What to do if the clutch pedal on a VAZ 2107 fails? Fix it yourself

The clutch pedal on a VAZ 2107 fails for several reasons

:

Damaged cable

, which transmits force from the clutch pedal. Most often this occurs at the tip site. If such a problem arose during the trip, then it is unlikely to be solved on the spot; the car will have to be evacuated to a service station. service or to the garage for self-repair.

Although, by the way, some pros who often encounter a similar situation carry a spare cable with them and replace it right in the field. But you must admit, it seems unrealistic to carry with you all the car parts that could suddenly fail.

The spring responsible for the pedal return has burst

. It can also fly off its mount, which will lead to the clutch pedal sticking. If the spring falls off, but the attachment point remains intact, it is simply returned to its original position. You can do this on the road, after tinkering with the car a little. If the spring is damaged, then there is only one thing left to do: evacuate the car to a service station.

The smartest ones try to drive to the repair site without a clutch, but to carry out such a procedure requires certain skills.

In hydraulic drive

, which is responsible for the clutch, air has entered, causing the clutch pedal to fail. A similar problem is treated by bleeding the hydraulic drive to remove air.

Sometimes there is a problem in which the clutch only engages when pressed sharply. If you move the pedal smoothly, it seems to not grab and falls through. The reason lies in a malfunction of the clutch cylinder, which can be eliminated by replacing the unit.

Driving to the repair site without a clutch

What should you do if you lose your clutch on the road and you can’t call for help? All that remains is to try driving without a clutch, yes, it is possible.

Here is an approximate algorithm of actions

, thanks to which you can start without using the clutch:

- We turn off the engine;

- The gear lever is moved to the 1st gear position;

- Now pay attention, you need to turn the ignition key and at the same time press the accelerator pedal. The essence of the action is to prevent the engine from stalling. According to all the laws of physics, the car must move.

If you managed to get your car moving in this way, then you should not change gears. If you try to engage 2nd, you will most likely damage the transmission, or subject it to significant wear. To go faster, you can try to start from second gear, but you need to do this on a descent.

The easiest way is to start the engine without a clutch when it is warm. It would be a good idea to think through the entire route to the service station, because you will have to move without stopping.

Be sure to turn on the hazard lights

, remember that those around you are not aware of your problem, so avoid complex maneuvers, it is better to stop and repeat the entire cycle to start the car.

The method described above is not suitable for beginners, but for confident drivers. If you do not consider yourself in this category, it is better to call a tow truck or wait for other help if the clutch pedal on a VAZ 2107 fails. After all, complications in driving conditions can lead to excessive nervousness and critical mistakes, which will cost an order of magnitude more than car evacuation.

Helpful information? Save it so you don’t lose it

Source

Problems with hydraulic drive

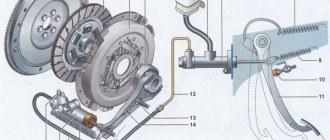

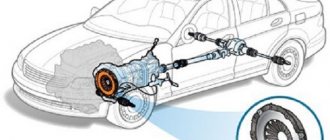

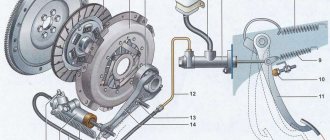

Domestic cars VAZ 2105-2107, as well as some foreign cars, for example, Audi A4 and Ford Focus, have a hydraulic clutch drive. It has a master and slave cylinders, as well as a pipeline through which the fluid flows. The principle of operation of such a system is as follows: the clutch pedal is connected to the master cylinder rod, which drives the cylinder piston.

When you press the clutch pedal, the piston squeezes out fluid, which drives the working cylinder, which, in turn, moves the rod connected to the fork. True, some models, for example, Ford Focus, do not have a fork. Therefore, the rod is connected directly to the release bearing. This complicates the repair somewhat, since it will not be possible to dismantle the working cylinder under road conditions.

Regardless of the type of hydraulic drive design, if the pedal does not return to its place, it is quite possible that the system has become air-filled or depressurized. In such a situation, you first need to open the hood and look at the fluid level in the tank. If necessary, liquid must be added.

If liquid quickly flows out of the tank, it means that the system has become depressurized. You can find out where the leak is occurring only by visually inspecting the system. If fluid leaks at the connections, they need to be tightened. If fluid leaks from under the rod, the master cylinder must be repaired.

To do this, the cylinder must be removed. Depending on the model, it can be mounted both from the passenger compartment (under the pedal) and from the engine compartment. Then the cylinder needs to be disassembled and cuffs, seals and other wearing parts replaced. In auto shops there are special repair kits that contain all the necessary parts to be replaced. Of course, it will not be possible to carry out such repairs on the road.

Repair may be needed not only for the master cylinder, but also for the slave cylinder, which drives the clutch fork.

If this happens and the cable gets stuck in the casing, dirt gets stuck in it, so the pedal does not return back even forcibly

We recommend that you read

- The car pulls to the right or left - what is the cause of the problem?

