Car enthusiasts cannot even think that high-voltage wires are the most significant part of a car’s ignition system. The correct choice of product directly affects the stable operation of power units.

The operation of the motor is accompanied by the solution of the following problems:

- providing a voltage of 40,000 volts;

- pulse transmission must be carried out practically without losses;

- elimination of interference for equipment that belongs to the radio-electronic version;

- wire insulation should not be accompanied by current leakage;

- The temperature range that is suitable for wire operation varies from -30 to +100 degrees.

The first types of products were characterized by minimal resistance indicators. They ensured high-quality transmission of impulses directly to the engine spark plugs. When radio receivers appeared inside the car, problems with signal reception also appeared. That is why specialists modernized the products, ensuring stable operation of the main equipment.

Self-check of automotive high-voltage spark plug wires of the ignition system

It is necessary to begin diagnostics with an external inspection of high-voltage wires. During such an external examination, the presence of noticeable defects in the form of cracks, fractures, etc. is not allowed.

- The easiest way to check is to use a known good spare ignition wire. It is necessary to disconnect each armored wire one by one, replacing it with a spare one. Stabilization of engine operation after replacing one of the wires will indicate a faulty element.

- To identify a possible breakdown of the ignition armored wire, you must wait until it gets dark. When darkness falls, you will need to open the hood and start the engine. If there is a breakdown, then during engine operation an electric spark on the damaged high-voltage wire becomes clearly visible.

- Also, checking high-voltage automotive ignition wires can be done by using an additional insulated wire. To check, the ends of such a wire are stripped (exposed). Then one end is shorted to ground, and the other end should be passed along the highest voltage wire, connections, bends, caps, etc. If there is a breakdown in a certain place, then an electric spark will appear between the breakdown area and the end of the tester wire.

- Checking the resistance of high-voltage car wires is carried out using a multimeter. To check, the multimeter must be switched to operating mode as an ohmmeter. The next step is to remove the wire from the spark plug on the first cylinder, after which the specified wire is also disconnected from the ignition coil. Then the contacts of the multimeter are connected to the ends of the wire, after which the obtained data is evaluated.

In a similar way, you should check the remaining high-voltage ignition wires. It should be taken into account that the spread in readings between all wires should not be higher than 2 or maximum 4 kOhm. Exceeding this threshold will indicate the need to replace high-voltage automotive ignition wires.

It should be added that if a faulty wire is detected, replacing only one defective element is not recommended, since it is a temporary measure. It is optimal to replace high-voltage armored ignition wires in a car as a set. This approach allows for the most efficient operation of the ignition system and smooth engine operation in all modes. For the same reason, it is highly not recommended to repair high-voltage wires for further operation without replacement.

Do-it-yourself tuning and modernization of spark plugs to improve fuel efficiency and other characteristics of the internal combustion engine. How to modify the candles yourself.

Signs of faulty spark plugs. Assessing the condition of a spark plug during a visual inspection, methods for checking spark plugs. Plaque on the spark plug electrodes.

For what reasons may misfire of the fuel-air mixture occur in one or more cylinders? Fault diagnosis, recommendations.

What to do if the ignition spark is lost. Diagnostics of individual elements: spark plugs, coil, ignition module. How to check the spark on an injection engine.

The main reasons for engine oil getting into spark plug wells. What should a driver do if oil flows into the spark plug well, how to carry out repairs with his own hands.

What you need to know when selecting spark plugs according to your car model: size, heat rating, interchangeability. Choosing candles by design, useful tips.

How to choose correctly

p, blockquote 43,0,0,0,0 –>

When replacing high voltage wires, it is better to purchase ignition wires as a complete set. In order to choose the right set of high-voltage wires, you must carefully study the vehicle's operating instructions.

p, blockquote 44,0,0,0,0 –>

For older cars with contact ignition, it is not advisable to buy wires with distributed resistance; this can lead to difficulty starting the engine.

p, blockquote 45,0,0,0,0 –>

If the car is operated in harsh climatic conditions, attention should be paid to wires with silicone insulation. They do not lose elasticity even at extremely low temperatures.

p, blockquote 46,0,0,0,0 –>

Original high-voltage wires are extremely difficult to find, so the car enthusiast usually decides on his own to choose a specific brand of wire set.

p, blockquote 47,0,0,0,0 –>

Attention should be paid to the following points:

p, blockquote 48,0,0,0,0 –>

- for high-voltage wires there is an international standard ISO 3808 and a domestic GOST 28827-90, it is desirable that a link to one of them be on the packaging;

- the packaging must indicate the brands of cars on which they can be installed, all accompanying inscriptions must be in Russian, which indicates the legitimacy of the supplier;

- you should pay attention to the operating temperature range, at least from minus 40 to plus 200 degrees Celsius;

- they should not have any cracks, damage, or discoloration (this may indicate long-term storage);

- Counterfeit high-voltage wires are usually made from high-quality cable, but the tips for the spark plugs and the ignition distributor are made using a homemade method, you should pay attention to the quality of these elements.

