The relatively complex scheme for distributing torque from the internal combustion engine to the wheels is explained by the universal purpose of the Niva 2121 - if used correctly, it can be used comfortably in the city and along muddy country roads.

Such properties are ensured by the presence of a transfer case with a center differential lock, complementing a 4- or 5-speed manual transmission, depending on the year of manufacture.

The lever located closer to the dashboard is responsible for turning off/on the center differential, the second “small” lever controls the range multiplier and has 3 positions: high and low rows, as well as neutral.

Box repair

Often the transfer case cover (Niva Chevrolet is no exception) begins to leak oil through it. At the same time, its level in the box begins to fall slowly but surely.

In this case, the transfer case seals should be changed. Chevrolet Niva is equipped with three sealing elements. To replace these seals, you need to take the box out. It is best to do this on a lift or inspection pit. So, first we clean the box from oil stains and thoroughly blow it out. Next, we dismantle the driveshaft. An important point: when removing the bolts, inspect their condition. If the threads are “licked”, such bolts can no longer be used. And to eliminate imbalance of the driveshaft, make a mark on it at the dismantling points. Next, insert two bolts into the holes of the shaft flange and screw the nuts onto them. Use a small spatula to keep the element from rotating. Using a 24 mm socket, remove the nut and take out the flange washer. We also take the last part out. Next, take a flat-head screwdriver in your hands and remove the transfer case oil seal. The seating surface must be wiped with a dry cloth and a little new oil applied to the sealing element. Using a mandrel, press it into place. The remaining seals are installed in the same way. After completing the repair work, add oil to the transfer case. Niva Chevrolet loves gear lubricant with a viscosity of 80W90.

Who is to blame and what to do?

I think that the first question is rhetorical))) But let’s try to answer at least “why this is so.” I am a mechanical engineer by education and work, production technology is at an average level, so I turned to a military plant technologist for advice. How it should be: the workpiece is made with a press, rough processing is carried out with allowances, a thermal treatment is made, the part is processed completely according to the “main and landing” dimensions. How it was done: the last stage was removed. After heat treatment, the part warps and does not come out clean. Or it is placed on a cylindrical mandrel during finishing processing, which cannot be done. Since with this design, everything is centered on the splines.

The answer to the second question. We buy a box at the factory containing 100 “semi-finished” flanges wrapped in oil paper, drag them to the lathe, set up the “finishing fixture” and finish the entire batch.

Malfunctions of VAZ transfer cases

The transfer case on the Niva is a fairly reliable unit; problems with repairs in the mechanism itself arise mainly due to insufficient oil level in the valve - if for some reason the oil leaks out, intensive wear of all parts occurs. Among the frequently occurring malfunctions are:

- vibration in the body at various speeds when the car is moving;

- vibration when the vehicle starts moving;

- noise in the transfer case when the car is slipping or turning;

- difficult upshift or downshift, difficult engagement of the lock.

Main problems with the range multiplier

The main function of the range multiplier has the properties of a gearbox divider; it turns them on or off the gear speed.

Most transfer case breakdowns are purely mechanical in nature (for example, a cut shaft between the gearbox and the transfer case). This is provoked by inattention to fuel and lubricant levels, wear of rubber bands, incorrect location (alignment) of the unit, and the condition of adjacent components. The first indicator of problems with the transfer case is characteristic noise and vibration in the body.

Vibration when driving on Niva

The first reason is that at a speed of more than 70 km per hour, it’s all about the cardan shaft; only the original one must be installed. Next, replace the crosspiece on the cardan shaft, after which you must drag the shaft to a stand and balance it, otherwise the vibration will resume.

Important: The shaft itself on the Niva lasts two years, then it must be replaced. It is better to order from the manufacturer, this is not difficult to do on the Internet.. The second reason for vibration is the intermediate shaft, it must also be original, otherwise it will quickly fail

We take only the original AvtoVAZ one from the factory, otherwise vibration and breakdowns cannot be avoided

The second reason for vibration is the intermediate shaft, it must also be original, otherwise it will quickly fail. We take only the original AvtoVAZ one from the factory, otherwise vibration and breakdowns cannot be avoided.

The third reason for vibration is the breakdown of the gearbox flange bearings. To eliminate the problem, place additional support on the gearbox.