- The brake pedal fails - how to find the cause of the problem and fix it

- The clutch pedal squeaks - how to identify and eliminate the causes?

To get rid of air in the system, which, as we have already said, can also cause the pedal to fail, it must be “bleeded”. It is advisable to do this procedure with a partner, since it is inconvenient to perform all the actions at the same time alone. So, the procedure is as follows:

- You need to remove the cap from the master cylinder bypass valve and put a hose on it. The free end of the hose must be lowered into a bottle one-third filled with brake fluid.

- Then you should open the bypass valve by unscrewing it one turn.

- Next you need to press the pedal. If you are doing the procedure alone, install a stopper to secure the pedal. It must be kept in this position until bubbles stop coming from the hose. In this case, it is necessary to ensure that the liquid level in the tank does not drop below normal. If necessary, liquid must be added.

- When the bubbles stop coming out, you need to close the valve and release the pedal. Then the procedure must be repeated, i.e. open the valve and press the pedal. And so on until air bubbles stop coming out.

If the pedal is stuck, i.e. it cannot be forced back to its original position; most likely the reason is a malfunction of the cylinder. As in the case of its depressurization, the cylinder must be dismantled and “rebuilt”.

What to do if the clutch pedal suddenly fails?

Imagine a situation where you are calmly going about your business and suddenly there is a click and the clutch pedal falls to the floor or when pressed it begins to rest against something. The first thought is that you are left without a clutch, and without it you can’t even engage a gear. It's right. But let's not panic, but let's figure out what could be the matter and how to move on. Usually, shortly before a breakdown, the clutch pedal becomes stiffer, you have to exert more effort to press it than before - this is the surest sign of an imminent breakdown of the clutch, or rather one of its components.

To determine the breakdown, let's start with what kind of clutch it is. It can be cable or hydraulic. In the first, pressing the pedal activates the cable; in the second, when pressing the pedal, energy is transferred to the hydraulic clutch system.

Low gearbox oil level

An insufficient amount of oil in the box makes the process of shifting gears extremely difficult, but the speeds must be engaged. When switching in this way, a metallic crunch is heard, and when driving in a gear, the transmission begins to make a lot of noise and “howl.”

A complete lack of lubrication in the gearbox will not allow you to change gears, since without oil the synchronizers will not be able to work properly, and the gears in the gearbox will not engage.

Any manifestation of these symptoms requires immediate cessation of operation of the vehicle and checking the transmission oil level in the gearbox. It is also necessary to inspect the gearbox for damage to the housing, oil leaks through the seals and gaskets.

It should be noted that for manual transmissions of many cars, the oil in the gearbox is filled from the factory for the entire service life. In practice, replacement is recommended every 60-80 km. mileage

It is imperative to fill only with lubricant recommended for viscosity and other characteristics. As for adding oil to the transmission, it is necessary to separately take into account the issue of compatibility with the already filled lubricant.

The clutch pedal has failed: causes of failure

- Violation of operating rules, “driving on the clutch”, etc.

- Natural wear of parts (broken or damaged cable, broken spring that returns the pedal).

- Air in the hydraulic drive.

- Release fork malfunction.

- Problems with the GTZ.

- Malfunction of the driven disk.

If everything is more or less clear with the first and second points, then with the rest everything is a little more complicated.

The cable may break or become frayed, preventing the pedal from moving normally. Typically the weak point is the tip area at the connection point. This issue is resolved by completely replacing the cable; the work is not difficult and can be done at home.

If the clutch pedal fails due to a broken spring, then the solution is basically the same; the spring should be replaced. This happens for the reason that during operation quite often the spring cannot withstand intense loads. As a result, the clutch pedal fails or, more simply put, does not return to the top position.

There is also a situation where the spring simply jumps off, but remains in good working order. The solution to the situation in this case is much simpler; the spring is put in place, after which you can continue moving.

Air in the hydraulic drive is a problem typical for VAZs from the first to the seventh generation. This breakdown can be solved by bleeding the entire system. During the repair process, it is also necessary to establish a source of air leakage. In this case, it is unlikely that you will be able to leave on your own; it would be better if you use the services of a tow truck.

The release fork is also prone to breakage. It is installed on the gearbox and has a short service life. When replacing the fork, I recommend paying attention to the condition of the clutch disc; it may also need to be replaced.

Malfunctions in the operation of the GTZ. If during operation one of the cylinders “breaks” or works ineffectively, the cuff on it sinks or breaks - this does not always mean repair. Often, after a few presses, the cuff may return to its position. If this does not happen, you will most likely have to disassemble the mechanism and replace faulty parts.

If the VAZ clutch pedal fails, the failure may also be due to a malfunction of the driven disk. This manifests itself as follows: the pedal becomes very soft and pliable. The reason may be deformation of the node, fur. damaged or due to a fluid leak.