In order for the ignition wires to last a long time, it is necessary:

p, blockquote 49,0,0,0,0 –>

- regularly clean them from dust and oil contaminants, preferably using non-aggressive solvents;

- monitor the condition of the high-voltage wire fastening system;

- when replacing spark plugs and repairing the engine, do not exceed the force applied to the connections of the wires with the caps;

- regularly diagnose the car, paying attention to misfires.

How and where you can select Denso spark plugs by car brand online.

Before buying, it will be useful to check the used car by VIN code.

Video - checking high-voltage ignition wires with a multimeter:

p, blockquote 51,0,0,0,0 –> p, blockquote 52,0,0,0,1 –>

May be of interest:

I would not recommend checking by pulling the wires off the spark plugs on a Twincam engine where the spark plugs are in wells. There is a very high probability of breakdown of the tip on a working wire. Basically, the wires on such engines fail due to large gaps in the spark plugs; it is easier for a spark to pierce the tip in the well in air than a large gap in a spark plug located in the compressed air-fuel mixture.

Very useful and instructive! It’s a pity that I didn’t find this advice in the summer. Unknowingly I burned down my plant.

I changed the high-voltage wires twice during the operation of my car. There are different reasons - one of them is when the engine starts to malfunction. At first I just bought a set and changed it. And then he began to deal with the ones that had been removed. It turned out that one of them was broken - the resistance was about 1 Mohm. By the way, I would not recommend checking by removing the spark plug and shorting it to the housing; there are known cases of failure of the switch or ignition module (who has what). By the way, this is the third time I bought silicone ones and in my opinion they are much more reliable than regular ones. They have been working without problems for seven years. But still, to be on the safe side, I keep good wires from the removed kit in the trunk, tested with an ohmmeter.

Typical ignition cable faults

There are 3 main problems associated with high-voltage wires:

- Internal break of current-carrying conductor.

- Breakdown of external silicone insulation.

- Unreliable contact at the junction of copper tips with the terminals of spark plugs and high voltage coils.

A break or fracture of the carbon core does not always lead to complete failure of the explosive wire. Since a high voltage pulse with a nominal value of more than 20 kilovolts is applied to the spark plug, the current still “breaks through” the break point and reaches the spark plug electrodes. But the power of the spark noticeably weakens, hence problems arise with the high-quality ignition of the air-fuel mixture in the combustion chamber. In the worst case, there is no spark at all and the cylinder fails completely.

A similar picture is observed with weak contact of copper conductors at the joints. Due to an oxidized or poorly fitting terminal, the power of the electrical impulse is lost to overcome this obstacle, and the discharge on the spark plug electrodes weakens.

We recommend: Motor oils and everything you need to know about motor oils for Lada Vesta

When two insulating layers break down, the voltage is lost differently. The principle is as follows: the current that detects a circuit of lower resistance tends to pass along that path. If the point of insulation breakdown is located close to the metal parts of the machine connected to the “minus” of the on-board network (ground), a spark discharge is formed between them. As a result, the spark plug receives only half the impulse, causing the ignition of the combustible mixture to occur sluggishly. By the way, it is impossible to check armored wires with a multimeter for insulation integrity; you will need special equipment.

Interruptions in the supply of spark discharges are monitored by the following signs:

- the engine is unstable due to misfires and insufficient spark power;

- one or more cylinders periodically fail, the engine vibrates at idle;

- while driving, acceleration dynamics deteriorate, a weak response to the accelerator pedal is felt;

- more fuel is consumed.

Similar symptoms appear on faulty spark plugs, but checking their performance is more difficult. Therefore, start diagnostics with high voltage wires.

Possible causes of the malfunction

p, blockquote 7,0,0,0,0 –>

The most common cause of malfunction of high-voltage wires is natural wear and aging. They are located in close proximity to the engine.

p, blockquote 8,0,0,0,0 –>

During vehicle operation, especially in the cold season, the daily temperature difference can be more than 100 degrees Celsius. The insulating properties of the wire coating material gradually decrease. The wire begins to crack, moisture, vapors of aggressive liquids (antifreeze, washer fluid), oils, and salt solutions for treating road surfaces penetrate into it.

p, blockquote 9,0,0,0,0 –>

Once the cracks reach the current-carrying conductor, a high-voltage signal can penetrate to ground. The insulating properties of the wire will be impaired, and the ignition impulse will not reach the spark plugs.

p, blockquote 10,0,0,0,0 –>

Often wires lose their conductive properties as a result of mechanical stress. This usually occurs at the junction of the live conductor with the contact connectors of the spark plugs and ignition coils.

p, blockquote 11,0,0,0,0 –>

When installing explosive wires, it is necessary to lay them correctly, be sure to attach polyester-vinyl crimp clamps, and avoid unnecessary mechanical forces.

p, blockquote 12,0,0,0,0 –>

Wires can fail if the maximum high voltage level is exceeded. This situation is possible in the event of a breakdown of the coil along the primary winding.

p, blockquote 13,0,1,0,0 –> adsp-pro-1 –>

Installation of high-voltage wires

Regardless of the make and model of the car, all high-voltage wires have a similar design. Currently, armored wires are widely developed in modern cars and have many engineering solutions to increase their conductivity and insulation resistance.