How to overcome noise when maneuvering in a transfer case

You can buy new handles for the levers. We change it ourselves, prying up the support with a screwdriver, take out the lever axis and get rid of the old handles. We remove the old lever springs and install new ones. Insert the lever axis and secure it with a corkscrew nut. Now, when driving with the new handles, there is no characteristic noise in the cabin. The handles can be easily changed without leaving the salon.

Stiff switching of the lock lever

This issue can be easily solved in the following way: when driving, just turn the steering wheel slightly and the lock will immediately turn on without any problems.

There are also: jamming of the pneumatic cylinder, sticking in the neutral position, or the rod is sitting tightly. Burnt gear and shift fork.

Transfer case for Niva, signs of breakdowns:

- problematic engagement of the front axle;

- overheating of the range multiplier;

- leakage or excessive consumption of oil during operation of the transfer case;

- self-switching of the front axle.

Repairing the transfer case in Niva 21213 with your own hands is quite possible in case of minor breakdowns. The owner of a Chevy Niva will only need the basic skills of a car mechanic. It is more difficult to correctly install and center the Niva transfer case. Here it is still recommended to contact a car service. A diagram of the unit itself is presented in the vehicle documentation.

Transfer case control

The Niva 2121 transfer case has manual control with a lever-type mechanical drive. The shift lever swings in the longitudinal direction and is performed on an axis that is installed in the bracket eyes in front of the transfer case. Friction is reduced by pressed plastic bushings into the holes of the lever.

The lower part of the lever is inserted into a groove on the rod, and fixation occurs using a figured spring. The other end of the rod, in turn, is connected to a fork, which moves the shift clutch. The rigidity of this connection is ensured by the bolt. The rod at the outlet of the transfer case is sealed with an oil seal, and dirt and dust are protected with a rubber corrugation. The entire switching drive is fixed in the set position by a spring-loaded ball that fits into special grooves in the rod.

Eliminate vibration with additional fasteners

Installing the third support of the transfer case on VAZ 21213/21214 vehicles allows you to reduce the level of vibration of the transfer case; with this support it is easier to center the transfer case. The part can be purchased at auto stores or made yourself. The finished product comes with three long studs (for model 2121); to install the third support on this machine, you will need to unscrew the short studs from the transfer case housing and install new studs from the kit. We carry out repairs as follows:

VAZ Niva transfer case: operating principle

The VAZ 2121 transfer case has only a few gears with gear ratios of 2.135 and 1.2. The SUV's axles are connected using a center differential, which redistributes torque to the wheels depending on their resistance to movement.

When driving a VAZ Niva on a flat, dry road surface, there is no need to use additional functions of the transfer case, since the wheels have good grip on the road. When road conditions worsen, it becomes necessary to engage a lower gear, which provides the car with a uniform and stable speed. In this case, it is necessary to switch to a lower speed limit only after the car has completely stopped.

In off-road conditions, it is possible to lock the differential, which ensures uniform rotation of both drive shafts of the vehicle and increases the vehicle's cross-country ability.

Modified versions

The Niva's standard transmission, for all its advantages, often causes uncomfortable noise in the cabin. This is generally related to the design, but using engineering developments, you can modernize it and make the car much quieter.

This approach has already been applied in VAZ-21213 cars; as a result, even at a speed of 100 km/h you don’t feel any unpleasant noise, you can talk calmly and hear your interlocutor without effort. For these purposes, a number of modernization methods have been used: from unloading the floor near the transfer case and manual transmission mounts, reducing the load on shaft bearings to smoothing out peak torques under conditions of increasing loads on the transmission.

Also interesting: Disassembly and assembly of the Niva 2121, Niva 2131 gearbox

The noise in the modernized Niva transmission is comparable to that of a Zhiguli. It becomes more comfortable to be in the car when driving off-road. Upgrade costs are negligible; modification requires only the master's understanding of the design itself and a little time.

Chevrolet Niva - transfer case control levers

The main element of the axle locking mechanism is the transfer case. The transfer case is controlled by a six-position lever. On a Chevrolet Niva, switching the transfer case depends on road conditions.

transfer case control levers

To downshift , the lever should be shifted to the right and up. This gear is engaged when the vehicle moves no more than 5 km/h.

This gear is used for minimum speed when overcoming a steep climb or dirt road. It is important that if the car is moving in second or third speed and there is a noticeable obstacle on the road ahead, then it is necessary to stop in advance and shift to a lower gear. This will prevent the clutch from burning out.

