On a VAZ 2114, error P0335 indicates that there is a problem in the crankshaft position sensor circuit, as a result of which it sends an incorrect signal to the computer.

The crankshaft position sensor (CPS) is located in the timing belt area, next to the crankshaft pulley and is bolted to the oil pump cover. The crankshaft sensor transmits information to the engine control unit about the position of the crankshaft at any time. This information is used by the electronics to determine when to turn on the spark plugs and deliver fuel to the rail in the required quantity and time.

In this article, you will learn what causes this error, what problems arise due to a malfunctioning measuring device, and how to troubleshoot error 0335.

In the picture: 1) fastening bolt, 2) PCV sensor.

Technical description and interpretation of error P0335

This diagnostic trouble code (DTC) is a generic transmission code. The P0335 code is considered a common code because it applies to all makes and models of vehicles. Although the specific repair steps may vary slightly depending on the model.

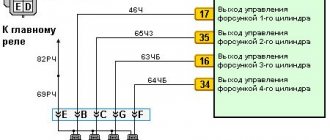

Depending on the vehicle, the PCM uses crankshaft position information to correctly determine spark timing. But in some systems, it only detects misfires and does not control ignition timing.

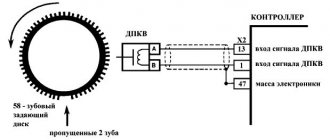

The CKP sensor is stationary and works in conjunction with a ring gear attached to the crankshaft. When this ring passes in front of the CKP sensor, the magnetic field generated by the sensor is interrupted. This creates a voltage signal that the PCM interprets as crankshaft position.

If the PCM detects a lack of crankshaft pulses or if it sees a problem with the pulses in the output circuit, a P0335 code will set.

In other words, while the engine is running, the PCM is constantly comparing input signals from the crankshaft and camshaft. If the crankshaft position is not within the specified degree of deviation from the camshaft position. Under a given set of programmed circumstances, for a given period of time. A P0335 code will be stored and the MIL may illuminate.

Quite often, when this code is set, the engine will not start. If the engine does start, it will likely run very poorly.

Idling

Code 0505 indicates a malfunction of the idle air control. Moreover, 0505 is most often “issued” when the engine is started with the gas pedal pressed. This often affects drivers who switched from a carburetor VAZ 2110 to an injection one.

However, 0505 also occurs if the ignition module, spark plugs are faulty, there are broken wires, or the engine speed is not the one set by the XX regulator.

Idle speed control

If you notice popping noises in the muffler, this may also indicate displacement of the crankshaft ring gear. Code 0505 can be displayed either alone or with 0300 (missing cylinders).

Symptoms of malfunction

The main driver symptom of P0335 is the MIL (Malfunction Indicator Light). It is also called Check engine or simply “check light”.

They can also appear as:

- The “Check engine” warning light on the control panel will light up.

- The motor can operate, but with reduced performance (drop in power).

- The engine may crank but will not start.

- The car stalls or has trouble starting.

- Jerking/misfire at idle or under load.

- Increased fuel consumption.

Depending on the make and model, the engine control unit may use the CKP sensor to estimate engine speed and position. Therefore, the engine will operate, but not at maximum efficiency. If this happens, you may experience difficulty starting, rough idling, or poor acceleration.

Help with an engine error - logbook Lada 2110 Bumblebee 2002 on DRIVE2

Guys, the problem is this... I washed my wife’s car 2112 today and washed the engine! After I blew everything out thoroughly, I started it without any problems! I went to change the springs on it. I changed it myself near the garage for about 2 hours - I collected it and started getting ready to pick it up for work. I start it up and it starts without problems. I went to the other end of the city - no problems. I picked it up and on the way back we stopped many times, turned it off, went shopping and started it up again without any problems. I came home and installed it - everything is fine! and after 4 hours I start it up and it turns stupidly but doesn’t start... the on-board engine gives an error 0335 HF SYNCHRONIZATION SENSOR ERROR - what is this anyway? where should I go to look? I removed all the chips from the sensors - everything is dry... everything is put back in place - nothing is torn off anywhere. but it won't start...