The wires consist of:

- Conductor;

- Insulation;

- Tips for connection;

- Protective caps for tips;

Conductor

The conductor has several design options, and this depends on the quality of the wire, its manufacturer, etc. Each manufacturer tries to add as many new solutions as possible to their wires that can increase the efficiency of wires.

- Copper, the simplest and most outdated, requires additional noise suppression resistors;

- Non-metallic with metal coating. The central part is made of fiberglass and impregnated with graphite. It is possible to cover it with ferroplasts, which prevent interference from spreading. And finally, everything is wrapped around a thin metal wire, creating the role of a screen. Just like copper, it requires the installation of additional noise suppression resistors.

- Non-metallic, has a high distribution voltage. No additional resistors are required.

Wire insulation

To ensure safety and protection against breakdown of wires, as well as to bring high voltage to the spark plug, the insulation of the wires must be at a high level and provide reliable protection against breakdown.

- Single layer (Fig. A). A conventional shell made of polymers does not have the best insulating qualities, which is why it is almost never used;

- Two-layer (Fig. B). Much better than a single layer, it consists of an inner coating and an outer one. High degree of protection against dust, various technical liquids and temperature changes;

- Multilayer (Fig. B). The most advanced option on the market. It consists of an inner layer of insulation that protects the core from breakdowns. The braiding of the inner layer, thanks to it, the core is protected from breakage, deformation and other damage. And an outer layer that provides complete protection from external factors.

Tips

In cars, two types of connecting tips are used (on the spark plug side):

- L-shaped;

- Straight;

As a rule, on a VAZ 2110 car, wires with straight tips and L-shaped ones are installed, on one side the tips have a direct contact, it is connected to the spark plug, and the wires are connected to the ignition module with an L-shaped contact.

Basic data on the design of products

Content

In our time, the most common option for eliminating interference was the use of wires in which the resistance is distributed along the entire length. Typically, wires consist of current-carrying strands, caps, and special plates, but other parts may also be present. The difference between the products is the type of cores that conduct current.

There are several options for such products:

- copper options with a large number of cores;

- non-metallic products, which are supplemented with metal “upholstery”;

- non-metallic conductors in which the resistance distribution is high.

Leading manufacturers of car spare parts offer several types of similar products. The most popular brands are slon, finwhale, fenox, CARGEN, which can be purchased on the website, and so on. Let's look at their features in more detail.

| GDP type | Breakdown voltage, kV | Resistance, kOhm of wires to cylinders | Workmanship | price, rub. |

| Slon | <50 | 4.24-4.74-5.19-7.60 | 5 | 470 |

| Ween | <35 | 6.17-6.57-7.52-9.89 | 4 | 250 |

| Cezar | <50 | 3.10-3.53-6.23-5.34 | 3+ | 460 |

| Tesla | >50 | 3.27-4.16-5.02-6.26 | 5 | 420 |

| Xopc | <50 | 3.15-3.90-4.09-6.24 | 4 | 350 |

| Finwhale | >50 | 1.95-2.18-2.60-3.42 | 5 | 570 |

Firing order

The cylinders in a car do not work chaotically, because for stable operation of the engine and alternate execution of all four strokes, their strict synchronization is required.

So there is a special order of operation of the cylinders of the VAZ 2114, thanks to which each of them at one point in time performs any of 4 strokes, namely:

- Injection of a mixture of fuel and air that fills the entire volume of the cylinder.

- Compression of the working mixture due to the upward movement of the piston.

- The combustion of the working mixture and the expansion of the resulting gases pushes the piston in the opposite direction, thereby driving the connecting rod and crankshaft.

- The release of exhaust gases from the cylinder with their further discharge into the exhaust system.

Ignition order of the VAZ 2114

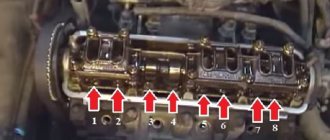

It is worth noting that on cars of different brands and even models, the engine may have a different operating circuit, but the operating order of the cylinders of the VAZ 2114 injector always looks like this: 1-3-4-2. According to this diagram, the high-voltage wires should be connected.

Types of damage and malfunctions

- Breakage of current-carrying conductors in high-voltage wires.

- Damage to the wire insulation. Sometimes, just one accidental scratch on the insulation is enough for a current leak to occur that can cause problems.

- The conductor is oxidized. This damage is a direct result of torn insulation, which allows moisture to enter the core.

- High wire resistance. Here the fault lies with the manufacturer (alternatively, the car owner himself may be to blame for installing wires from a car of a different brand).

- Bad contacts. They in the wire caps wear out over time and no longer fit tightly to the spark plugs (or to the contacts on the ignition coil).