To engage an upshift (lock ) - the lever is switched back all the way.

Overdrive is used in the following cases: when driving on rough terrain (where there is a risk of wheel slip), when there is a lack of engine traction, or when driving on a road covered with snow or ice.

Locking at high speed is extremely dangerous, as there is a risk of the car skidding. It is also important that the lock cannot be used if the car is suspended diagonally and the wheel begins to slip on different axles. This is due to the design feature of the gearbox.

Changing gears from low to high is also possible while the vehicle is moving. To do this, depress the clutch twice.

The intermediate position of the lever (neutral gear) completely disables the box, which means that the vehicle cannot be moved

The control lever has the following designations:

- Low (L) - reduction gear (move the lever to the right and up),

- High (H) – overdrive (lever back),

- Neutral (N) – neutral.

You can switch to locking (differential lock) in both high and low gears. To do this, pull the lever to the left until it stops.

The differential is one of the most important elements of the transmission. Its main purpose is to distribute traction force and, if necessary, rotate two consumers at different angular velocities.

A series of downshifts

You can often encounter the following type of misconception: switching the rear handle can increase the power characteristics of the motor. But this is not true. It serves to change the gear ratio between the engine and the wheels. By increasing it, the traction forces on the wheels will increase. There is also a reduction gear in the dispensing mechanism.

DON'T SPEND MONEY ON REPAINTING! Now you can remove any scratch from the body of your car in just 5 seconds.

Its operation can be controlled using the rear handle. When we shift the lever back, we will have a gear ratio of 2.135 - this is a low gear. It is recommended to downshift such a gear only when the car is stationary and the clutch is depressed. Despite the fact that the manual does not contain such a restriction, novice and inexperienced Niva drivers are not recommended to switch while driving, since the Niva transfer mechanism is not equipped with a synchronizer.

Blocking

It is worth noting that on domestic SUVs the transfer case (including Chevrolet Niva) has a differential locking function. Thus, torque transmission can occur either symmetrically or asymmetrically, depending on the position of the shift lever in the cabin. To connect the front axle, a chain drive is used. This unit consists of gear links (driven and driven) and a drive chain. On modern SUVs, all-wheel drive is engaged automatically. But here the transfer transmission is made in the form of a bevel gearbox.

Possible problems

Harsh operation and insufficient attention to how to use the transfer case on the Niva 2121 lead to the appearance of:

- Vibrations in the body while driving

- Vibrations at start

- Gula

- Noise when maneuvering

- Tight switching modes

Experience shows that the culprits are: insufficient oil level, incorrect centering of the steering wheel, loosening of the support fastenings and damage to the rubber bands. An additional influence is exerted by the condition of the cardan and the engine itself.

- Vibrations in the body while moving Vibrations when starting Hum Noise when maneuvering Tight switching on modes

Sometimes there is a knocking sound in the transfer case. The Chevrolet Niva is a more reliable car than the VAZ-2121, but such malfunctions should not be ruled out. The first thing you should pay attention to is the driveline. Previously, Nivas had crosses, the play in which caused a lot of noise and vibration.

Tips for owners

To make driving your car comfortable, read some important points:

- The usual, standard arrangement of the front and rear handles is forward and backward, respectively. Movement in this mode can and should be carried out in areas characterized by even and smooth surfaces.

- Locking the differential by switching the front handle to the rear position is best on roads characterized by increased slipperiness. This measure will give Niva stability. It is worth understanding that after overcoming the problem area, the handle will need to be returned to its original position.

- As noted earlier, downshift should be activated before a potential obstacle, but not while the car is already stuck.

- It is worth understanding that activating the lock when the vehicle is stationary is sometimes impossible, even if the clutch is depressed. This may be caused by the clutch teeth hitting the gear teeth. In this case, you can try to activate the lock by starting to drive slowly and make a slight turn. If problems arise with disabling the lock, it is recommended to perform the same procedure with the clutch depressed and the steering wheel slightly rocked.