Design and operating principle of clutch master cylinders

Typical diagram of a hydraulic clutch release drive

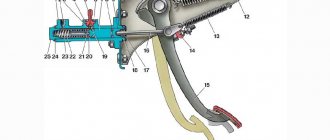

The most simple design of the GCS is with the tank removed and installed on the body. The basis of the device is a cast cylindrical body, on which lugs for mounting bolts and other parts are made. At one end the housing is closed with a threaded plug or a plug with a fitting for connection to the pipeline. If the housing is closed with a blind plug, then the fitting is located on the side surface of the cylinder.

In the middle part of the cylinder there is a fitting for connecting to the tank via a hose or a seat for installing the tank directly on the body. There are two holes made under the fitting or in the seat in the cylinder body: a compensation (inlet) hole of small diameter and a bypass hole of increased diameter. The holes are located in such a way that when the clutch pedal is released, the compensation hole is located in front of the piston (from the drive circuit side), and the bypass hole is located behind the piston.

A piston is installed in the housing cavity, on one side of which there is a pusher connected to the clutch pedal. The end of the body on the pusher side is covered with a corrugated protective rubber cap. When the clutch pedal is depressed, the piston is retracted to its extreme position by a return spring located inside the cylinder. In double-piston gas pumps, two pistons are used, located one behind the other, with an o-ring (cuff) between the pistons. The use of two pistons improves the tightness of the clutch drive circuit and increases the reliability of the entire system.

Such cylinders work as follows. When the clutch pedal is released, the piston is in its extreme position under the influence of the return spring and atmospheric pressure is maintained in the clutch drive circuit (since the working cavity of the cylinder is connected to the reservoir through a compensation hole). When you press the clutch pedal, the piston moves under the influence of the force of your foot and tends to compress the fluid in the drive circuit. As the piston moves, the compensation hole closes and the pressure in the drive circuit increases. At the same time, through the bypass hole, liquid flows behind the back side of the piston. Due to the increase in pressure in the circuit, the piston of the working cylinder moves and moves the clutch release fork, which pushes the release bearing - the clutch disengages and you can change gear.

When the pedal is released, the piston in the main circulation center returns to its original position, the pressure in the circuit drops and the clutch is engaged. When the piston returns, the working fluid that has accumulated behind it is squeezed out through the bypass hole, which leads to a slowdown in the movement of the piston - this ensures smooth engagement of the clutch and the return of the entire system to its original state.

If there is a leak of working fluid in the circuit (which is inevitable due to insufficient connection density, damage to seals, etc.), then the required amount of fluid comes from the tank through the compensation hole. This hole also ensures that the volume of working fluid in the system remains constant when its temperature changes.

The design and operation of a cylinder with an integrated reservoir for working fluid is somewhat different from that described above. The basis of this GCS is a cast body installed vertically or at an angle. In the upper part of the housing there is a reservoir for the working fluid, under the reservoir there is a cylinder with a spring-loaded piston, and a pusher connected to the clutch pedal passes through the reservoir. On the wall of the tank there may be a plug for adding working fluid or a fitting for connecting to a remote tank.

The piston has a recess in the upper part, and a small diameter hole is drilled along the piston. The pusher is installed above the hole; in the retracted state, there is a gap between them, through which the working fluid enters the cylinder.

It is not difficult to operate such a GVC. When the clutch pedal is released, atmospheric pressure is observed in the hydraulic circuit and the clutch is engaged. When you press the pedal, the pusher moves down, closes the hole in the piston, sealing the system, and pushes the piston down - the pressure in the circuit increases, and the working cylinder actuates the clutch release fork. When the pedal is released, the described processes are performed in reverse order. Leaks of working fluid and changes in its volume due to heating are compensated through a hole in the piston.

Possible clutch malfunctions

Clutch pedal squeaking

One of the most common malfunctions that is inherent in new domestic cars or old foreign cars is the clutch pedal squeaks when pressed. It is the noise that occurs throughout the entire mechanism when the pedal is pressed and released. In the case of domestic cars, it appears after the use of low-quality lubricants. In the case of imported cars, it can appear mainly after a long period of use.

Choose the best

The last point in the question of which clutch is best to install on a VAZ 2107 car will be a short review of the most famous clutch kits for classic cars. Differences in brand products lie in reliability and behavior during operation.

Valeo

The well-known company from France is also known for its high-quality brake pads. Judging by the reviews of car owners, the clutch is characterized by soft operation with a clear engagement moment.

Many note the reliability of the new Valeo kits, which often operate without breakdowns for more than 150,000 km. The disadvantage is the high cost.

World famous German manufacturer of friction clutches. The products have always been distinguished by advanced design solutions. For example, the use of a torsional vibration damper on the pressure and driven discs significantly dampens vibrations, which contributes to comfort. LuK couplings are the best choice in terms of price-quality ratio, however, there are many fakes on sale, so you need to be careful when purchasing.