All of the above damage can lead to sparks and “stray” electromagnetic pulses that will interfere with the normal operation of the car’s sensors. In addition, if the conductor is broken, voltage will not be supplied to the spark plug in a timely manner. This will lead to the fact that the fuel-air mixture in the combustion chamber will ignite late, and one of the engine cylinders will always be “late”, that is, the synchronization of the cylinders will be disrupted.

Preparatory activities and necessary tools

Installing the ignition of a VAZ 2109 carburetor begins with preparatory activities. In particular, you need:

- Warm up the car engine;

- Set the parking brake and install wheel chocks under the rear wheels.

Remember that you cannot ignore safety rules, because a car is a highly dangerous vehicle, and failure to comply with safety rules when driving, servicing and repairing it can cost you dearly.

An important point: before you start work, you should make sure that the carburetor is correctly configured on the car. It would be a good idea to carry out a visual inspection of all elements of the system.

If we are talking about a carburetor car, special attention should be paid to inspecting the condition of the distributor

If you have a car with an injection engine, it is worth checking the ignition module for serviceability. The thing is that, as practice shows, it is this module that fails most often and is the reason for the inoperability of the entire system.

To complete the work we need:

- strobe;

- a set of keys.

Checking high voltage wires

The high-voltage wires used in contact ignition are designed for a relatively low voltage of about 12 kV and have rigid insulation. This insulation breaks down, especially with temperature changes, resulting in voltage leakage to the housing. Determining this malfunction is quite simple. It is necessary to look under the hood with the engine running in the dark. The presence of sparking on the wires indicates a malfunction.

The insulation of silicone wires is practically not subject to damage during operation, unless it can be damaged mechanically during repairs. But these wires can often have a break in the conductive part. With a small break, due to the high voltage of the contactless ignition system, no sensitive changes in engine operation are noticeable. It’s another matter when this cliff burns out and grows over time. Depending on which wire is broken, unstable operation of the engine may occur, engine trouble, failures during acceleration, etc.

But a break in a high-voltage wire is scary not because of a deterioration in engine performance, which is of course unpleasant, but because of an increase in self-induction voltage. This leads to increased load on the switch or ECU of the injection engine. In case of large breaks, a breakdown of the control transistor (thyristor) of the switch or ECU occurs.

Checking the integrity of the wires is quite simple. It is necessary to measure the resistance of all wires and compare them with each other. Since the resistance of wires from different manufacturers may have different values. But the resistance of the wires of one set does not differ significantly and depends only on the length. If, when comparing the values, a large difference is revealed, then this wire must be replaced.

Recommendations for replacement

Never remove or touch high-voltage wires with your hands while the engine is running, as there is very high voltage that can cause serious harm to human health.

Replacement must be made only with high-quality and reliable wires, and best of all with a new set of spark plugs. Which spark plugs are best for VAZ cars can be read in our article here.

HF wires (stand for high-voltage) are needed as direct impulse conductors from the ignition device to the fuel ignition system (directly to the spark plugs). If the pulse does not flow or does not flow properly, the gasoline will not burn properly in the cylinder and the engine will not operate as it should.

In today's article we will talk about malfunctions, methods for checking resistance and replacing high-voltage (armored wires) ignition of the VAZ 2112

Diagram, procedure for connecting high-voltage wires of VAZs.

First, let's decide which of the four cylinders is first?

The first cylinder in front-wheel drive VAZs is located closer to the timing belt. If you look at the engine from the front, the first cylinder is the leftmost). And then everything is simple - from left to right - 1, 2, 3, 4.

In rear-wheel drive VAZ Classic and Niva, the first cylinder is located closer to the front bumper of the car.

Checking high-voltage wires. To check the wires, you will need a multimeter tester. Check the resistance of the wires - it should be no more than 20 KOM (in practice, the longest wire of 1 cylinder has a resistance of up to 10 KOM). If the wire resistance is more than 20 Kom, it must be replaced.

Laying wires. Do not try to connect the wires in a bundle. Disassemble the wiring harnesses, release the wires from the plastic holders. Connect the high-voltage leads to the corresponding cylinder spark plugs. Lay the wires so that they do not rub against each other, engine parts, or hoses. Avoid sharp bends and tension on the wires. After connecting all the wires, secure them into the bundle with special comb holders included in the delivery kit.

The procedure for connecting I/O wires to a VAZ carburetor (2108, 2109, 21099)

The central wire from the distributor cover always goes to the ignition coil (bobbin).

The outlet of the distributor cover, which faces towards the front of the car, is connected to the first cylinder.

The outlet of the distributor cap, looking down, is connected to the third cylinder.

The outlet of the distributor cap, looking rearward, is connected to the fourth cylinder.

The outlet of the distributor cap, looking up, is connected to the second cylinder.

The procedure for connecting high-voltage wires to a VAZ Classic, Niva with a carburetor and distributor.

Central wire from the ignition coil (bobbin)

Injection VAZ produced before 2004 with an old-style ignition module (4-pin low-voltage connector)

Actually, on the module body it is already indicated which cylinder the pins correspond to - but we duplicated them in red in case the module gets completely dirty, and you might not be able to see it in the photo.