Read news about the new Niva

- Diagram and location of the fuse box Niva VAZ-21213 and 21214

- Diagram and location of the fuse box Niva VAZ-21213 and 21214

- Front lower suspension arms VAZ-2121 - Drawings, 3D Models, Projects, Cars and automotive industry (Car service)

- Timing marks on a Chevrolet Niva car

- Chassis, front suspension, device, Design, operation, description, device, car repair Niva VAZ 2121, engine, assembly, disassembly, transmission, gearbox

- Suspension lift in the field yourself | Niva Repair

- Niva 2121 suspension lift do-it-yourself drawings

- Tuning Niva 2121 with your own hands: body, interior, suspension

Differential lock on a Chevrolet Niva - Online auto workshop

A self-locking differential (popularly “self-locking”) is a device that automatically redistributes power flows from the difference in torque on the drive wheels, depending on their coefficient of adhesion to the road. In other words, a wheel that is hanging out or slipping will receive a minimal amount of torque. Is such a differential needed for Lada 4×4?

The Chevrolet Niva owes its good off-road characteristics to its predecessors - the VAZ2121, namely permanent all-wheel drive, with the possibility of forced differential locking. But before setting up the transfer case and using the gearshift levers correctly, you must first understand how this mechanism works and what happens during its operation.

The transmission of this type of car consists of several main components: cardan, gearbox, transfer case and axles. The main component in the bridge structure is the differential. If it were not there, the wheels would rotate at the same speed, which would lead to wheel slipping and excessive load on the axle. The presence of a differential allows you to avoid destruction of the axle due to the fact that when turning, torque is transmitted to one of the wheels.

The design itself provides for the transmission of torque to the wheel, which experiences less traction with the surface. Therefore, for example, a wheel that stands on ice or sand will spin faster than one that stands on asphalt.

The Niva design provides for the presence of three differentials. This is due to the presence of permanent all-wheel drive in the car. If the same force were transmitted to all wheels, then the car could only move in a straight line. But when turning, the forces between the wheels are distributed unevenly.

Also interesting: Construction and repair of the VAZ 2121 Niva transfer case

There are some SUV models that do not have a center differential installed, but they use other technical solutions, such as clutches or all-wheel drive is not permanent.

A differential is a device designed specifically to transmit the so-called torque from a car engine to its wheels using transmission elements. A free differential, installed on vehicles during assembly at the factory, cannot affect the other when one of the wheels slips.

Differential locking can help achieve different wheel speeds when necessary (for example, on poor, usually dirt roads). It increases torque on one of the wheels, usually the one with the best traction. To achieve this result, a self-locking differential is used. An alternative option could be a forced blocking method.

It is important to understand whether it is worth installing a self-locking differential on the Niva, what this will do for the car and how to carry out the installation of the device.

Return

All-wheel drive in the Niva is equipped for all 4 wheels, and the center differential is locked. The mechanism consists of a gearbox, a transfer case designed for 2 stages, and cardan shafts located in the front and rear of the machine. This also includes the front and rear axles.

When the engine starts to rotate, an impulse is sent to the gearbox and transfer case, after which the torque is distributed to the front and rear axles simultaneously. Afterwards, the gearboxes are activated, and behind them the front and rear wheels of the Niva begin to rotate. Torque causes 4 wheels to rotate at once, which is why it is called full torque. But the rear wheels still drive.

7 The cutouts of the segments on the diff housing tenon are not shown.

8 Extension lines should protrude beyond the dimension lines by 3.

After they pass, it necessarily turns off. These mechanisms are a compromise between hard locking and free-running differential operation. So, on the basis of such systems you can use both.

A self-locking differential is installed on the Niva to reduce tire wear. Driving in urban environments, on country roads and highways requires different speed limits.

That is why proper operation of the device is a guarantee of long-term trouble-free driving. It is a mistake to assume that the differential controls the load applied to the wheels in any road conditions.

The purpose of the differential (also called a self-locking differential) is to help the car overcome off-road conditions. Much here depends on the operation of the gearbox.

This mechanism is a kind of distributor of traction forces coming from the motor to the wheels. An important feature is that the latter have the ability to rotate at different speeds. The importance of having a differential mechanism is due to the fact that during turning maneuvers, the wheel located inside makes fewer revolutions when compared with the number of turns of the outer wheel.

In the absence of a differential mechanism, this would cause detrimental consequences, such as wear and damage, because the result would be the following: when turning, one wheel would be in a slip state, and the second would simply rub against the road surface. The design features of the Niva transmission provide for the presence of 3 differentials. They are located in each of the bridges and in the transfer mechanism.