Reasons for the error

A P0335 code may mean that one or more of the following problems have occurred:

- Faulty crankshaft position sensor CKP.

- The CKP sensor connector is damaged.

- Teeth are missing or the keyway for securing the gear ring has been cut off.

- The timing chain is stretched, or a timing belt tooth has slipped due to wear.

- The timing belt/chain is out of alignment.

- Broken timing belt.

- The timing belt/chain tensioner is damaged.

- CMP actuator solenoid valve stuck open.

- Sometimes the cause is a faulty PCM.

Oxygen sensor

For some reason, it is quite difficult to find code 0525 in the decoding tables, but this is simply an error in the oxygen sensor, otherwise called a lambda probe. And if you see 0525 on the display again, it means that not everything is in order with the oxygen content in the exhaust.

This sensor is not installed on all VAZ models; it sends a signal to the engine regarding how much oxygen should be in the fuel system. That this sensor does not cope with its duties is evidenced by:

New Bosch lambda probe

In principle, the lambda probe should be changed after about 60 thousand mileage, but this can happen earlier, especially considering the quality of our gasoline. Therefore, it may display 0525, warning that it is time to replace the oxygen sensor.

How to Troubleshoot or Reset Trouble Code P0335

Some suggested steps to troubleshoot and fix error code P0335:

- Visually inspect the electrical wires and connectors of the crankshaft and camshaft position sensors.

- Check the level, condition and viscosity of the engine oil.

- Read all stored data and error codes using an OBD-II scanner. To determine when and under what circumstances the error occurred.

- Clear the error codes from the ECM and test drive the vehicle to see if the P0335 code appears again.

- Inspect drives, belts or timing chains for wear.

- If no problem is found, continue diagnosing by following the vehicle manufacturer's procedure.

When diagnosing and eliminating this error, you must follow the recommendations of the vehicle manufacturer. Failure to do so may result in severe engine damage and may result in hasty replacement of faulty components.

Electrical equipment

Malfunctions of the electrical equipment of the VAZ 2110 should be responded to as quickly as possible. By the way, this can be signaled by code 1602, although its decoding sounds like a loss of on-board power supply voltage in the RAM.

Sometimes it is enough to reset error 1602, and it will not appear again. Some people call these numbers “good”; 1602 may appear after the battery is disconnected, due to a voltage surge when starting the engine (for example, in cold weather). However, if 1602 “pops up” constantly, you need to look for a network break.

First, try to clean the battery terminals and secure them well. Did not help? Check the circuit, starting from the “+” of the battery, be sure to check the fuse, fuse link.

Oxidized battery terminals

And also inspect the mass of the ECU, TPS. There are cases when code 1602 appears due to the fact that the security alarm blocks the controller circuit, and it issues this as an error every time. You should contact the installer of your alarm system.

Diagnosis and problem solving

Begin your diagnosis by visually inspecting all system-related wiring harnesses and connectors. Inspect electrical circuits, sensors, and connectors that are contaminated with engine oil, coolant, or power steering fluid.

Petroleum-based liquids are known to corrode the protective insulation of wires and cause short circuits or open circuits. This may cause the P0335 code to appear.

Multimeter test

Then connect the scanner to the vehicle's diagnostic port and get all the stored trouble codes. After this, continue testing the voltage and ground signals. Most models use five volt power. Also check the ground signal and the third wire, the control circuit, should be sending a signal to the PCM.

Disconnect the electrical connector from the CKP sensor and test it according to the manufacturer's recommendations using a multimeter. Replace the sensor if resistance values do not meet manufacturer specifications. If all CKP circuit resistance values are within specifications, proceed to the next step.

Checking with an oscilloscope

Connect the positive test lead of the oscilloscope to the signal lead of the CKP harness, and connect the negative lead to the CKP ground circuit. Select the appropriate voltage setting on the oscilloscope and turn it on.

With the transmission in park or neutral and the engine idling, observe the waveform on an oscilloscope. Focus on unexpected spikes or glitches in the waveform pattern.

If you notice any spikes or glitches, gently move the wiring harness and connector while looking at the waveform diagram. You are trying to determine whether the problem is a weak connection or a faulty CKP.