Injection VAZ produced after 2004 with a new ignition coil (3-pin low-voltage connector)

As with the old-style ignition modules, the new coils are also marked with pins corresponding to the cylinders. But the connection order is different from the order on the old-style ignition module. Be careful.

Replacing high-voltage wires of the ignition system

High-voltage wires of the engine ignition system are special design elements that ensure the transmission of high-voltage pulses from the ignition coil to the engine cylinder spark plugs. If the high-voltage wires are in good condition, if other elements of the ignition system work smoothly, a spark appears in the cylinders in a timely manner, and the engine starts and runs stably in any weather. If even one of the high-voltage wires is damaged and needs to be replaced, starting the power unit becomes problematic, and during operation the engine will, at a minimum, stall and stall at the most inopportune moment.

Features of the design of high-voltage wires and their possible malfunctions

A standard high voltage wire consists of several elements. This is a conductor, a reliable layer of insulating coating, contacts and protective caps. In some cases, high voltage wires (armor wires, explosive wires, etc.) are equipped with resistors to suppress electromagnetic interference and other elements that make the design of the conductors more reliable and their operation more convenient. Depending on which particular element of the high-voltage wire has become unusable, the malfunctions of the transmission link of the ignition system also differ:

- if the insulating coating is destroyed, breakdown and leakage of currents occurs through the high-voltage wire, as a result, the voltage sufficient to form a spark and ignite the working mixture ceases to flow to the electrodes of the spark plugs;

- if a conductor becomes unusable, the resistance level of the conductor automatically increases (the consequences of this malfunction are almost the same as in the first case);

- If the contacts oxidize or break, then during engine operation short-term breaks in the electrical circuit occur, as a result of which the power unit begins to operate intermittently.

In all of the above cases, the high-voltage wires of the ignition system must be replaced, because it is impossible to repair them on your own or even by service specialists. This is simply not provided for by the design of high voltage wires.

Common malfunctions of high-voltage armored wires

Failure of a high-voltage wire is accompanied by symptoms that are similar to malfunctions during spark plug operation. Often the engine starts to run unstably, jerks when you press the gas pedal, and idles at idle. The electric current may not be supplied to the spark plug at all or may not reach the spark plug completely. In the second case, there is usually a breakdown of the high-voltage ignition wire.

If the ignition armored wire is pierced, then the engine begins to work with noticeable interruptions. The main reasons for the failure of high-voltage automotive wires are:

- malfunction of the high-voltage wire contacts at the junction with the spark plugs or ignition coil;

- The conductor of the pulse supply wire is damaged;

- destruction of the insulation of a high-voltage automotive ignition wire, which leads to current breakdown and leaks;

- increased resistance of high-voltage armored wires;

In the event that a break occurs in the main core, then a spark is formed inside the high-voltage wire at the site of such a break. The formation of an electrical discharge between the two ends of a high-voltage armored wire broken under the insulation leads to a voltage drop and causes an unwanted electromagnetic pulse. Such an impulse has a negative impact on the automotive sensors of the electronic engine control system (ECM), and the correctness of their readings is disrupted.

In some cases, when the cylinder fails completely, fuel consumption may noticeably increase and the color of the exhaust may change. This happens due to unburnt fuel entering the exhaust system from the combustion chamber.

Sn00pi › Blog › How to check BB wires? Troubleshooting.

How to check high voltage ignition wires?

Automotive high-voltage (HV) wires play an important role for internal combustion engines, since they help transmit high current from the ignition coil to the spark plugs. The serviceability and efficiency of the wires determines the timeliness and intensity of ignition of the fuel-air mixture, and therefore the correct and uninterrupted operation of the engine. Despite their simplicity, wires have many different “sores” and can cause a lot of troubles to their owner, which in one way or another will affect his nerves and pocket.

Malfunctions of high-voltage wires (common problems):

As a rule, the malfunction boils down to the fact that current either does not flow to the spark plug at all, or it does, but in limited quantities. This can happen for the following reasons: — There has been a break in the current-carrying wire through which the pulse travels. — There is a current leak, that is, the insulation is damaged and the current flows to the side. — The resistance exceeds the permissible value. — Problems in contacts (with a spark plug or ignition coil).

In the event of a break in the current-carrying wire, the effect of an internal spark occurs, in other words, an electrical discharge is formed between the ends of the broken wire, which reduces the voltage and causes an electromagnetic parasitic pulse. This impulse, in turn, negatively affects the correct operation of many of the vehicle's sensors. One such damaged high-voltage wire can cause vibration and interruptions in engine operation. Due to a damaged high-voltage wire, ignition in the cylinder occurs late or every other time, as a result, the synchronous operation of the cylinders and the engine as a whole is disrupted.