When the car moves on a flat road and in a straight line with differentials, the traction force is divided equally between all 4 wheels. If there is insufficient adhesion of the wheels to the surface or slipping occurs, the differentials will redistribute the load on the slipping and sliding wheel so that the first receives more force, and the second, accordingly, less.

We have already mentioned UAZ. Despite many similarities, it should be understood that the VAZ’s all-wheel drive is made in the “pat-time” style. This means that when connected, the axes are firmly connected to each other, and rotation occurs at the same speeds. This device imposes some restrictions on the use of all-wheel drive - it can only be used in cases where road conditions allow slipping. In cases with hard asphalt roads and highways, it is recommended to switch the car to single-drive mode.

Sometimes you can come across a misconception about why a small handle is needed next to the shift lever on a Niva. Some car owners believe that it is needed to connect front-wheel drive. However, the front-wheel drive of this car is permanently connected. As is the rear one. Cars of the Niva family have permanent all-wheel drive. The handle actually serves to switch the operating modes of the differential of the transfer mechanism.

In the “forward” position, the differential operates as usual, but if you move it back, the differential is locked, and the forces from the motor are applied to the differentials of the axles, which makes the drive more rigid. It is worth noting that there are also special types of locks for front and rear axles.

In theory, when used in conditions where the car is stuck, it will be able to overcome the obstacle if there is sufficient traction on at least one wheel. In this case, it is better to lock the differential before overcoming an obstacle, but never after entering an area that is difficult to overcome. This application of locking will avoid wear and damage to the transmission.

To lock the differential on the Niva, the manufacturer has provided a clutch for the locker. When forced locking is turned on, the wheels become interconnected and rotate in the same mode. When the inter-axle lock is activated, the axles located at the front and rear interact and distribute traction to all wheels. This mechanism is easy to use, which is confirmed by the unique cross-country ability of the Chevrolet Niva.

This mechanism is a kind of distributor of traction forces coming from the motor to the wheels. An important feature is that the latter have the ability to rotate at different speeds. The importance of having a differential mechanism is due to the fact that during turning maneuvers, the wheel located inside makes fewer revolutions when compared with the number of turns of the outer wheel.

If manufacturers decided not to include a differential in the transfer case structure, the result would be frequent tire wear. This would have been a blessing for tire manufacturers, but the developers turned out to be smarter. In addition, the differential reduces the load on the axle.

Nivov transmission units

The legendary Niva is an all-wheel drive vehicle. This ensures unprecedented road holding and reliability comparable to expensive high-performance cars. With the exception of updated versions under the Chevrolet brand, the traditional Niva has always had a rather modest design, but this did not prevent it from being the undisputed leader among car owners who prefer high-end car platforms.

What distinguishes the Niva's chassis from other all-wheel drive vehicles is the transmission of torque to two axles at once without disabling the axles, which significantly affects cross-country ability while simultaneously reducing the influence of critical loads on the transmission. This same quality makes this legendary Russian SUV very uneconomical in terms of fuel consumption.

The developed Niva transmission turned out to be so successful and efficient that it later became a prototype for the Vitara. This made the new model more adaptable to difficult roads. Niva transmission units can easily meet the requirements of any engine up to 2 liters, so if you want to upgrade, think about the fact that each car has its own capabilities. Many advantages are due precisely to the circuit and design of the transmission.

Niva transmission and its components:

- front-wheel drive;

- front axle;

- wheel grip;

- manual transmission;

- driveshaft (front);

- shaft (intermediate);

- transfer case;

- shift lever;

- center differential and locking lever;

- wheel differentials;

- driveshaft (rear);

- rear axle;

- rear drive.

The design implies the following states:

- unlocked differential;

- locked differential;

- low gear when engaged;

- neutral position;

- top gear engaged.

The features of the Nivov transmission include the presence of a center differential that connects the rear and front axles. As a result, the wheels can rotate not only at different angles, but also at different angular speeds, which significantly affects controllability in impassable roads.

The key difference between the Niva’s center differential is the ability to lock when driveshafts rotate with the same characteristics. The center differential is manually locked only in difficult terrain conditions, when you need to overcome a large hole, rut or snow drift without slipping.

In practice, mechanical locking, although somewhat inconvenient, turns out to be better than the modern electromagnetic clutch used for these purposes. For example, the Renault Duster is not so easy to cope with the task in harsh off-road conditions, since the digital control unit can provide limited torque transmission. However, this effect will not be observed in a Niva with a mechanical lock.