Kraft

The German brand has been known for 20 years, but recently products under this brand are increasingly being produced in Turkey, which, naturally, makes them cheaper. However, clutches have a lot of positive reviews, including:

Sachs

The German manufacturer has extensive experience in the production of transmission parts. All coupling models are equipped with asbestos-free linings, and they provide:

A domestic enterprise that supplies original products for Lada cars. The design of the coupling was developed by engineers from Tolyatti, but the components used in production are mainly imported. Most car owners, when deciding which clutch is best to install on the classic VAZ 2107, choose this manufacturer. The reason for this choice is the low price and acceptable quality.

Kraft tech

Turkish products licensed from the German company Kraft. The set is characterized by soft operation and is adapted to Russian working conditions. Some of the negative reviews relate to the fragility of the release bearing.

Bleeding the clutch

When bleeding the clutch system, it is necessary to control the pedal. When inflated and the outlet fitting is open, it is necessary that it drops to the floor when pressing on it. It is better to perform these manipulations with a partner. When it collapses under the pressure of the assistant’s foot, a characteristic noise of gurgling air bubbles is created. This procedure must be repeated several times.

With a fully functional clutch system, the pedal returns every time it is released, but if it fails again, it means that something is wrong and it is necessary to re-diagnosis and repair.

We conduct an inspection and analyze the situation

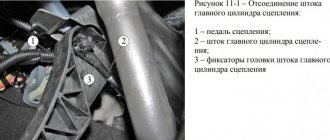

Disassemble the joint where the master cylinder rod is connected to the clutch pedal mechanism. If the pedal return spring is broken, the lever will freely return to its original position on the hinge. The situation is similar with the spring that pushes back the clutch release tab and the working cylinder rod mounted on the engine crankcase. Sometimes the springs look intact, but their stiffness and elasticity are clearly not enough to return due to poor hydraulic performance. Therefore, it would be a good idea to remove them and check their functionality.

Most symptoms indicate an intermittent problem that causes the clutch pedal to return poorly or not return at all. If the cause of poor performance were a weak spring, the defect in the pedal return would remain permanent.

Advice! Check for foreign inclusions in the brake fluid, tiny suspensions, changes in color and transparency of the reserve in the reservoir on the clutch master cylinder. If the above symptoms are present, it means that replacing the clutch pedal return spring is not necessary or there is no reason to check it.

The clutch pedal has failed: what to do in such a situation?

Everyone knows that the life of a car enthusiast involves constant stress. In addition to the dynamics of road traffic, which does not allow the driver to relax in principle, there are also unpleasant situations that are associated with an unexpected breakdown of a car (for example, Nissan Terrano 2014). Precisely away from home, precisely in the flow, precisely while moving.

Such troubles are standard: the clutch has disappeared and the brakes have failed. On the forums of motorists of almost all models and brands, the most common question is: the clutch pedal has failed, what to do...

There are certainly many reasons for clutch failure. It is worth trying to consider a certain list of reasons that lead to the clutch pedal not returning.

Causes of clutch pedal failure in a car

It is worth considering the causes and ways to get rid of them in a hospital setting. Either repair the clutch yourself in the garage, or at a service station. Operations such as repair or replacement of the main clutch or clutch master cylinder are completely acceptable activities in a garage, if you have a repair kit for the clutch slave or master cylinder.

For what reasons does the clutch pedal not return (“the clutch pedal fails”)?

— Clutch cable rupture in the place where the tip is sealed. This malfunction is unlikely to be fixed on the spot, although some people advise carrying a spare cable with you to replace the faulty one. But it’s problematic to constantly carry every detail and spare part with you;

— The return spring has burst or fallen off. If the spring has flown off, then it can be returned to its original place. If the spring breaks, then, as in the situation with a cable, either under its own power to the garage or service station, or in a “tug”. How to continue driving without a clutch? More on this below;

— Air has entered the hydraulic drive system. In this case, only bleeding the clutch to remove air can help;

— the clutch pedal has failed, but it is possible to turn it on for a short time only by very sharply pressing the pedal, the clutch master cylinder is to blame: wear or a defect in the clutch cuff, defects in the mirror. The problem is solved by changing the clutch master cylinder;

— failure of the clutch fork. The answer in this case is clear - it is necessary to replace the clutch fork.

How to get to a service station (service station) if the clutch is lost.

All the same, this happened - the clutch pedal failed and did not return back. Even with the help of my leg I still can’t get it back. There is heavy traffic, the middle of the day and the task is to get to the garage, car service, or at least the nearest parking lot.

If the clutch has disappeared, then there are three options: get there yourself, call a tow truck, or ask someone to pull it in tow .

The question arises, how to get to your destination if the clutch is lost. It's not easy, but it's quite possible. There are several tips that have been tested by car enthusiasts in practice.

The gear shift lever is placed in first gear.

