Diagnostics of the electronic engine control system (ECM) of cars of the Lada-Samara, Lada-Kalina family.

The ECM is capable of independently performing self-diagnosis to a certain extent. When a malfunction is detected, the ECM stores a fault code and may illuminate the malfunction indicator in the instrument cluster. The illumination of the malfunction indicator means that it is necessary to carry out diagnostics of the engine and ECM as soon as possible. It should be remembered that behind the electronics there is an internal combustion engine and the performance of the engine control system depends on the health of the mechanical systems. The following is a number of deviations that cause malfunctions that can be erroneously attributed to the electronic part of the engine management system: - insufficient compression; — air leak; — limitation of the patency of the intake/exhaust system; — deviations in valve timing; — malfunctions caused by wear of parts, improper assembly and failure to comply with maintenance schedules; - poor fuel quality.

SECURITY MEASURES

When working on a vehicle with ECM repair, the following requirements must be observed:

- Before dismantling the controller, it is necessary to disconnect the ground wire from the battery.

- Do not start the engine without a secure connection to the battery.

- It is not allowed to disconnect the battery from the on-board network while the engine is running.

- When charging, the battery must be disconnected from the on-board network.

- It is necessary to monitor the reliability of the contacts of the wiring harnesses and maintain the cleanliness of the battery terminals.

- The design of the wiring harness blocks allows them to be connected to the mating part only in a certain orientation. If the orientation is correct, the connection of the harness block with the mating part is made without force. A connection with the wrong socket orientation may result in failure of the socket, module, or other system element.

- Connecting or disconnecting the ECM element pads while the ignition is on is not allowed.

- Before carrying out electric welding work, it is necessary to disconnect the wires from the battery and the connector from the controller.

- To prevent corrosion of the contacts, when washing the engine with a jet of water under pressure, do not point the sprayer at the system components.

- Voltage measurements should be made using a digital voltmeter with a rated internal resistance greater than 10 megohms.

- If the probe is to be used with a test lamp, it is necessary to use a lamp with a current consumption of no more than 0.25 A (250 mA).

- To prevent electrostatic discharge damage to electronic components, do not disassemble the metal housing of the controller or touch the connector plugs.

On-board diagnostics.

“On-board diagnostics” means a system of software and hardware (controller, sensors, actuators) that performs the following tasks: 1) Determination and identification of errors in the operation of the ECM and engine, which can lead to: - exceeding the limit values for vehicle exhaust gas toxicity , which are determined by the environmental standards currently in force in the relevant country for passenger cars; - to a decrease in engine power and torque, an increase in fuel consumption, and a deterioration in the driving characteristics of the vehicle; — failure of the engine and its components (piston burnout due to detonation or damage to the catalytic converter in the event of misfire); — to accident-hazardous behavior of the car. Electronic throttle control systems do not have a mechanical connection between the accelerator pedal and the throttle valve. In this regard, increased requirements are placed on on-board diagnostics to ensure safe vehicle behavior when various malfunctions occur. 2) Informing the driver about the presence of a malfunction by turning on the malfunction indicator. 3)Saving information about the fault. At the moment of detection, the following information is entered into the controller’s memory: - fault code according to the international classification (see Table 1) ; — status flags (signs) characterizing a malfunction at the time of an information exchange session with a diagnostic device; — the so-called freeze frame — the values of parameters important for the ECM at the time the error was registered. 4) Activation of emergency operation modes of the ECM. If a malfunction is detected, the system switches to emergency operating modes, providing the ability to safely drive to a service station. The behavior of the vehicle in emergency mode depends on the specific malfunction detected. For example, in the event of a malfunction of the coolant temperature sensor, replacement engine temperature values calculated from indirect parameters are used to control the engine, and the cooling system fan is also turned on. If any malfunction of the throttle assembly (mechanical or electrical) is detected, the controller de-energizes the electric throttle drive and also limits the maximum engine speed. 5) Ensuring interaction with diagnostic equipment. The presence of a malfunction is indicated by the on-board diagnostic system by turning on the warning light. The on-board diagnostic system must then use special equipment to obtain diagnostic information stored in the controller's memory. For this purpose, a serial information transmission channel is organized in the engine control system, which includes an ECM controller, a standardized block for connecting a diagnostic tool and a wire connecting them (K-line). In addition to the block, the information transfer protocol and the format of transmitted messages are also standardized. In addition to obtaining information about detected malfunctions and the state of the engine control system, the on-board diagnostic system allows you to perform a number of verification tests by controlling the actuators. The main component of the on-board diagnostic system is the ECM. In addition to its main task (controlling the combustion processes of the fuel mixture), it performs self-diagnosis. When performing this function, the controller monitors signals from various sensors and actuators of the ECM. These signals are compared with reference values stored in the controller's memory. And if any signal goes beyond the control values, the controller evaluates this condition as a malfunction (for example, the voltage at the sensor output has become zero - short circuit to ground), generates and writes the corresponding diagnostic information to the error memory (see below) , turns on the warning lamp (alarm) indicating malfunctions, and also switches to emergency operating modes of the ECM. The on-board diagnostic system begins to function from the moment the ignition is turned on and stops after the controller switches to the “stand by” mode (occurs after the main relay is turned off). The moment of activation of one or another diagnostic algorithm and its operation are determined by the corresponding engine operating modes. Diagnostic algorithms can be divided into three groups: 1) Sensor diagnostics. The controller, by monitoring the value of the sensor output signal, determines the presence or absence of a malfunction. 2) Diagnostics of ECM actuators (driver diagnostics). The controller checks the control circuits for opens, shorts to ground, or shorts to the power source. 3) Diagnostics of ECM subsystems (functional diagnostics). There are several subsystems in the engine control system:

Functional diagnostics gives an opinion about the quality of their work. In this case, the system no longer monitors individual sensors or actuators, but the parameters that characterize the operation of the entire subsystem as a whole. For example, the quality of operation of the ignition subsystem can be judged by the presence of misfires in the combustion chambers of the engine. Fuel adaptation parameters provide information about the state of the fuel supply subsystem. Each subsystem has its own requirements regarding the maximum permissible deviations of its parameters from the average values.

FAULT ALARM

The fault indicator for cars of the LADA SAMARA and LADA KALINA families is located in the instrument cluster. When the warning light comes on, it means that the on-board diagnostic system has detected a malfunction of the ECM and the vehicle continues to move in emergency mode. A flashing warning light indicates a malfunction that can lead to serious damage to the ECM (for example, misfires can damage the catalytic converter). When the ignition is turned on, the indicator should light up - this way the ECM checks the serviceability of the indicator and its control circuit. After starting the engine, the indicator should go out if the controller memory does not contain the conditions for turning it on. To protect against random, short-term errors that may be caused by loss of contact in electrical connectors or unstable engine operation, the warning light turns on after a certain period of time after detecting a malfunction in the ECM. During this period, the on-board diagnostic system checks for a malfunction. After eliminating the causes of the malfunction, the alarm will turn off after a certain delay time, during which the malfunction does not appear, and provided that there are no other fault codes in the controller’s memory that require turning on the alarm. When clearing (deleting) fault codes from the controller’s memory using diagnostic equipment, the indicator goes off.

Table 1

M74 controller diagnostic codes

PROCEDURE FOR OPERATING THE DIAGNOSTIC DEVICE

The diagnostic tool allows you to: 1) view in the “Parameters” mode: - current values of the ECM parameters. “General View” menu item , we get the opportunity to control all the ECM parameters that the controller produces. This mode is convenient for comparing current values with those shown in Table 4 . By selecting the menu item “View groups” , we monitor the operation of individual subsystems (for example, fuel supply or idle stabilization). For this purpose, some parameters are grouped into appropriate groups. “Setting up groups” ; — current values of ADC channels; — information about the ECM (controller number, calibration, programming date, etc.); 2) in the “IM Control” mode , selecting the required actuator, check its functioning; 3) in the “Fault” mode: — view diagnostic information on fault codes stored in the controller’s error memory; — erase information from the error memory. The scan tool receives the controller signal and displays it in an easy-to-read form. If there is no signal, the “X” symbol is displayed in the upper right corner. If a signal is present, a symbol in the form of arrows (up and down) is displayed.

Error 1545. Visit to the dealer. When at first everything is through the railway. and then it seemed like nothing.

So, after error 1545 came out, I signed up for the service.

Since my dealer was busy at a time convenient for me, I made an appointment at Samara-Lada for 8 am. I was there at 7.55. True, like a sucker, he rushed to the entrance to the service, which opened exactly at 8.00, at a time when the rest of the savvy citizens entered through the central entrance and were there earlier. But there I had to wait literally 5 minutes, no big deal. The receptionist filled out the paperwork and said, go through the barrier, and I’ll meet you at the repair area. I pulled up and the hell was there. The security guard explained that from today on, the procedure for traveling through the territory is changing, and we must be accompanied by the same receptionist who is not in the dark about such a procedure. I just imagined a reason for such an innovation: clients running around the territory on their own with an evil laugh and hitting other people’s cars...

Me and two other fellow sufferers had to drag themselves back, call the receptionist, return, and wait. As a result, I took a ride as a passenger to the repair zone. And then I was informed that the diagnostician would come at 9.00. Like a fool, I made an appointment at 8 in order to get to work on time. But not everything is so simple! Okay, we're waiting.