How to check high-voltage wires? Effective ways:

First of all, it is necessary to check the explosive for the absence of visible damage (cracks, fractures, etc.). Make sure there is no breakdown, this can be determined even without instruments, just look under the hood in the dark; in the event of a breakdown while the engine is running, a spark will be visible on the explosive wire. You can check high-voltage wires using a wire. To do this, you need to take a piece of wire in the dark and strip it on both sides. Then one end must be shorted to ground (machine body), and the other end must be drawn along the entire length of the explosive wires, as well as joints, caps, etc. A spark will form at the breakdown sites.

This is interesting: What to do if your car is stolen?

You can also check the resistance of the high voltage wires, for this you will need a multimeter. — Turn on the ohmmeter mode. — Remove the wire from the spark plug of the first cylinder and the ignition coil. — Connect the multimeter electrodes to the ends of the wire and look at the readings.

In good wires, the resistance should vary from 3.5 to 10 kOhm, depending on the type of wires themselves. Information about resistance is most often indicated on the insulation of high-voltage wires. Check each wire, the spread between them should not exceed 2-4 kOhm. If there is a large variation, replace the wires. By the way, they are changed as a set, that is, all together.

To complete your reading of the resistance of the most popular high-voltage wires: Tesla - 6 kOhm Slon - from 4 kOhm to 7 kOhm (4 kOhm - 1st cylinder and up to 7 kOhm - on the last cylinder) ProSport - almost zero resistance Cargen - 0.9 kOhm

Note! The resistance of high-voltage wires varies depending on the length, thickness, and material from which the wires are made.

Signs of malfunction, initial diagnosis

p, blockquote 14,0,0,0,0 –>

The driver can judge a possible malfunction of high-voltage wires by the following factors:

p, blockquote 15,0,0,0,0 –>

- difficulty starting the engine, especially in wet weather;

- "triple" of the engine, which appears when cold, as well as at idle and periodically while driving;

- increasing the level of radio interference in the receiving and amplification path of car radios and audio amplification equipment;

- increased fuel consumption;

- change in color, appearance of darkened areas of leakage and breakdown.

In most cases, it is impossible to determine which of them is faulty by appearance. The simplest method of initial diagnosis is to turn them off one by one. If, when a particular high-voltage conductor is disconnected, the engine operates without changes, therefore, there is a reasonable probability of failure of that conductor.

p, blockquote 16,0,0,0,0 –>

However, disconnecting the wires while the engine is running should be done with extreme caution, using high-voltage protective equipment: a dielectric mat, high-voltage insulating gloves. Conventional electric gloves have a breakdown voltage of 6.3 kilovolts, and the impulse of the ignition system can exceed 20,000 volts.

You can also check the high-voltage wire by connecting a known-good spark plug to its output, connecting its metal base to the car engine housing. The absence of a spark plug when the engine is running is a sign of a faulty wire.

p, blockquote 18,0,0,0,0 –>

Video - how to check the ignition wires:

p, blockquote 19,0,0,0,0 –>

p, blockquote 20,0,0,0,0 –>

The presence of a breakdown in a high-voltage wire can be easily determined in the dark by turning off the lighting fixtures and starting the engine. A spark should be observed at the breakdown site.

p, blockquote 21,0,0,0,0 –>

The most reliable way of preliminary checking is to connect a new, serviceable high-voltage wire in place of the “suspected” one. To do this, experienced car enthusiasts have a spare ignition wire of maximum length in their mobile repair kit (to fit any cylinder).

p, blockquote 22,0,0,0,0 –>

Ignition: VAZ 2110 module, features and testing

So, the ignition of the VAZ 2110 for different engines (8 and 16 valve engines with working volumes of 1.5 liters and 1.6 liters) is set differently. At the same time, the operating principle, as well as the main components of the various ignition modules of the VAZ 2110, remain unchanged.

The most important thing in the ignition system is the creation of reliable and high-quality ignition of the fuel mixture at a time determined by the preliminary setting. Any deviations from the specified production parameters can lead to various breakdowns, including failure of the internal combustion engine.

If we consider the 2110 ignition coil and design features, it is important to know that VAZ 2110 cars at different times were equipped with different power plants with different ignition modules. For example, an 8-valve 1.5-liter engine has an ignition module with article number 2112-3705010, an 8-valve engine with a volume of 1.6 liters has a module with article number 2111-3705010, a 16-valve injector with a volume of 1.6 - module with article number 2112-3705010.. The modules are similar to each other in their main components and operating principle

The module for the VAZ 2110 consists of such basic elements as:

The modules are similar to each other in their main components and operating principle. The module for the VAZ 2110 consists of such basic elements as:

- two high-voltage switch switches in a common unit, through which current is transmitted to the spark plugs;

- two coils generating high-voltage pulses for pairs of spark plugs;

Moreover, the coil itself is actually a transformer with two windings (primary - about 500V and secondary - at least 20V), assembled into a single housing. The VAZ 2110 ignition module 8 valves and 16 works on the same principle (using the idle spark principle).

This means that the module, according to pulses transmitted from the ECU, distributes sparks in pairs to cylinders 1-4 and 2-3. The ECU sends low-voltage control signals to the module. The end of the signal corresponds to the beginning of the spark discharge. The duration of the discharge directly depends on the level of charge of the coil (the total value of the on-board voltage).