The ignition key is turned and the gas pedal is pressed simultaneously with the engine starting, so that the 2014 Nissan Qashqai does not stall. The movement begins.

While driving, you should not try to switch to second gear, as a new gearbox will cost more than calling a tow truck.

In the same way, in principle, you can start driving from second gear. But in this and in other cases it is worth paying attention to some important nuances:

When the pedal has failed and the clutch has disappeared, you should try to stop the car either on a straight section or on a slope (descent). But by no means uphill. If you stop on an incline, the clutch-less driving method will not work.

The engine must be warmed up before driving.

Important! Do not forget that you will have to move in first, or at most in second gear. That is why, before you start moving, you need to carefully think through the route: how many intersections, traffic lights there will be on the way, in what sequence and where you will need to turn, etc. If possible, it is worth planning a route to your destination so that you always follow the main road (so that you do not have to give way).

Methods for solving the problem

If the clutch pedal fails while driving a car, then there are not many ways to solve the problem. We recommend that you familiarize yourself with all the methods so that in the event of a corresponding breakdown you know how to behave.

Replacing the cable

To replace the cable, you will need the cable itself, as well as wrenches and pliers. It is advisable to use a spanner or open-end wrench, this will be much more convenient.

But if you don’t have a box and open-end wrench on hand, you can also use a regular wrench:

- Open the hood of your car. In the engine compartment you need to find the very place where the cable is attached to the tip. Since a break occurred, most likely the tip remained in the installation location, and the cable itself was dangling. You need to remove the tip using a wrench.

- Then get inside the car and disconnect the cable directly from the clutch pedal. Remove the cable.

- Take the new cable and install it in place of the old one, the entire assembly occurs in the reverse order.

- You need to measure the free code of the pedal, and then adjust the installed element. The free play should be no more than 3 cm, and the total should be no more than 14.7 cm. The accelerator travel is adjusted using the nuts on the end of the cable in the engine compartment.

1. Unscrew the fastening nuts

2. Remove the locking bracket

3. Adjust the new cable

We recommend: How can you reduce fuel consumption on a VAZ-2114?

If the spring breaks

If the return spring bursts, the procedure will be different. To replace, you will need the spring itself; if you do not carry it with you, you will have to go to the nearest spare parts store.

How to change a spring:

Open the hood and use a wrench (it’s more convenient to use a spanner) to unscrew the cable nut

You need to extract it. Carefully, so that the remains of the old return spring do not fall apart, remove them. Please follow all safety rules. Take the new part and install it in place of the old one

This also needs to be done carefully, since in this case it is very easy to damage your hand or fingers. Then reinstall the cable. Tighten the nut. After this, adjust the free and overall travel of the pedal. Start the engine and try to drive it.

1. Unscrew the fastening nut.

2. Remove the spring and replace it with a new one

How to get to the service station on your own?

Of course, it will be better for the driver if this breakdown occurs near his home, then you can consider yourself lucky. But if this happened on the road, and the nearest service station is not so close that you could push the car to it, then this is already a problem. But there is a way out of every situation, so if the clutch pedal fails, you can still get to the nearest service station, and now we’ll tell you how.

To drive in first gear - if you need to restore the pedal's functionality, you can do the following:

- The gearshift lever must be moved from neutral to first gear. In this case, the gas must be released.

- Start turning the key in the ignition. When the engine tries to start, apply gas, but do it so that the car does not stall.

- When the car starts to move, do not try to change to the next gear. This is fraught with breakdown of the gearbox, and its repair, believe me, will cost more than calling a tow truck.

In general, the same method allows you to start moving at second speed.

But before you do this, check out some important points:

- When the pedal fails, do your best to stop the car on a downhill slope or on a straight road without the car rolling backwards.

- Warm up the engine before driving.

- Before you start moving, carefully consider your entire route, because you need to take into account all the nuances. This includes the number of intersections, traffic lights, where you should turn from and where, and so on. It will be more convenient to drive only on the main road, so that you don’t have to stop to let other cars pass.

- Turn on the warning lights (hazard warning lights).

- Avoid unnecessary maneuvers and remember that no one knows about this problem except you. It’s better to stop once again and repeat the procedure than to create more serious problems for yourself.

- If you are not sure that you can cope with such a task on your own, then maybe it makes sense to call a tow truck or tow the car to a service station?

Causes and provoking factors

First, you need to find out why clutch pedals on cars can fail.

It is important to know not only the causes, but also the provoking factors that can lead to such dangerous breakdowns while driving.

- Broken cable. This often happens in the tip area. Breaks occur for a variety of reasons. But the fact is that a break has occurred and the problem needs to be solved. It is possible to cope with the task on the spot only if a spare cable accidentally ends up in the trunk. Given this potential danger, it is never a bad idea to have such a cable on hand just in case.