Notice the voltage blocks in the waveform pattern. If some of them are missing, this indicates a broken or worn toothed ring. Also check the CKP magnetic tip for excessive metal debris and clean if necessary. If the waveform is normal, proceed to the next step.

Now reconnect the oscilloscope test leads to the same circuits near the PCM connector and observe the waveform pattern. If an abnormality is detected, there is most likely an open or short circuit between the CKP connector and the PCM connector.

If no open or shorted circuits are found, the P0335 code may be due to a faulty PCM or its programming.

Throttle valve

The on-board computer issues two unpleasant errors - 0122 and 0123 when there is a problem with the throttle sensor. Moreover, 0122 will be displayed if the signal level of this sensor is low, and 0123 – if it is high.

Both one and the other, naturally, are not good. Especially if the on-board computer readings are accompanied by increased idle speeds, jerks at low speeds and dips. In this case, replacing the sensor does not always help.

Throttle position sensor

If codes 0122, 0123 are issued, be sure to check the signal and power wires for breaks, and also pay attention to whether there is any leakage through the injector rings. Remember: the main enemies of DPZD are engine washing and also the manufacturing plant, since there are a lot of defects here.

The following material is devoted to common malfunctions of the throttle position sensor: https://vazweb. ru/desyatka/pitanie/drosselnaya-zaslonka. html

On which cars is this problem most common?

The problem with code P0335 can occur on different machines, but there are always statistics on which brands this error is more common. Here is a list of some of them:

- Alfa Romeo

- Audi

- BMW (BMW E53, E60)

- Chery

- Chevrolet (Chevrolet Aveo, Captiva, Cruz, Lacetti, Rezzo, Suburban, Epica)

- Chrysler

- Citroen (Citroen C4, C5, Jumper)

- Daewoo (Daewoo Matiz, Nexia)

- Dodge (Dodge Caliber, Caravan, Ram, Stratus)

- Fiat (Fiat Albea, Doblo, Ducato)

- Ford (Ford Mondeo, Ranger, Transit, Focus, Fusion)

- Geely (Gili Emgrand)

- Honda (Honda Jazz, SRV, Fit, Civic)

- Hyundai (Hyundai Accent, Getz, Porter, Santa Fe, Solaris, Sonata, Terracan, Tucson, Elantra, i30, i40, ix35)

- Infiniti (Infiniti fx35, fx37, fx45, qx56)

- Jeep (Jeep Wrangler)

- Kia (Kia Magentis, Optima, Rio, Sid, Sorento, Soul, Spectra, Sportage, Cerato)

- Land Rover (Land Rover Freelander)

- Lexus (Lexus lx570, is250, rx300, rx350)

- Mazda (Mazda 3, Mazda 6, Mazda cx7, Bongo, Demio)

- Mercedes (Mercedes Sprinter, s320, w140, w211)

- Mitsubishi (Mitsubishi Airtrek, Outlander, Galant, Karisma, Lancer, Pajero, Fuso, L200)

- Nissan (Nissan Hell, Almera, Altima, Armada, Bluebird, Wingroad, Beetle, Ixterra, Cabstar, Qashqai, Quest, Maxima, March, Micra, Murano, Navara, Note, Pathfinder, Primera, Pulsar, Sunny, Serena, Teana, Tiida , X-Trail)

- Opel (Opel Astra, Vectra, Zafira, Combo, Corsa, Meriva)

- Peugeot (Peugeot 206, 307, 308, 408, Boxer)

- Pontiac (Pontiac Montana)

- Porsche

- Renault (Renault Duster)

- Skoda (Skoda Octavia, Fabia)

- Ssangyong (Sanyeng Aktion, Kyron, Rexton)

- Subaru (Subaru Outback, Impreza, Legacy, Forester)

- Suzuki (Suzuki Vitara, Grand Vitara, Jimny, Liana, sx4)

- Toyota (Toyota Avensis, Camry, Corolla, Land Cruiser, Mark 2, Prado, Rav4, Highlander, Hilux)

- Volkswagen (Volkswagen Jetta)

- Volvo (Volvo s60)

