you need, that is, the more you press the pedal, the more the throttle opens due to the cable that pulls it, thanks to this you decide for yourself how the car will drive and accelerate , but this cable can still jam, this happens due to its wear, over time it flails and therefore touches the shell in which it is located, and the worst thing about this is that the valve locks in the position in which the cable is stuck, that is For example, you pressed the gas pedal all the way and the cable stuck, you remove your foot from the pedal and the cable remains in that position (It should return when you remove your foot from the gas pedal) and thus the car continues to gain momentum but you press the pedal at the same time, do not press, especially the first time you encounter this problem, the first thing you will do is get scared and you may get confused, but in this situation the most important thing is not to panic and just press the gas pedal with your foot, at one moment when you press the pedal and sharply If you remove your foot from it, the cable may disengage and return to its place, as a result of which the car’s speed will drop to idle and the engine will start working normally again.

Note! In order to adjust the cable, you will need to take from the tools: A set of wrenches and perhaps you will also need a screwdriver!

Summary:

Where is the throttle cable located? It starts its path from the gas pedal and ends with the throttle sector, that is, it has two ends, one of which is attached to the gas pedal and the second is attached to the throttle sector (The sector is indicated by a red arrow, but unfortunately it is difficult to see, and the cable is indicated by a blue arrow), in order for the cable not to dangle near the engine, it is attached to a metal bracket which is located on the cylinder head cover (the bracket to which the cable is attached is indicated by a green arrow). By the way, this is where the cable is adjusted, using tightening and loosening the adjusting nut, read the article further and you will immediately understand which nut we are talking about.

When should you adjust the throttle cable? Let us mention again one important detail in which the cable does not need to be adjusted, but immediately replaced with a new one, in general, over time it can become loose and therefore jam, this is very dangerous and it is especially dangerous on the road, so from time to time or watch condition of the cable, or periodically (Once a year or two or three) change it to a new one, it is not very expensive and is easy to replace, if you do not yet know how to do this, then in this case, study the article entitled: “Replacing the cable throttle valve on a car,” now let’s move on to the main question and answer it, the cable needs adjustment when the throttle valve begins to either not fully open or not fully close, this is very easy to check, just disconnect the air pipe from the throttle valve ( It is disconnected by loosening the screw, which is indicated by the red arrow; the pipe itself, which you will need to disconnect from the throttle assembly, is indicated by the blue arrow) and look into the inside of the throttle assembly, you will see the throttle valve itself there, then ask an assistant or use improvised means ( With a brick or a stick) press the gas pedal all the way, at this time you look at the valve and make sure for yourself that it has opened completely (It should open perfectly evenly, there should be no distortions, otherwise adjust the drive), as soon as you are convinced that everything ok, tell the assistant to take his foot off the gas pedal and make sure that the throttle is closed (It may not close completely, this is normal, but you may not even see it, but if it is clearly visible that the flap has not closed and is in the floor open position, then adjust the drive, for more details about the procedure for this check, read the article: “Adjusting the throttle cable on a VAZ 2109”, there is a picture there, if you look at it you will immediately understand everything).

Need for maintenance

The prophylaxis procedure should not be carried out in the absence of obvious reasons. Before starting, you need to carefully evaluate the condition of the throttle valve. If there are no obvious signs of tar deposits and areas of coking, then the reason for unstable operation may lie elsewhere.

Also consider the mileage of the car. Experts recommend resorting to flushing no earlier than after 100 thousand km. But on some cars, for example, a Ford Focus, it may be necessary to flush it after 30 thousand kilometers.

You should know how to clean your throttle body to achieve the desired result. This requires a special carburetor cleaning solution, for example, Abro Carb & Choke Cleaner or similar products. The assembly must be dismantled; only in this case can the maximum effect be achieved, otherwise carbon deposits will remain inside the tubes. Disconnect all pipes from the throttle valve to gain good access to the inlet part of the assembly.

Remove carbon deposits delicately using a clean rag or soft brush. Do not use excessive force; you may damage the valve. The internal elements are coated with a thin layer of molybdenum, which novice car enthusiasts mistake for harmful deposits.

The consequences of zealous cleaning can be different: the moving part of the damper will begin to bite, or vice versa, in the closed position it will begin to let air through. In this case, it will not be possible to do without repairing the throttle valve.