- Wear, deformation and damage. Moreover, this may concern various parts that are directly related to the clutch assembly in the car. Damper and diaphragm springs, as well as flywheels and pressure plates, are most often affected. In some cases, the culprit is the bearing. It also cannot be ruled out that the release fork is simply stuck in the clutch.

- Malfunction related to the driven disk. This disk may fail if there are defects, as a result of deformation and various damages.

- Leak in the hydraulic system. It is quite possible that the pipeline responsible for the passage of hydraulic fluid has failed.

- Problems with the master and slave cylinder. Here, air is likely to get into them, which disrupts the normal operation of the clutch pedal.

- Wear of friction linings on the driven disk. This results in insufficient free play for the pedal.

- Aggressive and inept driving style. All of the above breakdowns can occur due to the fault of the driver himself, who has not learned to operate the clutch pedal correctly.

As you can clearly see, there are a lot of reasons and factors influencing the occurrence of problems with the clutch pedal in vehicles.

It is not always possible to eliminate them in the field and calmly move on with your business. In some cases, you may need to stop and call a tow truck. It is strongly not recommended to take risks and try to get to the service station or home on your own.

But sometimes circumstances work against the driver. And the only option to get help and return the clutch pedal to working order is to try to drive yourself to a car service center. Nobody wants to face something like this. But sometimes there is simply no other choice.

Exploitation

Thanks to its simple design, the clutch slave cylinder is quite durable and not subject to breakdown. The main malfunctions are associated with wear of rubber seals, which deteriorate from loads, exposure to low temperatures and brake fluid. If damaged seals are not replaced in time, dust and dirt that gets inside will damage the cylinder mirror, after which the brake fluid used in the hydraulic drive leaks out through micro-scratches, even if new clamps are installed. In this regard, it is advisable to inspect the working cylinder at every maintenance, and if drips appear, either repair it or replace it with a new one.

The working cylinder repair kit includes the necessary replacement parts for each specific model: boots, seals, retaining ring, and some kits may have a spare return spring, piston, rod.

A normally operating clutch cylinder does not manifest itself in any way and does not require any special precautions. Replacing it is quite simple and quick

There is no specific replacement schedule; the working cylinder will last as long as its technical reserve allows, as a rule, at least 150 thousand km.

Why does the clutch pedal fail?

Very often, until the moment when the clutch pedal on a cable drive failed, the breakdown was accompanied by a number of circumstances:

- the driver is trained to keep his foot on the clutch pedal, thereby contributing to increased wear of the driven disc;

- while driving, it frequently and sharply operates the clutch pedal to reduce jerking of the car when maneuvering in low gears;

- Just recently we replaced the clutch basket with disc and diaphragm spring.

It is often possible that it failed due to a break in the cable head, since the cable itself, its fastening on the foot, fails extremely rarely, but it also happens. To check the serviceability of the pedal lever and drive, simply disconnect the cable from the mechanism on the engine crankcase and operate the pedal. If the fastening on the pedal lever breaks, the cable will come out of the braid by 20-25 cm.

In the overwhelming majority, the main reason that it failed is the breakdown of the clutch release tab. All of these factors adversely affect the operating conditions of the most loaded drive part.

The tendency to release harshly and the new stiff diaphragm spring will often break one of the fork axle bearing ends or a tooth. Rarely, but still there are situations when the clutch release support pin, on which the fork tooth presses, fails; it simply breaks through and jams in one position.

The drive is working - we are looking for another reason

If the pedal fails, and you find out that the drive is in working order, then the reason is more serious - the clutch mechanism itself has broken down. There are several possible faults:

- the axis of the release fork gets stuck - the most “successful” type of breakdown;

- damage to the release bearing (clutch release);

- Damage to the diaphragm spring of the drive disc.

To accurately identify the cause of the malfunction, you need to completely disassemble the clutch mechanism and inspect it. To do this you will need a pit or overpass. Repairs are carried out only by replacing worn parts.

Typical Ford Focus II clutch malfunctions

Let's look at the cases in which Ford Focus 2 clutch replacement

or repair of its individual components:

- incomplete shutdown;

- incomplete inclusion;

- increased noise when the clutch is engaged;

- vibrations;

- Difficulty shifting gears.

Craftsmen recommend installing all new parts at the same time, and not just worn-out ones. This is explained by the labor-intensive nature of the process, and the service life of undamaged structural elements has already been reduced and they will soon also require replacement. The owner decides what to do.

What actions should be taken if the clutch slips?

The most rational and correct solution is to replace the clutch, but before that, you need to get to the garage. This must be done with extreme caution. To avoid problems, you need to drive with the lowest number of revolutions. It is necessary to start moving “under load”. This means that the clutch needs to be released as smoothly as possible, but at the same time add a minimum of gas, or even not at all. Gear shifting should be performed according to the number of revolutions prescribed by the manufacturer.

The clutch has fallen: why does the clutch pedal fail?

Let's start with the fact that such a malfunction, when the clutch is lost, can happen completely unexpectedly. To accurately identify the problem, it is important to know why the clutch fails and what to do in such a situation.