- VAZ 2107, 2109, 21099, 2110, 2111, 2112, 2114, 2115

- GAZ Maxus (LDV Maxus)

- Gazelle Business, Next, ZMZ 405, UMZ 4216

- Lada Vesta, Granta, Kalina, Niva, Priora

- UAZ Bukhanka, Patriot, Hunter, ZMZ 409

With fault code P0335, you can sometimes encounter other errors. The most common are: P0016, P0017, P0018, P0019, P0122, P0300, P0322, P0336, P0337, P0338, P0339, P0340, P0342, P0344, P0350, P0385, P0386, P0387, P0388, P038 9, P0522, P0642, P1133 , P1335, P1693, P2122.

FakeHeader

Comments 5

The problem remained until I soldered all the connections in the replaced wires.

The problem is either the pulley or the wiring.

Pulley if damper check tires

Check the wiring from the ECU to the dpkv. You measure the resistance of the sensor, connect the connector to it, remove the ECU harness, look for the terminals that come with the DCCV and measure the resistance. Ideally there should be no differences. If it's infinity then it's a break. You can try and ring the load: with a light bulb and the battery. Often the test near the connector breaks under the insulation

1. Check the wires and resistance of the crankshaft position sensor. Resistance may change slightly as temperature increases.

2. The output signal of the sensor should have an alternating current voltage amplitude of about 0.3 V when the crankshaft is cranked by the starter.

VAZ P0335 Incorrect crankshaft position sensor signal HOW TO CHECK:

1. Use the Errors menu to clear the error codes. Crank the crankshaft for 10 seconds or until the engine starts.

Code P0335 - Intermittent If it does not set and there are no other codes, analyze the conditions under which the code occurs. Check the drive disc on the crankshaft pulley for missing teeth, runout or other damage. Failure of contacts in the sensor or controller block can cause the intermittent code P0335 to be entered. Also setting an intermittent code P0335 can cause a damaged sensor harness shield.

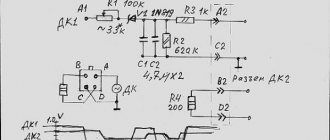

2. Turn off the ignition. Disconnect the harness connector from the controller. Using a multimeter, measure the resistance between contacts “48” and “49” of the harness block.

If the resistance is 550 Ohms or less, the sensor wires are shorted to each other or the sensor is faulty.

If the resistance is 750 Ohms or more, the connections are faulty or the sensor is faulty.

3. If the resistance is between 550-750 ohms, prepare a multimeter to measure the AC voltage. While turning the crankshaft, monitor the voltage between contacts “48” and “49” of the harness block.

If the voltage is below 0.3V, the connections are faulty or the sensor is faulty.

If the voltage is higher than 0.3 V, connect the harness connector to the controller. With the engine running, clear the error codes using the Errors menu. Crank the crankshaft for 10 seconds or until the engine starts. If code P0335 is entered again, check the condition of the drive disc on the crankshaft pulley for missing teeth, runout and other damage. If the drive is faulty, replace it.

Trouble

I’m driving home, at about the 60th kilometer I get error P0340 - camshaft position sensor error. The check light did not light up, I saw the error on the on-board computer (state).

I came home and reset the error. The next day I go to work and there are no errors. Well, probably a stray mistake. It happens to everyone.

A day later I was driving around the city and heard a squeak from the on-board vehicle and the inscription: there are errors in the ECM system. Crap…

The check did not light up again; this did not affect the driving performance of the car. I come to work, look at the error - P0340 again. Soooo, now it’s more interesting...

I drove like this for another day, but I couldn’t reset the error. As soon as you start the car, P0340 appears. You reset it, turn it off, start it again - and again the error occurs. I decided not to reset the error and try to start the car with this error. The car took a very long time to start! The starter spun for about 3-4 seconds, instead of the standard 1 second.

At this moment, error P0335 appeared in addition to error P0340. As they say, trouble does not come alone. Then I did not yet know that in my case they were interconnected.

I decided to change the camshaft sensor. The new one cost about 500 rubles, the most interesting thing is that it was exactly the same as the old one.