Cost and articles

Below are prices and articles for good and high-quality high-voltage wires for VAZ cars, both for 16 and 8 valve engines.

| Manufacturer | Number of valves | vendor code | Price, (rubles) |

| Standard | 16 | 21120-3707080-81 | 990 |

| SLON | 16 | 2112-3707080 | 1450 |

| VOLTON | 16 | VLT-2112005 | 915 |

| TESLA | 16 | Т516M | 1710 |

| LADA | 8 | 21110-3707080-82 | 695 |

| TESLA | 8 | Т514M | 875 |

| Standard | 8 | T684H | 620 |

| Original | 8 | 21110-3707080-12 | 710 |

Self-check of automotive high-voltage spark plug wires of the ignition system

It is necessary to begin diagnostics with an external inspection of high-voltage wires. During such an external examination, the presence of noticeable defects in the form of cracks, fractures, etc. is not allowed.

- The easiest way to check is to use a known good spare ignition wire. It is necessary to disconnect each armored wire one by one, replacing it with a spare one. Stabilization of engine operation after replacing one of the wires will indicate a faulty element.

- To identify a possible breakdown of the ignition armored wire, you must wait until it gets dark. When darkness falls, you will need to open the hood and start the engine. If there is a breakdown, then during engine operation an electric spark on the damaged high-voltage wire becomes clearly visible.

- Also, checking high-voltage automotive ignition wires can be done by using an additional insulated wire. To check, the ends of such a wire are stripped (exposed). Then one end is shorted to ground, and the other end should be passed along the highest voltage wire, connections, bends, caps, etc. If there is a breakdown in a certain place, then an electric spark will appear between the breakdown area and the end of the tester wire.

- Checking the resistance of high-voltage car wires is carried out using a multimeter. To check, the multimeter must be switched to operating mode as an ohmmeter. The next step is to remove the wire from the spark plug on the first cylinder, after which the specified wire is also disconnected from the ignition coil. Then the contacts of the multimeter are connected to the ends of the wire, after which the obtained data is evaluated.

In a similar way, you should check the remaining high-voltage ignition wires. It should be taken into account that the spread in readings between all wires should not be higher than 2 or maximum 4 kOhm. Exceeding this threshold will indicate the need to replace high-voltage automotive ignition wires.

It should be added that if a faulty wire is detected, replacing only one defective element is not recommended, since it is a temporary measure. It is optimal to replace high-voltage armored ignition wires in a car as a set. This approach allows for the most efficient operation of the ignition system and smooth engine operation in all modes. For the same reason, it is highly not recommended to repair high-voltage wires for further operation without replacement.

Do-it-yourself tuning and modernization of spark plugs to improve fuel efficiency and other characteristics of the internal combustion engine. How to modify the candles yourself.

Signs of faulty spark plugs. Assessing the condition of a spark plug during a visual inspection, methods for checking spark plugs. Plaque on the spark plug electrodes.

Operational repair

p, blockquote 36,0,0,0,0 –>

What to do if the spark plug wire breaks off or breaks far from populated areas.

p, blockquote 37,0,0,0,0 –>

First, using the methods outlined in paragraph 2, find the location of the damage, breakdown or break. Then, using a knife, strip the conductive wires on both sides of the damaged area.

p, blockquote 38,0,0,0,0 –>

The next stage is an electrical connection using any conductor (wire), preferably copper. It can be produced by ordinary twisting.

p, blockquote 39,0,0,1,0 –>

The most difficult thing is to perform high-quality insulation. Conventional electrical tape has a breakdown voltage of 2,000 to 6,000 Volts. It is necessary to provide insulation for voltages up to 40,000 Volts.

p, blockquote 40,0,0,0,0 –>

It is easy to calculate that in this case it is necessary to lay at least eight to ten layers of electrical tape. And this does not take into account the penetration of moisture between the layers. The insulating tape must be of high quality. To improve the quality of insulation, you can place the repair site in a plastic box.

p, blockquote 41,0,0,0,0 –>

Before repairs, high-voltage wires should be thoroughly cleaned of dirt and oil stains.

p, blockquote 42,0,0,0,0 –> adsp-pro-2 –>

Checking high voltage wires

Checking wires with a multimeter

The first sign of a wire malfunction is the presence of an external spark on the explosive wires. It is easy to see in the dark by looking under the hood.

The next method is also best done in the dark: take a piece of wire and strip it on both sides. Next, we connect the wire with one end to ground (battery or car body), and with the other end we run it along the wires at the joints, caps, etc. if there is a leak, a spark will form.

To check the resistance of the wires, we need a multimeter in ohmmeter mode.

In order not to confuse the wires, it is more convenient to check them one by one, i.e. remove the wire from the 1st cylinder and remove the other end of this wire from the ignition module.

- Turn off the ignition.

- Remove one end of the wire from the cylinder.