As a result, the diagnostician appeared around 9.20. I connected the scanner, counted the errors, and began playing around with the E-gas pedal.

He said that the matter was clear, that the matter was dark, and reached under the hood.

He fiddled with the throttle, put me behind the wheel, and asked me to press the pedal. Pressed. One time the damper did not open at all. Then I started it and revved it up. I scratched my head and went to consult with an engineer, because... It can reset errors, but it is not a fact that they will appear immediately. An engineer came and photographed the scanner readings. By the way, it turned out that at the time of diagnosis the fault still popped up one more time. The error has been reset. They turned off the gas, nothing appeared. In general, the verdict was this: I ordered a throttle from the factory while I was driving. If it comes out again, they will change the unit.

Although a specialist I know says that the problem is most likely not in the throttle, it would be good to extend the mass, and get into the firmware and expand the diagnostic parameters so that the permissible range is wider. But the dealer is unlikely to do this. In general, we will monitor developments.

Source

From english:

Decoding the error P1545 from Audi: Throttle Position Control Malfunction

Make:

Audi

Code:

P1545

Definition:

Throttle Position Control Malfunction

Description:

Engine started,battery voltage must be at least 11.5v,all electrical components must be off,parking brake must be engaged (to keep daytime driving lights off),automatic transmission selector must be in park,the exhaust system must be properly sealed between the catalytic converter and the cylinder head,coolant temperature must be at least 80 Celsius,and the ground between the engine and the chassis must be well connected.The signal from the Throttle Position Valve Module to the ECM detected was erratic,non existent or unreliable .Note: If the complete throttle valve control module is current-less (egconnector disconnected) the throttle valve moves into a particular,specified mechanical position,which signals an increased idle speed with an engine at operating temperature.If only the Throttle Position (TP ) actuator is current-less,the throttle valve also moves into the specified mechanical position (emergency running gap),however,since Closed Throttle Position (CTP) switch – can still be recognized,an “almost normal idle RPM” is reached via the respective ignition angle retardation.If the Engine Control Module (ECM) detects a malfunction at Throttle Position (TP) sensor – Throttle Position (TP) actuator is switched current-less by the Engine Control Module (ECM) and the throttle valve moves into the specified mechanical position (emergency running gap) again.Note: Terminal assignment at throttle control module is different in vehicles with and without cruise control.Characteristic: Steering column switch with operating module for cruise control.

Cause:

- Throttle valve control module is faulty

- Throttle valve is damaged or dirty

- Throttle valve must be in closed throttle position

- Accelerator pedal is out of adjustment (AEG engines only)

- Throttle position actuator is shorting to ground or power

Related Service Bulletins:

- View Bulletin 1

- View Bulletin 2

- View Bulletin 3

- View Bulletin 4

- View Bulletin 5

- View Bulletin 6

- View Bulletin 7

- View Bulletin 8

Error P-1545. Cleaning the throttle valve.

The first dzhekichan came out the other day)))))

Symptoms: The car suddenly stops moving. There is no response to the gas pedal. The rpm hangs at 1500-2000 when the pedal is depressed. And about 1000 at idle. The meat grinder comes out. Restarting the engine. Everything works fine, but there is an error. BC STATE reads it as P-1545 “Throttle valve actuator, deviation of the actual throttle valve position from the desired one is greater than the threshold value.” Resets it without problems.

But this error appears again periodically. Moreover, there is no connection with the style of movement, etc. She may not come out all day or come out 2-3 times per hour.

After reading Drive2 and listening to the advice of subscribers, I decided to carry out comprehensive work: cleaning the remote control, checking contacts, checking the masses. We purchased: Wurth cleaner, Kontakt U and copper grease.

I started by checking the masses and cleaning the contacts. All found masses were unscrewed, cleaned and coated with copper grease. Kontakt U processed all connectors from the ECU to the remote control.

By the way, at AvtoVAZ cars are assembled by real pi... bad people)))) The rubber plug in the engine shield was not inserted at all, but was hanging somewhere to the side. And it definitely didn’t fall out, it was put together like that))))) Crooked-armed freaks!

I unscrewed the air pipe and removed the remote control unit itself. It all comes off easily. The gasket on the intake manifold is not torn, is soft and does not need to be replaced. It’s very nice to tinker with a new car)))) Everything unscrews easily. The only unpleasant thing is that you already have to tinker with the new car)))))

After 32,000 km the throttle valve got a little stuck. Black plaque. But not hellish coke, as I saw from some here. There's a little bit of fuss on the outside, but there's more brightness inside.