In a nutshell, the clutch is necessary to “disconnect” the engine from the transmission in order to be able to engage and disable gears, and also allow the car to run at idle.

First of all, the clutch pedal usually goes down for the following reasons:

- The return spring is faulty. Said clutch return spring creates resistance that pushes the pedal back after the driver stops pressing it. Simply put, by removing your foot from the clutch, the pedal should return to its original position on its own. If the spring has burst, shifted or is extremely worn, then the clutch pedal may not return or may become stuck. To fix the problem, you need to disassemble the return mechanism and change the spring;

The next problem on the list is the failure of the clutch fork. As a rule, the specified fork needs to be changed, since it actively wears out and is then damaged during operation;

- The clutch cable has broken (the clutch cable has burst/broken), the fastening of the clutch cable tip has broken. In this case, the clutch cable needs to be changed;

Please note that if clutch failure occurs due to problems with the master cylinder, the functionality of the clutch pedal can be partially restored by pressing it sharply. This method is suitable as a temporary solution to get to the repair site.

However, it is not recommended to drive for a long time in this way, as this can result in other damage. For this reason, the owner of a car with a manual transmission must know how to drive without a clutch, how to engage a gear (speed) without a clutch, etc. Such skills allow you to combine available methods, which makes it possible to minimize the risks of additional malfunctions when driving with a faulty clutch.

What caused the problem?

Broken clutch pedal

So, if the clutch pedal in your vehicle has fallen, then first you need to determine the cause of the breakdown.

There can be many reasons, so your task, as a motorist, is to reliably identify them:

- The first and one of the most common causes is a broken clutch cable. Usually the cable breaks near the tip, on the engine compartment side. It is quite possible to solve such a malfunction on your own and right on the spot, but for this you will need the cable itself. You will learn more about the replacement below.

- Failure of the return spring of the clutch system (hereinafter - CC), which could either burst from wear or simply fly off. If the spring bursts, then there is only one way out - only replacement, so you need to go to the nearest service station either in tow, or as we will describe below. If the spring just flew off, then you can try to find it and put it in place.

- Often the pedal fails when air gets into the hydraulic drive. Driving such a vehicle will also be impossible until air is removed from the system. By the way, instructions for bleeding the system are available on our website, you can find them here.

- Failure of the CC fork can also cause the clutch pedal to drop. It is unlikely that you will be able to solve the problem on the spot, unless you are a car repairman. There is only one way out - replacing the element.

- Incorrect operation of the master cylinder CC, in particular, defects in the mirror, wear or failure of the cuff. In this case, the clutch pedal has failed, but periodically it can be returned to its place by pressing sharply. For normal driving of the car, it is necessary to replace the main cylinder of the system itself.

- Driven disk failure. As a result of this, if the clutch pedal fails, it will be very soft, you will feel it. Failure of the driven disk may be due to the appearance of defects, mechanical damage or deformation of the element. In addition, the cause may be a fluid leak from the hydraulic system or a pipeline breakdown. In this case, the driven disk could fail as a result of the breakdown of the main and working cylinders, or one of them.

Drive and its adjustment

To begin with, if the reason is still in the cable and it needs to be changed, dismantle the old part.

It is attached directly to the gearbox with a bracket. Here you also need to unscrew all the bolts and nuts slowly and evenly. Next, the fork is disengaged after the cable has been slightly loosened, but not completely removed. The cable itself needs to be looked for under the hood of the vacuum hydraulic booster of the brake system. Use a screwdriver or other similar element to pry up and remove the locking bracket, and only then dismantle the part. Sometimes the reason is not in the cable, but in the bushing to which it is attached. It may be bent or out of order, making it difficult to secure even a new cable correctly. Therefore, if a breakdown occurs, then this part is also replaced. It is also advisable to lubricate the new cable with a special compound to prevent damage from friction.

Cleaning system elements from oiling

First of all, you need to disconnect the battery, since to clean the flywheel and other elements of the system, you will need to dismantle the gearbox. And since when dismantling the box you will need to disconnect the electrical connectors, the battery should be disconnected. Remove the gearbox. If you do not have enough experience and knowledge for this, then it is better to seek help from a service station. Next, you need to unscrew the screws that secure the flywheel. Try to keep it from turning when you remove the screws. Remove the flywheel and clean it with white spirit or acetone. You can also use gasoline for these purposes. Do similar actions with the pressure and driven disk if these components are oily. Before direct installation, cleaned elements must be wiped dry.

Please note: if the driven shaft is too oily, it would be more advisable to replace it, since in practice cleaning the element rarely helps. It is also necessary to eliminate the cause of the oiling. In VAZ 2110 cars, oil leaks can occur through the gearbox or engine seals. Reassemble everything in reverse order.

Using a wrench, unscrew the screws that secure the flywheel. Dismantle the component and clean it of oil. Also visually check it for mechanical damage.