Leaving the center differential locked will not only cause increased wear, but will also significantly reduce the vehicle's handling. The activated differential lock mode will be indicated by a lit indicator on the Niva dashboard. Please note that locking will not prevent one wheel from losing traction.

To overcome difficult areas, the transmission allows the use of a low gear with a high gear ratio (2.135); in the highest gear, the parameter is 1.2 and is intended for driving in normal conditions. The transfer case indicates different high and low gear modes. The lower one is turned on before entering a snowy area, unsteady soils, hills, and when a towed load is connected.

Some drivers master the skill of shifting gears at speeds of 30-35 km/h. Otherwise, you will have to stop the car and perform the operation in the parking lot.

Please note that Niva requires a competent approach to the selection of tires, the quality of which can affect the degree of wear of the transmission in just one season. The tires must be the same in terms of wear and, of course, in size. Different characteristics will lead to increased load on the transmission and slipping in low gear, and during normal driving will increase wear on the differentials.

1, 3 – Front wheel drive; 2 – front axle; 4 – clutch; 5 – gearbox; 6 – front driveshaft; 7 – intermediate shaft; 8 – transfer case; 9 – transfer case gear shift lever; 10 – differential lock lever;

11 – rear propeller shaft; 12 – rear axle; I – differential unlocked; II – differential locked; III – low gear engaged; IV – neutral position; V – high gear engaged

Transmission Specifications

The Niva car is all-wheel drive, i.e. All wheels are driven. All-wheel drive is permanent: torque from the engine is always transmitted to both axles at once (the axles are not disabled). This scheme increases the vehicle’s cross-country ability, while simultaneously reducing the load on the transmission units, but slightly increases fuel consumption.

The front and rear axles are connected through a center differential, allowing the front and rear wheels to rotate at different angular speeds depending on the trajectory and driving conditions. The center differential is located in the transfer case and is similar to the cross-axle differentials located in the front and rear axles.

However, unlike them, the center differential can be forcibly locked (the locking lever is located on the floor tunnel). In this case, the front and rear driveshafts become rigidly connected to each other and rotate at the same frequency. This significantly increases the vehicle’s maneuverability (on slippery slopes, in mud, snow, etc.

), but worsens handling and increases wear on transmission parts and tires on surfaces with good grip. Therefore, the differential lock can only be used to overcome difficult areas and at low speeds. A warning lamp on the instrument panel serves to warn the driver that the locking mode is on.

And also interesting: Non-adjustable front hubs Niva and Chevrolet Niva with a reinforced hub, a double-row bearing from an Iveco truck and additional oil seals with ABS

You can engage the differential lock while the car is moving, if the wheels do not slip. Locking the center differential does not relieve the car from the danger of “diagonal hanging”, when one of the wheels on each axle loses traction with the ground - in this case, pour soil under the suspended wheels or dig it under the others.

To increase the torque supplied to the wheels, a low gear in the transfer case is used, its gear ratio is 2.135. The highest gear, intended for normal driving conditions, has a gear ratio of 1.20. Thus, the driver can use one of two rows of gear ratios - with a high or low gear in the transfer case.

The total gear ratios of the “top” row (from 1st to 5th gear) are 4.40; 2.52; 1.63; 1.20; 0.98, “lower” – 7.82; 4.47; 2.90; 2.13; 1.75. The low gear in the transfer case is switched on before overcoming snowy, sandy areas, steep climbs, when towing loads, etc., when there is a lack of engine traction or for driving at very low speeds.

It is necessary to engage a low gear in the transfer case in advance, with the car stationary, since the gear shift clutch does not have synchronizers. With some skill, it is possible to engage the highest gear even when driving at a speed no higher than 30–35 km/h, however, if possible, it is better to reduce the speed or stop.

A vehicle with permanent all-wheel drive places special demands on tires. They should be the same not only in size, but also in the degree of wear. Different tire rolling radii will cause increased wear on the differentials under normal driving conditions, and when the lock is engaged, increased wear on other transmission parts and wheel slip.

Video

The normal position for the RK handles, ensuring adequate behavior on the road of good quality:

- Front - away from you Back - towards you

The special operating mode of the transmission is switched on not long before the car begins to overcome an obstacle (rut, mud, ford or rise). The transition to the lowest row must be done while stopping. Returning to top gear is allowed on the go, although it causes problems for beginners due to the lack of the usual synchronizer.