I washed everything thoroughly with Wurth. All the crap was quickly washed away. I washed it carefully so as not to flood the electrical part of the remote control unit. Wipe with a lint-free cloth and set to dry. I did not touch the valve itself with my fingers.

I put everything back together, connected it, and adapted the remote control according to the instructions. The car started up better. On a fully warmed up car, previously at idle according to the BC the throttle was open by 3%, now by 2%.

I don't know if this will help solve my problem or not, but I've been driving around for a bit and the error doesn't appear. But she came out very randomly anyway. It could happen once a day, or it could pop up almost every 5-10 minutes. If it doesn’t help and comes out again, then I’ll go to the OD to compost their brains. Let them look for what is being made, remote control, braid of wires or ECU and change it.

Source

Related Service Bulletins:

- View newsletter 1

- View Bulletin 2

- View Bulletin 3

- View Bulletin 4

- View Bulletin 5

- View Bulletin 6

- View Bulletin 7

- View Bulletin 8

Poll: Where is your car repaired? (Number of votes: 240)

In my garage

From the officials

In Vasya's garage

To vote, click on the desired answer.Results

Kalina.1.6 8 cells M 74.Error P1545

Welcome to ChipTuner Forum.

Theme Options

ALEX 64

ALEX 64

ALEX 64

Melafon67

I didn’t immediately notice the ECU in the antifreeze on the reverse side and didn’t remove the rivet - my mistake. Now I’ll clean it with alcohol and check. I was probably too hasty in creating the topic, I apologize in advance. I’ll post the results.

Added after 22 minutes

I removed the antifreeze. The error remains. I reset it with initialization still P1545.

ALEX 64

ALEX 64

For viburnum and grant, a replacement ecu is required. At the slightest doubt, I throw in a changer and then check for the presence of antifreeze in the ECU.

Added after 36 seconds

Damn I didn't have time already wrote it

derenko2

Give the car to someone who can.

For viburnum and grant, a replacement ecu is required. At the slightest doubt, I throw in a changer and then check for the presence of antifreeze in the ECU.

Added after 36 seconds

Damn I didn't have time already wrote it

ALEX 64

Images:

ALEX 64

Give the car to someone who can.

Similar. I threw it in, it works normally with my ED ECU. I'm sending for the ECU.

No one else in our village can do this. It’s 300 km to Saratov. I’ll install a replacement throttle on the 23rd, and I’ll write about the results.

Added after 2 minutes

ALEX 64

zampotex

It’s good, of course, to have a replacement fund, but it’s not realistic to have this replacement for all cars.

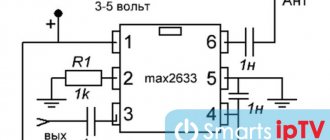

On M74, ECU block, X1-L4 and X1-M4, damper drive control. Resistance measurement is informative. You can apply +12 from the battery to these pins and, depending on the polarity, the damper will open or close. I'd start with this.

vento702

It’s good, of course, to have a replacement fund, but it’s not realistic to have this replacement for all cars.

Added after 5 minutes

For me, it’s easier to find the ECU. Although in any case there will be information.

Yes, somehow they are. There are two M74s, two M74CANs too, and there are 17 in total so far, which is almost enough.

For me, it’s easier to find the ECU. Although in any case there will be information.

Yes, somehow they are. There are two M74s, two M74CANs too, and there are 17 in total so far, which is almost enough.

I actually live in a village, but we can have at least three people. Two of them are in-store services. So you can do it too, albeit at random.

I can do it at random.

Added after 4 minutes

vento702

, That is, you directly supply 12 V and the damper should close or open depending on the polarity, this is 5 6 pins in the plug. Very useful information, thank you.

Source

On which cars is this problem most common?

The problem with code P0222 can occur on different machines, but there are always statistics on which brands this error occurs more often. Here is a list of some of them:

- Chevrolet (Chevrolet Aveo, Cruze, Lacetti)

- Daewoo (Daewoo Matiz)

- Ford (Ford Ranger, Focus)

- Hyundai (Hyundai Solaris)

- Jeep (Jeep Grand Cherokee)

- Kia (Kia Sid)

- Land Rover (Land Rover Range Rover)

- Mazda (Mazda 6)

- Mercedes

- Mitsubishi (Mitsubishi Lancer)

- Nissan (Nissan Pathfinder)

- Opel

- Peugeot

- Skoda (Skoda Octavia)

- Ssangyong

- Subaru

- Toyota

- Volkswagen (Volkswagen Passat, Polo Sedan, Tiguan)

- VAZ 2114

- Gazelle

- Lada Granta, Kalina, Niva, Priora

- UAZ Patriot

Moving and error P1545

We got together and decided to move from the Moscow region

back inland. Ten years of life at the pace of the capital were a necessary and very useful experience, but we need to move on