Gas pedal with mechanical throttle control

In the mechanical throttle control drive, a cable is attached to the gas pedal, which goes directly from the passenger compartment to the engine compartment and the other end is screwed to the throttle control drive (a semicircular iron part next to the throttle). When you press the pedal, the cable stretches and pulls this part, which is directly connected to the throttle valve and is usually located on the same axis of rotation with it. The damper slightly opens or closes the pipeline through which air is supplied to the engine. The rest is done by electronics. To achieve the desired torque, the electronic unit changes the ignition timing and the timing of fuel injection into the combustion chamber. This regulates the fuel-air mixture and achieves the required torque.

Electromagnetic throttle valve

The electronic analog, unlike a mechanical unit, allows you to achieve the optimal torque value in any engine operating mode. The level of fuel consumption is reduced, and driving such a car is comfortable and safe. The main distinctive features (and in this case, advantages) are the following:

- idle speed is controlled by moving the throttle valve;

- there is no mechanical connection between the pedal and the damper.

Due to the fact that there is no mechanical connection, torque can be controlled electronically instead of the gas pedal. The damper module itself consists of the following elements:

- housings;

- the damper itself;

- electric drive;

- return spring mechanism;

- damper position sensors.

Installing not one, but two damper position sensors in the module will improve reliability. For this purpose, magnetoresistive devices or potentiometers with sliding contacts can be used. It is precisely because of the breakdown of these elements that it is necessary to decide how to adapt the throttle valve on many cars.

If a malfunction occurs in the electric drive, the damper is brought to the emergency position due to the return spring mechanism. In this case, the module itself must be replaced, which can only be done as an assembly.

The car jerks in first gear or second speed: fault diagnosis

As mentioned above, in such a situation, the first step is to gradually eliminate problems in the power supply system, ignition, as well as failures in the ECM. For example, a common reason when the car jerks at low speeds when engaging first and/or second gear is insufficient fuel/air supply to the engine or impaired mixture formation.

Various ECM sensors (Hall sensor, TPS, mass air flow sensor, etc.) can also malfunction. If everything is fine with the sensors, then you need to check the engine ECU. Quite often, the problem of jerking in 1st-2nd gear is directly related to the ignition. It is necessary to check the condition of the spark plugs and high-voltage wires, distributor and other elements on a particular machine.

As a rule, if the car drives jerkily, in relation to injection cars, specialists conduct comprehensive computer diagnostics of the engine. If such a check does not produce results or the cause is not found, then the vehicle’s transmission deserves special attention.

So, if your car is noticeably jerky in 1st and/or 2nd gear, it is important to understand that the transmission may also be causing the car to jerk when driving. At the same time, it is easier to determine the cause in the case of a manual transmission, while various types of automatic transmissions require more serious checks

Let's start with the manual transmission.

Please note that if an inexperienced driver's car jerks in first gear when starting off, it should be borne in mind that often beginners simply make mistakes when releasing the clutch, while the car itself is working properly

To start without jerking, you need to smoothly release the clutch before the driver feels the grip point (the beginning of the transmission of torque from the engine to the wheels). After the force begins to be transmitted to the wheels and the car begins to move, you need to carefully add gas, dosing the traction with the pedal accelerator.

But jerking is usually caused by problems with the clutch on the manual transmission or its adjustments. For example, a car jerks in first and second when the clutch driven disc is badly worn, the clutch does not “close” completely, and slips. This leads to the car jerking when changing gears.

In this case, jerks most often appear precisely in “low” gears (first, second speed), when the smoothest possible operation of the clutch is needed and at the same time, through the clutch in these gears, a sufficiently large torque is transmitted from the internal combustion engine to the gearbox when accelerating the car.

Now let's move on to automatic transmissions. First of all, you need to take into account that the quality of operation and smoothness of automatic transmission shifts will depend on the type of automatic transmission.

First of all, jerking can occur when driving with robotic gearboxes that have both one and two clutches. The fact is that the clutch of such gearboxes resembles in its design and principle of operation a conventional friction clutch of a manual transmission. Often the solution to the problem is to replace the DSG or AMT clutch, after which it is imperative to adapt the clutch (training, setting the grip point).

Also, in some cases, the culprit that the car jerks when driving in 1-2 gears may be breakdowns and malfunctions in the actuators that are responsible for the operation of the clutch in automated mode.