It is somewhat more difficult to properly handle the forced manual locking of the center differential. On the contrary, it turns on when the car moves slightly (up to 20 km/h) due to misalignment of the grooves on the locking clutch, satellites and ring gear. To simplify turning the lever into the desired position, taking into account the Niva 2121 transfer case, pick up a small speed, then, shaking the steering wheel, pull the handle towards you.

Problems can also arise when disengaging the lockout, as the clutch teeth literally catch on the ring gear. Engage reverse and, rocking the steering wheel, push the lever away from you. This action is performed immediately after overcoming a difficult section in order to avoid overloading the gearbox. It is most effective to disable the differential together with the transition to lower stages.

Removing the Niva transfer case

To repair the transfer case on a VAZ 21213 (21214), the unit must first be removed. We carry out removal in the following order:

- in the cabin we dismantle the plastic lining of the gearbox and gearbox levers;

- unscrew the knobs of the transfer case shift levers, remove the casing under them;

- disconnect the speedometer cable, for RK 21214 you will need to additionally disconnect the speed sensor;

- we unscrew the bolts with nuts securing the elastic coupling of the front and rear propeller shafts; in order to remove the bolts, the cardan shafts must be turned - they are removed one at a time in one specific position of the shaft;

- We install a jack (or other support) under the transfer case and mark the places where the side supports of the RC were attached. This is done in order to minimize the alignment of the transfer case during installation;

- unscrew the 4 nuts securing the gearbox to the gearbox;

- unscrew the 4 fastenings of the RC supports to the car body;

- Now all that remains is to dismantle the transfer case.

Disassembly

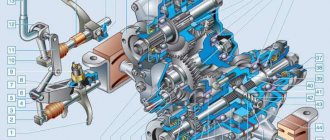

1 — front axle drive housing; 2 — crankcase cover; 3 — speedometer drive housing fig. 3-39fig. 3-38

rice. 3-38fig. 3-39

1- intermediate shaft; 2 - drive shaft; 3 — differential; 4 - front cover

1 - flange; 2 — oil seal; 3 — thrust ring of the bearing, 4 — front bearing; 5 - drive shaft; 6—high gear; 7 — hub; 8 - coupling; 9 — low gear; 10 — bushing: 11 — rear bearing; 12 — bearing installation ring; 13 — intermediate shaft bearing; 14 - intermediate shaft

- remove the lock ring 1 (Fig. 3-45) and spring washer 2 of the front bearing;

- remove the rear and front bearings from the differential housing (Fig. 3-46), using a universal puller and stop 67.7853.9559;

- by turning the bolts of the differential housing, separate the housing;

- remove the differential driven gear;

- remove retaining rings 8 (Fig. 3-45) and spring washer 14, then press out the pinion axis and remove the satellites and drive axle drive gears with support washers.

Also interesting: Adjusting VAZ 2114 and 2115 headlights: tips and tricks

1 - retaining ring; 2 - spring washer; 3 - bearing mounting ring; 4 — differential housing bearings; 5 — driven gear; 6 - front differential housing; 7 — front axle drive gear; 8 — retaining ring of the satellite axis; 9 — satellite; 10 — rear differential housing; 11, 15 — support washer; 12 — rear axle drive gear; 13 — satellite axis; 14 - spring washer

1 — puller A.40005/1/6; 2 — stop 67.7853.9559; 3 - bearing

- the axial clearance of each axle drive gear should be 0-0.10 mm, and the moment of resistance to rotation of the gears should not exceed 14.7 N m (1.5 kgf m). If the gap is increased, replace the support washers with others of greater thickness; if the specified gap cannot be obtained when installing support washers of the greatest thickness, replace the gears with new ones due to their excessive wear;

- The drive and intermediate shafts are installed in the transfer case housing simultaneously (see Fig. 3-47);

- Press the bearings onto the differential housing using mandrel 67.7853.9558 (see Fig. 3-48);

- Before installation in covers and crankcases, lubricate the working surfaces of the oil seals with LITOL-24 grease;

- Tighten threaded connections to the torques specified in Appendix 2;

- when compressing the transfer case shaft nuts, use mandrel 67.7820.9520 (see Fig. 3-49).