How to get to a car service center with a broken clutch?

If the clutch fails, the easiest and safest way to get to the nearest service station is to call a tow truck or tug. Inexperienced drivers should not even try to risk starting and driving with such a malfunction. This can lead to gearbox failure, which is much more serious and significantly more expensive in terms of repair costs.

When you are confident in your own abilities, the first thing you need to do is try to start the car. If you feel that the clutch has failed, you should not put the car downhill. It is better that you are on a flat road, or the ideal option is to start moving from a hill. It must be started in first gear. When turning the ignition, you must simultaneously gently press the gas pedal. In this case, the car will not stall, but will drive jerkily, since the revolutions do not correspond to the driving speed. After this, you can begin to move slowly. It is very important to think through the route so that there are a minimum number of stops along the way. After all, you won’t be able to stop the car just like that; you’ll have to turn off the engine. And the engine starting procedure will need to be repeated. It is also not recommended to change gears, as this may damage the gearbox.

Using a tow truck, you can easily and safely deliver your car to a car service center.

To stop the car, you just need to turn off the engine or, if the speed is high, first depress the brake pedal.

Additionally, it is extremely important to be very careful when driving with a broken clutch. It is better to drive along the main highway so that you have less to give way to. It is necessary to avoid pedestrian crossings and unnecessary maneuvers. And one more thing, so that other participants understand that you have a malfunction, it is better to drive with the emergency lights on.

How to determine this defect?

Clutch slipping can be easily detected independently, without the use of special equipment.

- start the engine;

- engage neutral gear;

- apply the handbrake;

- press the gas pedal;

- depress the clutch;

- go to first speed;

- release the clutch pedal.

By all rights, as a result of these manipulations, the engine should eventually stall. If this does not happen, the engine continues to work, and even extraneous sounds or a burning smell appear, this means that the clutch is slipping and measures to repair it should be taken immediately. This is caused not only by financial reasons, but also by reasons of personal safety.

How to fix problems with the VAZ 2107 clutch with your own hands?

Life is full of surprises. And especially for motorists. Not only do you need to be constantly attentive on the road, but you also need to be able to notice and fix problems in your car in a timely manner. Especially when there are no populated areas nearby and the nearest service station is far away, or when you are stuck in a traffic jam and the clutch pedal is stuck or the brakes have disappeared.

This problem is a constant topic of discussion on many forums for car owners of almost all brands. Of course, a clutch can fail for many reasons. Let's look at the most common cases of problems with the clutch pedal of the VAZ 2106 and VAZ 2107.

Source

Reasons why the pedal goes to the floor with a hydraulic drive

If the clutch drive is hydraulic, as on classic VAZ, Ford Focus 2, Volkswagen Passat, Skoda Octavia, Peugeot 206, Fiat Ducato, Scudo from 2000, most likely the system is simply airy. In this case, it requires bleeding, like any brake circuit. This is done according to the same principle as bleeding the simplest brake system. The purpose of bleeding is to completely remove air from the system. The fluid used is exactly the same as in the brake system. On the Audi 80, for example, the main hydraulic cylinder is directly connected to the pedal, and the working cylinder is installed in the crankcase.

Bleeding the system will take two minutes; the main thing is not to forget to add fluid to the tank to the maximum level. In hydraulic clutch drives, a leak will indicate a malfunction. So, on the Mazda 6, the drive hose is located under the battery platform, so some flexibility may be required to detect a leak. But there are no unsolvable problems. If you approach any problem wisely, it will be solved in no time, and we will gain valuable experience.

Hits 2016: rating of crossovers by cost and quality

They are the result of genetic modeling, they are synthetic, like a disposable cup, they are practically useless, like Pekingese, but they are loved and expected. Those who want a fighting dog get themselves a bull terrier; those who want an athletic and slender dog get one.

Rating of the best-selling cars of the 2016 model year

Since the time of the first steam propulsion device, Cagnoton, created in 1769, the automobile industry has made great strides forward. The variety of brands and models nowadays is amazing. Technical equipment and design will satisfy the needs of any buyer. The purchaseability of that one.

Rating of reliable cars 2015-2016

Reliability is, of course, the most important requirement for a car.

Design, tuning, any bells and whistles - all these trendy tricks inevitably pale in importance when it comes to the reliability of the vehicle. The machine must serve its owner, and

HOW to choose a car, Buying and selling.

How to choose a car Today the market offers buyers a huge selection of cars, which simply makes their eyes wide open. Therefore, before buying a car, there are many important points to consider. In the end, having decided on what exactly you want, you...

Review of the most popular crossovers and their comparison

Today we will look at six crossovers: Toyota RAV4, Honda CR-V, Mazda CX-5, Mitsubishi Outlander, Suzuki Grand Vitara and Ford Kuga. To two very fresh new products, we decided to add the debuts of 2015 for a test drive.

https://avtomotospec.ru