It should also be noted that the automatic transmission itself can “slip”, and the quality of its operation greatly depends on the level/condition of the transmission oil (ATF fluid). Jerking in automatic transmissions of this type may occur due to insufficient or overfilled oil, the use of a lubricant with unsuitable properties, etc.

Jerking in a car with an automatic transmission in certain gears (especially during shifts) may indicate problems with the brake band, valve body, automatic transmission solenoids, sensors, separate automatic transmission ECU, etc.

Taking into account the above, we can conclude that the machine needs to be checked comprehensively, paying special attention to the level of lubrication and the quality of the oil itself

Electronic gas pedal Lada Granta

On modern cars, instead of the usual cable drive for throttle control, a so-called “electronic gas pedal” is installed. In such cars, the throttle position is controlled electronically. When you press or release the gas pedal, information about this goes to the control unit (ECU) and only after processing and adjustment is a command given to the throttle module. The pros and cons of such a system, as well as signs of malfunctions, will be discussed in this article.

For those who are accustomed to mechanical drives, where pressing the gas pedal directly causes the throttle to move, driving a car with an electronic system will be unusual and unknown. To understand, you need to understand the principle of operation of the “electronic pedal” and its difference from a conventional mechanical one.

When is the damper adaptation performed?

The need for such an operation, which involves bringing high idle speeds to a standard value, arises not only after flushing the throttle assembly, but also in other cases, in particular in the following:

- after the vehicle battery is completely discharged;

- after replacing or removing the accelerator pedal;

- after replacing or reconnecting the vehicle's electronic control unit.

Undoubted signs indicating that the damper needs to be trained immediately are the following phenomena:

- whistling when revving;

- inadequate behavior of the engine at idle;

- lack of power at idle or failures.

Why does a Nissan engine consume oil?

The family includes engines ranging from 1.3 to 1.8 liters. And in fairness, we note that all of them are “lovers” of eating butter. I wonder if we will find signs of oil in our unit?

The fact is that restyled engines released in 2003 showed a special “oil appetite”. At the height of the problem, cunning engineers and servicemen released information that oil consumption of up to 500 grams per 1000 km is not a warranty case. If the engine began to consume more, it was replaced under warranty. True, even on the new engine, the problem of oil consumption began to appear already after a mileage of 15,000 km.

Decoking, replacing the membrane (breather) of the crankcase ventilation system, replacing or cutting out the catalyst do not in any way affect the oil consumption of QG series engines.

In general, the QG18DE motor is not anything special structurally, and therefore it is difficult to expect much trouble from it. However, some features of this engine entail large investments in repairs.

Throttle valve clogged and cleaning intervals

From time to time, the throttle valve inevitably becomes clogged, which manifests itself in various ways. In this regard, a reasonable question arises: how often should it be cleaned? It is not entirely possible to answer this unequivocally, since there are no recommendations on this matter. Some car owners visit auto repair shops when they suspect an engine problem.

Some people believe that the damper needs to be cleaned after every 40,000-50,000 km. Others have a different opinion and clean the damper more often, after 30,000-40,000 km.

Typically, black carbon deposits on the valve indicate low quality fuel. When operating a vehicle with such gasoline, there is a risk of oily deposits forming. After this, there should be no question whether the throttle needs to be adapted.

As a rule, if the piston group is experiencing some problems, then a characteristic sign is the valve becoming coked with soot and oily impurities. Sometimes this indicates crankcase ventilation is clogged.

Sources

- https://la-granta.ru/kak-snjat-drosselnyj-uzel-na-avtomob.html

- https://FB.ru/article/337282/kak-adaptirovat-drosselnuyu-zaslonku-polnaya-instruktsiya

- https://automotocity.com/avtovaz/kak-obuchit-drosselnuju-zaslonku-na-lada-granta.html

- https://tuningkod.ru/chip-tuning/drosselnaya-zaslonka/obuchenie-drosselnoj-zaslonki.html

- https://o-ladagranta.ru/adaptacija-drosselnoj-zaslonki-granta-16-klapanov/

- https://www.spike.su/index.php/%D0%94%D1%80%D0%BE%D1%81%D1%81%D0%B5%D0%BB%D1%8C%D0%BD %D1%8B%D0%B9-%D1%83%D0%B7%D0%B5%D0%BB-%D0%9B%D0%B0%D0%B4%D0%B0-%D0%93%D1% 80%D0%B0%D0%BD%D1%82%D0%B0.html