And of course it didn't help. The error came out again.

Messages 1

1 Topic by za-nefrit 2016-02-25 23:48:00

- za-nephrit

- New member

- Inactive

- From: Stalingrad

- Registration: 2013-06-25

- Messages: 22 Thanks : 4

- Car: VAZ 21124, camshafts, Volgofors, Volgodrossel, online firmware, etc.

Topic: Resolved: High consumption, twitching and DPKV error (0335), the reason is mass

To all experts - good day! Let me make a reservation right away - the problem has been solved, I decided to share the solution, because... This has never happened before (to me)) So, I’ll start in order. Last night a neighbor called, he has a VAZ-21123 from 2004, he explains the problem - the “Dzhekichan” is blinking, the on-board driver beeps and swears obscenely at the DPKV (error 0335) and several times at the camshaft sensor. In this case, the car starts up immediately, but runs intermittently, consumes gas, jerks and generally behaves in an uncultured manner. A neighbor (a young guy of 19 years old), having smoked forums from his mobile phone, buys and changes the DPKV and a bunch of camshaft timing sensors (how to get there, it’s not convenient damn it at all))), read something else there about the dying mass air flow sensor, but there wasn’t enough money for it ) The result is zero, panic trembling in the voice and all that. Okay - I say - drive or pull to my garage by 8 am, we'll see. It was getting light. ) At the appointed time, the comrade was already on the spot, dancing from the slight cold. Letting him warm up in the garage, he asked what, how and when the problems started. Yesterday he independently (well done guy, I respect him) changed the hydraulic compensators for the first time, removed the DPKV, DF and mass air flow sensor chips. Reassembly was done in reverse order. As usual, I did one thing and another broke) Well, I think - either I didn’t hit the marks, or I broke the wiring on the chip, they have such a disease over time. I start with the easiest and most accessible one - I look at the chip, everything is fine. I look further at the wire - yeah, it’s melted, and good, it’s clearly on the collector. I call the wiring and the screen - everything is fine, just in case I replace the damaged area. We put it in place, we try, there is no result, but I didn’t really count on it, because... I rang the wire in the tolerances, at the same time I looked to see if there was any runout in the damper (no runout). Then I look at the marks - I ask how I set them, he says by the damper teeth - the marks are normal. But just in case, I remove the pulley to see if the gear on the key has turned and check the marks. There is no play or rotation, the marks are in place. I'm putting it back together) He asks me to check the mass air flow sensor - we check it with a multimeter, everything is OK. We remove the DPKV and measure the resistance on the old and new ones - everything is normal. We are trying to change the sensors and mass air flow sensor to a known working one. The result is zero. The engine trembles, shudders, the laptop swears and shows a frenzied opening of the injectors (non-phased injection), a lot of air, a current consumption of up to 33 liters and a DPKV error) Moreover, the error either blinks or lights up constantly with different frequency, regardless of the crankshaft speed. Less often, but still, the DF error (0340) pops up. Not good thoughts creep in about the dying state of the ECU. After smoking and drinking tea, I decide to check the generator, is it causing interference to us? I take off the excitement chip, start it up and... Bummer. Those. the bummer is that the error remains, the good news is that the generator is alive and well, does not cause interference and generally keeps the voltage well) After smoking again, talking with the owner of the patient, I decide to remove the braid and check the wiring more carefully, because. It is quite possible that somewhere there is wear and tear and with vibration from a running engine, something that closes and opens somewhere, as opposed to a state of rest). I begin to remove the decorative cover, pulling out the wires and starting to inspect the corrugation, I notice a “mass” lying on the engine cover (one of two) going to the IKZ. The second was fastened efficiently and in place) Having uttered a certain number of words that are not used in communication with ladies, I screw the mass into place and. The motor whispers and purrs, the BC and the laptop are silent, there are no errors) According to the wiring diagrams, the IKZ and DPKV do not intersect in any way. Along the way, the “mass” in such a powerful current consumer (IKZ) caused interference and EM disturbances in the network board + a weak spark in two cylinders. Result: 3.5 hours wasted, new experience was gained, the car ran 250 miles today without any complaints)