- Remove the other end of the wire from the ignition module (as in the figure).

- We connect both ends to an ohmmeter and watch the readings.

- We carry out the same operation on all wires.

For serviceable wires, the resistance should vary from 3.5 to 10 kOhm, depending on the manufacturer (written on the wire insulation). And the permissible spread is 2-4 kOhm. If the spread is greater, then the wires need to be replaced (Replacing VAZ high-voltage wires).

Connecting armored pipelines VAZ 2110 injector 8 valves

Where did all this even start? Yes, because one day after work I started the car and realized that it was a complete mess. I opened the hood and looked. I think we need to check which cylinders are working. I take the wire of the first cylinder. And then the machine gave me a thousand pricks from the discharge that this wire emitted... Everything is clear, it breaks through. Having warmed up to 40 degrees, the tripping disappeared o_O. Ok, you can live. went home. I started thinking about what to do with the wires that I bought a year and a half ago. "Elephant". I looked at how much new ones cost - 900 or more, silicone wires. Hmm...a little expensive. I started digging into the drive. And then I remember that I saw an article about homemade explosive wires. 1 minute in Google and 15 articles on the drive are ready to read. Someone makes it from ZIL wires, there is a copper core - the resistance tends to 0. Someone makes a corrector vacuum from acoustic wires and silicone hoses. I settled on this decision. The article that I took as the BASIS! Special thanks for the advice Stuff0rd McSystem

What we need: - MGTF wire -0.35mm 2 meters (enough almost point-blank)

(I came across this brand of wire by accident in the comments) I read that the cross-section is not so important as the insulation of the wire, and that 0.2-0.5 cross-section is enough for the eyes. — Silicone vacuum corrector hoses 3 pcs

— Heat shrink 8mm (more than the diameter of the hoses) — 2 meters. - BB wires. - VDeshka - Someone’s mother... (Required!)

1. First, we take the old (or the only ones - like I did) wires and begin to disassemble them. I simply pulled the terminal on the spark plug side out of the insulator. It's hard but it works out. But the corner terminal must be carefully disassembled and the wire pushed towards the terminal so as not to damage it. Since I also pulled out the first one by force and almost broke it at the bend))

Stories from our readers

“Fucking basin. "

Hi all! My name is Mikhail, now I’ll tell you a story about how I managed to exchange my two-wheeler for a 2010 Camry. It all started with the fact that I began to be wildly irritated by the breakdowns of the two-wheeler, it seemed like nothing serious was broken, but damn it, there were so many little things that really started to irritate me. This is where the idea arose that it was time to change the car to a foreign car. The choice fell on the melting Camry of the tenth years.

Yes, I had matured morally, but financially I just couldn’t handle it. I’ll say right away that I am against loans and taking a car, especially not a new one, on credit is unreasonable. My salary is 24k a month, so collecting 600-700 thousand is almost impossible for me. I started looking for different ways to make money on the Internet. You can’t imagine how many scams there are, what I haven’t tried: sports betting, network marketing, and even the volcano casino, where I successfully lost about 10 thousand ((The only direction in which it seemed to me that I could make money was currency trading on the stock exchange, they call it Forex. But when I started delving into it, I realized that it was very difficult for me. I continued to dig further and came across binary options. The essence is the same as in Forex, but it’s much easier to understand. I started reading forums, studying trading strategies. I tried it on a demo account, then opened a real account. To be honest, I didn’t manage to start earning money right away, until I understood all the mechanics of options, I lost about 3,000 rubles, but as it turned out, it was a precious experience. Now I earn 5-7 thousand rubles a day. I managed to get the car buy after half a year, but in my opinion this is a good result, and it’s not about the car, my life has changed, I naturally quit my job, I have more free time for myself and my family. You’ll laugh, but I work directly on the phone)) If If you want to change your life like me, then here’s what I advise you to do right now: 1. Register on the site 2. Practice on a Demo account (it’s free). 3. As soon as you get something on the Demo account, top up your REAL ACCOUNT and go to REAL MONEY! I also advise you to download the application to your phone, it’s much more convenient to work from your phone. Download here.

How long does it take to change high-voltage wires on a VAZ 2110? The service life of high-voltage wires depends on their quality and environmental conditions. Therefore, in harsh winter conditions, low-quality wires may not last very long. Typically, high-voltage wires are replaced when signs of malfunction appear:

- Radio noise

- The engine pulls poorly at low speeds

- The car starts to jerk

- Increased fuel consumption

- Exhaust toxicity increases

Products from Carden: main features

Products from this brand are used on cars of various brands: GAZ, ZAZ, VAZ and so on. The products are designed to operate at temperatures up to +180 degrees. The minimum indicator is minus forty degrees. The length of the wires may exceed the length of those products installed on the vehicle.

Carden high voltage wires

The characteristics of products from this company are high, since they contain two layers of silicone insulation. The company guarantees that the wires will withstand considerable voltage - up to 45,000 volts. Before installing new products, it is necessary to check the spread of their resistance. If it is too high, then you should think about replacing the old options.